+44 (0)23 8052 2345

2

MV Heating UK Ltd

Contents

Heater Removal .................................................................................................3

Heater Installation .........................................................................................3

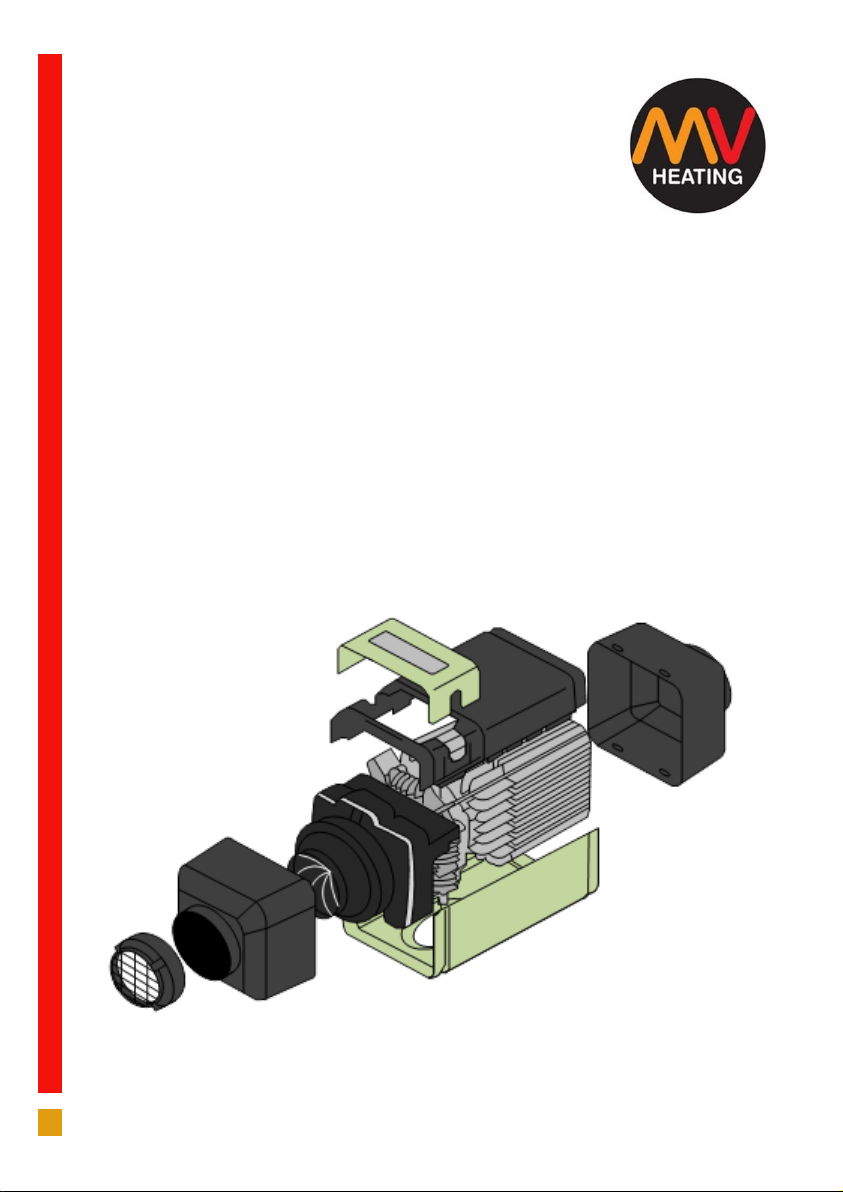

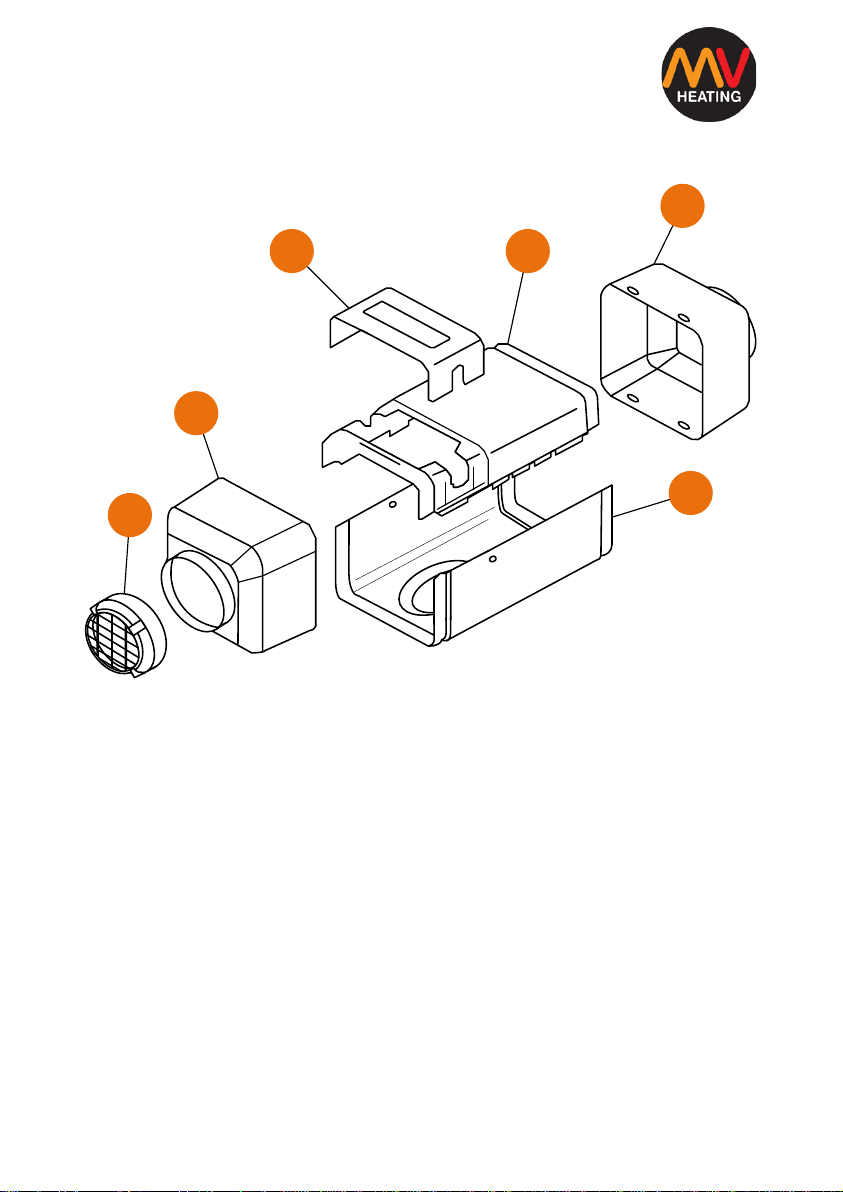

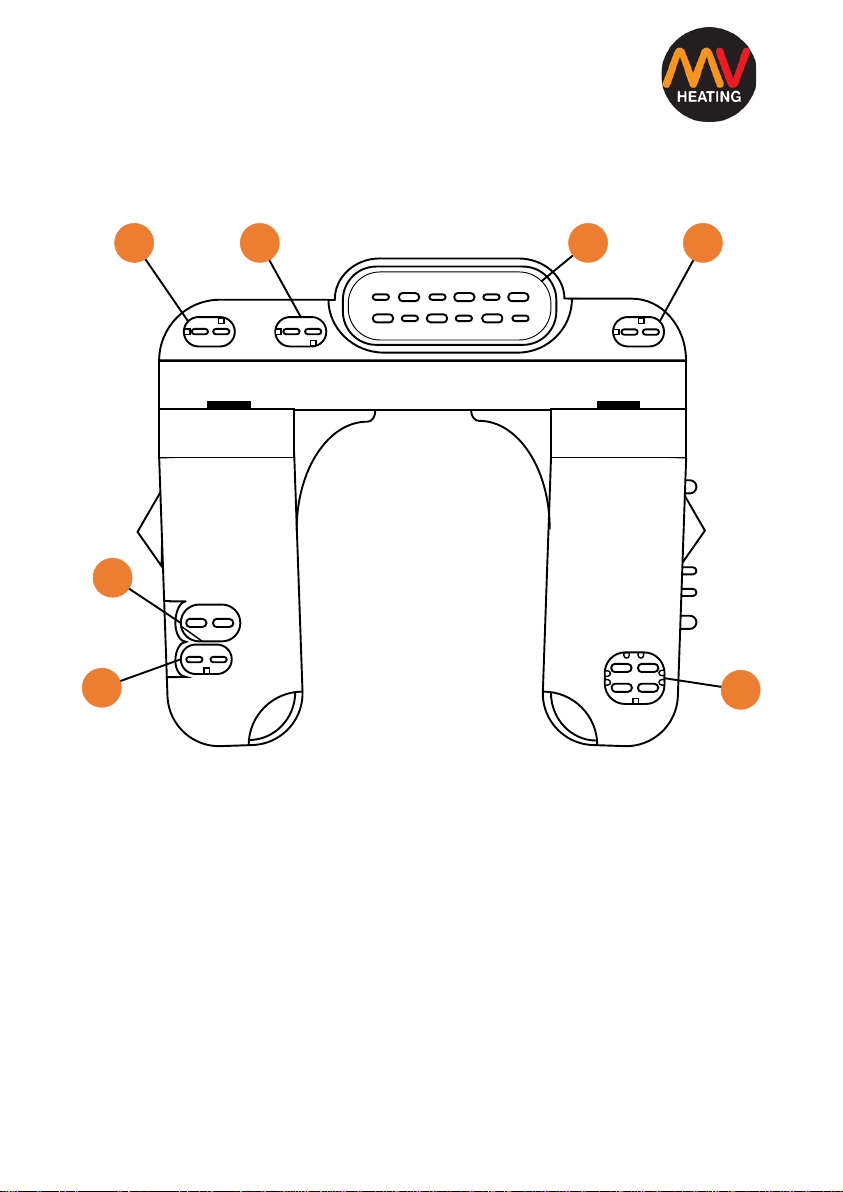

Heater Cases Diagram........................................................................................4

Internal Structure Diagram ................................................................................5

E.C.U. Connections Diagram ..............................................................................6

Removing and Refitting of Parts ........................................................................7

Pre-Checks and Notes ....................................................................................7

Part 1: The Case Assembly.............................................................................8

Part 2: The Overheat Sensor..........................................................................9

Part 3: The E.C.U. .........................................................................................10

Part 4: The Air Motor ...................................................................................11

Part 5: The Burner and Glow Pin Assembly Removal ..................................12

Part 5 Cont’d: The Burner and Glow Pin Assembly Refit .........................13

Part 5 Cont’d: The Burner and Glow Pin Assembly Refit.........................14

Part 6: The Combustion Chamber................................................................15

Part Numbers...................................................................................................16

Notes................................................................................................................17

Note: The following flow charts will refer to the exploded diagrams, or figures

as (F:P), where ‘F’ donates the figure, and ‘P’ donates the part in that figure.

For example (2:4) would mean ‘Figure 2: Part 4’.