1

ArchiTech Mortise Lock & Surface-Mounted Networx Control Unit Mounting and Installation Instructions

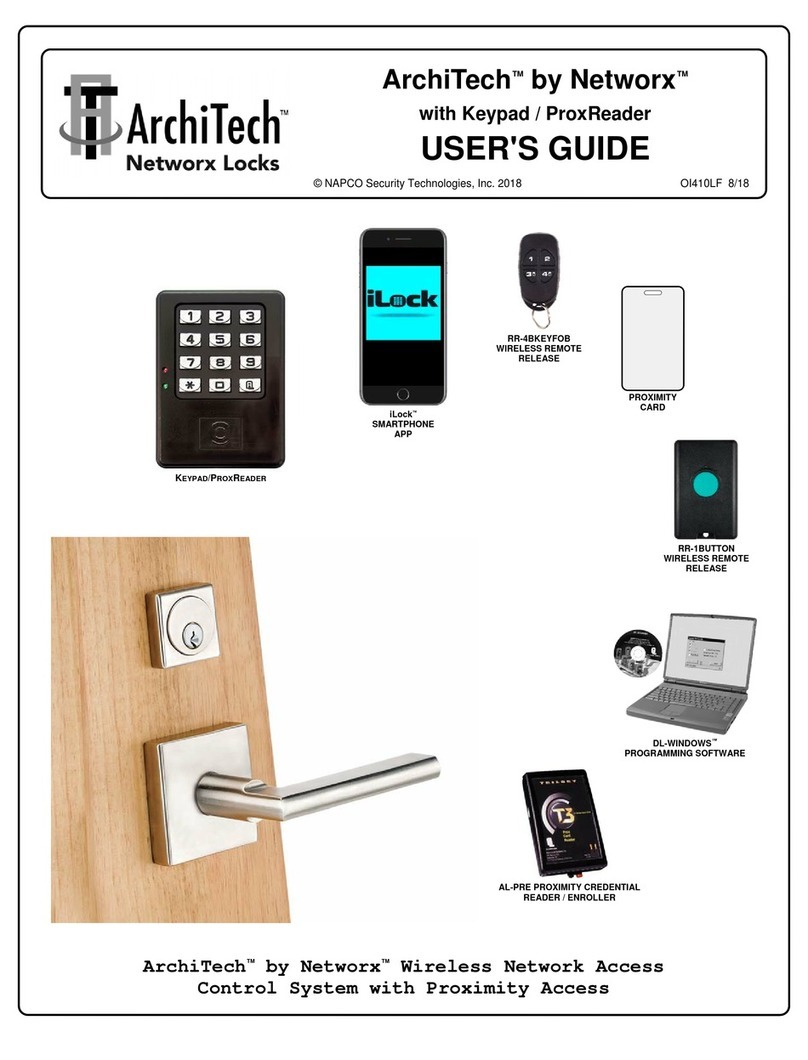

ArchiTech™by Networx™

FOR MORTISE LOCKS USING SURFACE-MOUNTED NETWORX CONTROL UNITS

MOUNTING AND INSTALLATION INSTRUCTIONS

© NAPCO Security Technologies, Inc. 2016 WI2090B 09/16

DESCRIPTION

These instructions detail the hardware installation procedure for the ArchiTech mortise door locks using the Surface-

Mounted Networx Control Units for hollow metal and solid wood doors.

Installation instructions for the Door Contact Sensor, Door Contact Magnet (installed in the door jamb) and the

Oval and Rectangular Proximity Readers are also included.

PARTS OVERVIEW

For reference, the images in Fig. A below display each component (not to scale). In addition to the various screws

included with your mortise lock, please be aware that two types of Proximity Readers are available (either Oval or

Rectangular) but only one type is included with your lock. Furthermore, one of two types of Door Contact

Magnets (installed in door jamb) are included (either 3/8" or 3/4" diameter). We recommend taking the time to

read through these instructions, find and familiarize yourself with each component before you begin your installation.

As detailed in the instructions that follow, the Proximity Reader wires, the Door Contact Sensor wires and the Mortise

Lock Motor Wire are routed through the door and are plugged into the Surface-Mounted Networx Control

Unit. The Mortise Lock Motor Wire can easily be routed within hollow metal doors. For solid wood doors, a

Mortise Drill Jig (part #N95I1DJ) must be used to drill a hole pathway within the solid wood door to route the

Mortise Lock Motor Wire.

REQUIRED TOOLS

In addition to the standard door prep kit tools used to install a mortise lock into a metal or wood door (Phillips and flat

head screwdrivers, etc.), you will need: A small level, and the following drill bit sizes: 5/8", 3/8", 3/4" and 7/64".

IMPORTANT: For installation on UL Listed Wood Fire Doors fill the through hole wire passage with UL Clas-

sified Fire Stop Sealant after connecting all wiring and testing the Lock.

FIG. A: OVERVIEW OF BASIC PARTS (NOT TO SCALE)

OVAL AND RECTANGULAR

PROXIMITY READER COVERS AND

MOUNTING COMPONENTS

MORTISE DRILL JIG

(N95I1DJ)

(SOLID WOOD DOORS ONLY)

DOOR CONTACT

MAGNET

(TWO TYPES)

OR

"SURFACE-MOUNTED" NETWORX

CONTROL UNIT

AND ITS MOUNTING PLATE

DOOR

CONTACT

SENSOR