INSTRUCTIONS BOOK HORIZONTAL PRESS BRAKE PP200 2

3

3

3

3

4

5

5

6

6

6

7

7

7

8

8

8

9

9

10

10

10

11

12

13

13

14

14

15

16

INDEX

1. CHARACTERISTICS OF THE MACHINE ...............................................................................

1.1. Machine identification ..................................................................................................

1.2. General dimensions ....................................................................................................

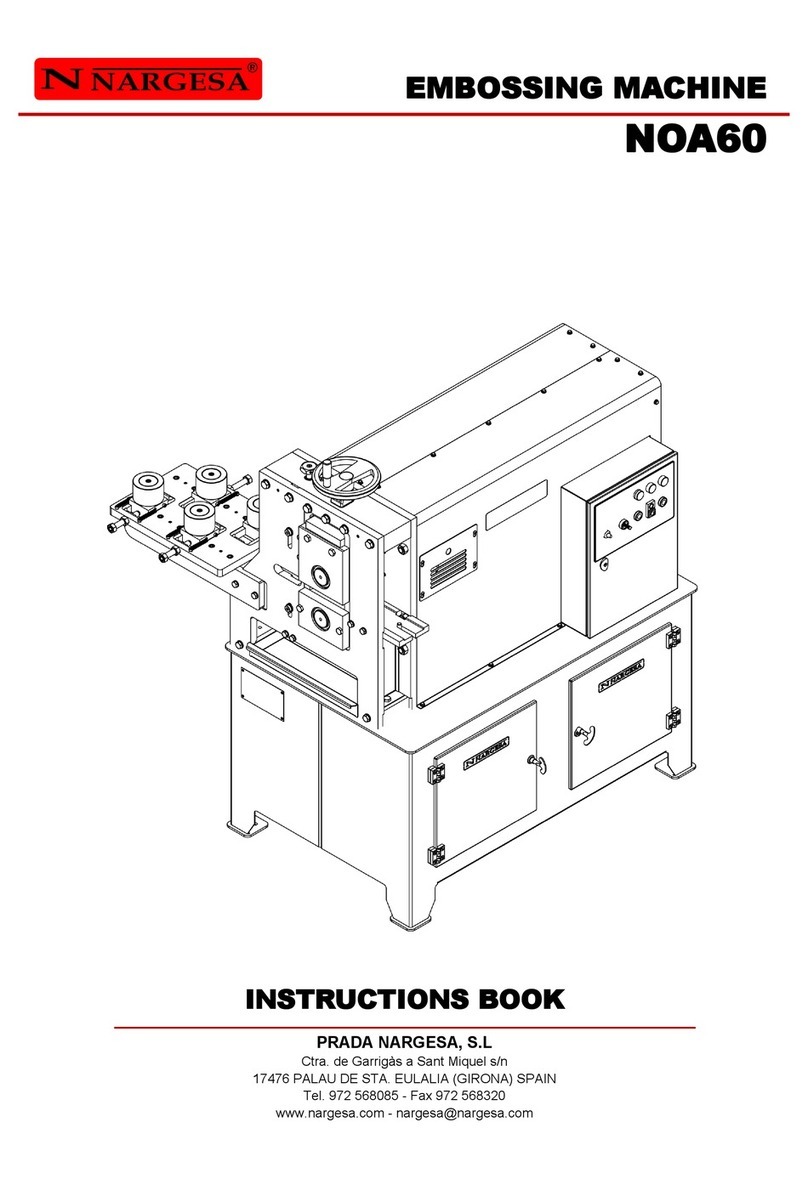

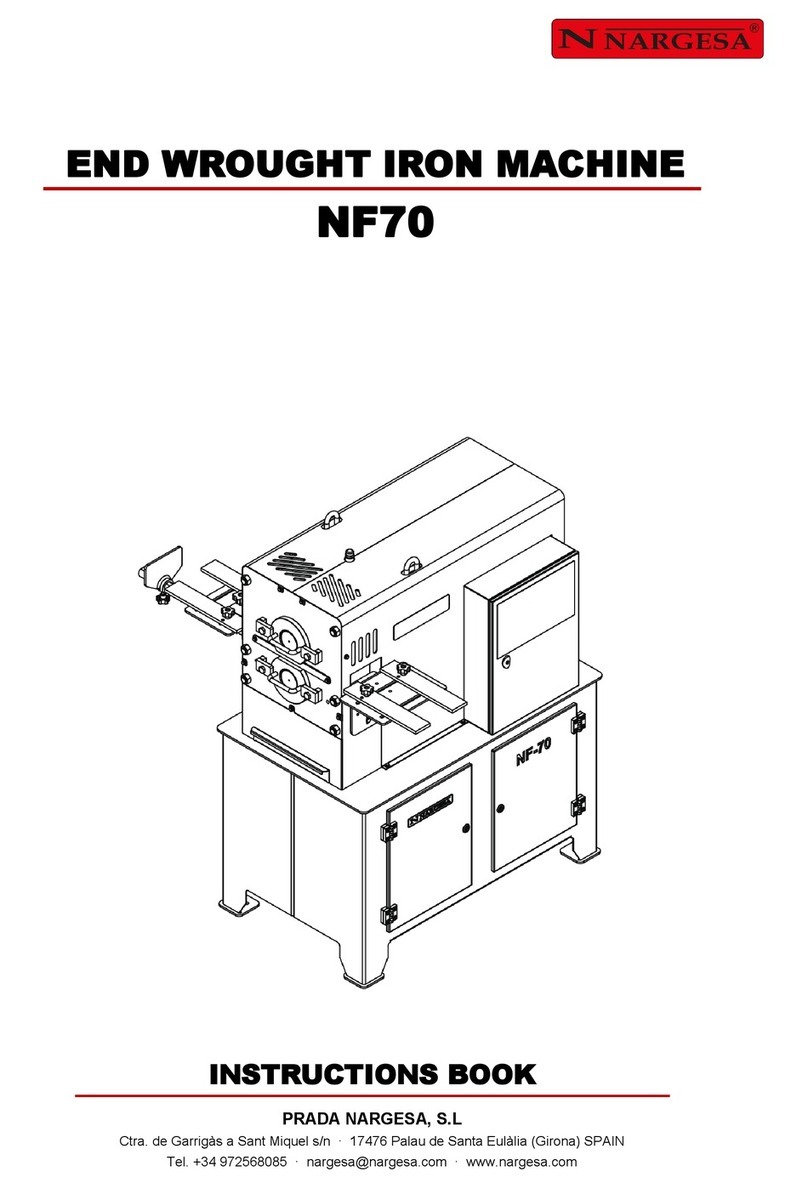

1.3. Machine description ....................................................................................................

1.4. Identification of components .......................................................................................

1.5. General characteristics ...............................................................................................

1.6. Identification of protective panels ................................................................................

2. TRANSPORT AND STORAGE ...............................................................................................

2.1. Transport .....................................................................................................................

2.2. Storage conditions ......................................................................................................

3. MAINTENANCE AND CLEANING ..........................................................................................

3.1. Hydraulic maintenance ................................................................................................

3.2. Cleaning ......................................................................................................................

4. INSTALLATION AND START UP ...........................................................................................

4.1. Placement ...................................................................................................................

4.2. Work area ....................................................................................................................

4.3. Acceptable external conditions ...................................................................................

4.4. Electrical connection ...................................................................................................

5. INSTRUCTIONS FOR USE .....................................................................................................

5.1. Description of the control panel ...................................................................................

5.2. Start up ........................................................................................................................

5.3. Displacement adjustments ..........................................................................................

5.4. Adjustment of the working strength .............................................................................

5.5. Manual mode ..............................................................................................................

5.6. Automatic mode ..........................................................................................................

6. FAULT FINDING ......................................................................................................................

6.1. Electrical faults ............................................................................................................

7. CAUTION .................................................................................................................................

8. TOOLING .................................................................................................................................

TECHNICAL ANNEX