Oxygen detectors –URS40SS

Gas detection systems for industrial environments

Oxygen excess

Since oxygen weighs more or less the same as air, unless there is forced or natural air

circulation, it tends to spread at the point of the leak.

So, the excess oxygen detectors must be installed near any likely leakage points, in order to

detect the excess oxygen as quickly as possible.

Oxygen deficiency

Detection of oxygen deficiency has the purpose of indirectly detecting the presence of other

gases that deplete the oxygen in the air, therefore causing asphyxiation problems, for example.

In this case, the detectors must be located at the breathing height of the occupants in the

premises. Take into consideration the following specific installation guidelines, as well as the

above instructions, for location of the detectors.

The detectors must be installed:

1. where accidental gas leakages are possible

2. at least 1.5m away from heat sources or from vent holes

3. not in spaces where ventilation is poor and where gas pockets may form

4. away from hindrances to natural gas flow

5. away from equipment that may leak gas during normal operations

6. in environments with a temperature range of -20°C to 50°C and relative humidity below

90% (non-condensing)

7. Disconnect equipment from the power supply when mounting and dismantling detectors.

Environmental

compatibility

and disposal

This product has been designed and constructed using materials and processes that take into

account the environmental issue. Refer to the following notes for disposal of the product at the

end of its working life, or when it is replaced:

-for disposal purposes, this product is classified as an electric and electronic device: do not

dispose of it with normal household waste, in particular as regards the printed circuit

-comply with all local laws in force

-as far as possible reuse basic materials to keep environmental impact to a minimum

-use local depots and waste recycling companies, or contact the supplier or manufacturer to

return used products or to ask for information on environmental compatibility and waste

disposal

-the product packaging can be reused. Keep it for future use or to return the product to the

supplier.

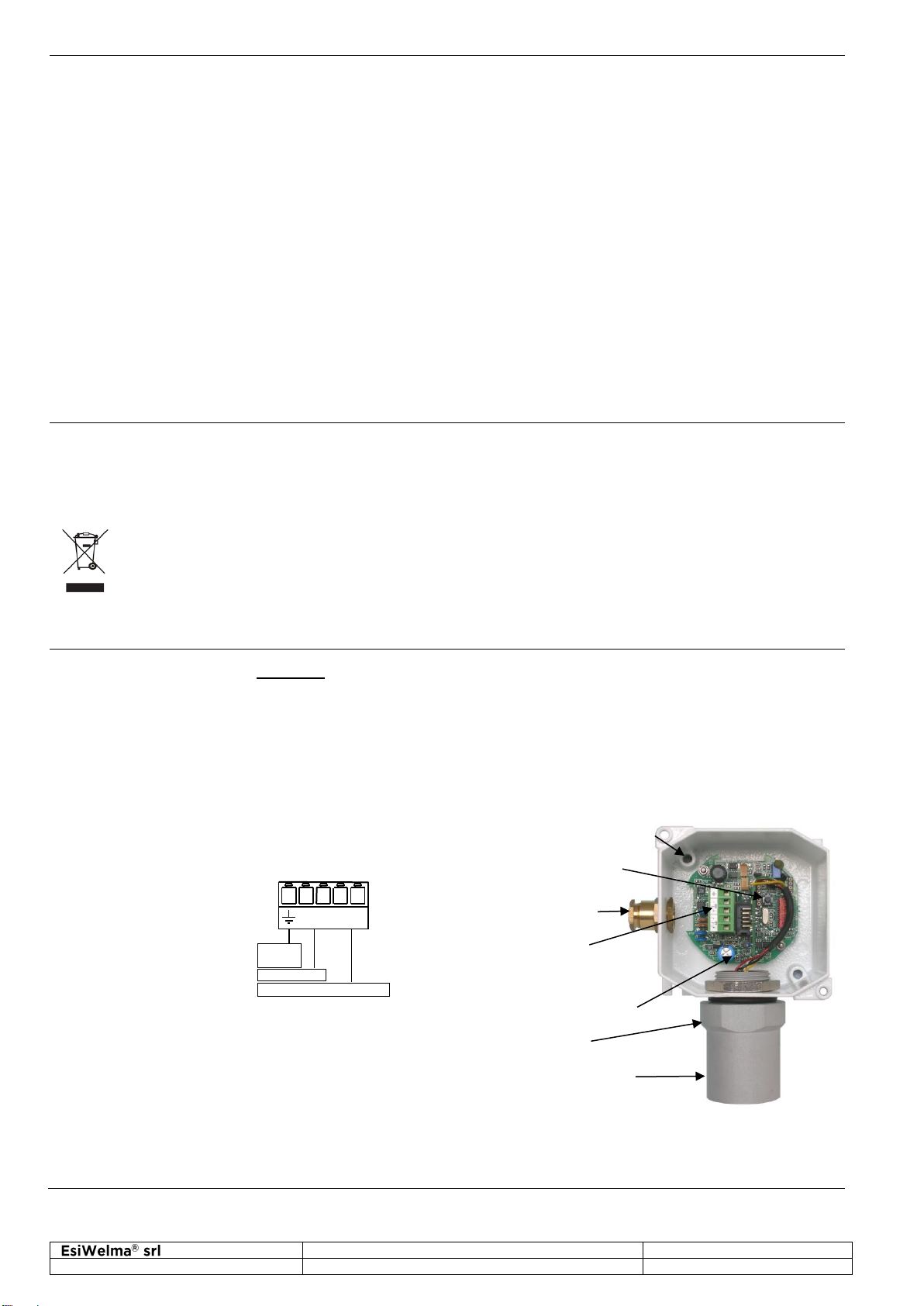

Electrical installation

and configuration

Terminal board and

electrical connections

Cabling:

CAUTION: Make the area safe and ensure that the device power supply is off

before cabling and configuration operations.

Install the sensor in compliance with EN60079-14.

The cable gland provided on the housing is used for cable entry. The diameter of the cable

sheath must be no more than 8 mm.

Ground the sensor using the internal grounding system.

Refer to the Control Unit manual for all cabling information (cable type and specifications, bus

topology, length of connections etc.) and configuration.

Depending on the connecting distance, use at least 4-core cable, min. diameter 0.75mm2up to

100m, 1mm2up to 200m, 1.5mm2up to 500m.

Use shielded cable where there is a risk of electromagnetic interference.

Power supply

and BUS

connector