Neilsen CT1056 User manual

Other Neilsen Tools manuals

Neilsen

Neilsen CT4852 User manual

Neilsen

Neilsen CT4342 User manual

Neilsen

Neilsen CT4794 User manual

Neilsen

Neilsen CT3583 User manual

Neilsen

Neilsen CT1057 User manual

Neilsen

Neilsen CT1535 User manual

Neilsen

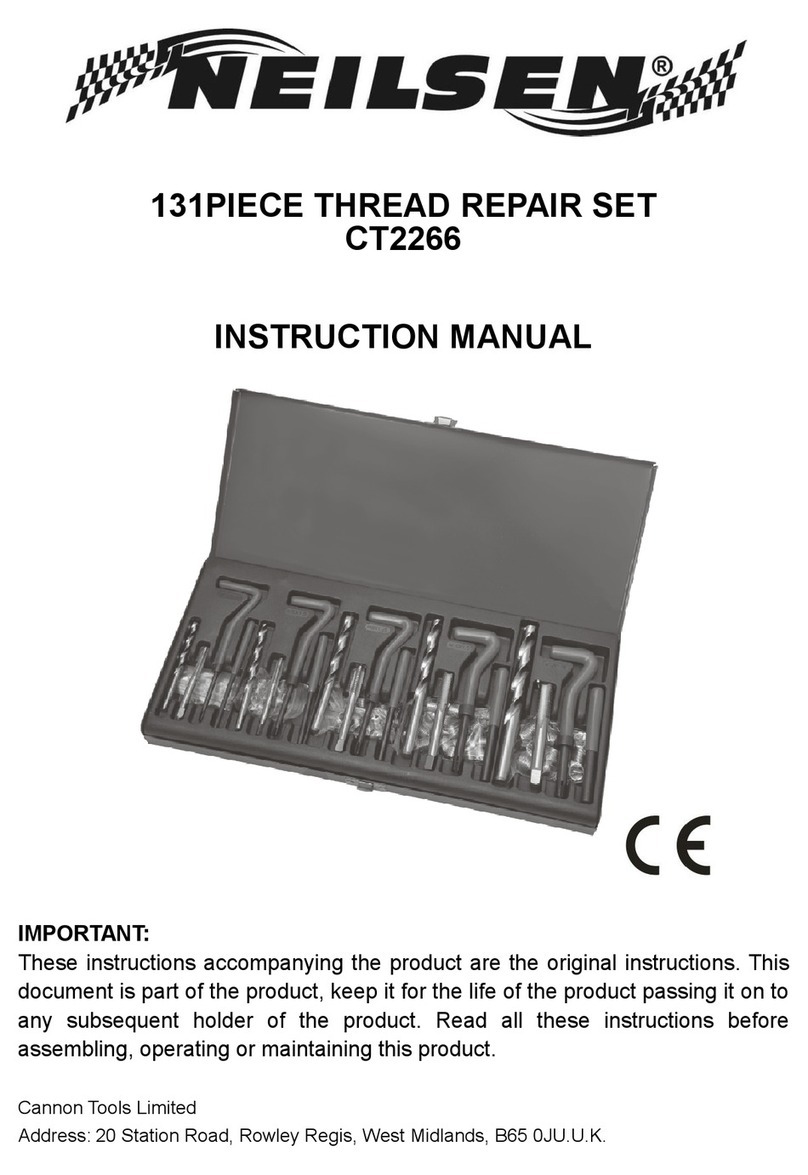

Neilsen CT2266 User manual

Neilsen

Neilsen CT2102 User manual

Neilsen

Neilsen CT2247 User manual

Neilsen

Neilsen CT1533 User manual

Neilsen

Neilsen NAH-A30B User manual

Neilsen

Neilsen CT4188 User manual

Neilsen

Neilsen CT0729 Operation instructions

Neilsen

Neilsen CT4790 User manual

Neilsen

Neilsen CT2737 User manual

Neilsen

Neilsen CT5271 User manual

Neilsen

Neilsen CT4448 Operation instructions

Neilsen

Neilsen CT0676 User manual

Neilsen

Neilsen OPEL VAUXHALL CT2909 User manual

Neilsen

Neilsen CT1509 User manual