3 of 8

www.NabcoEntrances.com GT1505BumpOutConvenienceWindowInstallaonManual

Rev. 12-15-17 P/N C-00208

CHAPTER 3: SCOPE

SECTION 31: To the Installer

The purpose of this manual is to familiarize the installer and purchaser with the proper installaon and operaon of this system. It is

essenal that this equipment be properly installed and operaonal before the window is used in conjuncon with the public. In the

United States, ANSI Standard 156.38 applies. Other local standards or codes may apply. Use them in addion to the ANSI standards.

The owner should determine the window is operang properly and should immediately call for service if there is any malfuncon. All

installaon changes and adjustments must be made by qualied, NABCO trained technicians.

If aer troubleshoong a problem, a sasfactory soluon cannot be achieved, please call Nabco Entrances at 1-877-622-2694 between

8 am – 4:30 pm Central me for addional assistance. All installaon changes and adjustments must be made by qualied, NABCO

trained technicians.

SECTION 32: Objecve

Bumpout Convenience Windows were developed for commercial use in businesses that oer Drive-Thru service and are energy

ecient. The objecve is to increase server producvity.

CHAPTER 4: GETTING STARTED

SECTION 41: Common Service Parts

DN 1820

④

②③⑤⑥

⑦

⑧

①

HEADER COMPONENTS

5

6

12

13

14

15

16

SequentialActivation

SQ

Auxiliary Output(Open-Collector )

OUT

5Amax.(0-20V), 3.2Amax.(20-30V)

30V(42.4Vpeak)max.

Contact Output (Class2 Load only)

Common

N/C

N/O

OUT.A

OUT.B

OUT.C

12VDC-(Common)

7

FUNCTION [SLIDING DOOR]

SYMBOL

No.

Reduced Opening Switch

11

10

9

8

7

6

5

4

3

2

1

Breakout Detector

Sidelite Presence Sensor

Exterior Activation

BA

62

SLS

M1

H

M0

Holding Beam

Interior Activation

12VDC-(Common)

12VDC+

6B

9DC12V

7

61

Mode Switch (see Mode SW Usage shown left)

HANDY TERMINAL・6P

RELATEDDEVICE S・16P

Toprotect against risk of fire

or electricshock,use only the

certifiedNABCO power supply .

WARNING

No.

MOTOR・12P

ERROR

POWER

BA

62

H

6B

61

INDICATORS

POWER・2P

Donot d isassemble the control box.

There are no user serviceable parts

inside.

Tomaintain warranty,repairs must be

made by authorized NABCO facilities.

CAUTION

Adjustments to the door can only be made

with the NABCO Handy Terminal.

Mode SW Usage

Gnd

GndGnd

Open

Open

Open

Gnd

Open

M0

M1

MODE

TWO WAY

ONE WAY

NIGHT

HOLD OPEN

248901-

Microprocessor Controller

20VAC50/60H z

GYROTECH

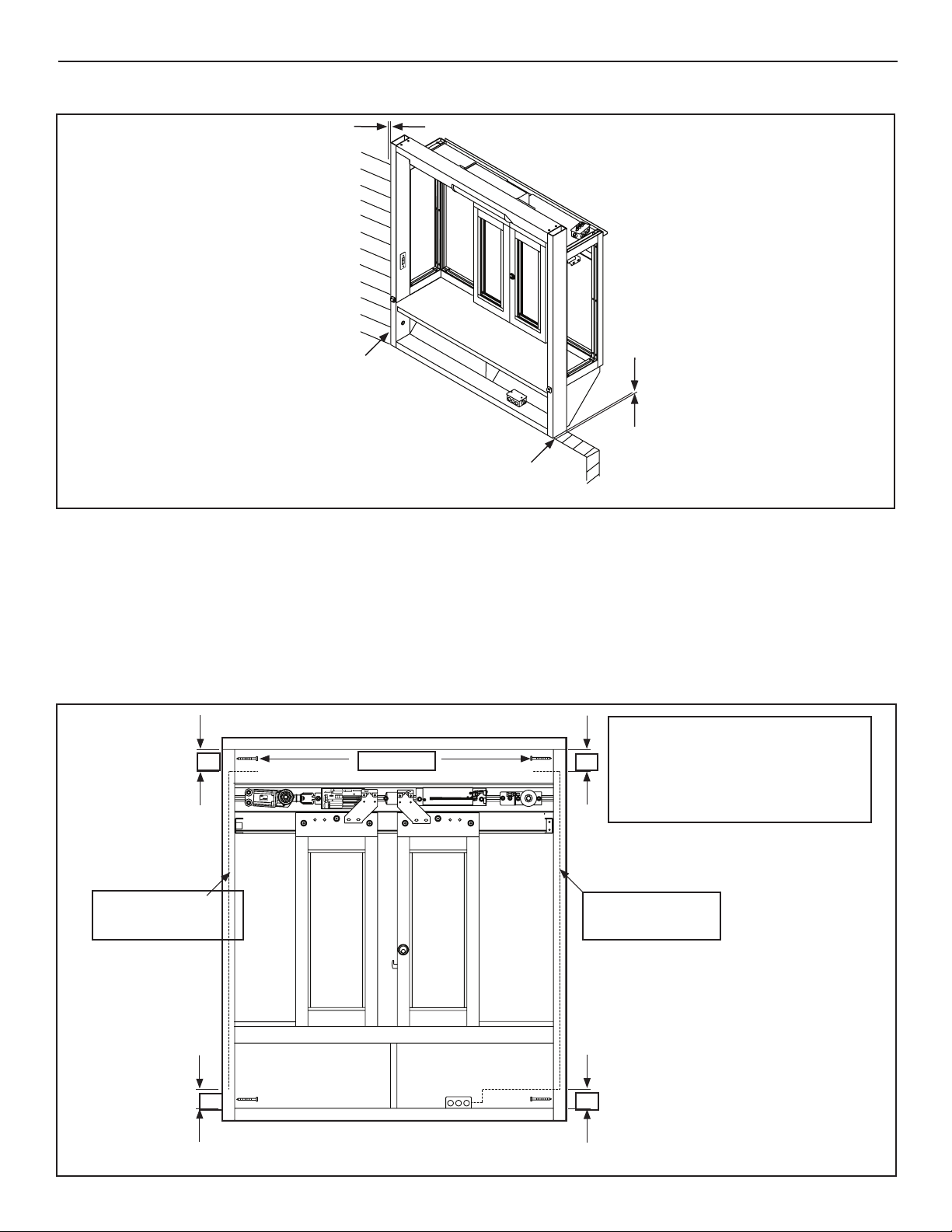

Component Description Part Number Component Description Part Number

1 Idler Pulley A-00042 5 U30 Microprocessor Control V-00020

2 Drive Belt Tensioner A-00078 6 Motor/Operator Assembly M-00395

3 Power Supply A-00717 7 Holding Beam w/Ext Cable V-00073

4 Photoeye, Optex Assy A-00129 8 Rocker Switch A-01356

SECTION 42: Electrical Specicaons

Note: All power wiring and component wiring has been pre-installed at the NABCO Factory. Only the Juncon Box must be

connected to a power supply by a licensed electrician.

Model Electrical Specification

GT 1505 without Air Curtain 120 (±10%) AC 50-60Hz, 1/2 Amp

GT 1505 with Unheated Air Curtain 120 (±10%) AC 50-60Hz, 2 Amps

GT 1505 with Heated Air Curtain 120 (±10%) AC 50-60Hz, 15 Amps

CHAPTER 5: INSTALL THE BUMPOUT WINDOW

SECTION 51: Inspect the Rough Opening

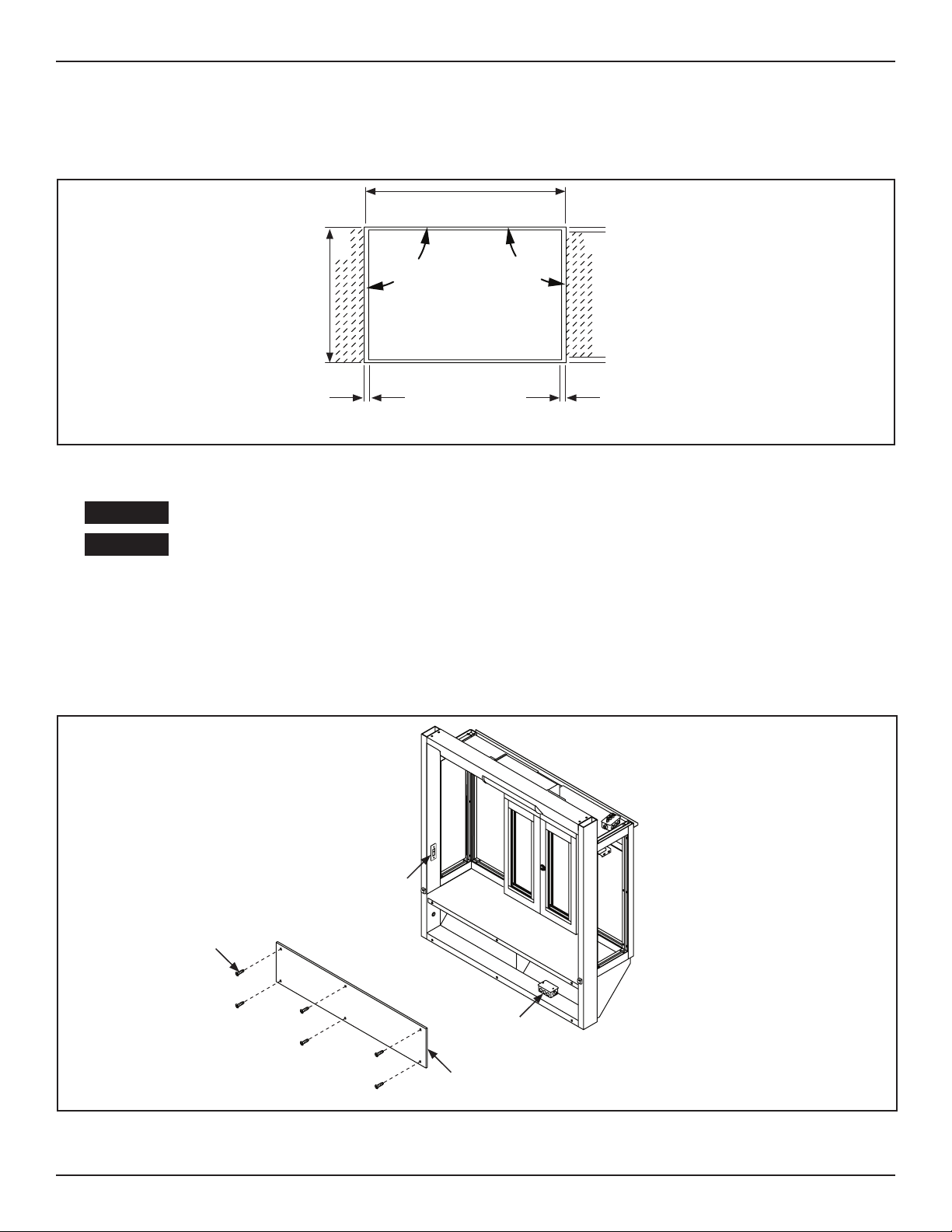

1. Ensure the Rough Opening equals: Package Width + 1/4 inch on each side, and Package height + 1/4 inch on Top and Boom.

2. Ensure the Rough Opening is level. If the boom is not level, be prepared to shim the unit.

3. Inspect the area around the rough opening. There should be no obstrucons that will interfere with the installaon or

performance of the unit.