8

ΣΗΜΑΝΤΙΚΕΣ ΟΔΗΓΙΕΣ ΑΣΦΑΛΕΙΑΣ!

ΔΙΑΒΑΣΤΕ ΠΡΟΣΕΚΤΙΚΑ ΤΟ ΠΑΡΟΝ ΕΓΧΕΙΡΙΔΙΟ ΠΡΙΝ ΧΡΗΣΙΜΟΠΟΙΗΣΕΤΕ ΤΟ ΠΡΟΪΟΝ ΚΑΙ ΦΥΛΑΞΤΕ ΤΟ ΣΕ ΑΣΦΑΛΕΣ ΣΗΜΕΙΟ ΓΙΑ ΜΕΛΛΟΝΤΙΚΗ

ΑΝΑΦΟΡΑ!

Οδηγίες ασφαλείας

Το εγχειρίδιο χρήσης αποτελεί βασικό μέρος του ψεκαστήρα. Παρακαλούμε να το διατηρείτε σε καλή κατάσταση. Προκειμένου να χρησιμοποιήσε-

τε και να συντηρήσετε τον ψεκαστήρα με τον προβλεπόμενο τρόπο θα πρέπει να διαβάσετε προσεκτικά το εγχειρίδιο χρήσης πριν από τη λειτουρ-

γία. Εάν έχετε οποιαδήποτε αμφιβολία, επικοινωνήστε με το κατάστημα λιανικής πώλησης από όπου αγοράσατε το προϊόν.

Οι ψεκαστήρες πρέπει να χρησιμοποιούνται μόνο με προϊόντα φυτοπροστασίας εγκεκριμένα από τις τοπικές/εθνικές ρυθμιστικές αρχές (π.χ. Bba)

για προϊόντα φυτοπροστασίας για χρήση με ψεκαστήρες πλάτης.

Σκοπούμενη χρήση

Ο ψεκαστήρας είναι κατάλληλος για τον έλεγχο παρασίτων μικρών φυτωρίων, λουλουδιών και κήπων, καθώς και για τον καθαρισμό του οικιακού περιβάλ-

λοντος και την αποστείρωση κτηνοτροφικών και πτηνοτροφικών εγκαταστάσεων.

- Μην προσπαθείτε να απομακρύνετε τις συσσωρεύσεις φυτοφαρμάκου φυσώντας τμήματα του προϊόντος με το στόμα σας.

- Μην συνδέετε το προϊόν με άλλη πηγή πεπιεσμένου αέρα π.χ. αεροσυμπιεστή.

- Ασφαλίστε και σταθεροποιήστε το προϊόν, προστατεύοντας το από πτώση, ανατροπή, κραδασμούς, εξαιρετικά υψηλές ή χαμηλές θερμοκρασίες, άμεσο

ηλιακό φως και χτυπήματα κατά τη μεταφορά για να αποφύγετε ζημιές και διαρροές.

- Μην επιχειρήσετε να επισκευάσετε ή να τροποποιήσετε το προϊόν με οποιονδήποτε τρόπο. Καθαρίζετε και συντηρείτε το προϊόν όπως περιγράφεται

στο παρόν εγχειρίδιο οδηγιών χρήσης. Χρησιμοποιείτε μόνο ανταλλακτικά και αξεσουάρ που συνιστώνται από τον κατασκευαστή. Οι επισκευές πρέπει να

πραγματοποιούνται μόνο από τον κατασκευαστή, τον αντιπρόσωπο σέρβις του ή από άτομα με παρόμοια προσόντα. Σε αντίθετη περίπτωση μπορεί να

προκύψει κίνδυνος.

- Ελέγχετε το προϊόν τακτικά κάθε χρόνο μετά το χειμώνα δοκιμάζοντας την λειτουργία του με χρήση καθαρού νερού. Ελέγχετε το προϊόν πριν από κάθε

χρήση.

- Λάβετε υπόψη τον άνεμο, τη βροχή και άλλες κλιματικές και περιβαλλοντικές συνθήκες για να αποφύγετε κινδύνους από ανεξέλεγκτο ή ακούσιο ψεκα-

σμό. Αποφύγετε την συχνή και άσκοπη αλλαγή κατεύθυνσης κατά τη διάρκεια των εργασιών ψεκασμού.

- Μην χρησιμοποιείτε τον ψεκαστήρα όταν υπάρχουν διαρροές ή ανομοιόμορφος πίδακας ψεκασμού.

- Το υγρό για εφαρμογή σε αυτόν τον ψεκα-

στήρα δεν πρέπει να υπερβαίνει τους 40°C.

- Πριν από τη λειτουργία απαιτείται δοκιμα-

στικός ψεκασμός με καθαρό νερό και έλεγχος

της δεξαμενής, του σωλήνα, του κλείστρου

και του ακροφυσίου για πιθανή διαρροή.

- Η παρασκευή των χημικών ουσιών πρέπει να ακολουθεί τις οδηγίες και τον τύπο που παρέχονται από

τον παρασκευαστή του φυτοφαρμάκου. Απαγορεύεται η μη εξουσιοδοτημένη μεταβολή του ποσοστού

αραίωσης της χημικής ουσίας, η οποία μπορεί είτε να θέσει σε κίνδυνο τον άνθρωπο και τα ζώα είτε να

οδηγήσει σε αποτυχία της καταπολέμησης των παρασίτων.

Ελέγξτε την αναλογία αραίωσης πριν από την εργασία.

- Μετά το τέλος της λειτουργίας, πρέπει να αλλάξετε ρούχα και να πλύνετε τα εκτεθειμένα μέρη του

σώματος, όπως τα χέρια και το πρόσωπο. Στην περίπτωση ιδιαίτερα τοξικών φυτοφαρμάκων και μικροβι-

οκτόνων, απαιτείται ντους μετά την εργασία ψεκασμού για να διασφαλιστεί η ασφάλεια.

Διαβάστε τις οδηγίες πριν από τη χρήση και

φυλάξτε τις σε ασφαλές σημείο για μελλοντι-

κή αναφορά!

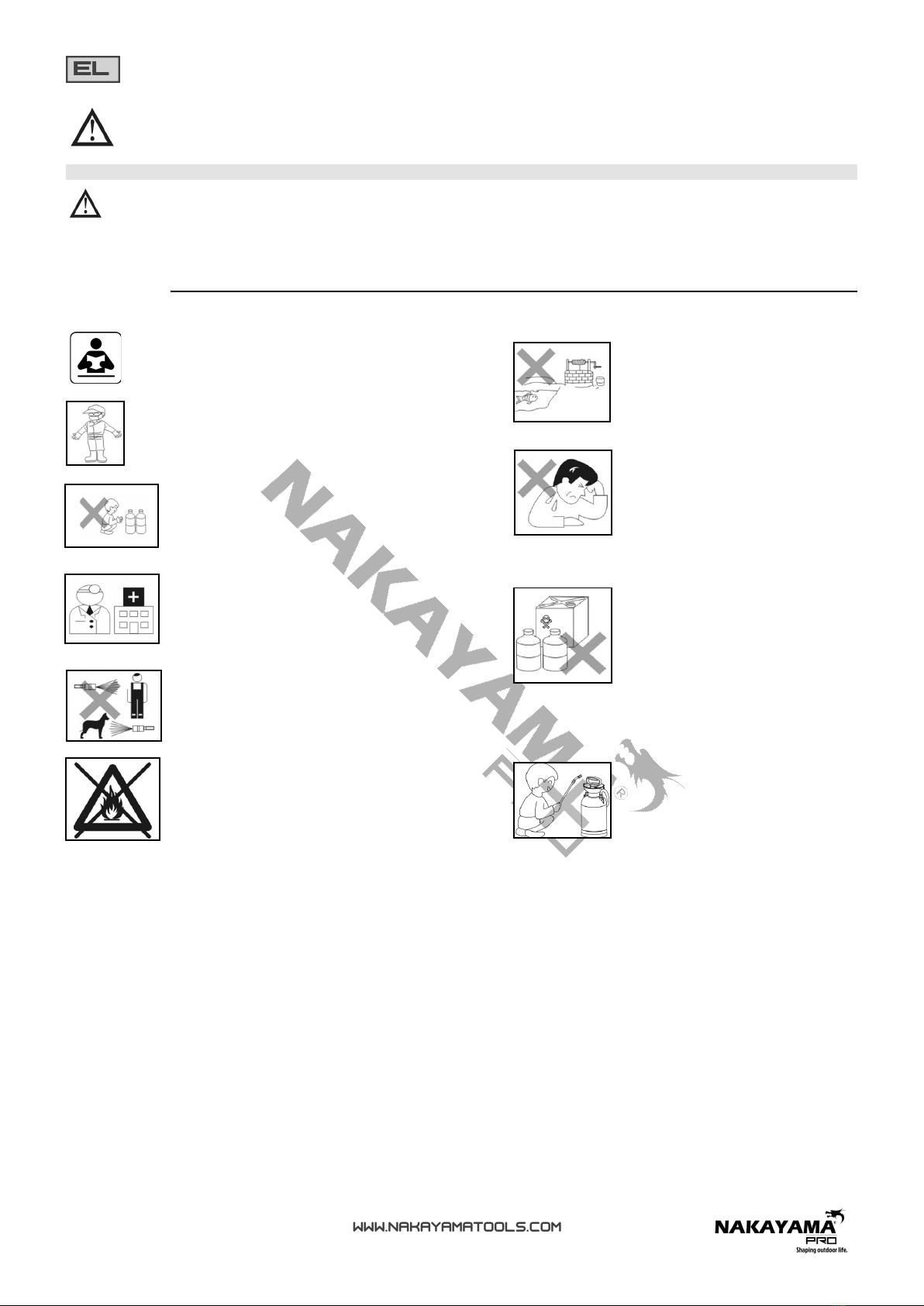

Εξοπλισμός ατομικής προστασίας: Ο χειριστής πρέπει να φο-

ράει μάσκα, κάλυμμα κεφαλής, ρούχα προστασίας, αδιάβροχα

γάντια και λαστιχένια υποδήματα (πχ γαλότσες ) κ.λπ. Κατά τη

διαδικασία της εργασίας ψεκασμού.

Αποθήκευση και συντήρηση φυτοφαρμάκων. Πρέπει

να φυλάσσονται μακριά από παιδιά. Η απόρριψη του

φυτοφαρμάκου πρέπει να πραγματοποιείται βάσει των

οδηγιών ασφαλείας που παρέχονται από τον κατασκευ-

αστή του.

Σε περίπτωση εισπνοής: Εγκαταλείψατε αμέσως το

δηλητηριώδες μέρος και μεταβείτε σε ένα επαρκώς αερι-

ζόμενο χώρο και ζητήστε ιατρική βοήθεια. Σε περίπτωση

δηλητηρίασης μέσω επαφής με το δέρμα, ξεπλύνετε

αμέσως με νερό. Σε περίπτωση κατάποσης: Προκαλέστε

εμετό με καθαρό νερό ή αλατόνερο και μεταβείτε στο

νοσοκομείο το συντομότερο δυνατό.

Ποτέ μην ψεκάζετε ανθρώπους ή ζώα. Ποτέ

μην ψεκάζετε σε αντίθετη κατεύθυνση σε

σχέση με τον άνεμο, όταν οι συνθήκες είναι

δυσμενείς.

Ο ψεκαστήρας ΔΕΝ είναι παιχνίδι.

Το υπολειμματικό χημικό πρέπει να αποθη-

κεύεται σε δοχείο αντί να απορρίπτεται στον

αγρό, στο έδαφος και στα ποτάμια. Οι άδειες

φιάλες και οι σακούλες πρέπει να συλλέ-

γονται και να αποστέλλονται στην αρμόδια

αρχή ανακύκλωσης.

Μόνο εκπαιδευμένοι, υγιείς και ξεκούραστοι

χειριστές μπορούν να εργάζονται με το προϊ-

όν. Μην χρησιμοποιείτε το προϊόν όταν είστε

κουρασμένοι, άρρωστοι ή υπό την επήρεια

αλκοόλ, ναρκωτικών ή φαρμάκων.

Βεβαιωθείτε ότι οι άπειροι χρήστες λαμβά-

νουν κατάλληλη εκπαίδευση πριν από τη

χρήση.

Ποτέ μην χρησιμοποιείτε ισχυρά οξέα, ισχυρά

αλκαλικά και εύφλεκτα διαλύματα. Ποτέ

μην χρησιμοποιείτε ισχυρά τοξικά και πολύ

ανθεκτικά φυτοφάρμακα για την καταπολέ-

μηση παρασίτων σε λαχανικά, καλλιέργειες

πεπονιού, οπωροφόρα δέντρα, τσαγιού,

φυτικά φάρμακα κ.λπ. Βεβαιωθείτε πως ο

χρόνος συγκομιδής μετά την εφαρμογή του

φυτοφαρμάκου είναι ο προβλεπόμενος βάσει

των οδηγιών του κατασκευαστή.

Κρατήστε τον ψεκαστήρα σε ασφαλή από-

σταση από πηγές θερμότητας και αποφύγετε

την έκθεση σε έντονη ηλιακή ακτινοβολία.

Τα φυτοφάρμακα δεν θα πρέπει να βρίσκο-

νται σε δημόσιο χώρο χωρίς επιτήρηση, ώστε

να αποφευχθεί οποιοσδήποτε κίνδυνος για

τη δημόσια ασφάλεια.