INDEX

1. MACHINE INFORMATION ....................................................................................................... 3

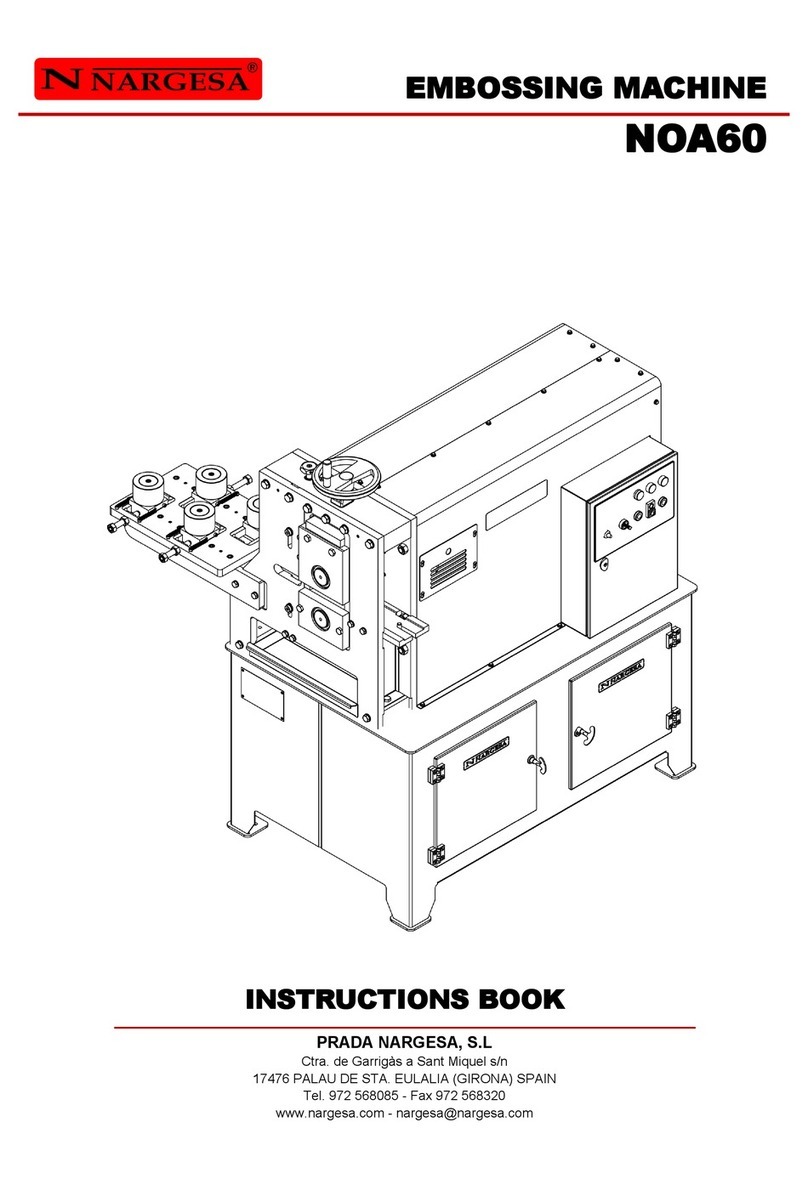

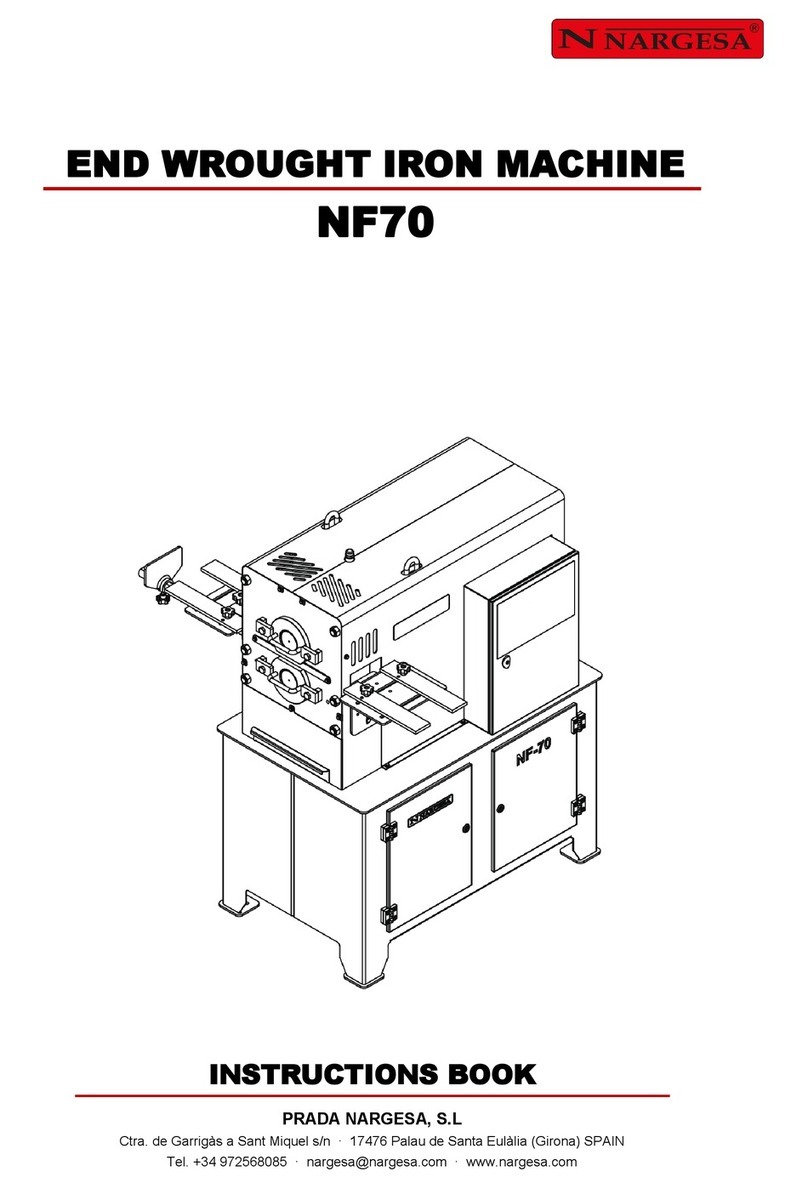

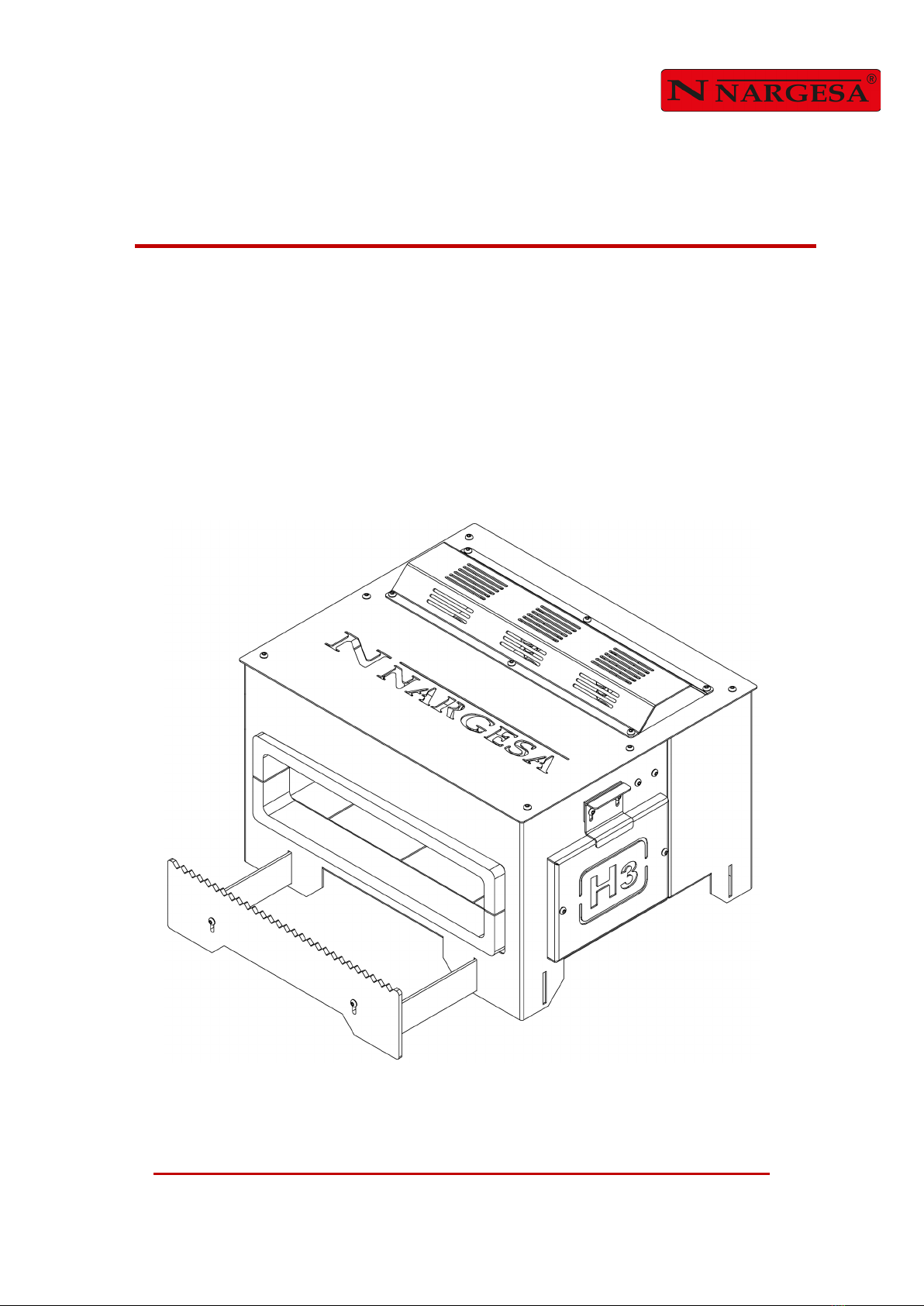

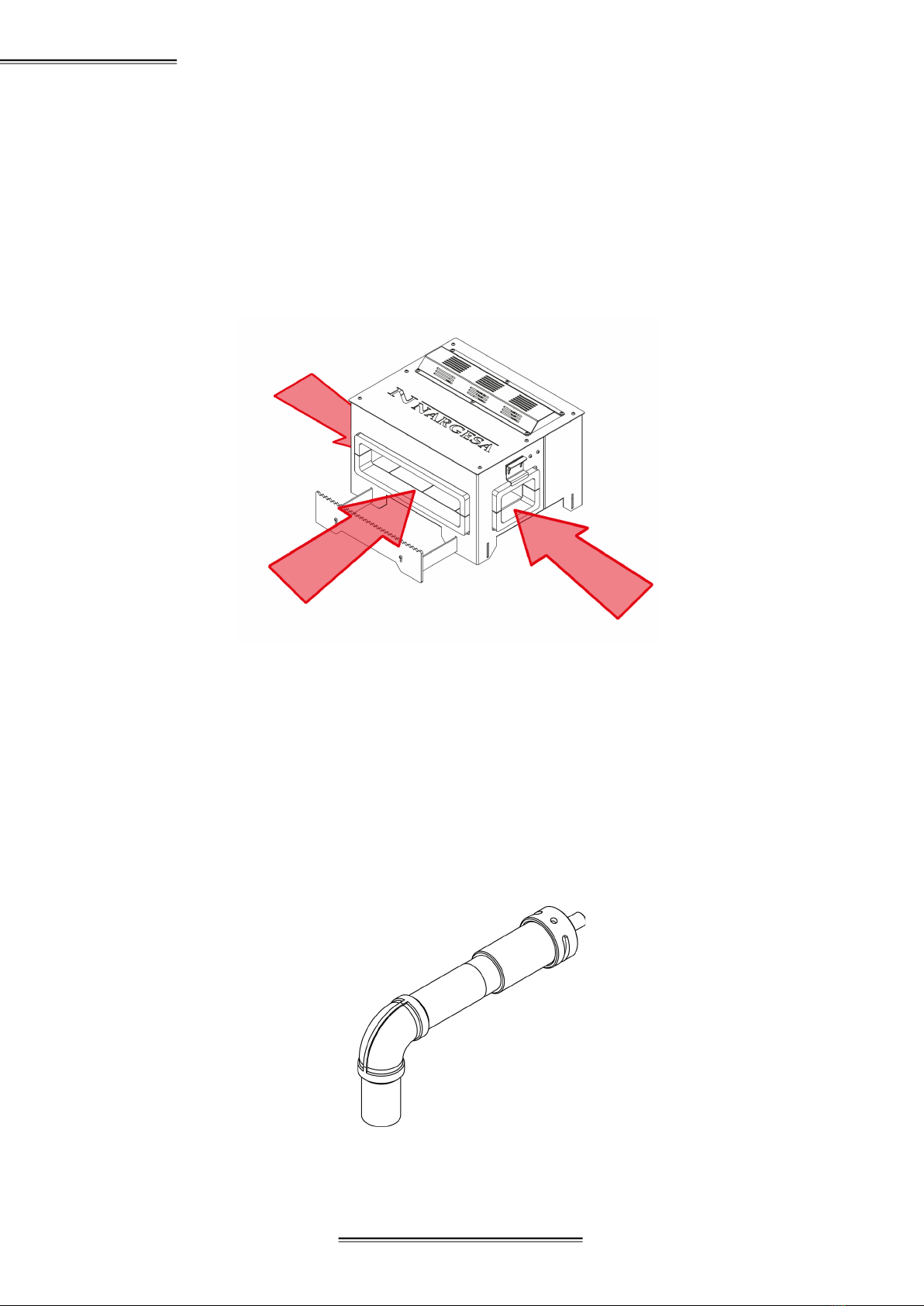

1.1. Identification of the machine …................................................................................ 3

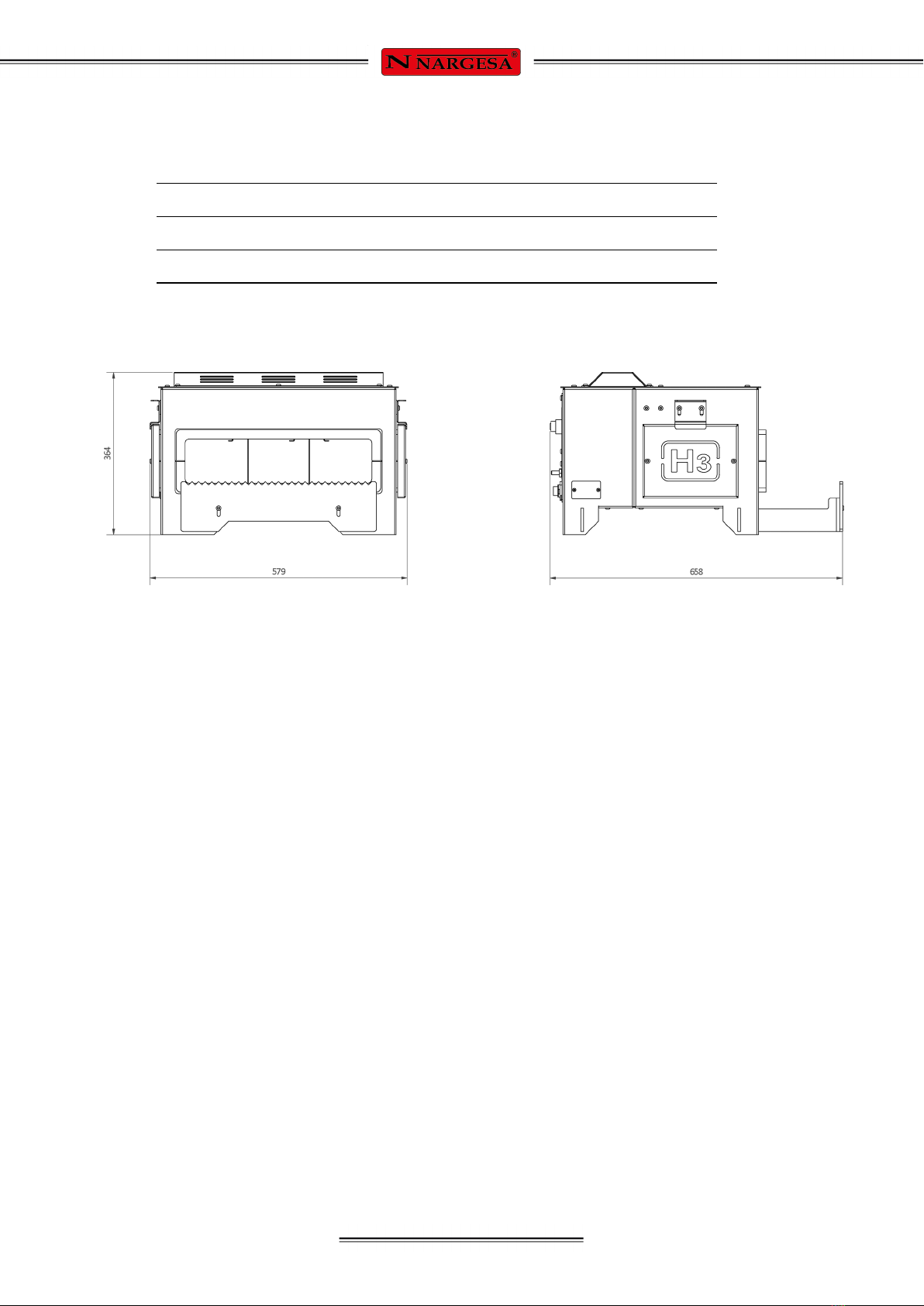

1.2. Dimensions ............................................................................................................... 3

1.3. Description of the machine …......................................................................................... 3

1.4. Fuel for the furnace ................................................................................................ 4

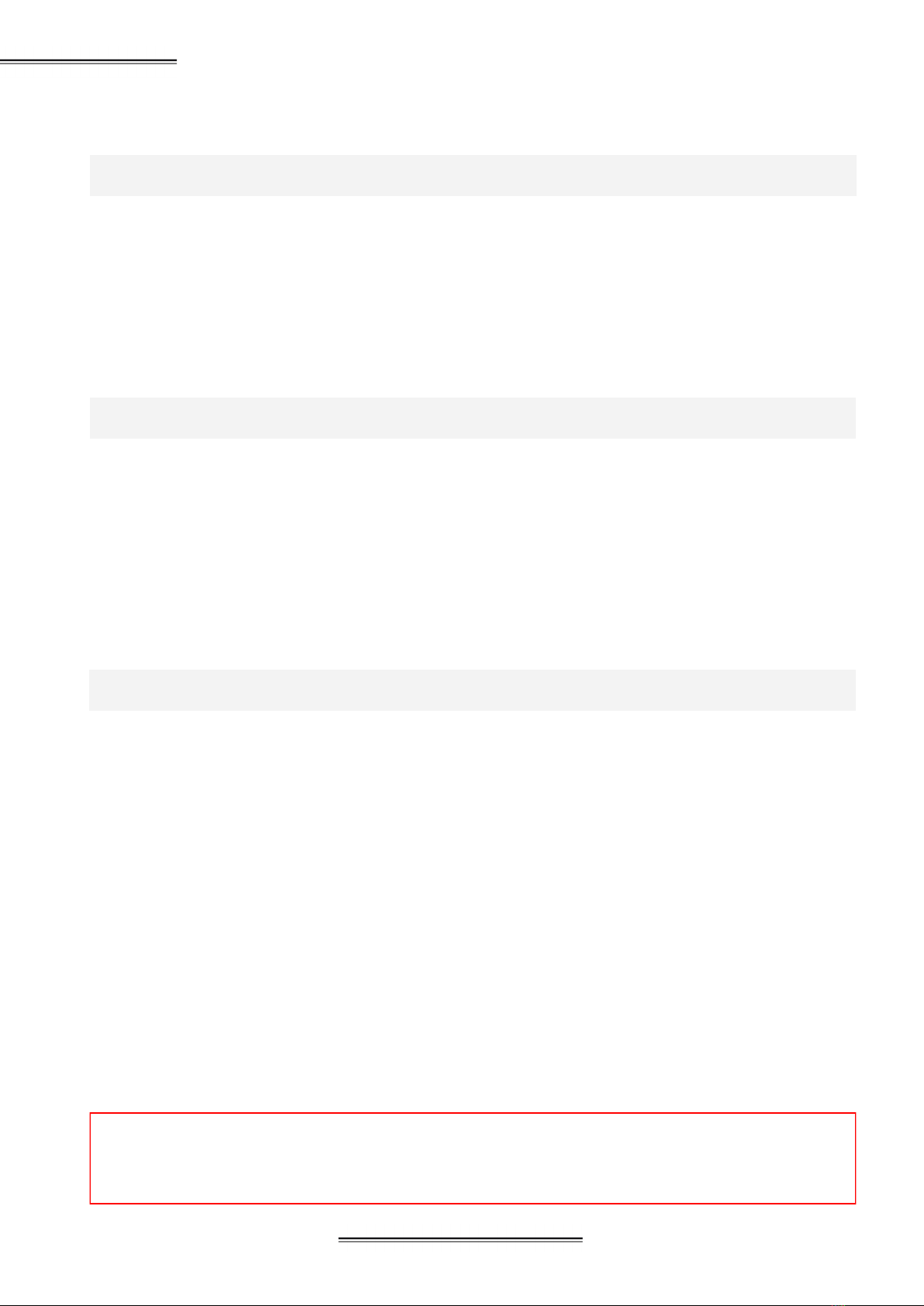

1.5. Identification of elements ....................................................................................... 5

1.6. Description of elements ……......................................................................................... 6

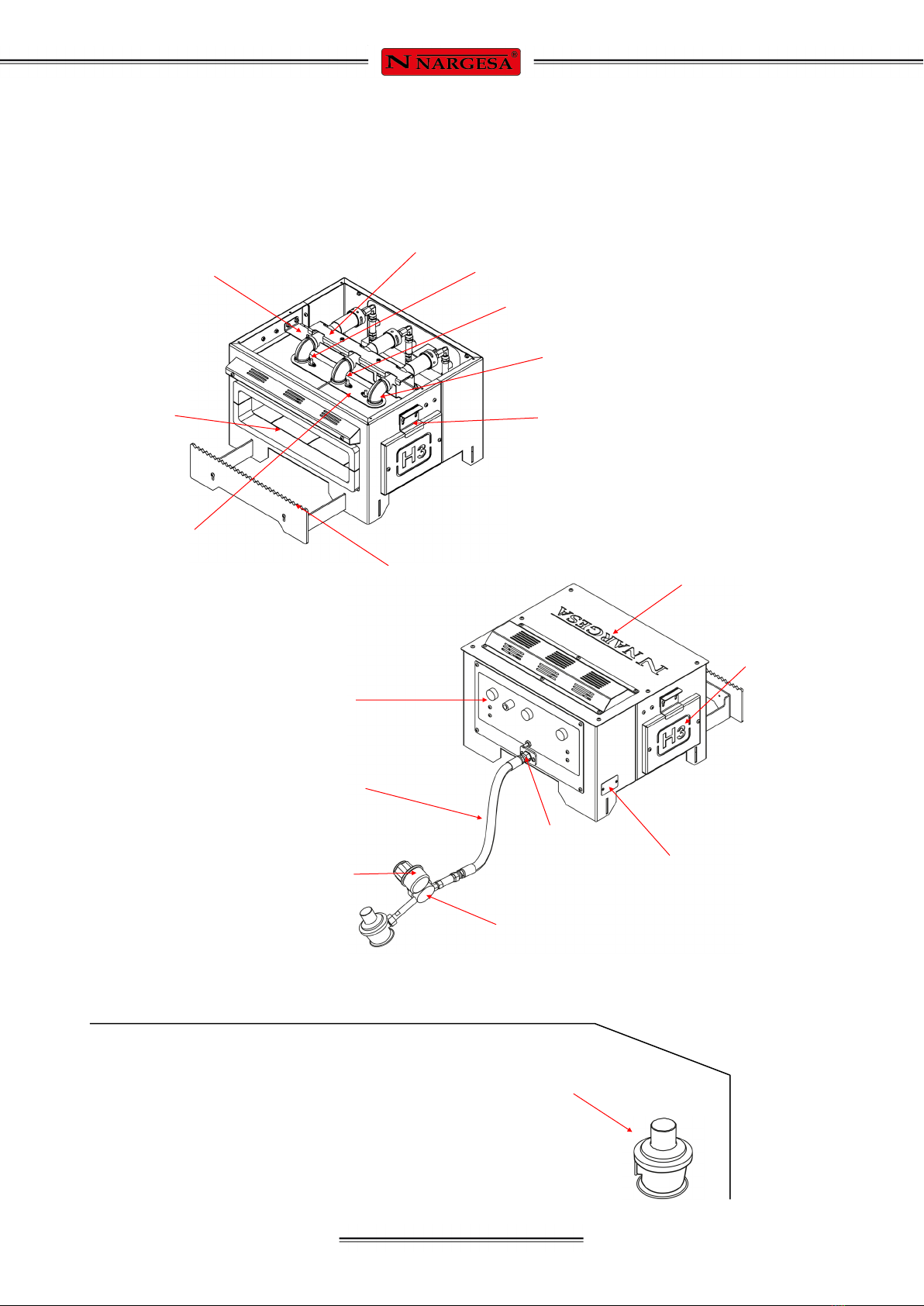

1.6.1. Openings …………………………………………………………………………… 6

1.6.2. Burners ……..……………………………………………………………………… 6

1.6.3. Thermocouple ……………………………………………………………………..… 7

1.7. General Features ……..…………………………….……………………………………… 8

2. TRANSPORT AND STORAGE ......................................................................................... 9

2.1. Transport ...................................................................................................................... 9

2.2. Storage conditions ....................................................................................................... 9

3. MAINTENANCE ....................................................................................................................... 10

3.1. General maintenance ................................................................................................ 10

3.2. Change of the insulating material of the furnace .......................................................... 11

4. HANDLING BOOK .............................................................................................................. 16

4.1. Gas valve ……………............................................................................................... 16

4.2. Pushbuttons ................................................................................................................ 16

4.3. Pressure controller and manometer ........................................................................... 16

5. INSTALLATION AND SET UP .......................................................................................... 17

5.1. Location of th machine .............................................................................................. 17

5.2. Dimensions and work área .......................................................................................... 17

5.3. Admissible external conditions ................................................................................ 17

5.4. Set up ……………………………...……….................................................................... 18

5.5. Openings ………………………..………….................................................................... 18

5.6. Adjustment of the material support position ………………................................... 19

5.7. First set up of furnace ……………………………………………………………………. 20

5.8. Ignition of the furnace ……....................................................................................... 22

5.9. Shutdown of the furnace …..……................................................................................ 22

6. POSSIBLE BREAKDOWNS .................................................................................................... 23

7. WARNINGS ............................................................................................................................ 24

7.1. Hazard wastes ........................................................................................................... 24

7.2. Protection elements for the operator ……................................................................... 24

TECHNICAL ANNEX