7.

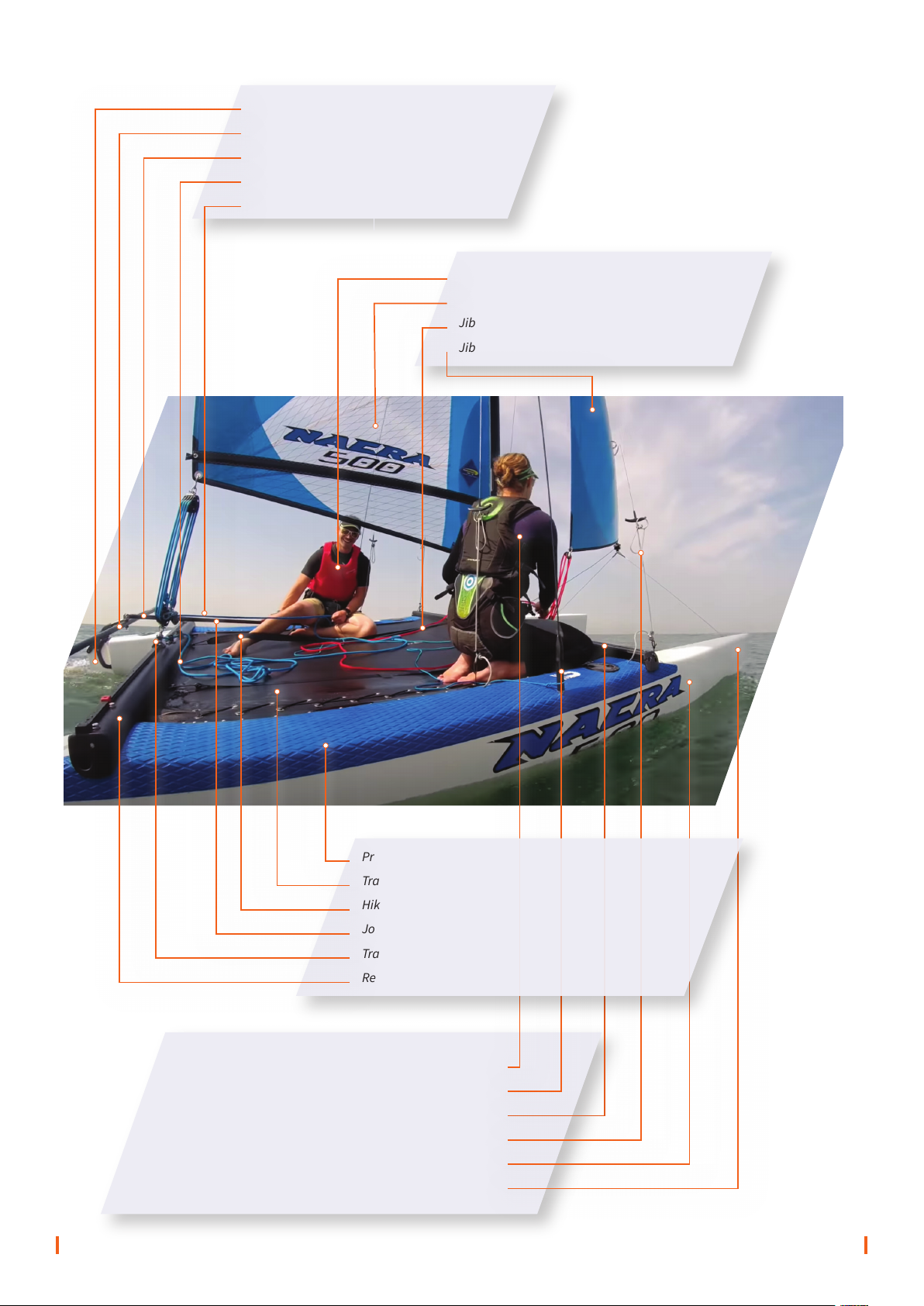

500 MK2 1

About Nacra Sailing 2

Welcome! 3

Icon reading guide 4

Glossery 5

Trim sheet 6

Table of contents 7

Setup 9

1. Basic platform assembly 10

1.1. Beam assembly threaded 12

1.2. Front crossbar pre-bend 14

1.3. Trampoline track on hull 15

1.4. Trampoline tensioning rear lacing 17

1.5. Bridle with connector 18

1.6. Quick righting line 500mk2 19

2. Basic mast assembly 20

2.1. Diamond wires 22

2.2. Fixed Spreaders 23

2.3. Diamond tension 25

2.4. Forestay full battened jib 26

2.5. Forestay furling jib 27

2.6. Fixing the stays 28

3. Mainsail setup 29

3.1. Main halyard 30

3.2. Mainsheet 1:8 31

4. Jib setup 32

4.1. Bridle with furler 33

4.2. Jib sheet 1 to 2 35

5. Rudders 36

5.1. Kick up rudder 37

5.2. Kick up rudder sensitivity adjustment 39

5.3. Rudder alignment 40

6. Trapeze setup 42

6.1. Trapeze shockcord through trampoline 43

6.2. Trapeze wires steel 44

6.3. Can’t miss trapeze wires (optional) 45

6.4. Adjustable trapeze wires (optional) 46

7. Cunningham system 47

7.1. Cunningham 1:8 48

8. Spinnaker system 49

8.1. Divisible bowsprit 50

8.2. Snuerbag 51

8.3. Spinnaker halyard 52

8.4. Spinnaker halyard Furler 53

8.5. Spinnaker snuer system 500MK2 55

8.6. Spinnaker system furling 60

Rigging 64

9. Setting the mast 66

9.1. Preparation 67

9.2. Preparation shroud adjuster 68

9.3. Preparation trapeze non-adjustable 69

9.4. Preparation trapeze adjustable 70

9.5. Raising the mast 71

9.6. Adjusting the stays 74

10. Mainsail rigging 75

10.1. Batten tensioner 76

10.2. Top batten 77

10.3. Traveler system without splittail 78

10.4. Raising the mainsail 79

11. Jib rigging 80

11.1. Hoisting the furling jib 500MK2 81

11.2. Hoisting the fully battened jib 500MK2 82

11.3. Furling the furling jib 83

11.4. Jib cunningham non adjustable 84

11.5. Jib sheet 1 to 2 hook in 85

11.6. Cunningham 1 to 8 non continous with shockcord 86

11.7. Cunningham 1 to 8 87

12. Spinnaker rigging 88

12.1. Bowsprit divisible snuer 89

12.2. Bowsprit divisible furler 90

12.3. Spinnaker snuer system 500MK2 91

12.4. Spinnaker furling system rigging 94

After Sails 97

12.5. Lowering the mainsail 98

12.6. Lowering the jib 99

12.7. Lowering the furling spinnaker 101

12.8. Lowering the mast 102

13. NOTES 103

13.1. Maintenance 104

13.2. Repair 105

14. Parts 500mk2 Sport 106

14.1. Arrival of parts 106

14.2. Rigbox 107

14.3. Rigbox assembly kits 108

14.4. Line Lengths 112

14.5. CONNECT WITH YOUR LOCAL NACRA DEALER 113

Table of contents