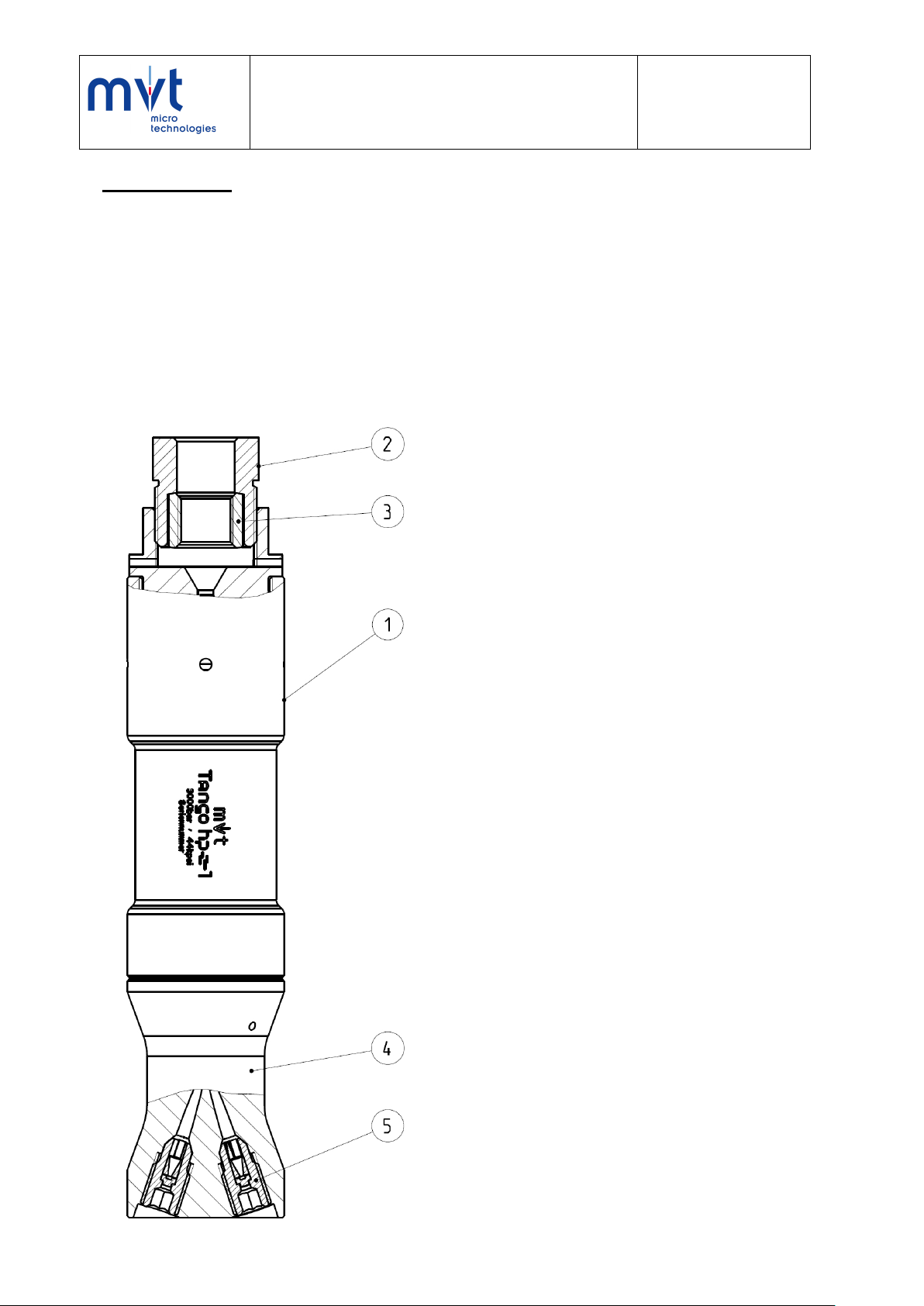

Operating Instructions, Rotary

Nozzle

TANGO hp - 1

Op Instrs

As at 09.01.2020

3/14 Copyright © 2020 mvt AG, Port, Switzerland

1 Safety

1.1 Important information

If the equipment is used improperly, the high-pressure jet from the nozzle can be dangerous

and result in serious injury and damage. The water jet must never be aimed at people,

animals, active electrical equipment or at the high-pressure cleaner itself.

Before use, the high-pressure hoses, the high-pressure spray gun and the pump must all,

without fail, be inspected for possible damage. Hose lines must not be pinched, fed over sharp

edges, driven over by vehicles, tugged or bent. The rotary nozzle must not be operated if any

of the components mentioned above are damaged.

Any person engaged in operating, servicing, inspecting or assembling the equipment must be

appropriately qualified to carry out those tasks. The company operating the equipment must

produce precise instructions covering areas of responsibility, competence and how employees

are supervised.

Training and instruction must be given to any employees who do not have the necessary skills

and knowledge. If necessary, the manufacturer or supplier can provide this training on behalf

of the company operating the machine or pump. The company operating the equipment must

also ensure that their employees fully understand the contents of these operating instructions.

In addition to the safety instructions mentioned in these operating instructions, the

relevant statutory accident prevention and safety regulations must be observed and

adhered to!

1.2 Significant risks

Risk from the possible escape of liquid under high pressure

The water jet from high-pressure water jet equipment nozzles poses a risk due to its cutting

effect and its ability to penetrate objects, and because the high-pressure water jet nozzle and

hose may change direction or wander. Serious or even fatal injuries may be caused.

Hazardous substances may be released and it is also possible that parts of any object being

cleaned by the water jet may become loose.

Risk posed by handheld spray fixtures

Handheld spray fixtures pose a particular mechanical risk due to the recoil forces from the

water jet.

Risk posed by noise

Exposure to noise poses a risk. Exposure to noise can lead to loss of hearing, tinnitus or

physiological problems.

Noise can increase the risk of accidents because it may not be possible to hear alarms or

faults developing in the equipment.

Risk posed by vibrations

Pulsating vibrations from the pressure unit in handheld spray equipment poses a risk.