INSTRUCTION MANUAL

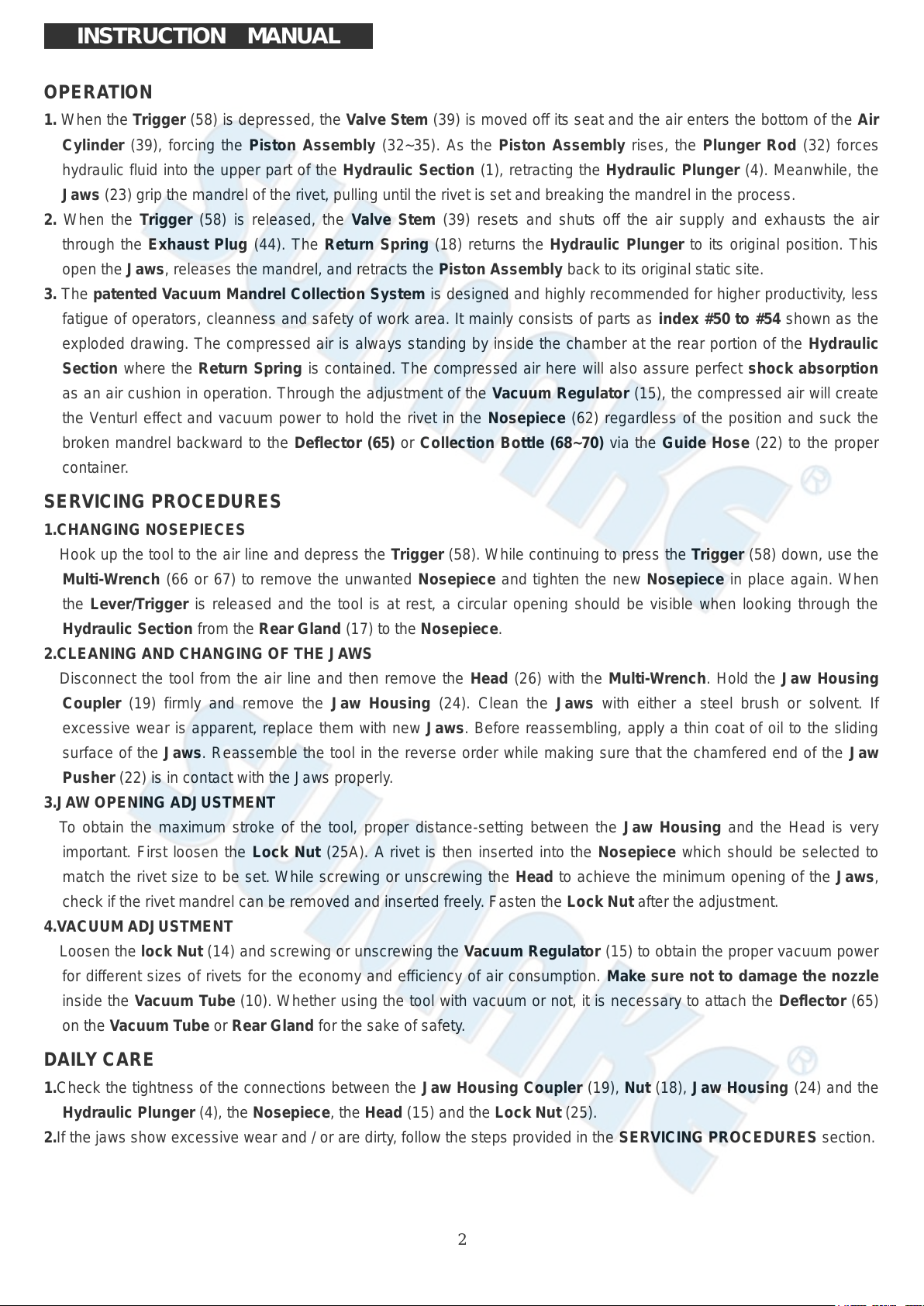

OPERATION

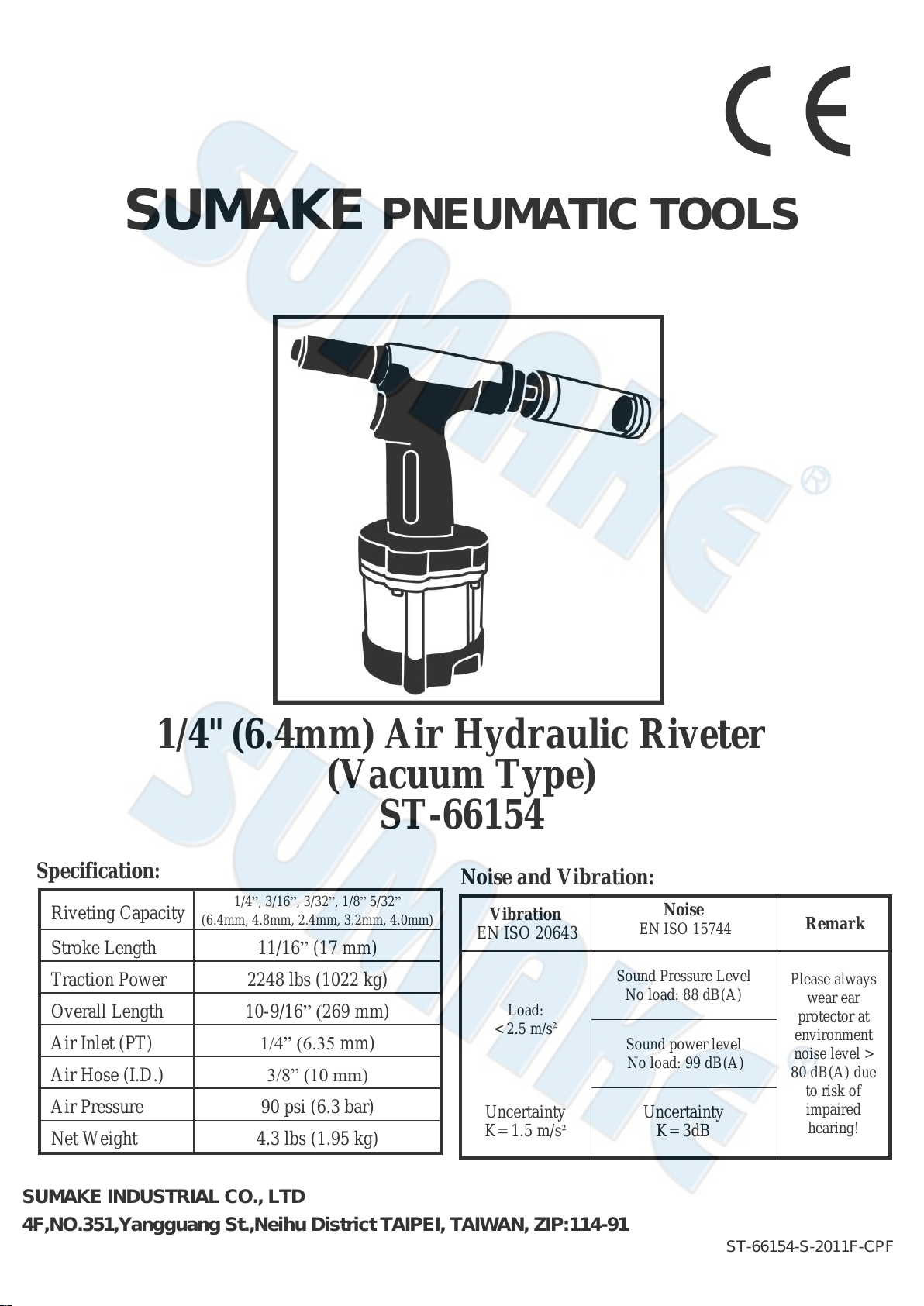

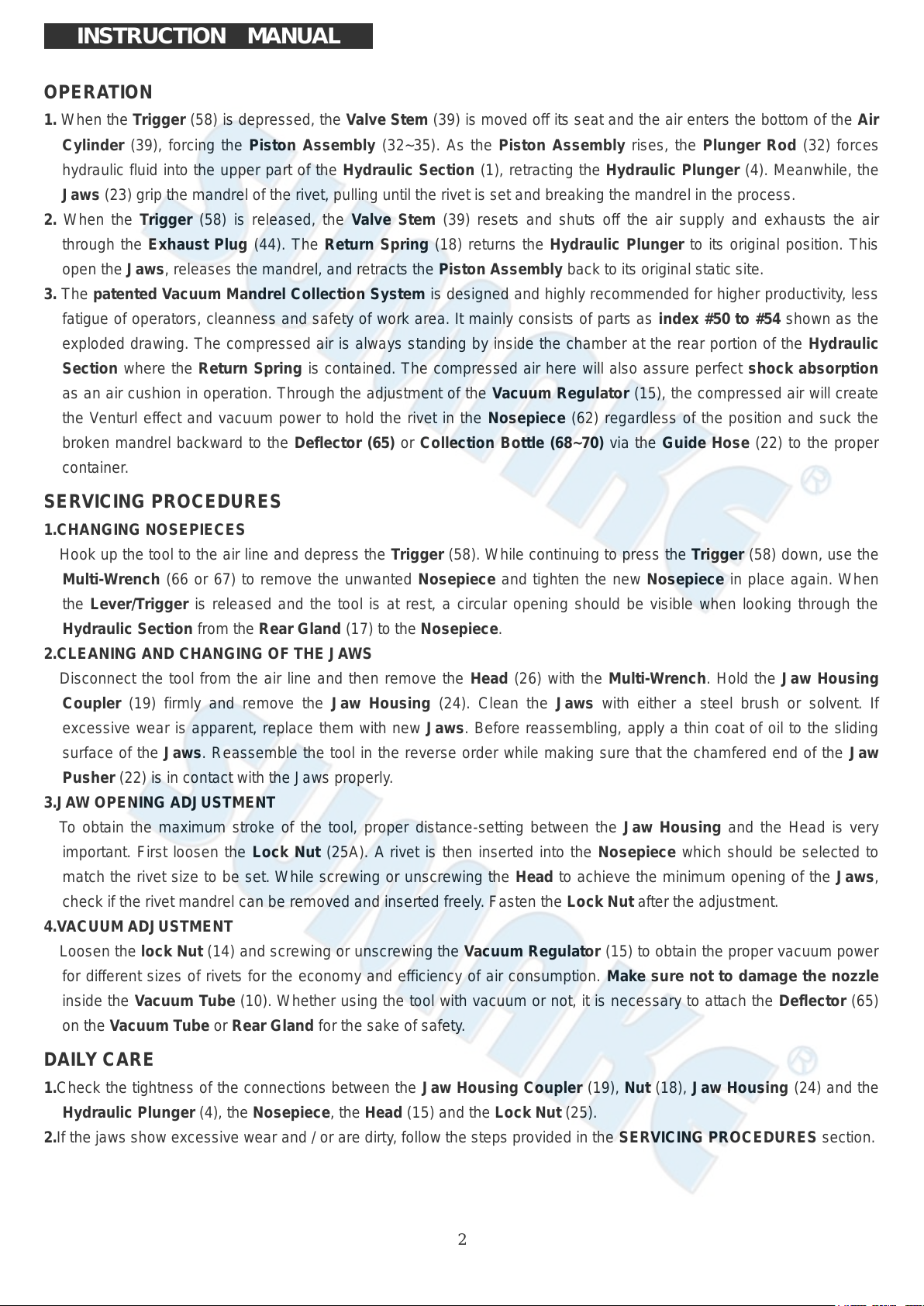

1. When the Trigger (58) is depressed, the Valve Stem (39) is moved off its seat and the air enters the bottom of the Air

Cylinder (39), forcing the Piston Assembly (32~35). As the Piston Assembly rises, the Plunger Rod (32) forces

hydraulic fluid into the upper part of the Hydraulic Section (1), retracting the Hydraulic Plunger (4). Meanwhile, the

Jaws (23) grip the mandrel of the rivet, pulling until the rivet is set and breaking the mandrel in the process.

2. When the Trigger (58) is released, the Valve Stem (39) resets and shuts off the air supply and exhausts the air

through the Exhaust Plug (44). The Return Spring (18) returns the Hydraulic Plunger to its original position. This

open the Jaws, releases the mandrel, and retracts the Piston Assembly back to its original static site.

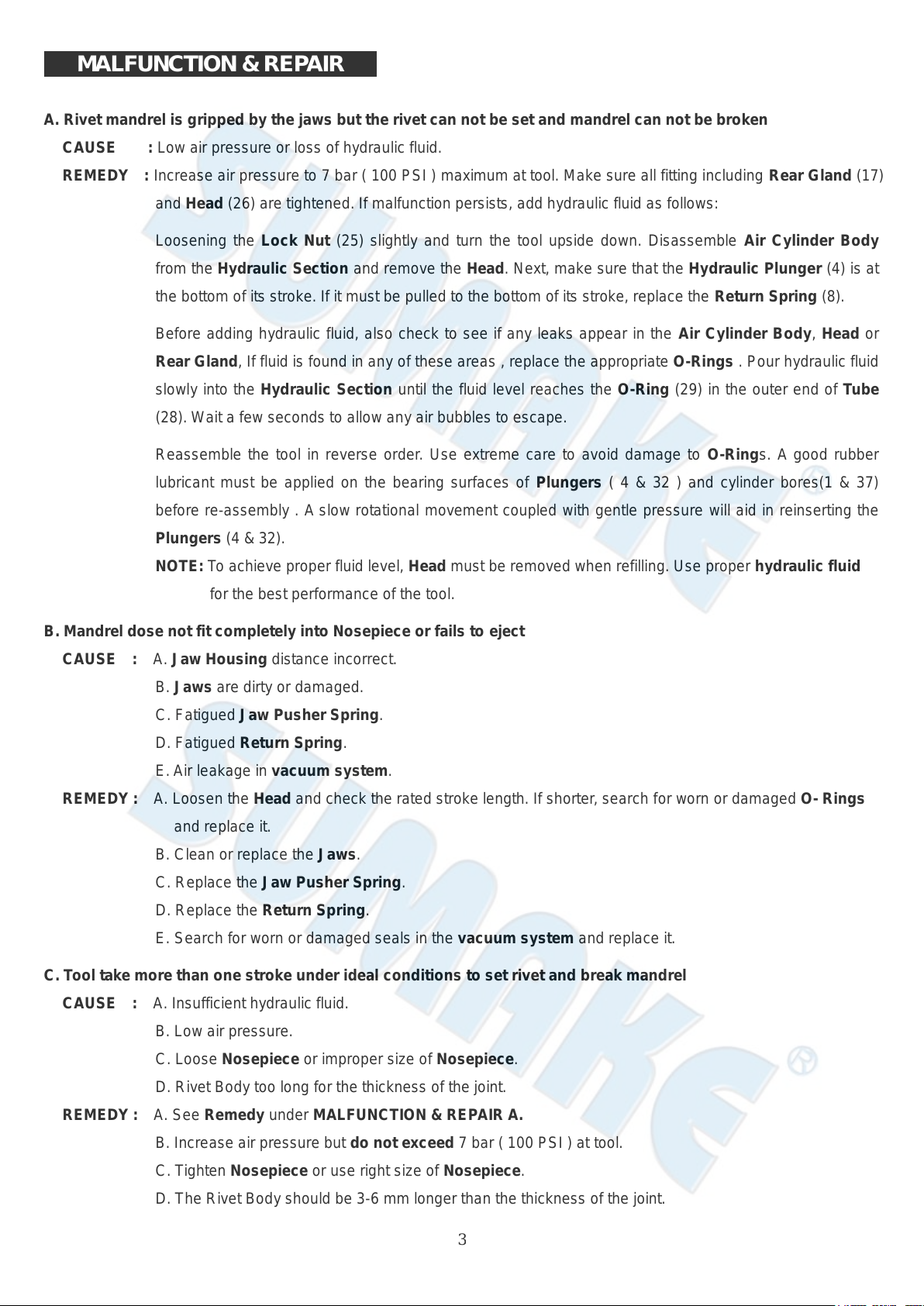

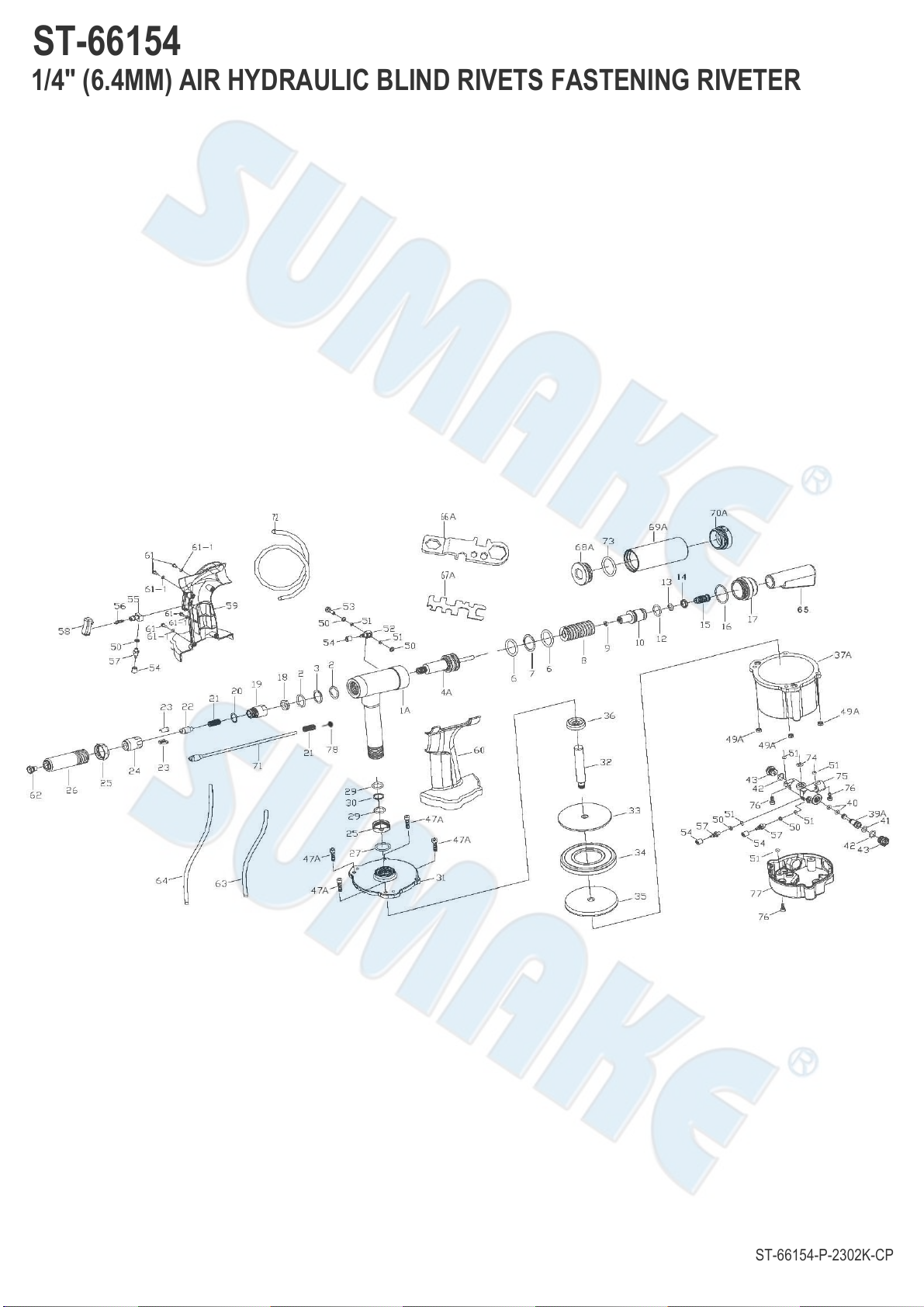

3. The patented Vacuum Mandrel Collection System is designed and highly recommended for higher productivity, less

fatigue of operators, cleanness and safety of work area. It mainly consists of parts as index #50 to #54 shown as the

exploded drawing. The compressed air is always standing by inside the chamber at the rear portion of the Hydraulic

Section where the Return Spring is contained. The compressed air here will also assure perfect shock absorption

as an air cushion in operation. Through the adjustment of the Vacuum Regulator (15), the compressed air will create

the Venturl effect and vacuum power to hold the rivet in the Nosepiece (62) regardless of the position and suck the

broken mandrel backward to the Deflector (65) or Collection Bottle (68~70) via the Guide Hose (22) to the proper

container.

SERVICING PROCEDURES

1.CHANGING NOSEPIECES

Hook up the tool to the air line and depress the Trigger (58). While continuing to press the Trigger (58) down, use the

Multi-Wrench (66 or 67) to remove the unwanted Nosepiece and tighten the new Nosepiece in place again. When

the Lever/Trigger is released and the tool is at rest, a circular opening should be visible when looking through the

Hydraulic Section from the Rear Gland (17) to the Nosepiece.

2.CLEANING AND CHANGING OF THE JAWS

Disconnect the tool from the air line and then remove the Head (26) with the Multi-Wrench. Hold the Jaw Housing

Coupler (19) firmly and remove the Jaw Housing (24). Clean the Jaws with either a steel brush or solvent. If

excessive wear is apparent, replace them with new Jaws. Before reassembling, apply a thin coat of oil to the sliding

surface of the Jaws. Reassemble the tool in the reverse order while making sure that the chamfered end of the Jaw

Pusher (22) is in contact with the Jaws properly.

3.JAW OPENING ADJUSTMENT

To obtain the maximum stroke of the tool, proper distance-setting between the Jaw Housing and the Head is very

important. First loosen the Lock Nut (25A). A rivet is then inserted into the Nosepiece which should be selected to

match the rivet size to be set. While screwing or unscrewing the Head to achieve the minimum opening of the Jaws,

check if the rivet mandrel can be removed and inserted freely. Fasten the Lock Nut after the adjustment.

4.VACUUM ADJUSTMENT

Loosen the lock Nut (14) and screwing or unscrewing the Vacuum Regulator (15) to obtain the proper vacuum power

for different sizes of rivets for the economy and efficiency of air consumption. Make sure not to damage the nozzle

inside the Vacuum Tube (10). Whether using the tool with vacuum or not, it is necessary to attach the Deflector (65)

on the Vacuum Tube or Rear Gland for the sake of safety.

DAILY CARE

1.Check the tightness of the connections between the Jaw Housing Coupler (19), Nut (18), Jaw Housing (24) and the

Hydraulic Plunger (4), the Nosepiece, the Head (15) and the Lock Nut (25).

2.If the jaws show excessive wear and / or are dirty, follow the steps provided in the SERVICING PROCEDURES section.