SHAREBOT Next Generation XXL+ User manual

Sharebot Next Generation XXL+

user's manual

Version 0.4 - 06/201

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 1

Sharebot Next Generation XXL+

user's manual

ATTENTION – EXTRUDER

The fusion and extrusion system of the thermoplastic filament requires a heated end up to temperatures of 250 degrees and more. The contact, even for a very limited

time, with the heated part causes burns. You must avoid to put your hands or other body parts in the printing area when printing and for minutes after the printing process

is over. The current temperature of the extruder is indicated on the LCD screen.

ATTENTION – HEATED PRINTING BED

All the printing plate is made of metal with the addition of a glass plate. This device is electrically heated and serves to bring to desired temperature the entire printing

bed, including the glass plate. The temperature is measured directly on the heating plate: so the temperature of the glass plate will be less than the one shown for several

minutes after the beginning of the heating process, but likewise it may be warmer than what is indicated on the display for several minutes after the end of the printing

due to the the phenomenon of thermal inertia. Remember that it can be set in special cases for temperatures of 90 degrees, while the recommended temperature for

prints is usually 80 degrees. At these temperatures the unintentional contact does not produce damage and burns if you retract immediately the body part that is in

contact, while at higher temperatures it greatly reduces the time necessary to create burns. You have always to check the temperature indicated on the display before you

start maneuvering like the removing of the glass plate on the printing bed.

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 2

Sharebot Next Generation XXL+

user's manual

Indice generale

ATTENTION – EXTRUDER..................................................................................................................................................................................2

ATTENTION – HEATED PRINTING BED........................................................................................................................................................2

Support Policies ...................................................................................................................................................................................................5

Technical characteristics .....................................................................................................................................................................6

1 - Preliminar Operations .................................................................................................................................................................................

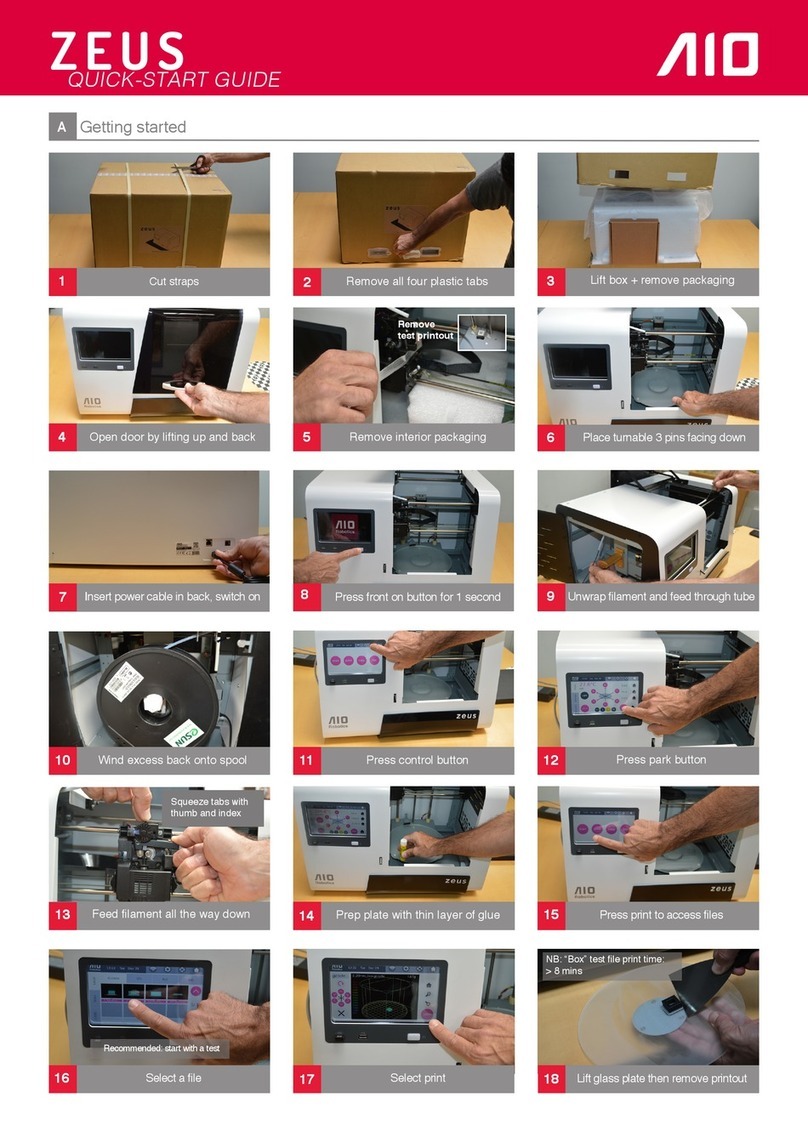

Experience Sharebot XXL+..................................................................................................................................................................8

Opening the package ...........................................................................................................................................................................10

Positioning the printer .........................................................................................................................................................................11

Assembling the spool-holder ............................................................................................................................................................12

2 – The workflow of 3D printing....................................................................................................................................................................12

3D model file............................................................................................................................................................................................13

Downloading from internet ...............................................................................................................................................................13

From a 3D model to a printing file .................................................................................................................................................14

A good STL, a good slicing, a good print ......................................................................................................................................14

The printing file: G-code.....................................................................................................................................................................15

Storing the files ......................................................................................................................................................................................15

3 - LCD screen........................................................................................................................................................................................................15

Informative screen..................................................................................................................................................................................16

The Control knob ...................................................................................................................................................................................16

Access to principal menu ....................................................................................................................................................................1

Printer waiting for work..........................................................................................................................................................1

Printer during printing.............................................................................................................................................................1

“Prepare” menu........................................................................................................................................................................................1

“Tune” menu..............................................................................................................................................................................................18

4 - Setting the printer........................................................................................................................................................................................20

Loading the filament ............................................................................................................................................................................20

How to calibrate the printing bed....................................................................................................................................................22

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 3

Sharebot Next Generation XXL+

user's manual

Plate levelling (calibration)...................................................................................................................................................23

Adjusting pression force on filament..............................................................................................................................................24

5 – Our first 3D printing....................................................................................................................................................................................24

SD card........................................................................................................................................................................................................24

Let's print!..................................................................................................................................................................................................25

Stop the printing process.....................................................................................................................................................................25

Modify the parameters during printing..........................................................................................................................................25

Detach the printed part........................................................................................................................................................................26

6 – Generate our Gcode.....................................................................................................................................................................................28

Slic3r............................................................................................................................................................................................................28

Load the Sharebot profiles in Slic3r..................................................................................................................................28

Import the STL to print...........................................................................................................................................................29

Fundamental parameters of Slic3r.....................................................................................................................................30

The Slicing process...................................................................................................................................................................30

Simplify3D.................................................................................................................................................................................................31

- Printing behaviour of thermoplastic materials ................................................................................................................................32

Printing behaviour of PLA...................................................................................................................................................................33

The heated bed........................................................................................................................................................................................33

8 - Consideration about models orientations............................................................................................................................................33

The orientation........................................................................................................................................................................................34

Cutting the object...................................................................................................................................................................................34

The support material.............................................................................................................................................................................34

Details in prints.......................................................................................................................................................................................36

Clips position............................................................................................................................................................................................3

10 - Ordinary maintenance................................................................................................................................................................................3

Taking care of the printer....................................................................................................................................................................3

Printing plate............................................................................................................................................................................................38

Regulation of pressure upon filament ...........................................................................................................................................38

Nozzle..........................................................................................................................................................................................................38

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 4

Sharebot Next Generation XXL+

user's manual

Lubrication.................................................................................................................................................................................................38

Belts tension.............................................................................................................................................................................................39

Checking of proper ventilation..........................................................................................................................................................39

Firmware Update.....................................................................................................................................................................................39

Warnings on the safety.......................................................................................................................................................................................39

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 5

Sharebot Next Generation XXL+

user's manual

Support Policies

If you have any problems in using our printers, the procedure to be followed is as follows:

Check the manual and guides available on the web site;

Contact the dealer from which you purchased the machine;

Contact our technical support by filling out the form beside remember to fill in all fields. Our technicians will reply within 3 working days.

http://www.sharebot.it/index.php/support-en/?lang=en

In case your printer should return in the factory to be repaired, our technical support will assign it a file number to return and we will provide all the additional

information required.

Atte tio : the package should be the origi al o e, pe alty forfeiture of the guara tee.

Check out this video to see how to pack the printer for assistance.

Upon receiving your printer, our technicians will assess whether the problem results from a failure, in this case the repair under warranty will be carried out for free, or by

improper use of the printer or by an improper use of material not approved by Sharebot: in the latter case we will provide you a quotation to request your consent to

repair. For out-of-warranty printers may be required a quote for the inspection. Troubleshooting is a very important task for us and we think is necessary to share

experiences, problems and solutions. Because of that please give priority to the use of the form that will also allow others to take advantage of our and your efforts. Visit

our website for more information.

If you are interested in customized assistance programs please contact [email protected]

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 6

Sharebot Next Generation XXL+

user's manual

Technical characteristics

Printing technology : Fused Filame t Fabricatio

Printing volume : 705 x 250 x 200 mm +/- 10mm

Theorical positioning resolution axes X and Y : 0,06mm

Risoluzione di posizionamento Z: 0,0025mm

Extruder diameter: 0,4mm

Positioning resolution axis Z : 1,75mm

PLA best extruding temperatures: PLA: 200-230°

Maximum temperature heated printing bed: 90°

Supported and tested printing filaments : PLA

External Dimensions: 955 x 470 x 445 mm

Weight: 40 kg

Power consumption: 500 watt

Electro ic board compatible with Ardui o Mega 2560 with Firmware Ope Source https://github.com/Sharebot3D/Marli

X-Y carriage auto-calibrated

LCD scree 20 x 4 with me ù avigatio (e coder)

Filame t se sor

Extruder block with regulatio pressure upo filame t

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page

Sharebot Next Generation XXL+

user's manual

1 - Prelimi ar Operatio s

Experience Sharebot XXL+

Your professional 3D printer Sharebot Next

Generation XXL+ is a tool of precision, designed,

developed and assembled in Italy by qualified staff.

Before leaving the factory it was submitted to a

quality control and to a quality test that guarantees

its operation. It’s very important, before you can use

the printer, knowing all the technical terms used in

this handbook and identify all the specific

components that form a Sharebot XXL+.

1 Filament teflon sheath

2 Extrusion head cable

3 LCD screen

4 Calibration screws

5 Clips position

6 Frontal ventilation of electronic

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 8

Sharebot Next Generation XXL+

user's manual

SD card slot

8 LCD control knob

9 Glass printing bed

10 Lateral ventilation of electronic

11 USB connection (only for update)

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 9

Sharebot Next Generation XXL+

user's manual

1 Presence filament sensor

2 Label with Identification Code (inside the printer, on the right part of the chassis)

3 Switch and power cable socket

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 10

Sharebot Next Generation XXL+

user's manual

Opening the package

Your Sharebot XXL+ is equipped with a series of accessories that allow you to make it immediately operative; there is no software because it is open source and constantly

updated. Software must be downloaded from the Sharebot website to always have the latest version . Alternatively, we recommend the purchase of Simplify3D from our

website to take advantage of the potential of Sharebot XXL+.

With care and without damaging the packaging remove the various parts and elements that fix the printer inside the package and then - helped by another person - pull it

out by the two short side of the frame. Do NOT pull the cable that comes to the extruder: it is a power cord and NOT an handle. Proceed with the recovery from the

packaging of all the parts and check that the material listed below are all in the package:

Warning: Do not throw away the original package. You could use it if you have to send it or move it. A shipment without original packaging prejudices the warranty.

1. Our letter of presentation and welcome plus “Warranty and support”

2. Spool-holder + threaded bar + two nutse

3. PLA spool

4. Power cable

5. SD Card (already in its slot)

6. USB cable

. Hair spray

8. Cutter

9. Nippers

10. Spatula

11. 2,5 Allen screwdriver

12. Glass printing bed (in the printer)

13. Clips to stop the glass

14. Spare part kit (two hot-ends and two fans)

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 11

Sharebot Next Generation XXL+

user's manual

Positioning the printer

For proper operation, the printer must work in a clean and dust-free space, with an ambient temperature between 10° C and 30° c. It is also preferable a position away

from drafts or air conditioning.

In the left back you’ll find power switch so we recommend to leave it easily accessible; the power cable is the only way of separation of the plug from the mains. A t the

front -bottom left – and on the left side of the printer, you will find the ventilation of the electronic parts from wich depends the correct circuit cooling: these must be left

unobstructed .

Remember that the filament is usually in a spool and that this should be positioned on the reel-carrier included in the packaging Remember that the wire is usually in a

spool and that this should be positioned on the reel-carrier included in the packaging . The recommended position is behind the printer, on the same floor, unrolling the

filament bottom up. There are alternative positions that possibles, but in that case you have to disable the filament presence from the “prepare” menu. The important thing

is that the filament flow and is dragged smoothly without whatsoever impediment throughout all the print area useful. For this reasons, the printer may not be placed in

places that haven't at least 35 cm free space around the rear or side.

Assembling the spool-holder

Using the screwed bar and the nuts, assemble the spool-holder. Do not overtighten the screws to avoid

breaking the plexiglass. Orientate the sides with the hole for the threaded bar facing up and logos readable

from the outside.

To insert the filament spool, remove one side of the spool-holder and the relative nut.

Place the spool-holder behind the printer remembering that the filament must flow rectilinearly, smoothly and

without obstacles.

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 12

Sharebot Next Generation XXL+

user's manual

2 – The workflow of 3D pri ti g

Before you start printing with your Sharebot XXL+ it is important to understand how you arrive at a finished object. This allows you not only to know what you need to do

to give form and substance to your ideas, but it helps you to identify any constraints and limitations of the technology used by this printer. In the table we summarized the

steps required to obtain a 3D printing:

Worki g e virome t Operatio Output

Common used

CAD software

Design the object Your 3D model in your CAD

extension

Common used

CAD software

Import/save file as .stl format

(or .obj)

Your 3D model in .stl format

Slicing software:

Slic3r or Simplify3D

Generate command file

for 3D printer

File .gcode

3D printer: Sharebot XXL+ Select the file from SD card Printed object

3D model ile

It all starts with creating or downloading a three-dimensional model of the object that you want to print in 3D. The creation is done through one of the many modeling

software available. There are many and each of them has specific characteristics. In this respect it is worth noting that you can have different modelling requirements and

this is reflected in the variety of applications . In this respect it is worth noting that you can have different modeling requirements and this is reflected in the variety of

applications. Some are more suited to mechanical design, other artistic modeling, other than architecture . Remember that 3D modeling was primarily used to create

projects or for rendering. In the first case the model was thought to be accomplished physically and therefore is subject to a series of specifications and constraints that

allow the project to be turned into something real. In the latter, the aim is to create an image for certain requirements: the model might then be flawless as display but

physically impossible and so, unprintable.

When you choose the program that you want to use for your models you must then ensure that it is able to create a file suitable for the production (especially 3D printing).

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 13

Sharebot Next Generation XXL+

user's manual

Downloading rom internet

Internet offers many ready-made 3D models, but also in this case there are differences between the models that you “see fine” and those who “print well”. A good indicator

of the ability to print the file extension: the most popular 3D printing is STL (websites that intend to offer printable objects use this format). If there is no STL it is likely

that the intended use is different and the result on a 3D printer is not guaranteed.

From a 3D model to a printing ile

The real “secret” of three-dimensional printing is the transformation of three-dimensional object into a sequence of two-dimensional slices that overlapped, reconstruct

the object. Imagine a series of slices of bread: If the stack rebuilt the loaf from which they were cut.

In the case of 3D printing every slice may consist of two-dimensional shapes not connected together as it is their sum to create the finished object. Thanks to this

breakdown, the object can be complex as desired because the printer will draw with the plastic one layer after another overlapping it; a square or a doodle for the printer

have the same difficult.

The most important work the software makes is starting from the 3D model – usually a mesh of triangles in space called mesh – and transforms it into a sequence of

slices according to a number of parameters (slicing). In order that the process is completed correctly the mesh should be closed and not have triangles that are oriented

incorrectly confusing the “inside” and “outside”. It happens that some model is made to art: at this point or the software that does the slicing manages to repair the mesh or

the result of errors that will prevent the correct reproduction of the object.

A good STL, a good slicing, a good print

The STL file is the starting point for the entire procedure, so from the file should be removed anything you don’t want to print (hidden objects, etc.) . The 3D drawing must

be a solid and not a sum of single solids interpenetrate or adjacent. Similarly, the design must be as definite and precise as possible: the 3D objects must have an inside

and an outside well defined so that the surfaces perfectly match each other without leaving holes. Most 3D design software gives you the possibility to carry out an

analysis of borders to check for holes. The 3D drawing must be oriented in such a way as to have a face adjacent to the XY plane of your drawing software: in other words,

the design should not “float in a vacuum”, otherwise the machine will not print. If you’re working on a STL downloaded from internet or given to you by a client, there are

free software for checking and correction of STL as Netfabb.

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 14

Sharebot Next Generation XXL+

user's manual

The “slices” are saved in a specific format (called G-Code); This format is nothing more than a set of instructions for moving the instrument (extruder head) along a path X,

Y, and Z axes.

Each slice contains the movements on two axes, the moving the of the plane and the commands of the motor that extrudes the plastic to create one by one the layers that

make up the object. Every 3D object can be transformed with the process of slicing in a variety of G-Code files, each different from each others because generated with

different slicing parameters: for example you can slice an object with an 100% internal infill, or completely empty or partially empty, or the walls are made with one, two,

three or more perimeters. Even the thickness of each layer is one of the parameters. The same object can be printed with 100 or 200 slices and so on.

The printing ile: G-code

The G-Code files - containing instructions for the movements of the various mechanical parts of the printer according to specific parameters and settings - has no

compatibility between different printers. While the STL file can be used by anyone with a 3D printer to create a printing G-Code, a G-Code file is definitely running for the

printer for which it was created but could be unusable with other printers. Do not print G-codes downloaded from internet if they are not clearly compatible with Sharebot

XXL+.

The file also contains the heated printing bed temperatures and those of the extruder, linking the file not only to the printer but also to the material to be used. As we

shall see in the following pages, with the LCD Panel it is possible to modify some parameters while printing: Sharebot XXL+ offers you the possibility to modify a lot of

parameters of the G-Code during the printing.

Storing the iles

As we have seen, the process consists of the stages of modeling, exportation of the STL file, slicing it into a G-Code file and print. We recommend that you save the 3D

model file in the native format of the 3D modeling sostware, so as to keep any primitives that compose the object. Similarly the STL files should be stored in order to

make slicing with different parameters, and finally we suggest you save the G-Code, even in different versions for the same model, so you can repeat a print with specific

features using the G-Code files that you already know the final result.

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 15

Sharebot Next Generation XXL+

user's manual

3 - LCD scree

Sharebot XXL+ is a printer that supports both printing stand-alone both control from one computer (OS X, Windows or Linux). In both cases the LCD screen provides

functions both for consultation both editing.

Our suggestion is to pri t always i sta d-alo e mode, savi g gcodes o the SD card.

In ormative screen

When the printer is on - printing or waiting for comands – dispays the

following information on the four rows:

The first row contains the actual extruder temperature followed by the

one setted; on the right of the same row is displayed in the same way

the temperature of the heated bed. The temperature is in degrees

Celsius.

The second row displays the current position of the extruder and the z-

axis. The values are in millimetres, with two decimals indicate

hundredths of millimetres.

The third row has on the left the percentage control of speeds: turning the control knob we modify in percentage all the different speeds that are present in the gcode.

On the same row but in the middle is displayed the progress percentage of the printing and on the right of the same row is displayed the time elapsed in hours and

minutes.

The fourth line contains messages that can be generated by the G-Code file with a special command, or messages from the firmware about specific situations . Once the

printing is concluded we will find the real printing time on this row.

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 16

Sharebot Next Generation XXL+

user's manual

The Control knob

To the right of the LCD there is a knob which rotates with small clicks and can be pressed as a button. With this knob you can interact with Sharebot XXL+: turning it

clockwise you decrease the selected value, turning it anticlockwise it increases. During menu scrolling, rotation anticlockwise flows downward and vice versa. When the

LCD is on the information screen, the rotation of the knob acts on FR percentage, increasing or decreasing the speed of all the movements and so the printing speed.

Access to principal menu

Pressing the control knob, you access the main menu. Remember that the menu displayed depends on the state of the printer: if it is waiting to run offers the menu

“prepare”, while if you are printing offers the menu “adapt”. The voices and the features available in these two modes are different.

Pri ter waiti g for work

Info Screen

Prepare

SD Card Menu

Reset

Pri ter duri g pri ti g

Info Screen

Tune

Pause print

Stop print

Reset

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 1

Sharebot Next Generation XXL+

user's manual

“Prepare” menu

This menu is used to set up and manage the printer, such load and unload the filament, pre-heating the extruder and the printing bed, launching 'autohome or moving all

the different axis. In practice, you have complete control of the printer and you can perform all management and maintenance operations.

Info screen

Change filament

Disable steppers

Autohome

Preheat:

–Preheat all

–Preheat bed

Cool down

Move axis

Move down plate

Test Plate (level plate)

Check filament: ON/OFF

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 18

Sharebot Next Generation XXL+

user's manual

“Tune” menu

The item is displayed only while the machine is printing; the commands we find in are:

Info Screen

Check filament: ON/OFF

Change filament

Fan speed

Nozzle

Bed

Flow

Speed

The first voice is about the sensor that monitors the presence of the filament. When the sensor no longer detects the filament, the printer goes automatically into change

filament procedure (identical to that described afterwards); the buzzer sounds and the printer waits to receive the new filament just for 24 hours. By pressing the control

knob the buzzer will stop and the machine will be ready for the loading of the new filament. Clicking control knob another time will resume the printing.

You can disable the sensor of the filament: select the "prepare" menu and from "check filament” you can chose "ON" or "OFF"; at the start of each print the value is reset to

"ON". The same procedure is possible from “tune” menu.

The following voice is used to change the filament while printing: since the printer has the “check filament sensor” this item permits you to change filament when you

want, for instance if you want change color.

The procedure starts with the shift of the extruder in parking area, then the extruder motor expels the current filament and the internal buzzer is activated as soon as the

filament is unloaded. Press now the control knob to insert the new filament: the extruder motor will help you dragging the filament, while you insert it in contact with the

cogwheel of the stepper motor. When the flow of the new filament is ok, press the control knob again to resume printing.

The next item is the fan speed, adjustable from 0 to 255; with very low values the fan may not even start.

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 19

Sharebot Next Generation XXL+

user's manual

“Nozzle” is to set the temperature of the nozzle: the value is in degrees Celsius and any change must be confirmed by pressing the menu knob. Same thing for following

item, the heated bed.

“Flow” is relative to the percentage increment or decrement of the extrusion phase: the slicing software calculates exactly how the material is extruded to create

individual layers, but with this item we can "get fat" or "lean" the print as we prefer.

The last item is about the printing speed: we can change the percentage of all the speeds of the gcode. It is identical to the one that we can change directly in the info

screen. Note that generally, increasing the speed, decreases the quality.

4

-

Setti g the pri ter

Your Sharebot XXL+ is a mechanical device built with care both in design and in the assembly from qualified staff in Italy. To keep it in a state of optimal

functioning is necessary to compensate some normal processes of adjustment, for example, due to repeated thermal cycles of extruder motors and print

heated bed.

During each printing process, the entire machine is subject to vibrations and movements that in the long run can loosen the four screws that hold the

printing bed. This leads to not have more precise and uniform spacing of the glass plate from the extruder which inevitably fails to apply the first layer with

the accuracy and uniformity necessary for quality printing. Just exit out of the box, Sharebot XXL+ should be even with the exact factory calibration, but a long

journey or vibrations during transport may have done move some calibration screw.

Loading the ilament

The first thing to do before printing is load the printing filament. Sharebot XXL+ has a specific procedure to load the filament from “Prepare” menu: select “change

filament” and the procedure starts heating the extruder; when the temperature of 230° c is reached, you can load or unload the filament (the procedure is identical to that

which is accessible from the menu “Tune” described in the previous chapter).

When the extruder is cold it retains the material: don't force it by pulling or pushing it into the extruder. To load the filament, obliquely cut the filament tip and insert it in

the PTFE guide through the check filament sensor till the extruder head, making sure that the filament is dragged, surpassing the cogwheel and into the hole below. You

can help yourself by releasing the teflon guide pressing the orange quick-release on the extruder block.

Sharebot srl Nibionno Italy

All rights reserved. No part of this manual may be reproduced or transmitted in any form or by any means without prior permission

page 20

Table of contents

Other SHAREBOT 3D Printer manuals