ULTRAPENX2™ PTBT5 Operation Manual

Dissolved Oxygen (DO) and Temperature Pen for use with your Mobile Device Running the PTBTX2™ App

PTBT5OM-X2 01-20 1

INTRODUCTION

Thank you for purchasing the Myron L® Company ULTRAPENX2 ™ PTBT5 Dissolved Oxygen (DO) Pen. This instrument

is designed to be extremely accurate, fast, and simple to use in diverse water quality applications. Advanced features

include:

• Real time readings.

• Proprietary sensor design and microprocessor-based circuitry that measures DO with an accuracy of up to ± 2%.

• Temperature compensation algorithm that dynamically corrects for changes in membrane / sample temperature.

• Adjustment for Altitude and sample Salinity.

• Three calibration methods, AIR (Water Saturated Air), WATER (Air Saturated Water), and ZERO (0 ppm DO).

• A rugged, reliable design with an aircraft aluminum body.

• Waterproof housing.

• Replacement membranes contained in easy to install, screw-on caps.

• Enabled.

FEATURES

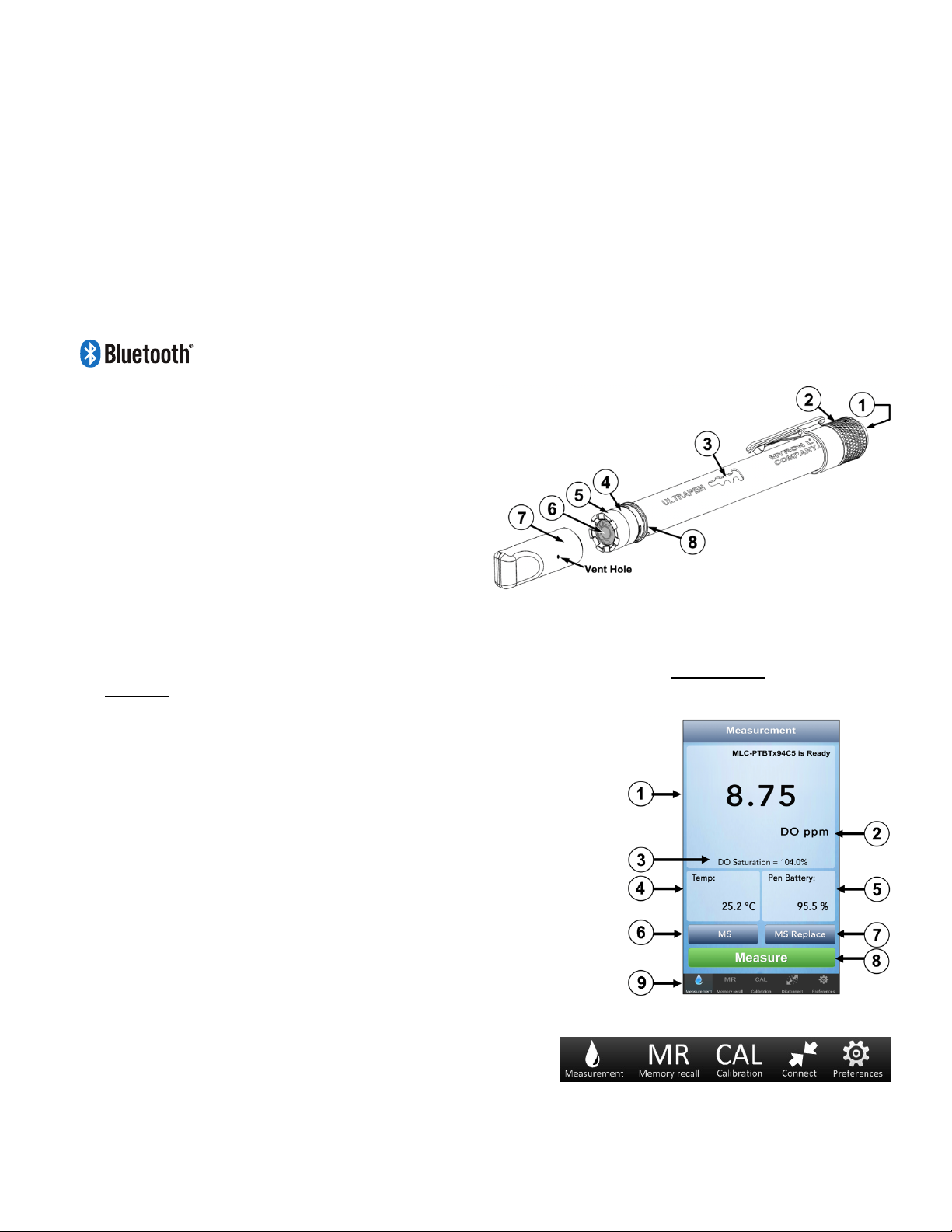

I. PTBT5 - LAYOUT

1. PEN BUTTON – Press to turn PTBT5 ON and place it in Standby mode.

2. BATTERY CAP – Unscrew to change battery.

3. LED INDICATOR LIGHT – Flashes rapidly when the PTBT5 is measuring and

once every 5 seconds when the PTBT5 is in Standby mode.

4. DO SENSOR BODY – Contains electrodes and reagent for

Dissolved Oxygen and Temperature measurements.

5. DO SENSOR CAP – Holds the DO sensor membrane

in place.

6. DO MEMBRANE – Permeable membrane through

which Dissolved Oxygen passes.

7. PROTECTIVE / HYDRATION CAP – Protects sensor from damage. The sensor should be kept moist at all times.

• Always replace the protective / hydration cap containing a sponge moistened with DI, RO or distilled water.

• See the MAINTENANCE section below for instructions for storing > 1 month.

• When removing or replacing the cap, gently wiggle it back and forth while pulling / pushing. DO NOT twist!

• Vent Hole: Allows air pressure to equalize during AIR calibration.

8. CAP STOP – Pushing the protective / hydration cap beyond the cap stop could damage the sensor.

II PTBTX2 APP MEASUREMENT SCREEN

1. MEASUREMENT VALUE FIELD – Displays the measured value of the solution.

When the PTBT5 turns OFF, displays the message, "Ultrapen is Offline".

2. UNITS OF MEASURE – Displays DO units of measure (ppm or %).

3. SECONDARY MESSAGE FIELD – In Default mode displays DO Saturation.

Otherwise displays the current parameter (DO Concentration or Saturation)

4. SOLUTION TEMPERATURE – Measured temperature of the solution.

5. PTBT5 BATTERY LEVEL – Flashes RED when PTBT5 battery is ≤ 25%.

6. MEMORY STORE BUTTON – Tap here to record the measurement in the App's

database.

7. MEMORY REPLACE BUTTON – Tap here to replace a previously stored

measurement with data from a new measurement.

8. MEASURE BUTTON – Tap this to start a new measurement.

9. FEATURE NAVIGATION BAR – These buttons activate various App features.

III. FEATURE NAVIGATION BAR

This bar appears at the bottom of all screens. It’s used to navigate between the App’s main functional areas.

MEASUREMENT – Returns the App to the Measurement screen.

MEMORY RECALL – Displays a list of saved measurements.

CALIBRATION – Places the App in Calibration mode.

CONNECT – Opens the App's Bluetooth Connect / Disconnect screen. Once a PTBT5 is connected to the App the button label changes

to say, “Disconnect."

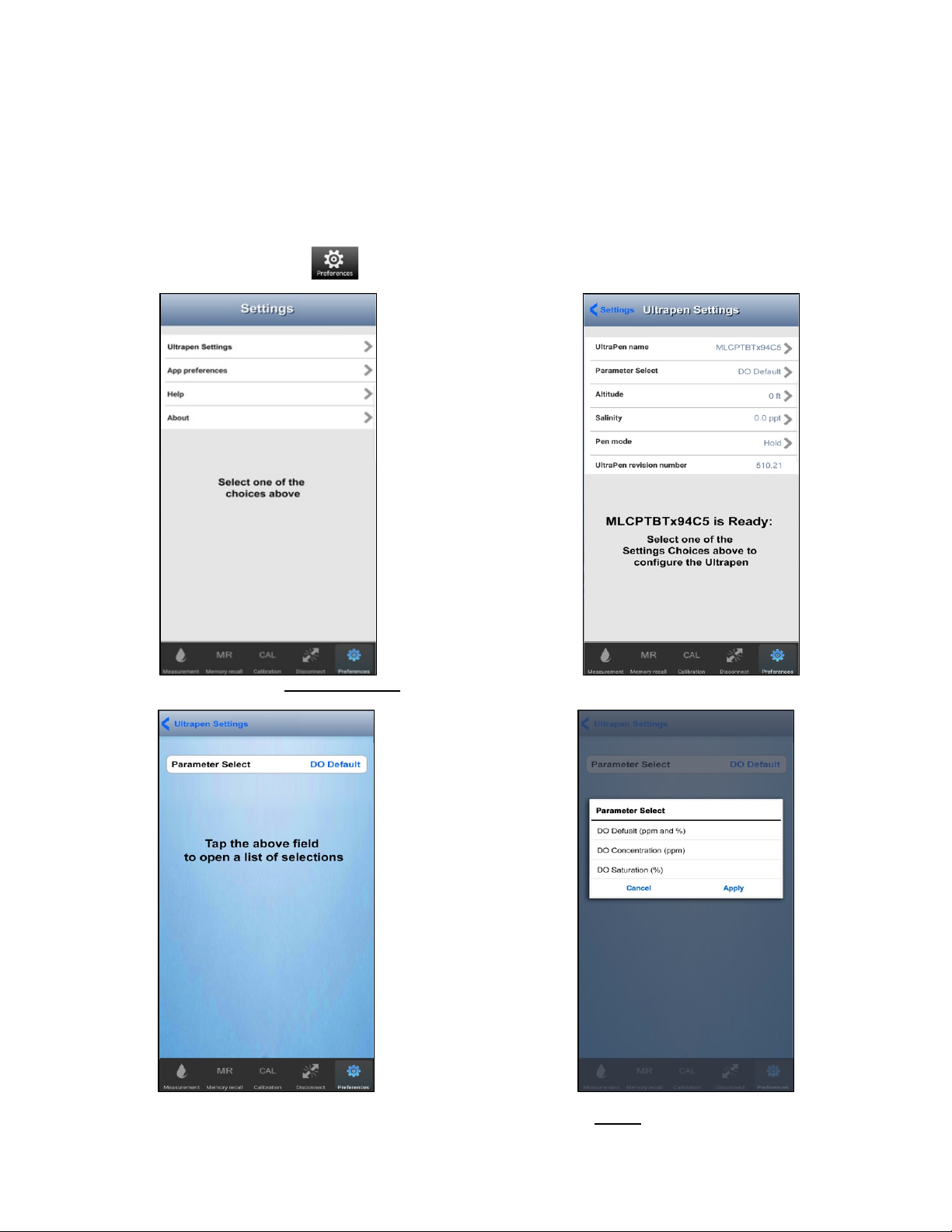

PREFERENCES – Opens the App's Preferences & Settings modes, including an internet link to the full App Operation Manual (HELP).