Nailor Industries Inc. reserves the right to change any information concerning product or pricing without notice.

SCHEDULE TYPE:

PROJECT:

ENGINEER:

CONTRACTOR:

DATE B SERIES SUPERSEDES DRAWING NO.

4 - 25 - 22 3700 8 - 13 - 19 37SST-1

Page 2 of 2.

Dimensions are in inches (mm).

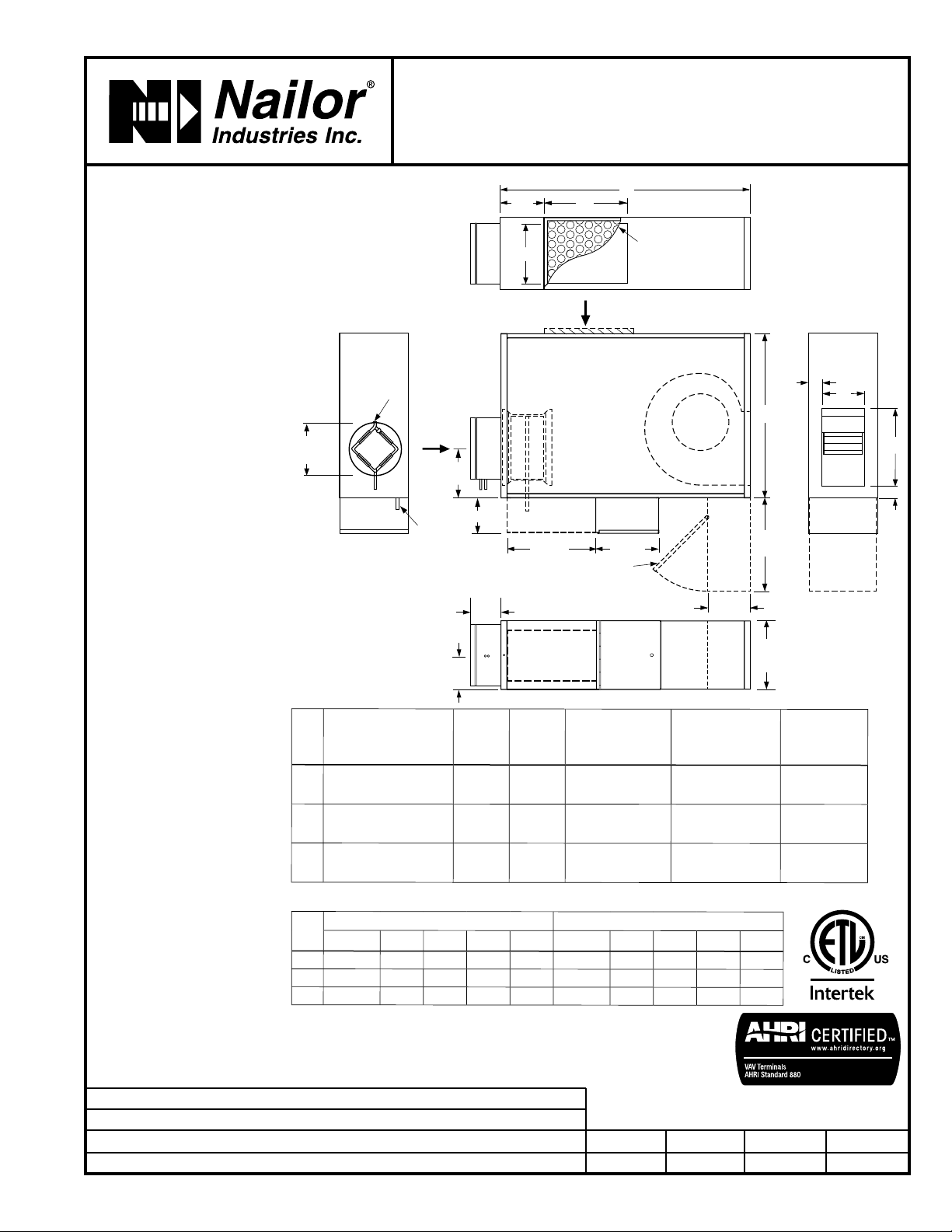

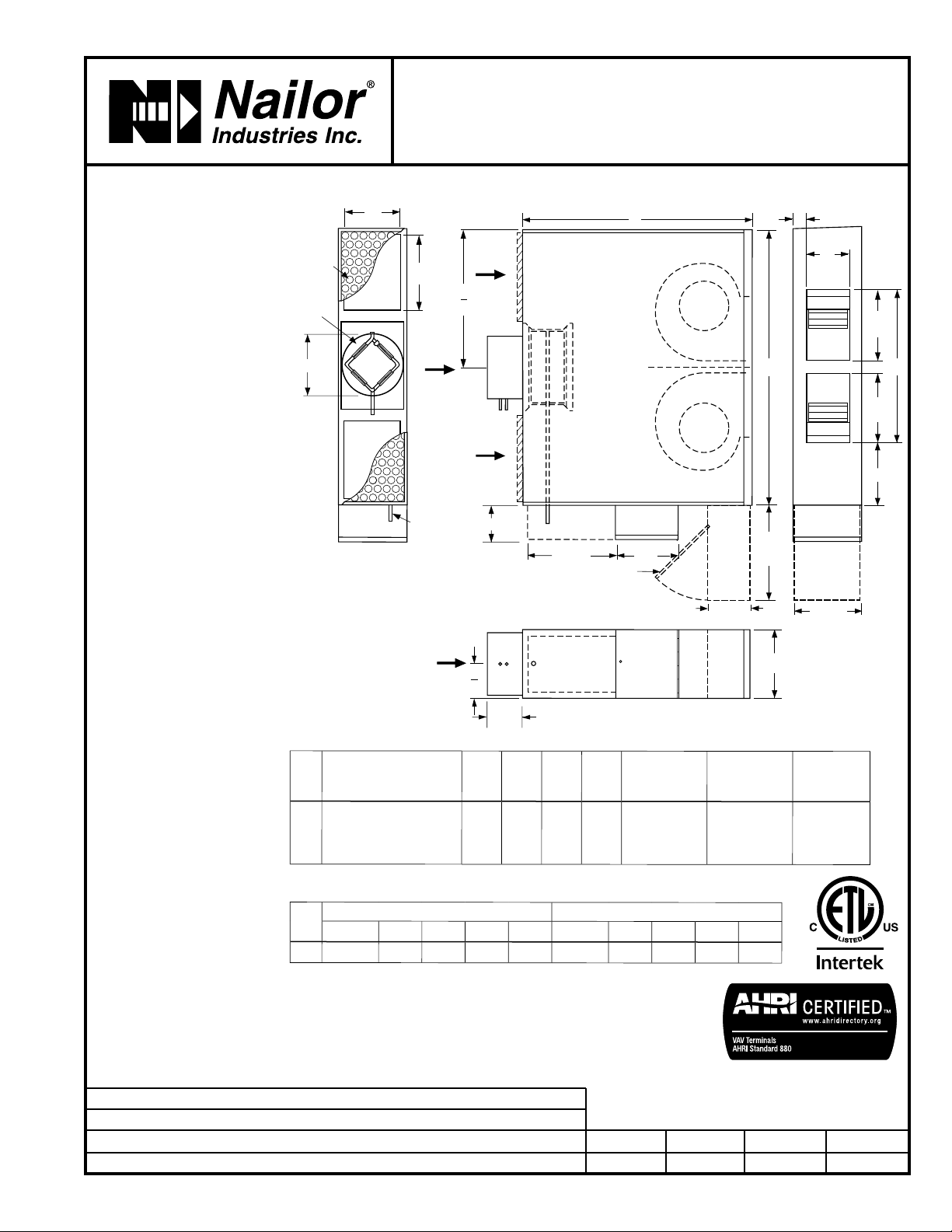

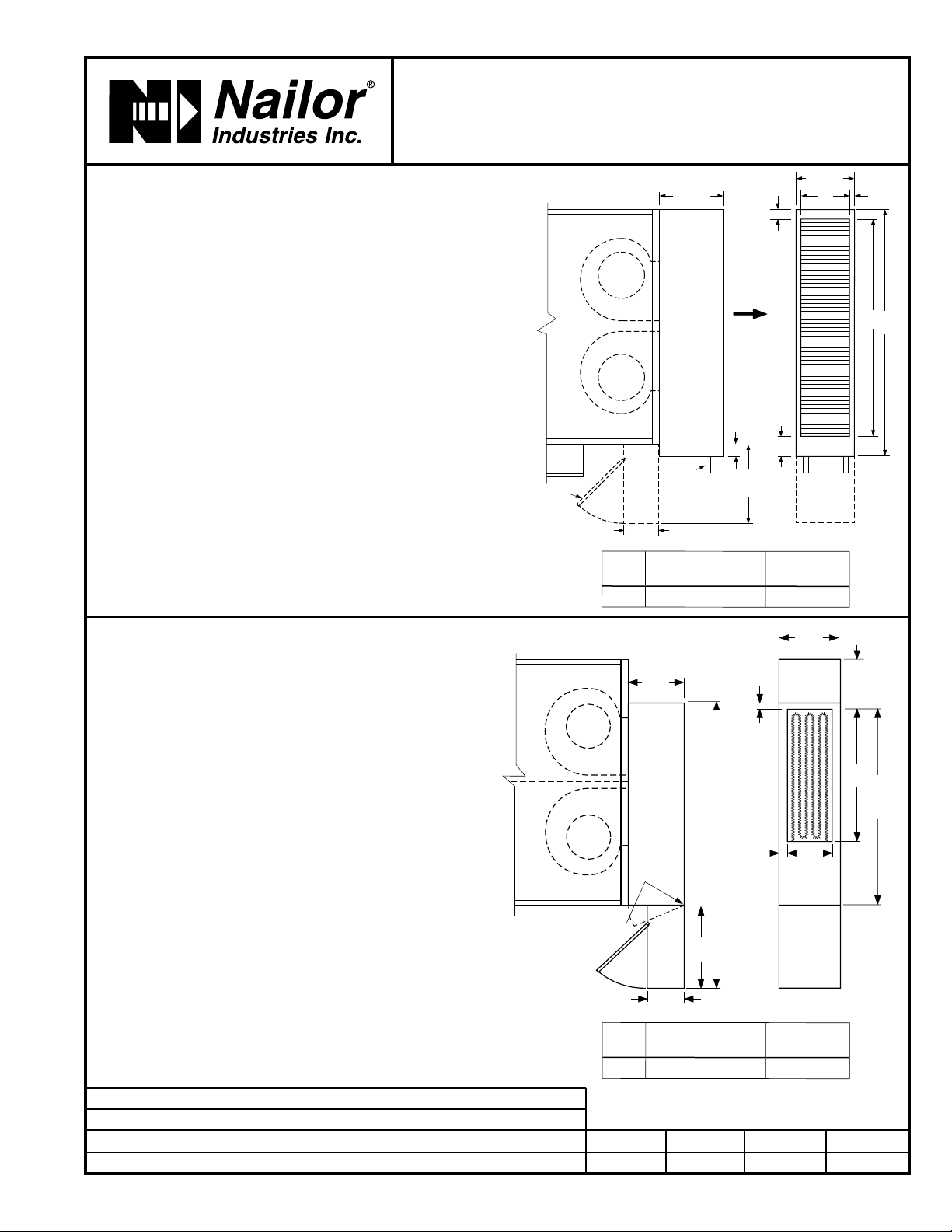

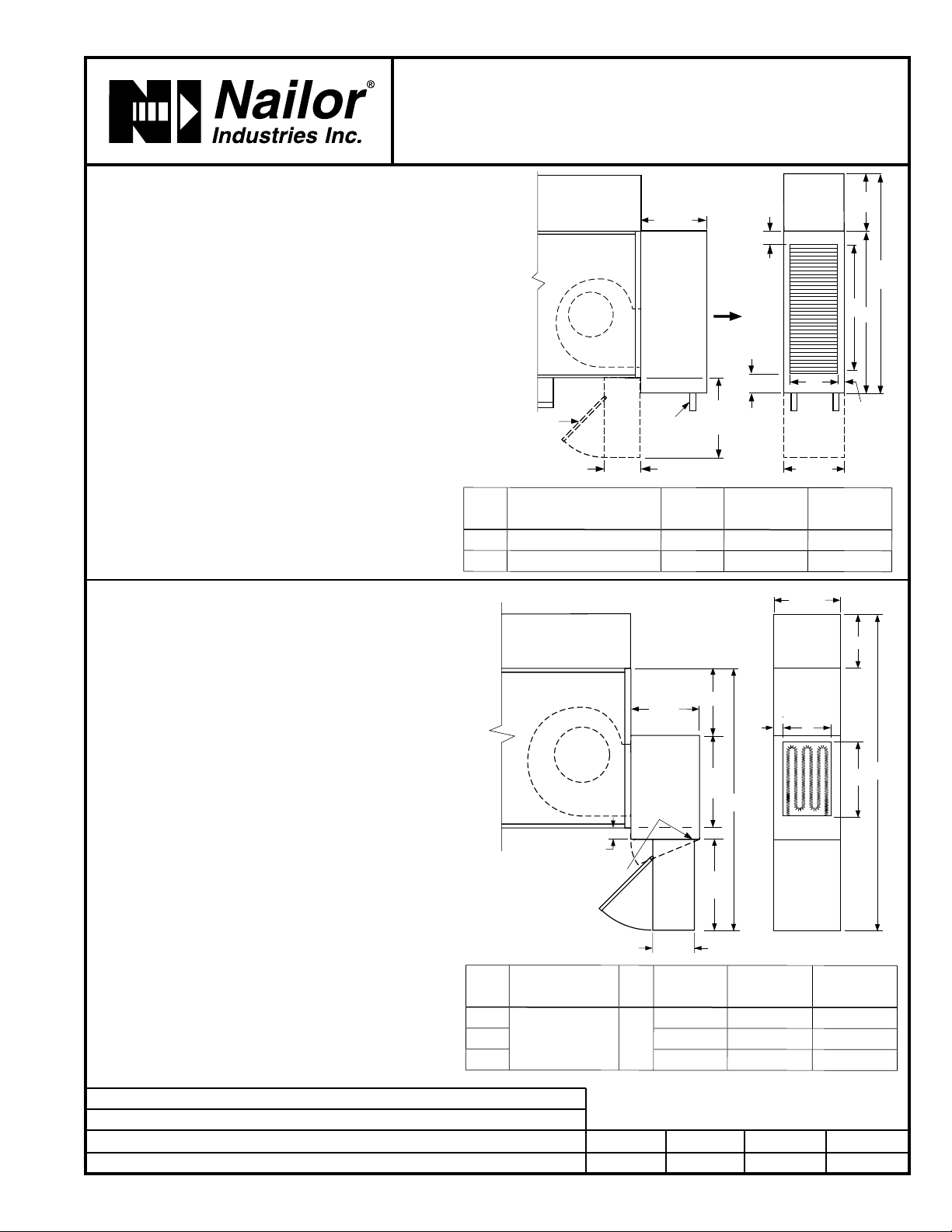

LOW PROFILE FAN POWERED TERMINAL UNIT WITH

EPIC ECM OR PSC MOTOR • HEAT ACCESSORIES

'STEALTHTM' • SERIES FLOW

CONSTANT OR VARIABLE VOLUME

MODELS: 37SWST AND 37SEST • UNIT SIZES 1 – 3

q Hot Water Coil Section Model 37SWST

Standard Features:

• Coil section installed on unit discharge.

• Coil (and header on multi-circuit units) is installed in insulated

casing for increased thermal efficiency.

• 1/2" (13) copper tubes.

• Aluminum ripple fins.

• Sweat connections: One row 1/2" (13) O. D. male solder. Two

and three row 7/8" (22) O.D. male solder.

• Top and bottom access panels for inspection and coil cleaning.

• Flanged outlet duct connection.

Coil Rows:

q1-Row q2-Row q3-Row

Coil Hand Connections:

(Looking in direction of airflow).

q Right hand (illustrated). Standard.

qLeft hand (terminals are inverted). Optional.

Connections must be selected same

hand as controls enclosure location.

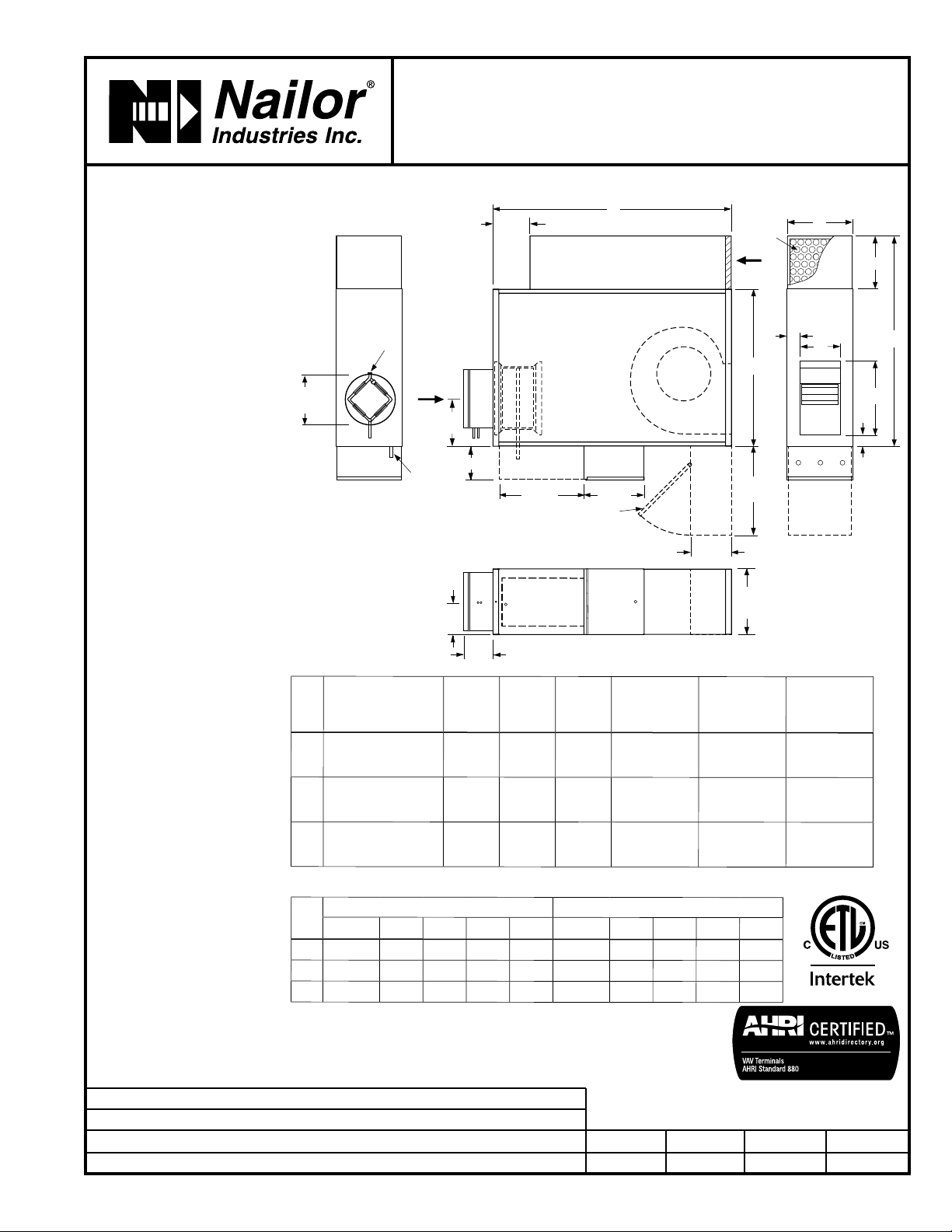

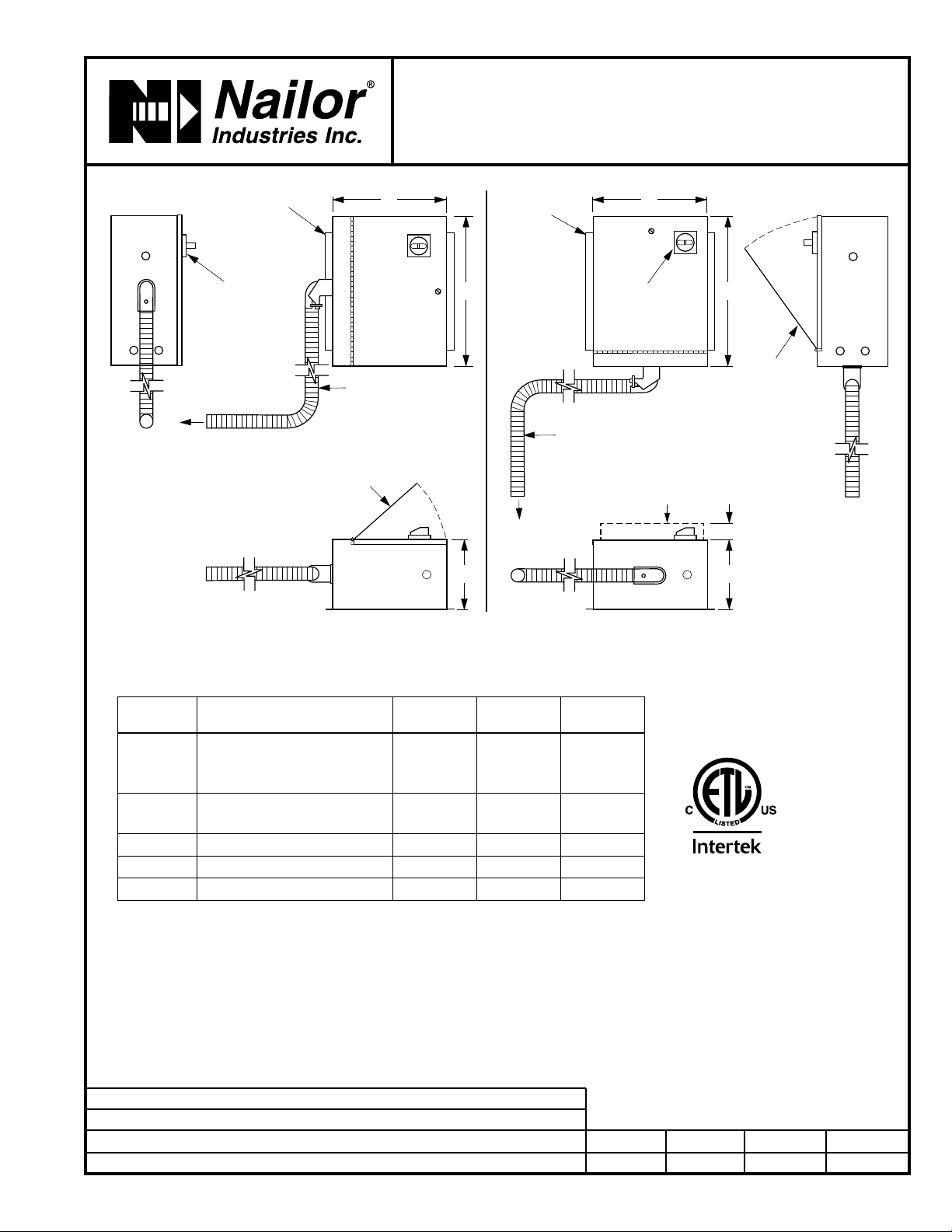

q Electric Coil Section Model 37SEST

Standard Features:

• Controls enclosure incorporates a hinged access door opening

upstream that helps ensure NEC clearance requirements

and reduces footprint. (FN2 90° design is standard).

• Unique hinged heater design permits easy access, removal and

replacement of heater element without disturbing ductwork.

• Class A 80/20 Ni/Cr wire.

• Coil installed on unit discharge.

• Insulated coil element wrapper.

• Automatic reset high limit cut-outs (one per element).

• Single point electrical connection (except 600V).

• Fan interlock relay or positive pressure airflow switch.

• Flanged outlet duct connection.

• Terminal unit with coil is ETL Listed as an assembly.

• Controls mounted as standard on RH side as shown.

Terminals ordered with LH controls (optional) are inverted.

Voltage:

Single phase, 60 Hz.

q 120V q208V q240V q277V

Three phase, 60 Hz.

q208V q480V (4 wire wye).

q600V (dual point connection). q _______________ .

12" (305)

COIL

CONNECTION

1 3/4"

(44)

3 5/8" (92) D

IW

CE

1 1/8"

(29)

11" (279)

6 3/4"

FANHOT

WATER

COIL

OPTIONAL

90° FN2

HIGNED FAN

CONTROLS

ENCLOSURE

15"

(381)

FAN

F

G

1"

(25)

K

15"

(381)

IW

6 3/4"

11 1/2"

(292)

HINGED FOR ELEMENT

REMOVAL

2" (51) ELECTRIC

COIL AND

90° FN2

HINGED FAN

CONTROLS

ENCLOSURE

(STANDARD)

15 3/8"

(391)

M

ELECTRIC

HEATER

Unit

Size

Outlet Duct Size

C x D IW W3 E

114 1/2 x 8 3/4 (368 x 222) 9 (229) 29 (737) 20 (508)

2, 3 24 x 8 3/4 (610 x 222) 12 (305) 41 3/8 (1051) 29 3/8 (746)

Unit

Size

Outlet Duct Size

F x G IW M W3 K

112 3/8 x 9

(314 x 229)

9

(229)

3 5/8 (92) 44 7/8 (1140) 35 7/8 (911)

211 1/8 (283) 52 1/2 (1334) 43 1/2 (1105)

311 1/8 (283) 52 1/2 (1334) 43 1/2 (1105)

Options:

qToggle disconnect switch

(includes fan).

q SCR control.

qDoor interlock disconnect

switch.

qMercury contactors.

qPower circuit fusing.

qDust tight construction.

qManual reset secondary

thermal cut out.