8

Glass Cleaning

After having cleaned it thoroughly with the spa-

tula, we recommend cleaning the print surface

(glass) smooth with a damp cloth or a paper tis-

sue without using any detergents and abrasives.

Print Speed and Quality

Printing of a small simple model takes a few

minutes or hours, but in bigger and more com-

plex objects, the printing time is calculated in

days and model prints of 5 days nonstop are

of no exception. Quadron printers are tailored

to have no problem printing the projects over

several days and nights without breaks. You can

inuence the print time with several factors by

increasing the layer; not more than 0.5 mm is re-

commended.

This will, of course, demonstrate itself in a visual

model appearance; individual layers will be more

visible and the model will not be so detailed. If,

however, you prefer a detail at the expense of

time, select 0.10 mm. The print time becomes

approximately doubled, but the model will be

much more detailed. The print speed itself is in

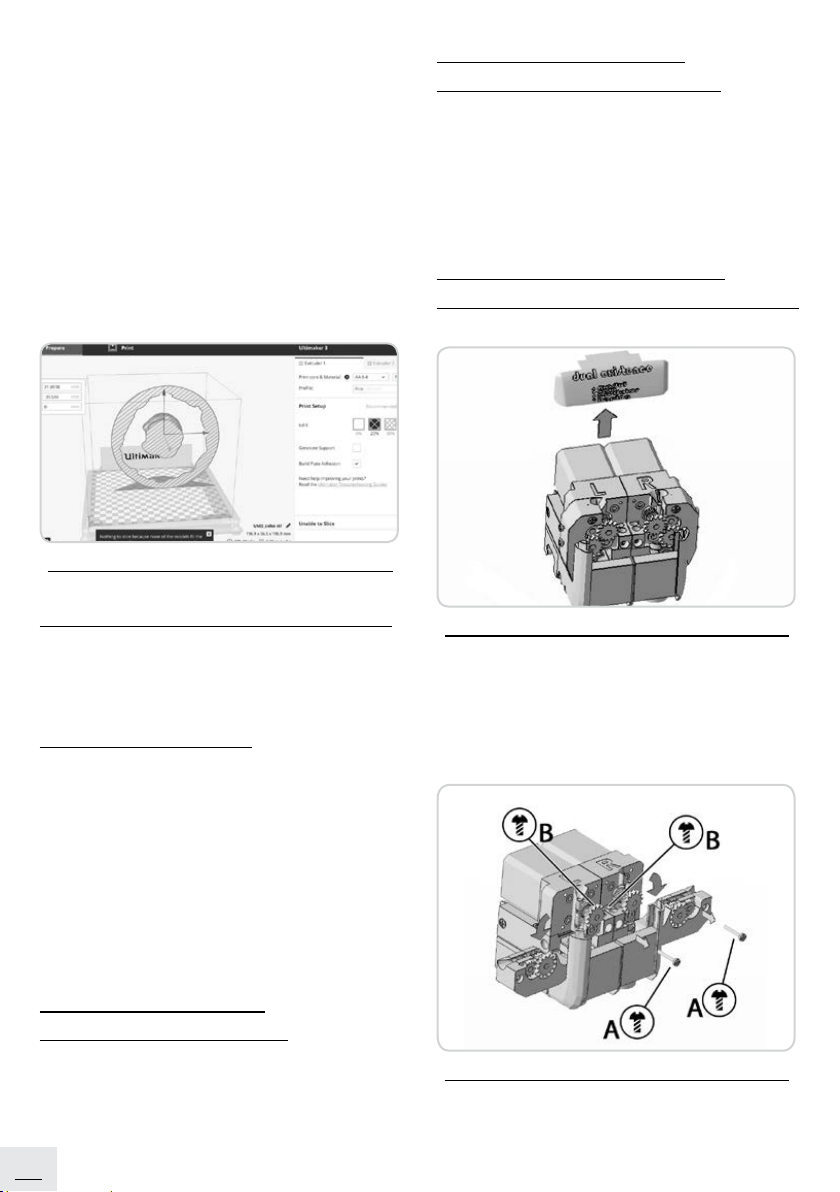

CURA program. There, you can set the detailed

speed in mm/s for individual print items (prin-

ting of borders, llers, etc.). Again, the higher the

speed, the lower resulting quality of the model.

You can also change the speed during printing

directly on the printer. The LCD display contains

the print speed information, too. By rotating the

button in the menu clockwise, you can increase

the print speed up to 200%.

Watch how the accelerated print is reected in

the model appearance and adjust the speed,

if necessary. If you increase the print speed, al-

ways check whether the object manages to cool

down, especially when printing the small ob-

jects. Turning the main button counterclockwise

will slow down the print; slowing is important up

to 30% of the standard speed.

Keep in mind that if printing on the printer using

a computer via a USB, it must be connected to the

printer for the entire printing period, and must

not go into sleep, hibernation, or shutdown.

Interruption of the connection with the compu-

ter will cause interruption of the print without

Materials: PLA, PETG,

CARBON, FLEX, PVA

Filament is supplied on a spool containing the

the manufacturer's basic information, the type

of material (PETG, PLA, CARBON, FLEXI, etc.) and

the thickness of the print string. Two types of -

bers are used for 3D printing as a standard: 1.75

and 2.85 mm. The material thickness of 2.85 mm

is commonly called 3 mm. This Quadron printer

only supports material with a diameter of 1.75

mm. Please, before introducing ber into the

print head, check whether it is the right type.

Do not try to introduce a wider string; it could

damage the print head.

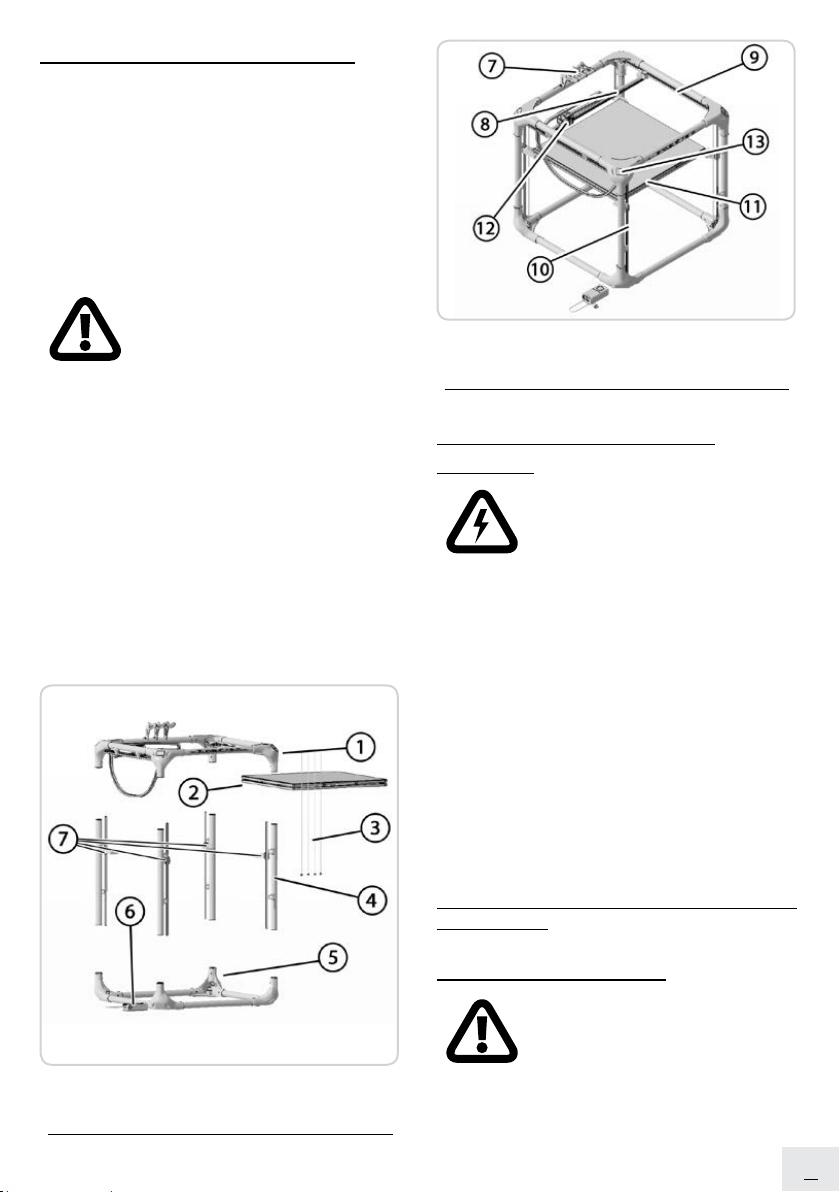

Figure 8: Print lament

Printing

Never leave the printer pre-heated for a long

time without launching the model printing.

If the printer is heated, the material in the print

head degrades over time, causing the nozzle

to clog. Follow the printing of rst layers to check

how the lament attaches to the pad (5-10 mi-

nutes). Press the main button to go to the main

menu, nd the "Print form SD" option, click on

it and select the “Model name.g.code" model.

The printer starts printing that model. Keep in

mind that the le name in .gcode may contain

no diacritics; otherwise, the le will not appear

on the SD card on the printer. During printing,

do not remove the SD card from the device.

If you do so while printing, the printer automa-

tically stops.

Peeling the Model o the Pad

After printing, pour fresh water under the model

and, after 15 minutes, peel it o with a spatula

that is included in the pack.