Thank you for purchasing ROTUS Air Motor " IM - 301 · IM - 300 ". The attachment andAir Line Kit (with lubricator)

are rquired to drive this Air Motor. Read this and all the associated component Operation Manuals carefully before

use. Always keep this Operation Manual in a place where a user can referred to for reference at any time.

①No heat is generated for long continuous use due to air driven operation.

②Air consumption is 75 Nℓ/min and can be used with air compressor of 1HP (7.5kW).

③By mounting a silencer on the back exhaust air / oil hose, the quiet operation of air turbine is remarkably

improved.

④Ring switch can be FWD./REV. turned to rotate the motor.

⑤AIR MOTOR (IM - 301) has a " free joint mechanism " which prevents a hose from being twisted.

⑥Clean air from tool can put away metal chips because Air Motor (IM - 300) has a chip air mechanism.

* IM - 300 is used with Attachment (IH - 300). IM - 300 can not be used with Attachments except IH - 300.

Model IM - 301 IM - 300

Maximum Motor Rotation Speed 30,000min-1 (rpm) (at 0.4MPa (58psi) Air Pressure)

Appropriate Air Pressure 0.3 - 0.45MPa (43.5 - 65.3psi)

Air Consumption 75Nℓ/min (at 0.4MPa (58psi) Air Pressure)

Supply and Exhaust Air / Oil Hose

Dimensions (With Eraser) Supply : I.D. 䃥3.7 mm x O.D. 䃥5.7 mm Length : 2 m

Exhaust : I.D. 䃥5 mm x O.D. 䃥6.5 mm Length : 2 m

Vibration Level Less than 2.5m / s2

Weight (Except hose) 130g

Noise Level at 1m distance Less than 85dB (A)

Standard Accessories

・Supply and Exhaust Air / Oil Hose・・1pc.

(IM - 301 : K - 206, IM - 300 : K - 207)

・Pin Wrench (K - 233)・・1pc.

・Nozzle (Only IM - 300)・・1pc.

・Silencer (K - 209)・・1 pc.

・Operation Manual・・1set.

ROTUS Air Motor

I

M

-301

・I

M

- 300

OM-K0359E 002

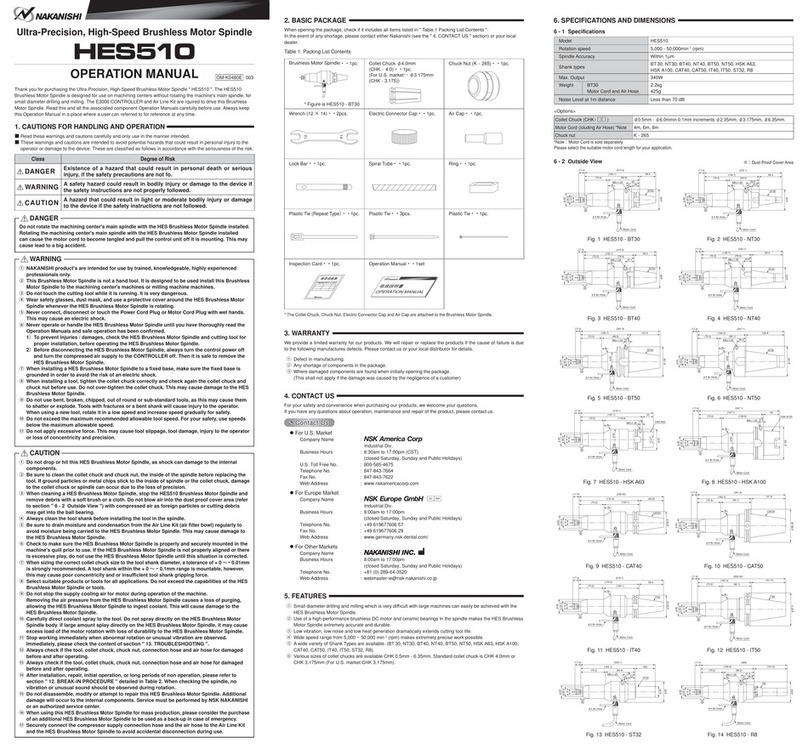

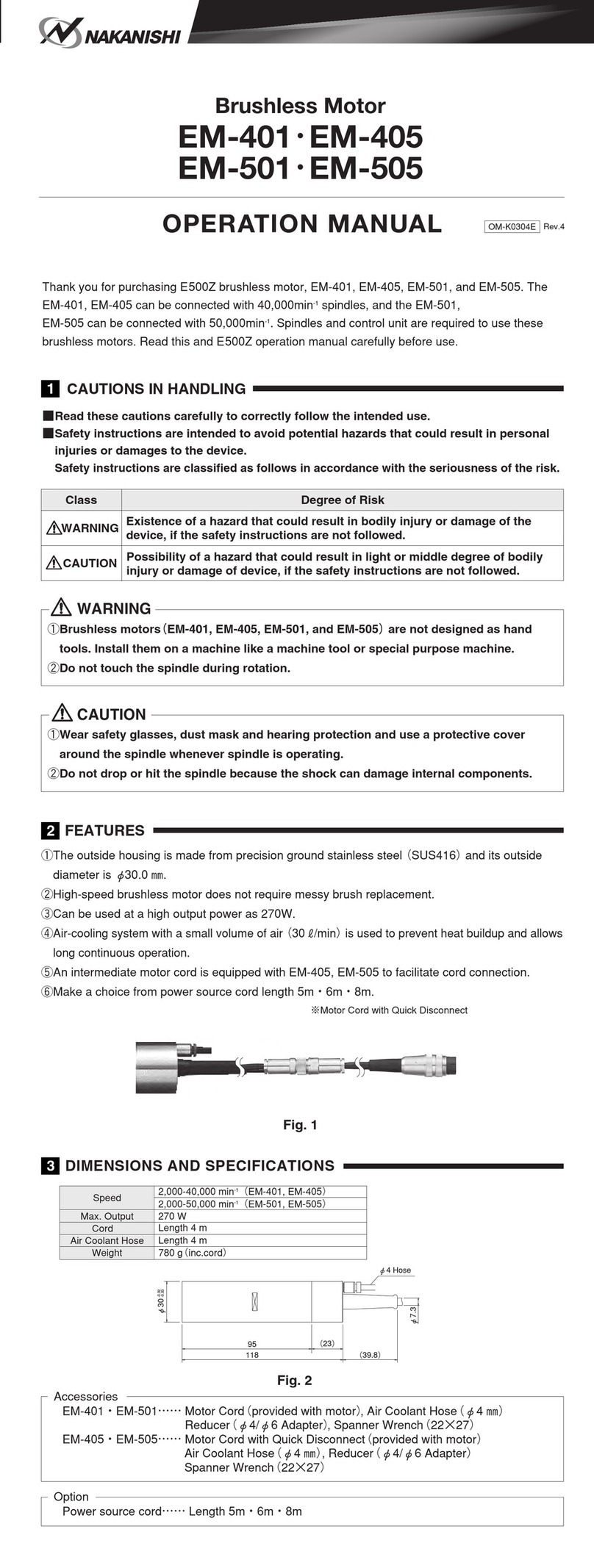

4. CONNECTION OF THE AIR MOTOR TO THE ATTACHMENT

Fig. 4 Connection of Air Line Kit " AL- H1207F (Sold Separately) "

Align the thread on the front end of the Air Motor and the rear of the attachment, and turn the attachment clockwise.

If the drive shaft of the Air Motor does not engage properly to the drive dog on the attachment, it may only turn

aprroximately two threads before stopping. DO NOT FORCE THEM TOGETHER. Loosen the attachment from the

Air Motor, rotate the attachment shaft by hand then re-try. The drive shaft and the drive dog must be fully engaged.

When fully engaged, secure the Air Motor and attachment using the provided wrench. (Fig. 3)

Tighten

Transmission Clutch

Fig. 3

5. CONNECTION OF THE AIR LINE KIT

5 - 1 Connection of the Air Motor

Foot Control Hose (Output) ⑤

Foot Control Hose (Input) ④

Foot Control (AFC - 45)

④

⑦⑥

②

①

⑤

Chip Air Hose (For IM - 300)

Connection Hose

(Chip Air Type)

IM - 300

FR

(360° Free Joint Type)

IM - 301

Exhaust Air / Oil Hose

Supply Air / Oil Hose

Silencer

FR

④ ⑤

Chip Air Adjusting Valve

Filter Joint

Secondary Joint

(ȭ6 One - Touch Joint)

Control Valve

Primary Joint

Connector for Air Hose

Filter Regulator

To Air Compressor

③

Lubricator

Adjusting Dome

(1) Connect the Filter Joint of the Air Motor to the Secondary Joint ( ȭ6 One - Touch Joint) on the Air Line Kit.

(Fig. 4 ①)

(2) Place " Exhaust Air Silencer / Oil Hose " into an empty container (Fig. 4 ②).(Exhaust outlet air and oil from

the Siliencer.)

* If using the ROTUSAir Motor " IM - 300 ", insert the ChipAir Hose to the ChipAirAdjusting Valve on the

Control Valve (Fig. 4 ③).

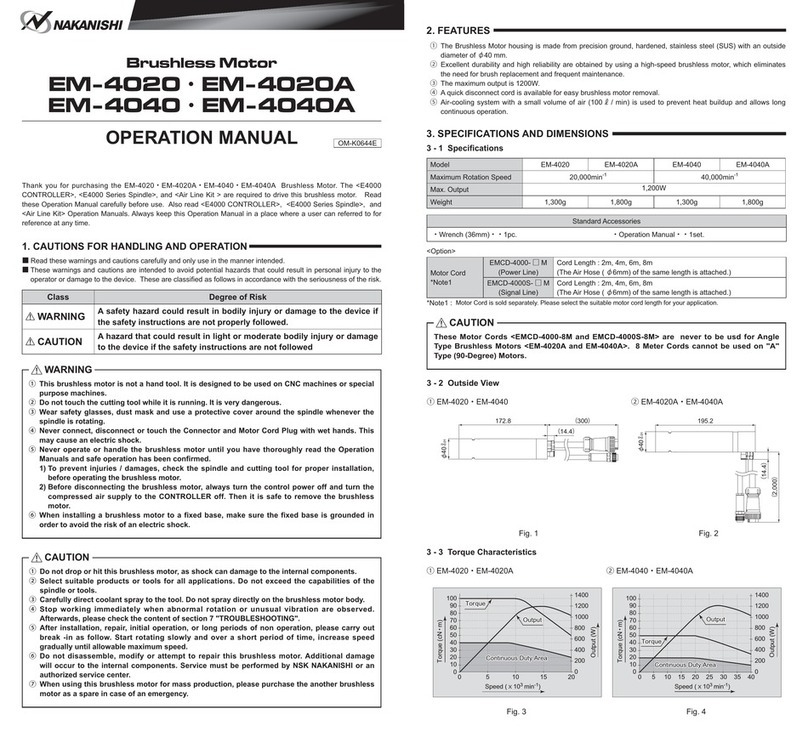

3- 2Outside View

Fig. 1

FR

9.237.711 43

(100.9)

ȭ22.8

ȭ19.5

(ȭ21.5)

RF

ȭ22.8

ȭ9.5

11 37.7 9.2 39.6

(ȭ15.8)

(97.5)

Fig. 2

5- 2Foot Control Hose Connection (Sold Separately)

(1) Insert the Foot Control Hose (Input) ④to the One - Touch Joint ④of the Control Valve (Fig. 4).

(2) Insert the Foot Control Hose (Output) ⑤to the One - Touch Joint ⑤of the Control Valve (Fig. 4).

1. CAUTIONS FOR HANDLING AND OPERATION

■Read these warnings and cautions carefully and only use in the manner intended.

■These warnings and cautions are intended to avoid potential hazards that could result in personal injury to the

operator or damage to the device. These are classi¿ed as follows in accordance with the seriousness of the risk.

Class Degree of Risk

WARNING

A safety hazard could result in bodily injury or damage to the device if

the safety instructions are not properly followed.

CAUTION

A hazard that could result in light or moderate bodily injury or damage

to the device if the safety instructions are not followed.

WARNING

①This product is designed for hand use. Never install this attachment or any hand tool on a

machine such as a special purpose machine, NC lathe or mill.

②Do not touch the cutting tool while it is rotating. It is very dangerous

③Always wear safety glasses, dust mask and use a protective cover.

①Do not drop or hit this Air Motor, as shock can cause damage to the internal components.

②Before use, carefully read " Air Line Kit Operation Manuals " regarding the correct connection,

operation and cautions when using the Air Line Kit.

③When cleaning a Air Motor, stop the motor and remove dirt with a brush or a cloth. Do not

blow compressed air into the Air Motor. Foreign particles or cutting chips may get into the ball

bearings.

④Stop operating immediately when abnormal rotation or any unusual vibrations are observed.

Afterwards, please check the content of section " 7. TROUBLESHOOTING ".

⑤When using ROTUS Air Motor, Air Line Kit (AL - H1207F or any other equal characteristics) is

recommended for long lifetime.

⑥Operating the Air Motor in low Lubricant conditions will cause low rotation speed, damage to

the internal components and shorter life of the Air Motor.

⑦Be sure to drain moisture and condensation from the Air Line Kit (¿lter regulator) regularly to

avoid moisture being carried to the Air Motor. This may cause damage to the Air Motor.

⑧Do not use or storage the supply connection hose, supply and exhaust air / oil hose in a bent

state.

⑨Prior to starting the day's work please check the following items: check the ¿lter regulator

for proper sir pressure setting, check that ¿lter is clean, and check that the lubricator has the

proper amount etc.. Afterward start rotating slowly and increase speed gradually.

⑩After installation, repair, initial operation, or long periods of non operation, please carry out

break -in as follow. Start rotating slowly and over a short period of 15 - 20minutes, increase

speed gradually until allowable maximum speed.

⑪Do not disassemble, modify or attempt to repair the Air Motor. Additional damage will occur

to the internal components. Service must be performed by NSK NAKANISHI or an authorized

service center.

⑫Securely connect the connection hose and supply air / oil hose to the motor Air Motor and Air

Line Kit to avoid accidental disconnection during use.

CAUTION

2. FEATURE

3. SPECIFICATIONS AND DIMENSIONS

3- 1Speci¿cations

CAUTION

Make sure your hands and all interlocking parts of the attachment and Air Motor are clean before

connecting the Air Motor to the attachment. This is critical to prevent contaminants from entering

the Air Motor or attachment.

CAUTION

Make sure to turn the compressed air supply to the Air Line Kit OFF, before replacing the

Lubricating Oil or draining the water in Lubricating Oil.

CAUTION

If the " Foot Control Hose (Input / Output) " is connected to the wrong position, airÀow adjustment

will not be possible.

Temperature Humidity Atmospheric Pressure

Operation Environment 0 - 40°C MAX.75%

(No condensation) 800 - 1,060hPa

Transportation and Storage

Environment -10 - 50°C 10 - 85% 500 - 1,060hPa

①IM - 301 (360°Free Joint Type)

②IM - 300 (Chip Air Type)

OPERATION MANUAL