BIQU PIXEL L 9.1 User manual

9.1 LCD 3D Printer User Guide

Notes:

● Please keep the 9.1 LCD printer and its accessories out of the reach of children.

●Please clean the cured resin in the resin vat and build platform after a failed print, or it can

damage the printer.

●Please pour the photosensitive resin into the vat till the resin reaches about 2/3 of the vat, so as

to prevent resin spilling as the build platform falling down.

●Please use 95% degree (or higher) ethyl alcohol or isopropyl alcohol to wash your model unless

you are using water washable resin.

●Please place the LCD indoors, and protect it from direct sunlight, dust, rain and moisture.

●Please wear a mask and gloves before using and avoid direct skin contact.

●Please level the build platform for the first time of use.

●In case of an emergency during use, please shut off the printer in time.

For technical support, please contact the official store customer service where you purchased it.

Content

1. Product Description ......................................................................................错误!未定义书签。

2. Machine Installation and Commissioning ....................................................错误!未定义书签。

3. Function Introduction ...................................................................................错误!未定义书签。

3.1 About screen ...................................................................................... 错误!未定义书签。

3.2 Thermostat mode ...............................................................................错误!未定义书签。

3.2.1 About thermostatic control panel .......................................... 错误!未定义书签。

3.2.2 Function description ............................................................... 错误!未定义书签。

3.3 Exposure test ...................................................................................... 错误!未定义书签。

3.4 Resin vat cleaning ...............................................................................错误!未定义书签。

3.5 Tolerance compensation .................................................................... 错误!未定义书签。

4. Model Printing ..............................................................................................错误!未定义书签。

4.1 Installation and setting of slicing software........................................ 错误!未定义书签。

4.2 Slicing ..................................................................................................错误!未定义书签。

4.3 Model printing ....................................................................................错误!未定义书签。

5. Post-Processing of Printed Model ................................................................错误!未定义书签。

1. Product Description

Packing List

resin vat

build platform

9.1 LCD

main body

acrylic protective cover

power cord

adapter

spiral micrometer

auto feeder

photosensitive resin

(250g)

thermostatic control

mask

release film

PVC gloves

filter

tool kit

manual

more

Specification

Name

LCD printer, 9.1”

Size

296*300*563mm

Weight

19.05kg (net weight)

Printing Size

196.704*122.880*220mm

Molding Tech

LCD technology

Screen Resolution

4K

Screen Type

monochrome screen

Operation Screen

4.3” touch screen

Printing Pixel

0.05mm

Layer Thickness Precision

0.025mm~0.03mm

Rated Voltage

24V

Real Power

210W

Light Source

matrix parallel light source

Printing Material

photosensitive resin

Printing Method

U disk

File Type

ctb

Light Source Wavelength

405nm

2. Machine Installation and Commissioning

Step 1

①nut

②resin vat

Loosen the nut to remove the resin vat.

Step 2

①nut

②screw connector

③build platform

Remove the protective film of the build platform, and mount the build platform to the screw

connector.

Step 3

Place a piece of A4 paper on the screen board.

Step 4

Connect the power supply and switch on. The interface is as shown, click ‘Tool”.

Click “Manual” to control the movement of build platform.

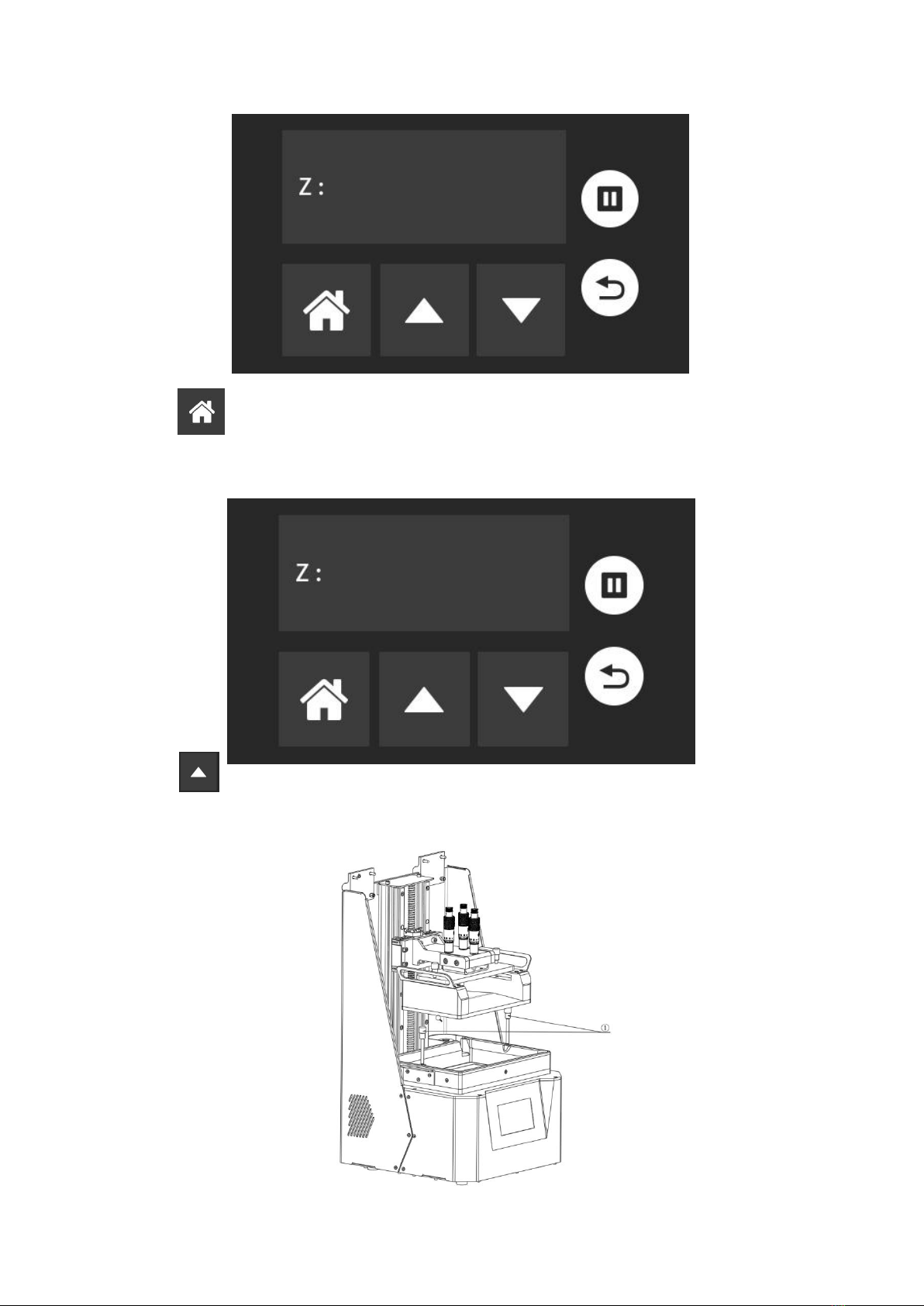

Click ” ” to make the build platform decline to the origin of coordinates.

Step 5

①M5x12 socket head cap screw

②fixed block

Unscrew the M5x12 socket head cap screw to loosen the build platform.

Step 6

①build platform rack

②spiral micrometer thimble

Rotate the top of 3 spiral micrometers (on the screw connector), and ensure that the thimble

contacts the build platform rack. Check whether the platform fits evenly with the paper.

Fix the screw connector to the build platform rack with the M5X12 socket head cap screw and

fixed block.

Step 7

Click , set the home position of the Z-axis: the build platform close to the screen.

Step 8

Click to to make the build platform ascend to the safe position, clean the surface of the LCD

screen and release liner, then put the resin vat on the screen and fix it.

①nut

Note: Before printing, make sure the bolt nut fixing the build platform and resin vat set are fully

tightened.

Step 9

Pour the photosensitive resin into the vat till the resin reaches about 2/3 of the vat, so as to

prevent resin spilling as the build platform falling down.

Step 10

①auto-feeder

②photosensitive resin bottle

Screw the auto-feeder into the photosensitive resin bottle, insert it into the resin vat and fix it by

rotating.

The auto-feeder will add the resin according to the liquid level to ensure a sufficient filament.

Installation and debugging of printer completed

3. Function Introduction

3.1 About screen

In the following interface, you can modify the system language, check system information, screen

calibration, etc.

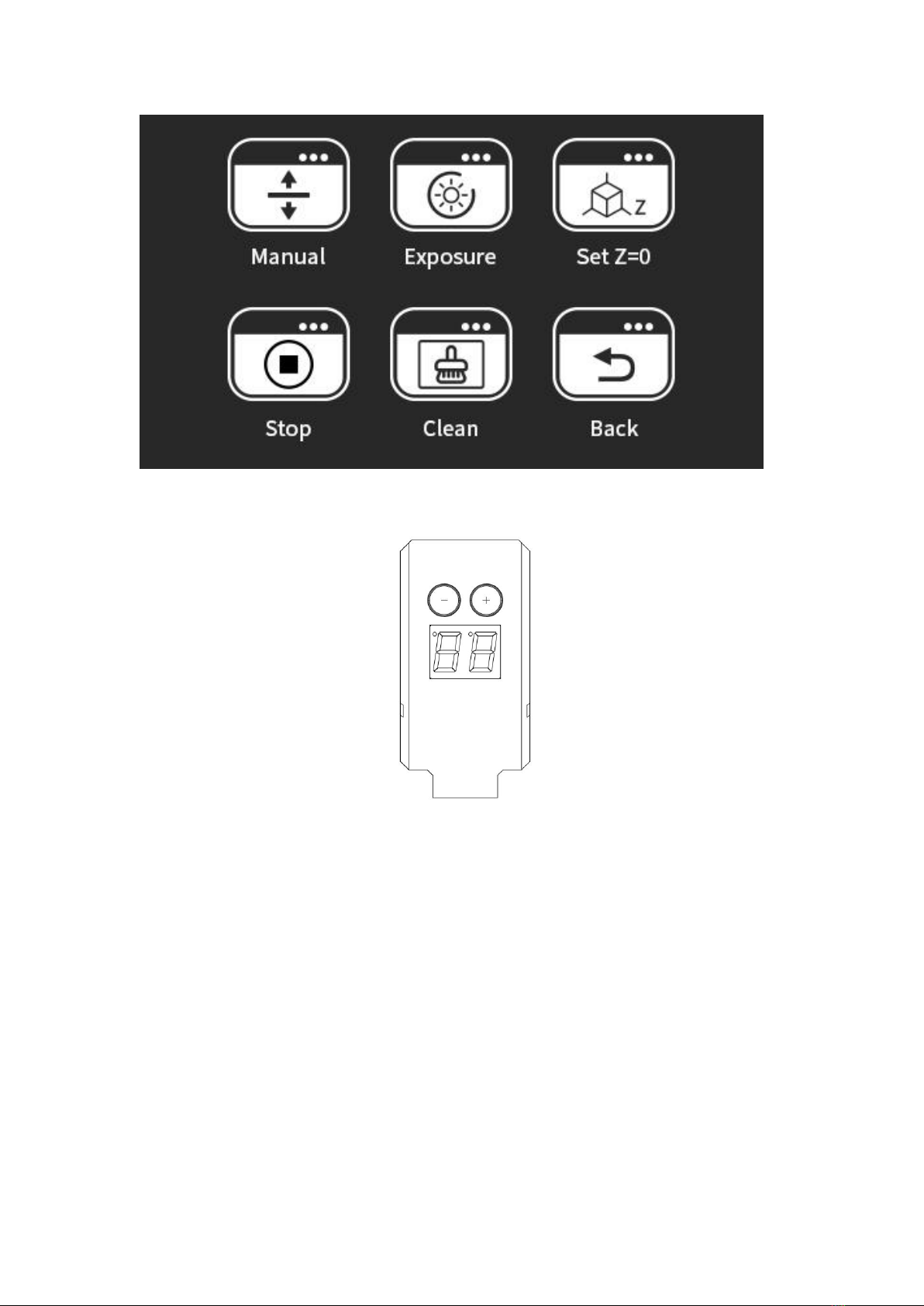

As the below interface shown, you can operate the machine, such as movement, exposure test,

Z-axis zero setting, vat cleaning, etc.

3.2 Thermostat mode

3.2.1 About thermostatic control panel

“+” “-” Function

3.2.2 Function description

1) Connect power supply, then press both “+” and “-” simultaneously to activate, and LED will

display the current thermistor temperature.

2) Adjust the temperature by pressing “+” and “-”

Short press “+” “-” to add or subtract the setting temperature.

Long press “+” “-” to add or subtract the setting temperature constantly.

LED will display the actual temperature after temperature setting in 2s. LED flickers when it turns

under the setting temperature.

3) Protection mode

When the resin vat does not contact the main body or is in poor contact, LED will display "E.0",

and protection mode can be activated. Then take up the resin vat and put it down to avoid short

circuit and electric arc.

When the LED displays “E.0”, and the resin vat does not work, press both “+” and “-” to activate

it.

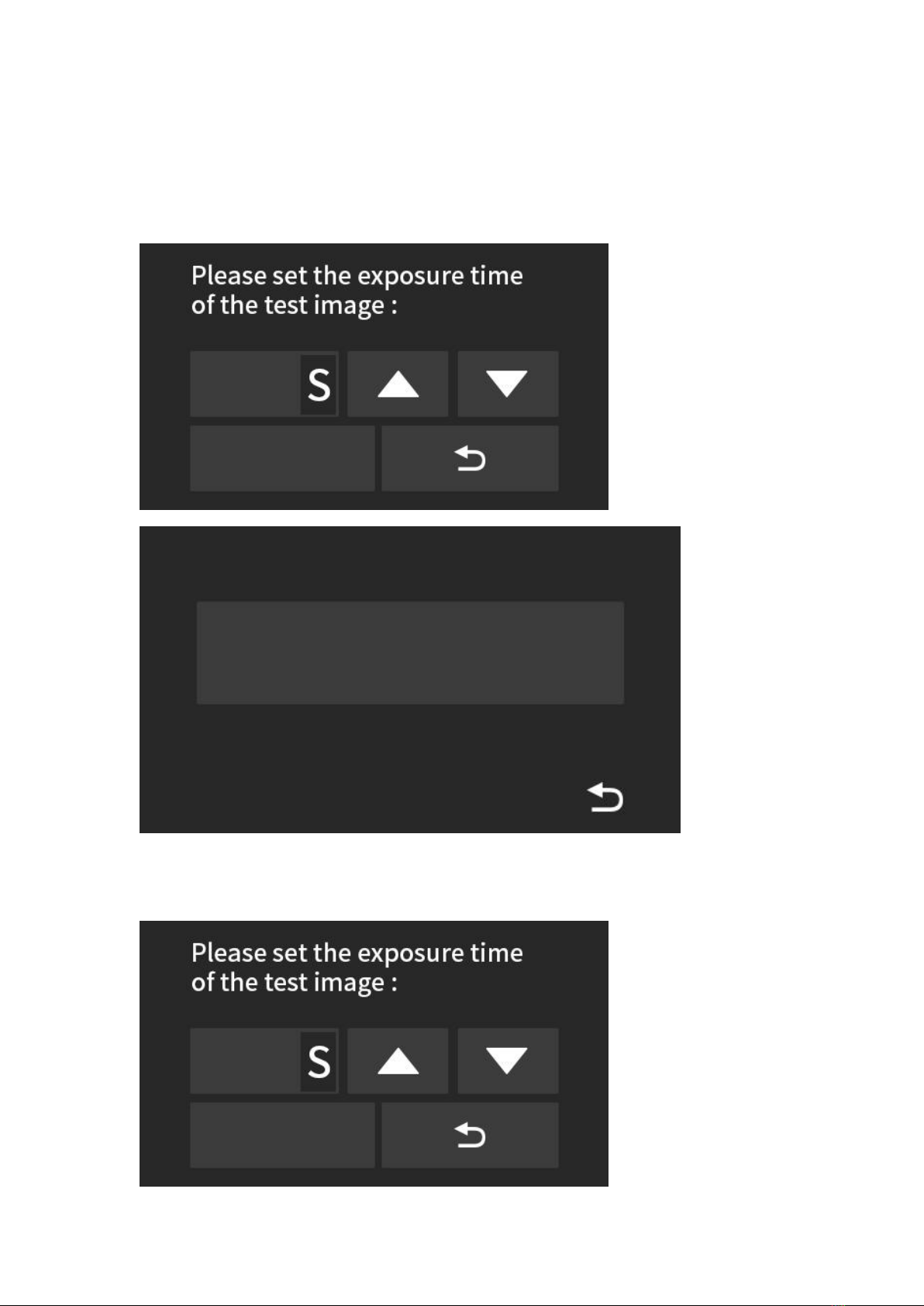

3.3 Exposure test

This function is to test if the light source and screen are normal.

3.4 Resin vat cleaning

Large-area exposure of the screen solidifies the remaining solid impurities, which cured into a

thin sheet. Then remove it with the plastic blade.

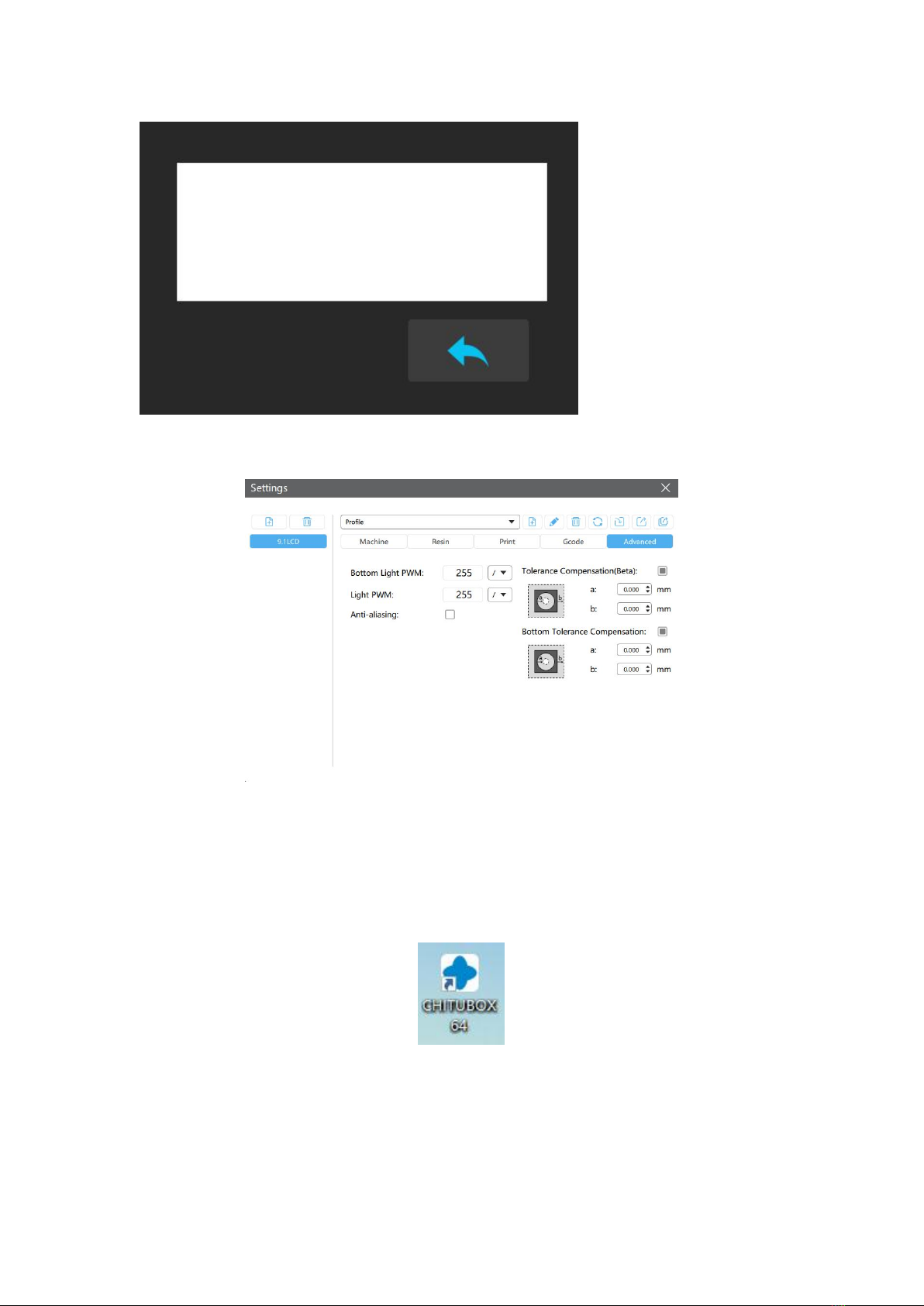

3.5 Tolerance compensation

As for the matching parts, set the parameter of “Tolerance Compensation” shown as above to

ensure a perfect match.

4. Model Printing

4.1 Installation and setting of slicing software

Install CHITUBOX (download link: https://www.chitubox.com/download.html)

4.1.1 Printer settings

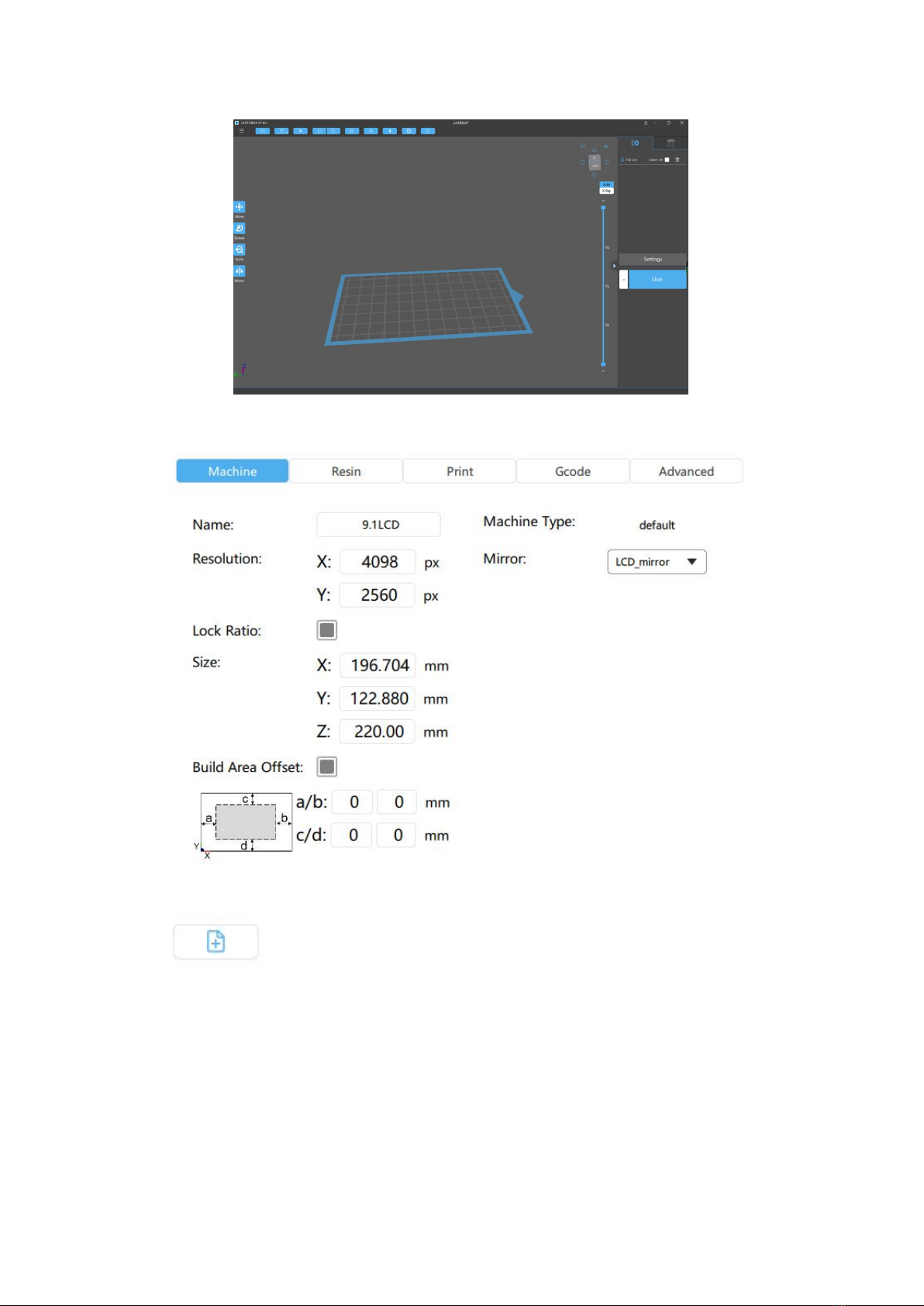

Open CHITUBOX software, the interface is as shown, click "Settings".

(Fig. 1)

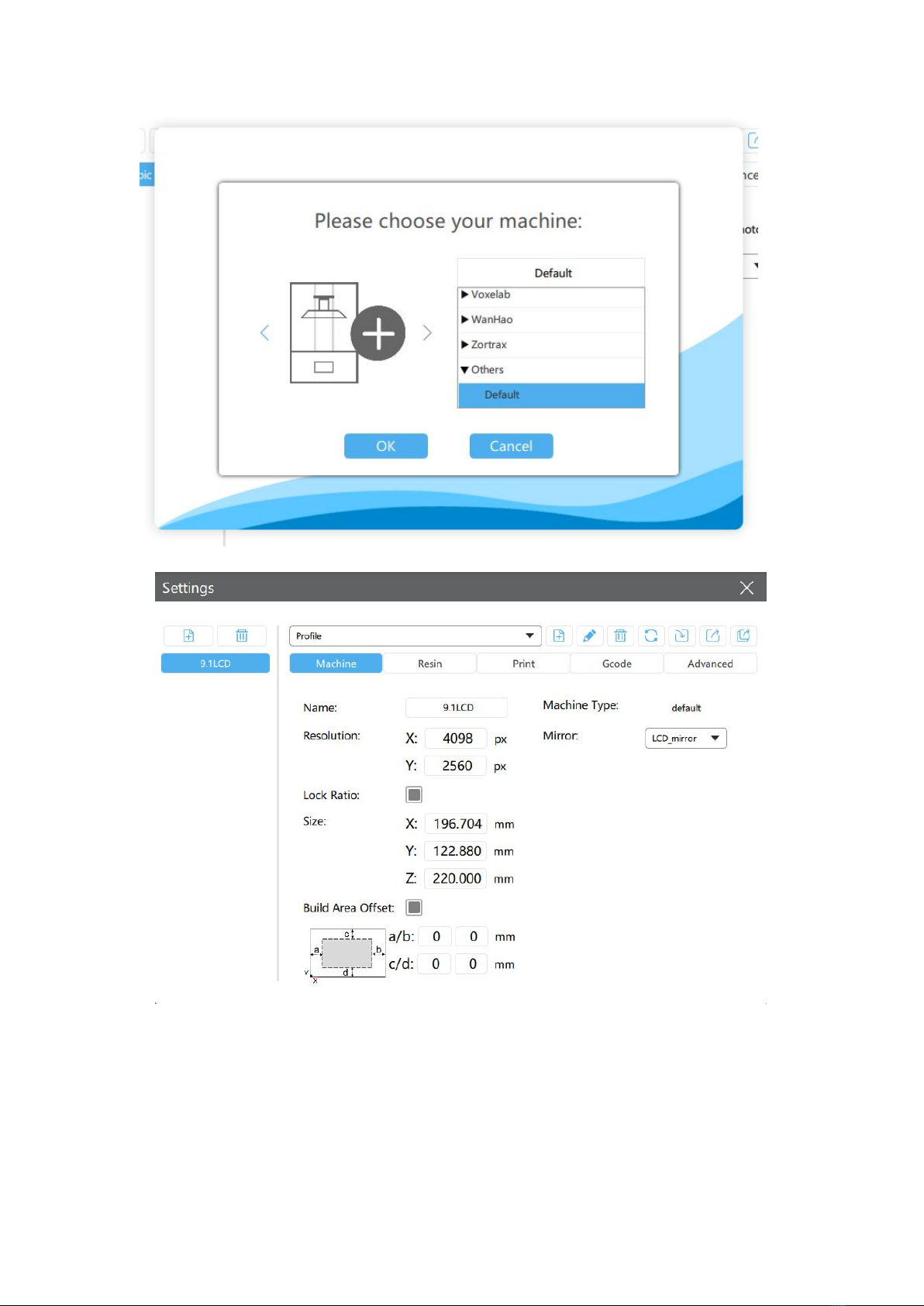

Click , choose “Others” →“Default” to add printer.

(Fig. 2)

(Fig. 3)

Resolution: 4098x2560 Size: 196.704x122.880x220.000mm

(Fig. 4)

The "Exposure Time" and "Bottom Exposure Time" above are for reference only. As for the

specific parameters, please set according to the photosensitive resin material file.

4.2. Slicing

4.2.1. Check the model by CHITUBOX

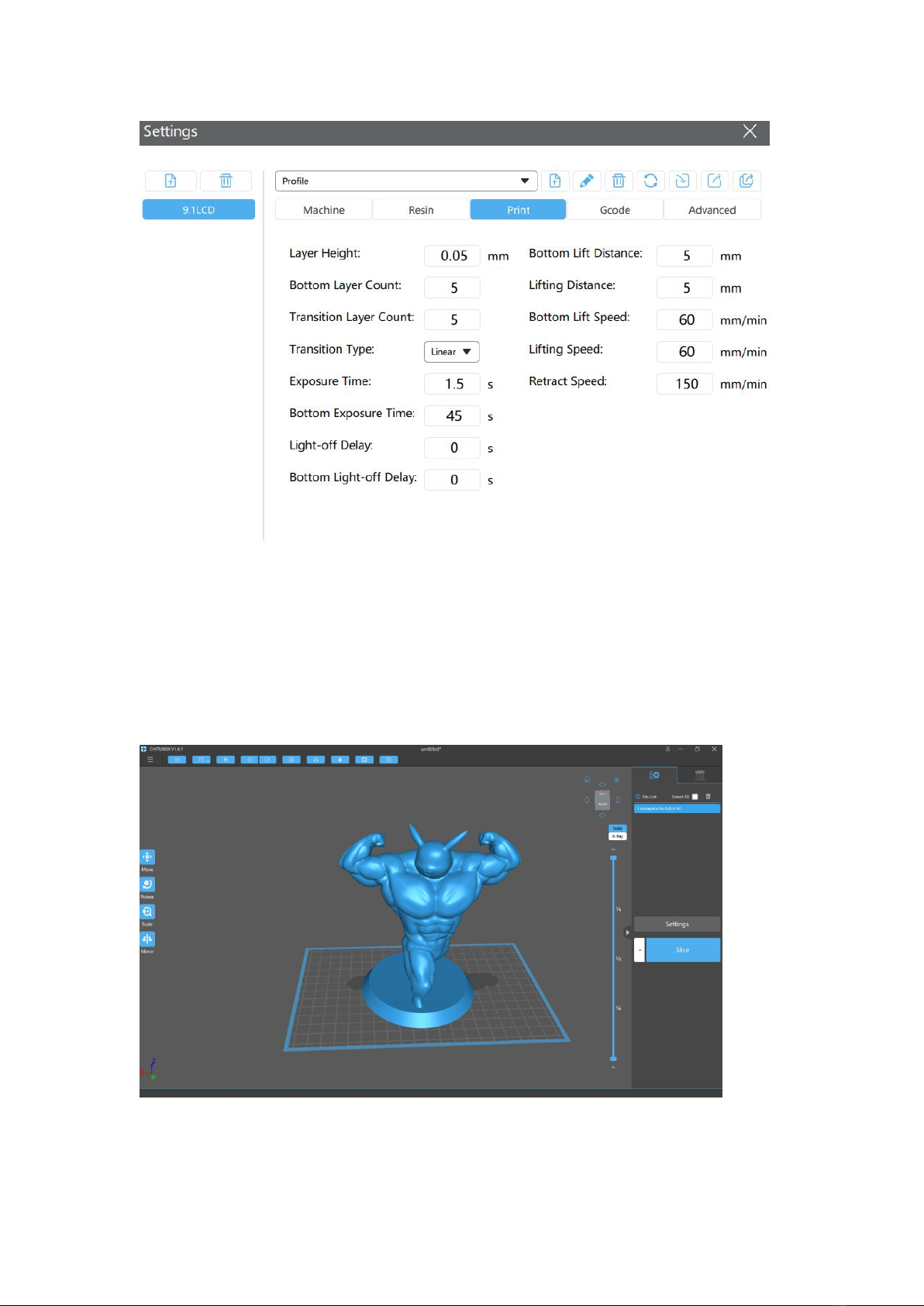

(Fig. 5)

Models can be scaled, rotated, moved, copied, auto placed, shelled, digging holes, repaired, etc.

4.2.2. Set support parameters

(Fig. 6)

For some parts with large inclinations or hanging in the air, it needs to add support to ensure that

the model can be printed completely.

Click "+AII" to add support automatically or manually.

Click the right side of screen to change the size of support.

(Fig. 7)

(Fig. 8)

Click ”Slice” to slice the model.

(Fig. 9)

Double check the shape of each slice layer, click “save” to save the slice file.

Note: The file format is “ctb”, and the U disk needs to be connected to the printer.

4.3 Model printing

Click to print.

Table of contents

Other BIQU 3D Printer manuals