INSTALLATION AND OWNER’S MANUAL

N944 LIGHT BAR for Honda® VTX1300 S

PARTS LIST

Screwdriver, #2 Phillips

Socket, 12mm, and Ratchet Wrench

Wrench, 12mm

Pliers, Slip Joint

Hex Key 5/32” or 4mm

Description Qty.

Lightbar Assembly, N944 1

Connectors, Scotchlok 6

10-24 Screw 4

M8 x 35 Screw 2

Washer , Flat 2

1. Make certain the motorcycle is securely positioned for this

installation. Cover the front fender with a protective cloth to avoid

scratches.

2. Remove Headlight from Headlight Shell (screwdriver), set aside.

3. Disconnect Turn signal wires inside Headlight Shell.

4. Remove the nuts holding the headlight shell to the lower triple

clamp. Nuts will be reused. (12mm socket and ratchet)

5. Remove Turn signals from motorcycle, set aside they will not be

reused.

6. Use the 10-24 screws to mount the Turn Signals to the light bar.

PREPARATION

INSTALLATION

1. Mount the Light Bar Assembly:

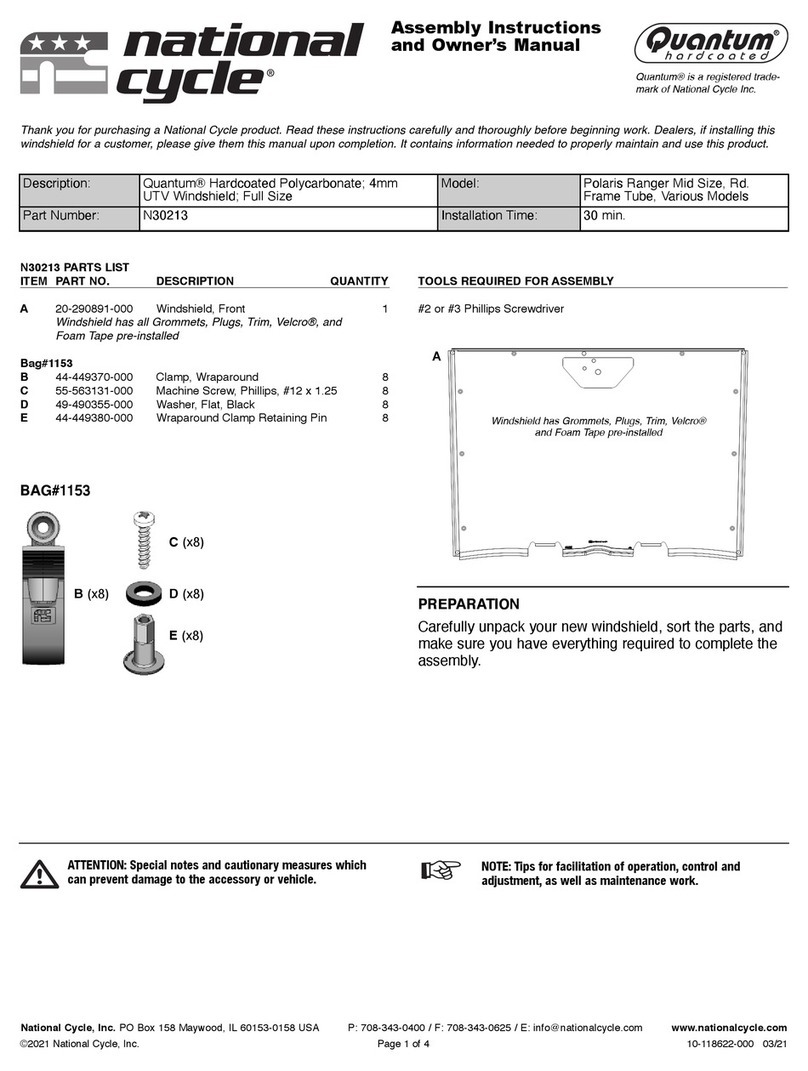

A. Place the Light Bar assembly so the center mount bracket is

between the lower Triple Clamp and the mounting bracket for

the Headlight Shell.

B. From the top, insert the M8 x 35 screws provided through the

Light Bar center mount bracket and into the triple clamp.

From underneith, install a flat washer and secure with stock

nut. Tighten to manufacturers specified torque. Figure 1& 2.

2. Wire the Light Bar assembly:

A. Route Spotlight wires into Headlight Shell.

B. Attach wires as recommended in the following list. Do

one at a time and check for correct operation. You may

need to change wire connections to get the correct oper

ation. (Connectors and Pliers).

Light Bar Motorcycle

Turnsignal, Left Short Red = Orange

Turnsignal, Right Short Red = Blue

Running Light, Left Short Black = Orange/White

Running Light, Right Short Black = Blue/White

Passing Lamps Long Blue = White (lo beam)

Ground = Green

3. Reinstall the headlight and rim.

4. Verify proper operation of all lights before riding.

10-110744-000 11/02

NOTE: Check local regulations for proper passing lamp opera-

tion. Some states require passing lamps be lit only with hi-beam.

NOTE: right and left on the motorcycle are determined from the

rider’s position.

Page 1 of 2

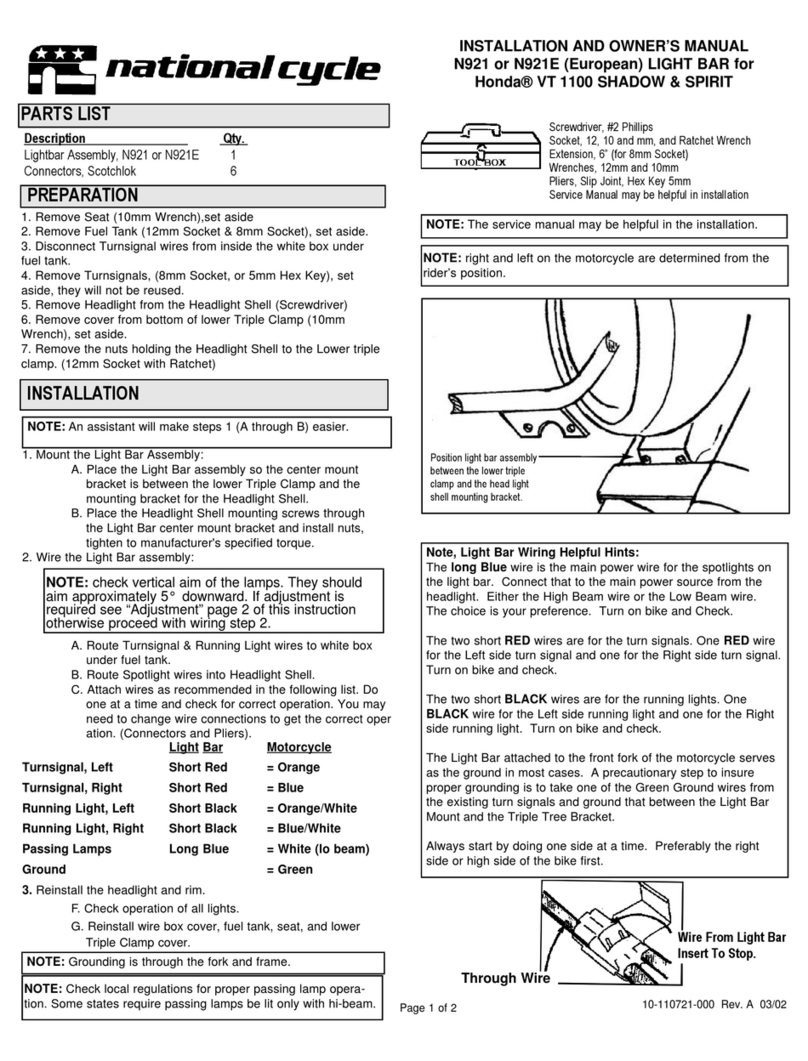

Wire From Light Bar

Insert To Stop.

Through Wire

NOTE: The service manual may be helpful in the installation.

NOTE: Grounding is through the fork and frame.

NOTE: An assistant will make steps 1 (A through B) easier.

Note, Light Bar Wiring Helpful Hints:

The long Blue wire is the main power wire for the spotlights on

the light bar. Connect that to the main power source from the

headlight. Either the High Beam wire or the Low Beam wire.

The choice is your preference. Turn on bike and Check.

The two short RED wires are for the turn signals. One RED wire

for the Left side turn signal and one for the Right side turn signal.

Turn on bike and check.

The two short BLACK wires are for the running lights. One

BLACK wire for the Left side running light and one for the Right

side running light. Turn on bike and check.

The Light Bar attached to the front fork of the motorcycle serves

as the ground in most cases. A precautionary step to insure

proper grounding is to take one of the Green Ground wires from

the existing turn signals and ground that between the Light Bar

Mount and the Triple Tree Bracket.

Always start by doing one side at a time. Preferably the right

side or high side of the bike first.

NOTE: check vertical aim of the lamps. They should

aim approximately 5° downward. If adjustment is

required see “Adjustment” page 2 of this instruction

otherwise proceed with wiring step 2.

Figure 1. Attach

Turn Signal with

10-24 Screws.

Figure 2

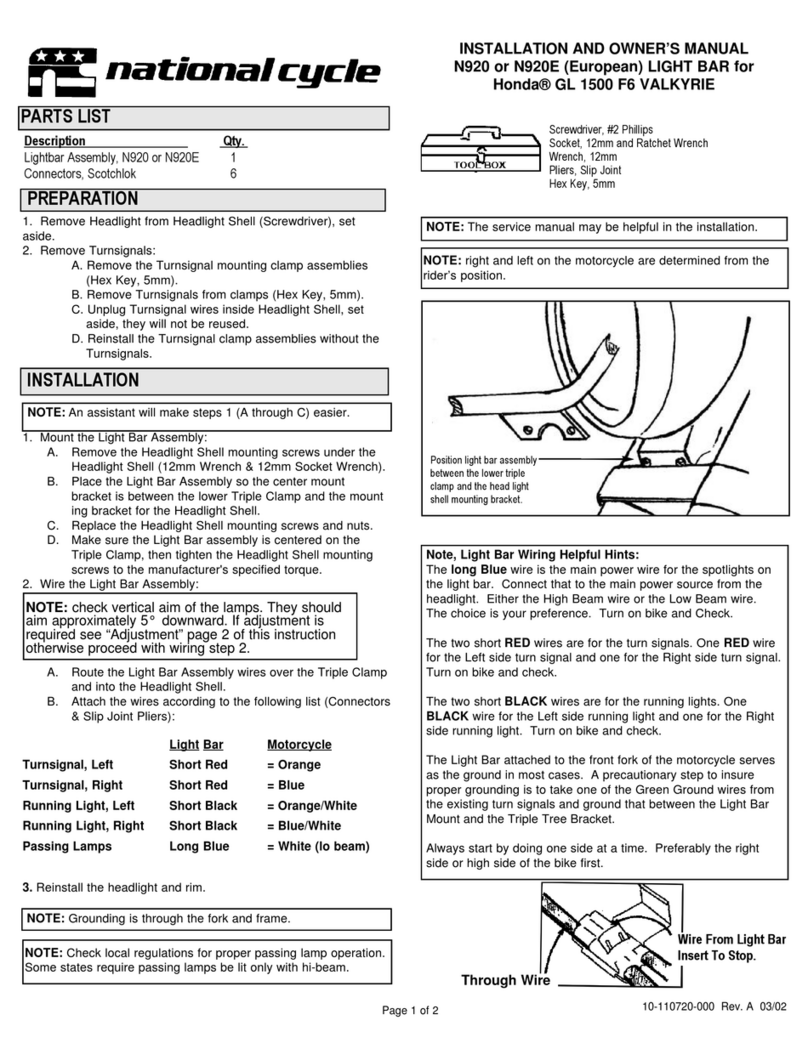

Figure 3