6

** Federal Occupational Safety & Health Standards for

Agriculture Subpart D, Section 1928.57 (a)(6).

WORK AREA SAFETY

• Work Area is dened as the area surround-

ing grain handling equipment.

• Make sure that no children or unauthorized

persons enter the work area.

• If anyone not involved in the actual opera-

tion DOES enter the work area, the operator

on duty should immediately shut down the

equipment until all unauthorized persons are

safely out of the work area.

• Prior to start-up and during operation, make

sure that the work area is clean and free of

any tools and debris. KEEP AREA CLEAN.

WEAR PERSONAL

PROTECTIVE EQUIPMENT (PPE)

• Utilize protective equipment, such as:

Hand protection, ear plugs, eye shields,

conned space equipment, and fall

protection equipment - to mention a few.

ANSI and NFPA STANDARDS

• Install all equipment in compliance

with ANSI and NFPA Standards.

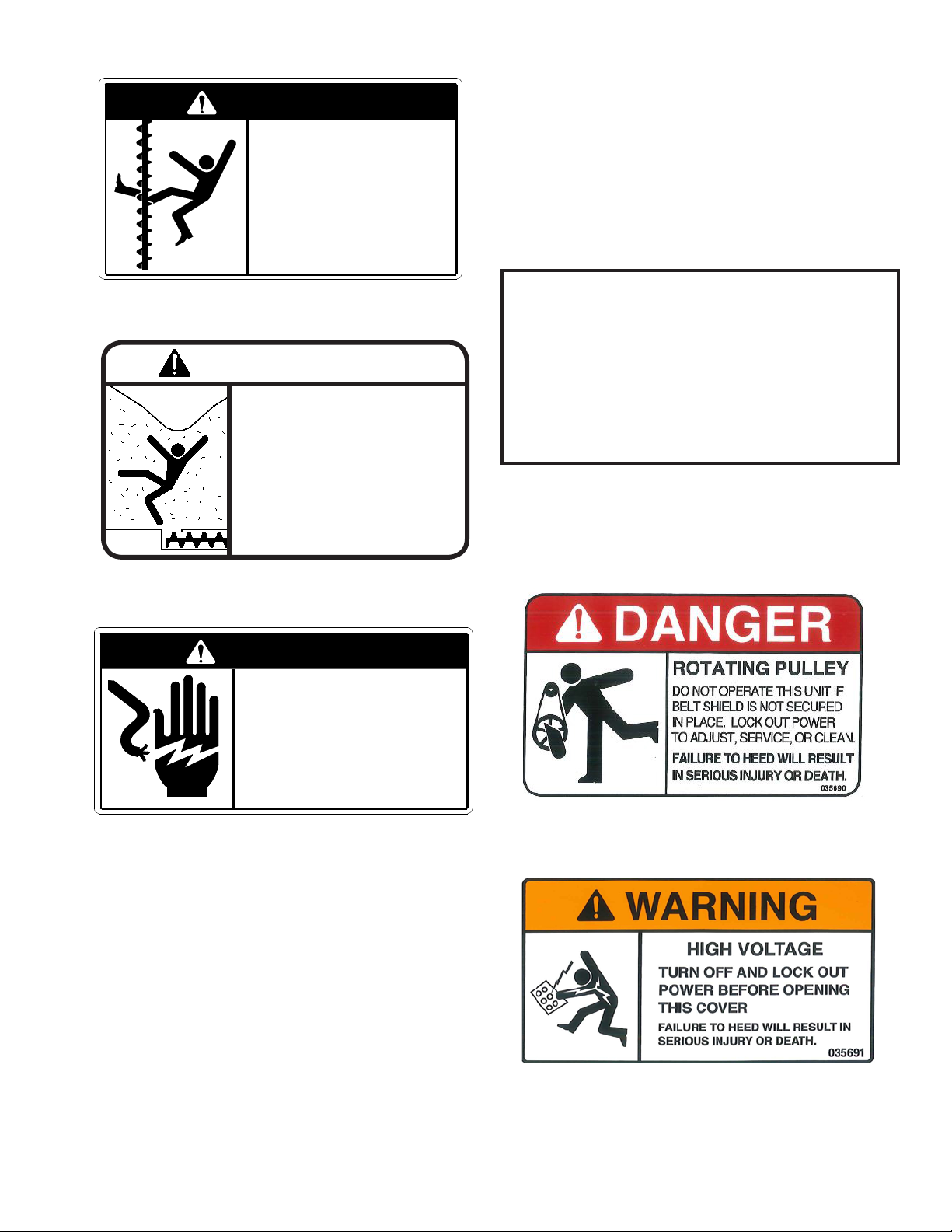

OPERATOR QUALIFICATIONS

• Anyone who has not read or does not

completely understand all operating and

safety instructions contained within this

manual is not qualied to operate the

equipment.

• Only competent and experienced persons

should operate farm equipment. Anyone

operating or working around power equip-

ment must understand and meet all legal

and contractual requirements.

`

• The owner / operator must know the regula-

tions in your own area. For example, some

regulations specify that no one under the

age of 16 may operate power machinery

including farmstead equipment.

• Current OSHA regulations state in part, “At

the time of initial assignment and at least

annually thereafter, the employer shall in-

struct every employee in the safe operation

and servicing of all equipment with which

the employee is, or will be involved. **

• Know and use proper LOCK OUT / TAG

OUT procedures and know the emergency

shut-off locations of any and all utilities

connected to the equipment.

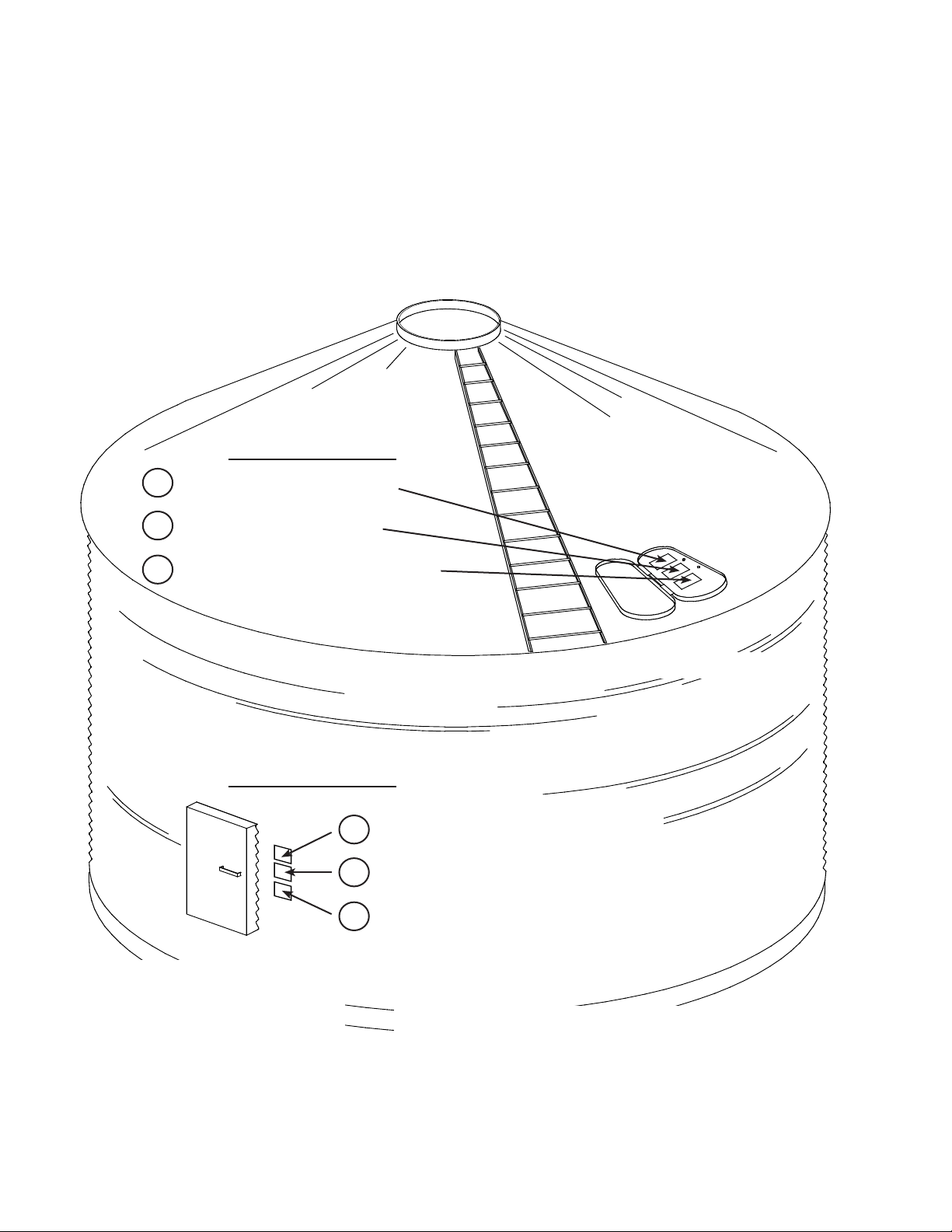

OPERATING PROCEDURES

• Safely follow all operating procedures out-

lined within this manual.

• Prior to startup, make sure that all safety

shields and warning decals are in place.

• NEVER leave equipment running without a

qualied operator present.

• Inspect the equipment periodically and be

alert for unusual noises, vibrations.

1. SAFETY

READ

and

UNDERSTAND