2

qRepeated or long-term exposure to excessive vibration may cause temporary or

permanent physical injury, particularly to the hands, arms and shoulders.

wIt is strongly recommended that anyone using vibrating equipment, such as

power hand tools, first be physically examined by a doctor and then have regular

medical check-ups to make sure the user does not have any medical problems

that are being caused or worsened by using vibrating equipment.People who

have impaired blood circulation to the hand, past hand injuries, nervous system

disorders and Raynaud’s disease should not use vibrating equipment.

e

If you feel any medical or physical symptoms related to vibration (such as tingling,

numbness and white or blue fingers), report the situation to your employer and

seek medical advice as soon as possible.

rAvoid smoking while using vibrating equipment, as nicotine reduces the blood

supply to the hands and fingers.

tSuitable gloves should be worn to reduce the vibration effects on the user.

yTools with the lowest vibration should be used when there is a choice between

different processes.

uWork schedules should be arranged to include vibration-free periods throughout

each day.

q

LUSTER should only be used after reading and understanding the Operation Manual.

wGrip LUSTER as lightly as possible (while still keeping safe control of it).

Let LUSTER do the work.

eTo ensure your safety, LUSTER should be maintained as explained in this

Operation Manual.

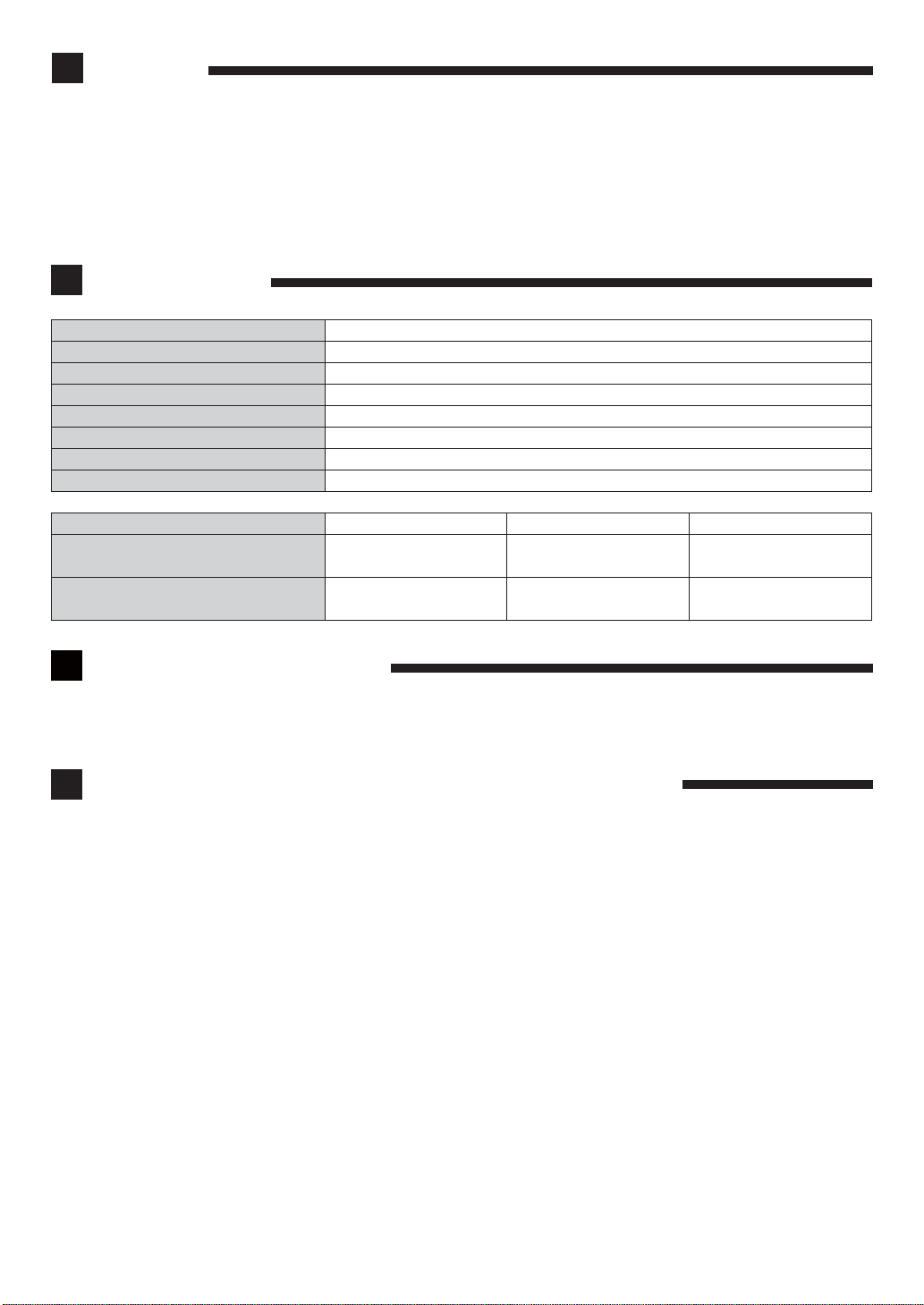

rDo not use LUSTER at vibration levels of 2.5 m/s2and higher.Select the

combination of motor speed and stroke so that the vibration level stays in the

shaded area as shown on the chart lower right.

tDo not use LUSTER with vibration at 2.5 m/s2or higher each day for an extended

period of time.

y

If any abnormal vibration occurs stop using LUSTER

immediately and return to NAKANISHI for service.

u

Do not exceed the motor speed of 30,000min

-1

(rpm) to

prevent trouble or damage.

i

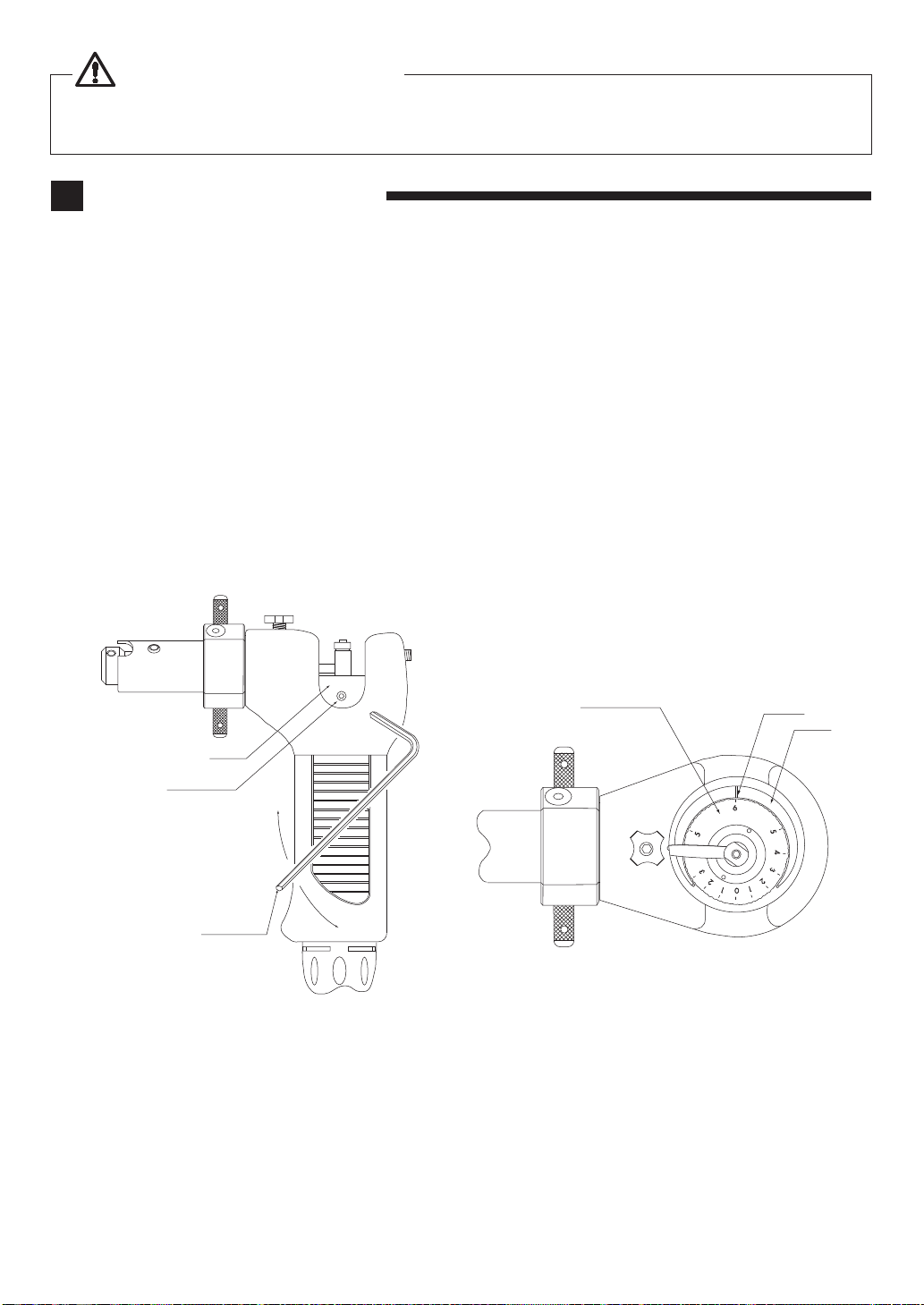

Remove the plug from the control unit when adjusting

the stroke length for safety reasons.

Caution on Vibration

General Warnings for All Vibrating Equipment

Additional Warnings for the Safe Use of LUSTER

0

5

10

15

20

25

30

35

40

123456

Stroke (mm)

Motor Rotation Speed ( x 103min-1(rpm))

(2.5 m / S2)(2.5 m / S2)

(Refer to Graph - 1).

Remove the plug from the control unit when adjusting

the stroke length for safety reasons.

Graph - 1