nekos K-LOCK User manual

4420088 – Rev. 1710

K-LOCK

INSTRUCTION MANUAL

ELECTROMECHANICAL LOCK

Force 600N – Strokes 18 - 36 mm

Electrical feeding 24V

EN

2

nekos products have been manufactured in accordance with safety standards and conforms to the

stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, they will not

generate any danger for persons, animals or items.

Symbols used in the manual

DANGER

This indication draw the attention about potential dangers for safety and

health of peoples and animals.

INFORMATION

This information give further suggestions.

ATTENTION

This indication draw the attention about potential dangers for the product

itself.

WARNING

This indication draw the attention about potential damages to goods.

ENVIRONMENTAL

INSTRUCTION

Environmental indication draw the attention about potential dangers for

the environment.

3

Contents

1. SECURITY RULES....................................................................................................................... 4

2. TECHNICAL INFORMATION FOR APPLICATION AND OPERATION ..................................... 5

3. TECHNICAL DATA ....................................................................................................................... 5

4. CONSTRUCTION AND REGULATORY REFERENCES ............................................................ 6

5. ID PLATE AND MARKING DATA ................................................................................................ 6

6. ELECTRIC POWER SUPPLY ...................................................................................................... 7

7. SETTING THE DIP-SWITCHES – Selecting the stroke and setting the operating mode........... 7

8. ASSEMBLY INSTRUCTIONS ...................................................................................................... 8

8.1. Preparation of actuator for assembly .................................................................................... 9

8.2. Installation ............................................................................................................................. 9

8.2.1. Milling of the seats for recessed assembly ................................................................. 9

8.2.2. Recessed assembly................................................................................................... 10

8.2.3. Drilling for external assembly .................................................................................... 10

8.2.4. External assembly ..................................................................................................... 10

9. ELECTRICAL CONNECTION .................................................................................................... 11

10. START-UP OPERATIONS ........................................................................................................ 11

10.1. With actuator .................................................................................................................... 11

10.2. Without actuator (test) ...................................................................................................... 12

11. MAINTENANCE OR CLEANING ............................................................................................... 12

12. EMERGENCY OPERATIONS OR MALFUNCTIONS ............................................................... 12

12.1. Emergency operations ...................................................................................................... 12

12.2. Malfunctions of the device ................................................................................................ 12

12.3. LED Light signals .............................................................................................................. 13

13. ENVIRONMENTAL PROTECTION ............................................................................................ 14

14. CERTIFICATE OF GUARANTEE .............................................................................................. 14

15. DECLARATION OF INCORPORATION (for a partly completed machine) AND EC

DECLARATION OF CONFORMITY .......................................................................................... 15

4

1. SECURITY RULES

PLEASE NOTE: IMPORTANT SAFETY INSTRUCTIONS. CAREFULLY OBSERVE ALL THE

FOLLOWING INSTALLATION INSTRUCTIONS TO ENSURE PERSONAL SAFETY. IMPROPER

INSTALLATION CAN SERIOUSLY ENDANGER SAFETY. KEEP THESE INSTRUCTIONS AFTER

INSTALLATION.

MANDATORY RISK ANALYSIS AND PROTECTION MEASURES.

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard IEC

60335-2-103 (Particular requirements for drives for gates, doors and windows) and other directives

and regulations indicated in the attached Declarations of Incorporation and CE Conformity (at the

end of the manual). According to the Machinery Directive, actuators are “partly completed

machinery” intended for incorporation into doors and windows. The manufacturer/supplier of the

window is required, with exclusive responsibility, to ensure the compliance of the entire system

with the applicable standards and to issue CE certification. We strongly discourage any use of the

actuators other than that specified and therefore, in any case, the supplier of the complete system

retains full liability.

For systems installed at a height of less than 2.5 m above floor level or other levels accessible to

users, the manufacturer/supplier of the window must conduct risk analysis regarding potential

harm (violent blows, crushing, wounds) caused to people by normal use or possible malfunction or

accidental breakage of the automated windows, and to implement suitable protective measures in

view of these. Such measures include those recommended by the specified standard:

- controlling the actuators via a “deadman’s button” placed near the system and within the

operator’s field of view, to ensure that people are out of the way during operation. The button

should be placed at a height of 1.5 m and operated by key if accessible to the public; or:

- use of contact safety systems (also included in the actuators) that ensure a maximum closing

force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of IEC 60335-2-

103; or:

- use of non-contact safety systems (lasers, light grids); or:

- use of fixed safety barriers that prevent access to moving parts.

Automated windows are deemed adequately protected if they:

- are installed at a height of >2.5 m; or:

- have a leading-edge opening of <200 mm and a closing speed of <15 mm/s; or:

- are part of a smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a system

component need to be fixed or secured in order to prevent them from suddenly falling or

collapsing: e.g. the use of safety arms on bottom-hung windows.

The device is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lacking experience and knowledge. Do not allow children

to play with the fixed controls and keep any remote-control units out of their reach.

The actuator is destined exclusively for installation indoors. For any special application we

recommend you consult the manufacturer beforehand.

After removing packaging, check for any damage on the appliance.

MAINTENANCE and REPAIRS

Periodically check the installation by inspecting the cables, springs, rods and mechanical

parts for wear or damage. Do not use if repair or adjustment is required.

Disconnect the power supply during cleaning or maintenance operations.

Do not use solvents or jets of water to wash the appliance. The appliance should not be

submerged in water.

In the event of breakage or malfunction, switch the appliance off at the general switch and

call for the services of a qualified technician.

5

Repairs should only be performed by qualified personnel at assistance centres authorised

by the manufacturer.

Always request exclusive use of original spare parts. Failure to respect this condition could

compromise safety and invalidate the benefits contained in the warranty for the appliance.

In the event of any problems or queries, consult your agent or contact the manufacturer

directly.

2. TECHNICAL INFORMATION FOR APPLICATION AND OPERATION

The K-LOCK electromechanical lock is a technical development for automatic locking of

windows, continuous facades and doors. It can be adapted to almost any type of profile in

aluminium, PVC or wood and performs the forward / backward movement of the sliding

accessory of a window or door.

Mounted by itself the device is an effective protection against intrusion, blocking the latch of

windows and doors, but it’s actually constructed to interface only with 24V chain actuators

of the INKA 356 series, even in the SYNCRO³ version, in natural ventilation and smoke and heat

exhaust systems (RWA). The reduced cross-section (just 25x25 mm) allows recessed

insertion in the profiles.

K-LOCK can be combined with the 230V~ actuators of the INKA 356 series (SOLO and

SYNCRO³ versions) by requesting, when placing the order for the actuators, the inclusion of a

small interface device.

The electromechanical lock is composed of a linear actuator that moves the locking hook of

the sliding accessory, with a selectable stroke of 18 or 36 mm. The easy-to-install mechanisms

can be recessed or mounted externally with just two screws.

In combination with the 24V actuators of the INKA 356 series, the device is certifiable under

standard EN 12101-2 – (Smoke and heat control systems – Part 2: Specifications for natural

smoke and heat exhaust ventilators).

3. TECHNICAL DATA

Model K-LOCK 24V

Push and pull force 600 N - 850 N starting force

Strokes 18 mm / 36 mm

Power supply voltage 24V (20,4÷28,8V )

Current absorbed at nominal load 0,85 A during the stroke

1,2 A at intervention of the current interlock

Power absorbed at nominal load ~ 20 W

No-load speed 5 mm/s

No-load stroke time 4 s (18 mm) – 7.2 s (36 mm)

Double electrical insulation Extra-low voltage (SELV) device

Insertion ratio 30 %

Service S

2

of 1 minute

Structure material Extruded aluminium alloy

Operating temperature -20°C - +70°C

Degree of protection for electrical devices IP 40

Opening and closing stroke-end Electronical by means of dip-switches

Operation with chain actuator Selectable

Operation without actuator Selectable

Power supply cable in SILICONE 3x0,5 mm² - 2,00 m

Open/Close overload protection Current cut-off due to power absorption

Dimensions (mm) 25.5 x 25.5 x 357

Weight (kg) 0.560

The data provided in these illustrations is non-binding and subject to change, even without advance notice.

6

4. CONSTRUCTION AND REGULATORY REFERENCES

INTENDED USE.

The

K

-

LOCK

lock has been designed and constructed to move

any sliding accessory, available on the market, applied to doors or windows that

have a coupling cylinder with Ø8; any other use is strongly discouraged, with the

supplier of the entire system in any case retaining sole liability.

The appliance is manufactured in accordance with the EC Directives and

Regulations listed in the attached Declaration of Incorporation and Conformity .

Pour assurer une déconnexion efficace du secteur, il est conseillé d’installer un

poussoir « homme mort » bipolaire de type agréé. En amont de la ligne de

commande, un interrupteur général d’alimentation omnipolaire avec ouverture des

contacts d’au moins 3 mm sera prévu.

- The electromechanical lock is constructed according to European Union

directives and certified in conformity with the mark.

- Any service or control device must be manufactured according to current

regulations and in compliance with EC standards.

The electromechanical lock is composed of a small linear actuator that moves the locking

hook with a 2 m cable in silicone with three wires.

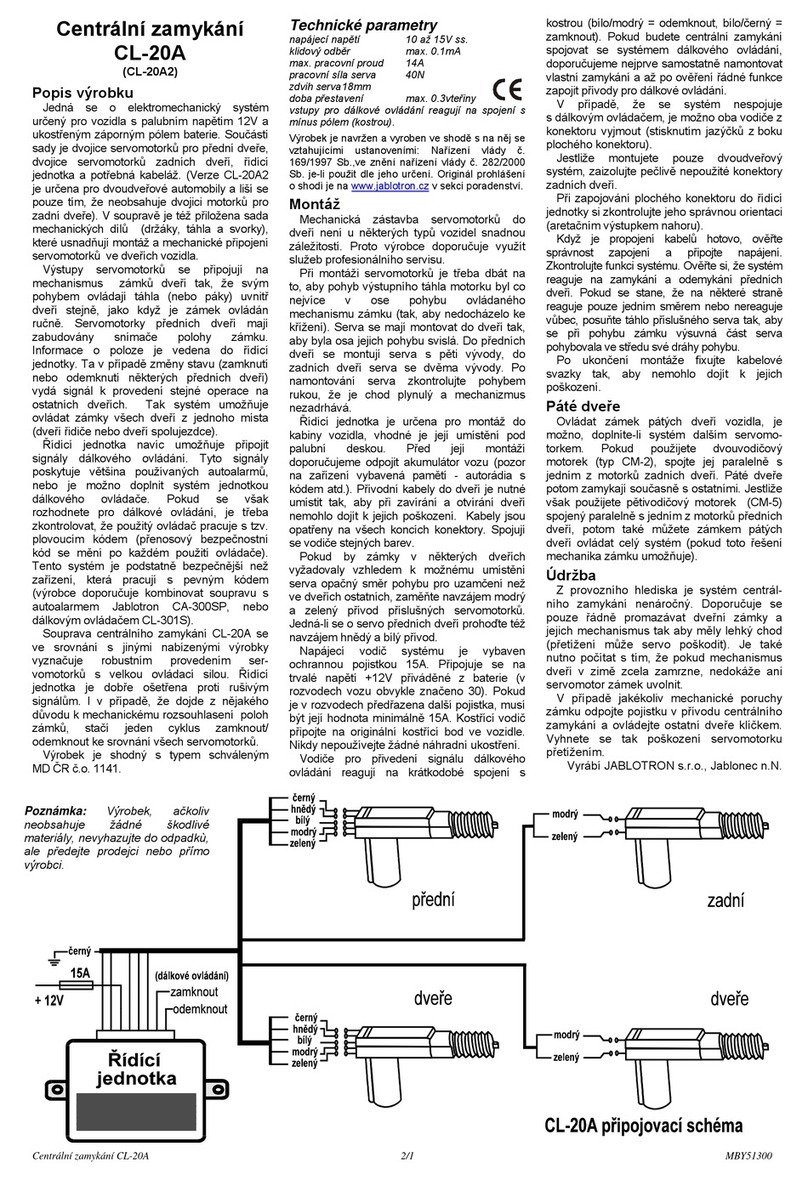

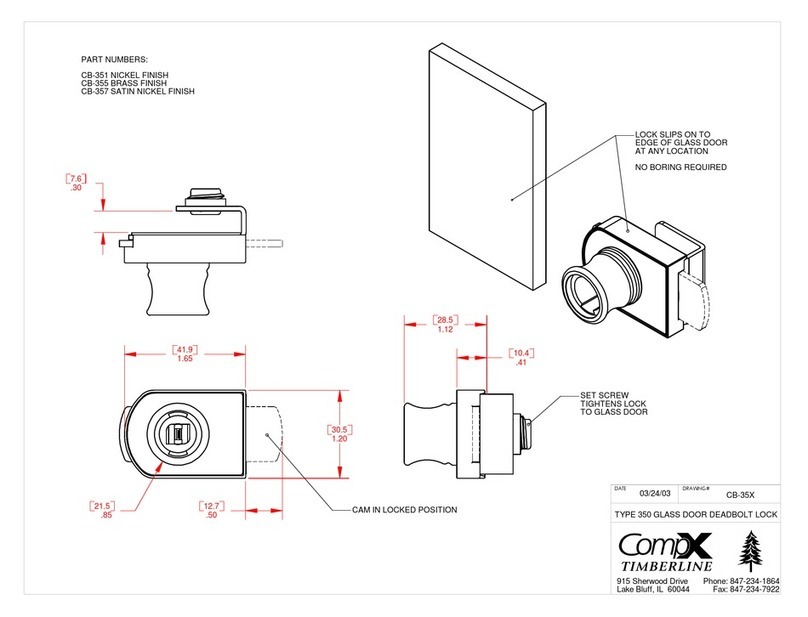

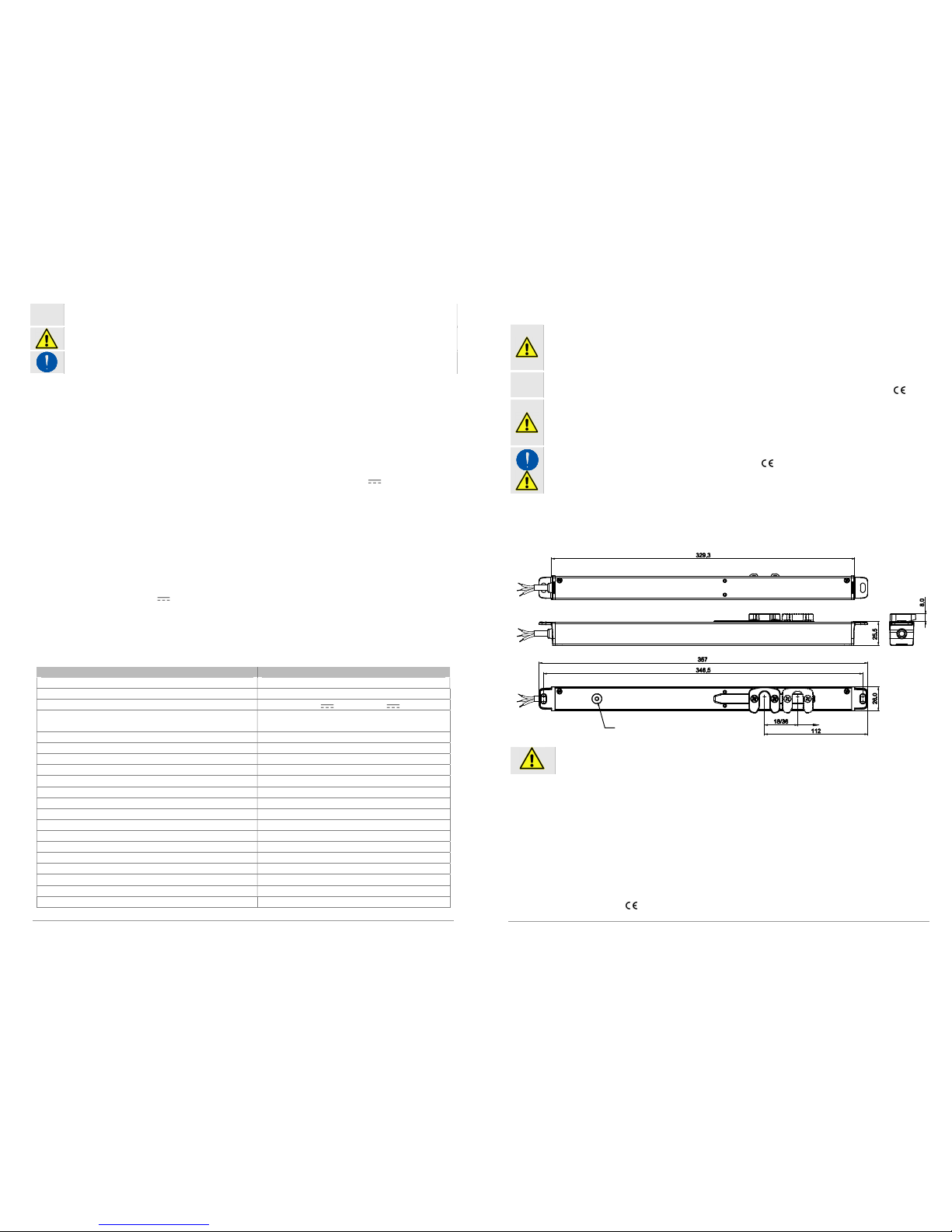

General dimensions of the linear electric actuator

Always mount the latching plate under the hook.

The device is packaged in a cardboard box that contains:

One linear electric actuator, having a stroke of 18 and 36 mm, with a 2 m cable.

Package of small metal parts.

Instructions manual.

5. ID PLATE AND MARKING DATA

The Machine Directive classifies actuators as “partly completed machinery” and they are

supplied with a Declaration of Incorporation, attached to this booklet; with regard to the

electrical side, they bear marking and come under the LVD and CEM Directives and the

Stroke adjusting

dip-switch stopper

7

other Regulations listed in the attached Declaration of Conformity. With this marking, the

actuators can be sold and used throughout the European Union with no further

requirements. The plate data is displayed on an adhesive label placed on the outside of the

container, printed in black on a grey background.

←

Note!

The label is attached to the actuator; when mounted, the label is not visible.

6. ELECTRIC POWER SUPPLY

Risk of electric shock.

- Comply with the CE standards for electrical installation.

- The electrical connection must comply with current standards on the design

and implementation of electrical systems.

- Disconnect the electric power supply before carrying out any electrical

connection work.

Risk of destroying the motor.

The device requires a voltage of 24V . Higher voltage may destroy the motor.

- Low-voltage line and power line must be separate.

The lock must be powered with a voltage of 24V . The power supply cable has three

wires with red copper conductor, sheathing and insulating core in silicone, where:

BLACK “1” connected to the + (positive) CLOSE;

BLACK “2” connected to the + (positive) OPEN;

BLACK “3” is the communication signal with the chain actuator.

The electromechanical lock must be powered using a station with emergency batteries or a

security power supply unit with an output voltage of 24V (min. 20.4V, max. 30V).

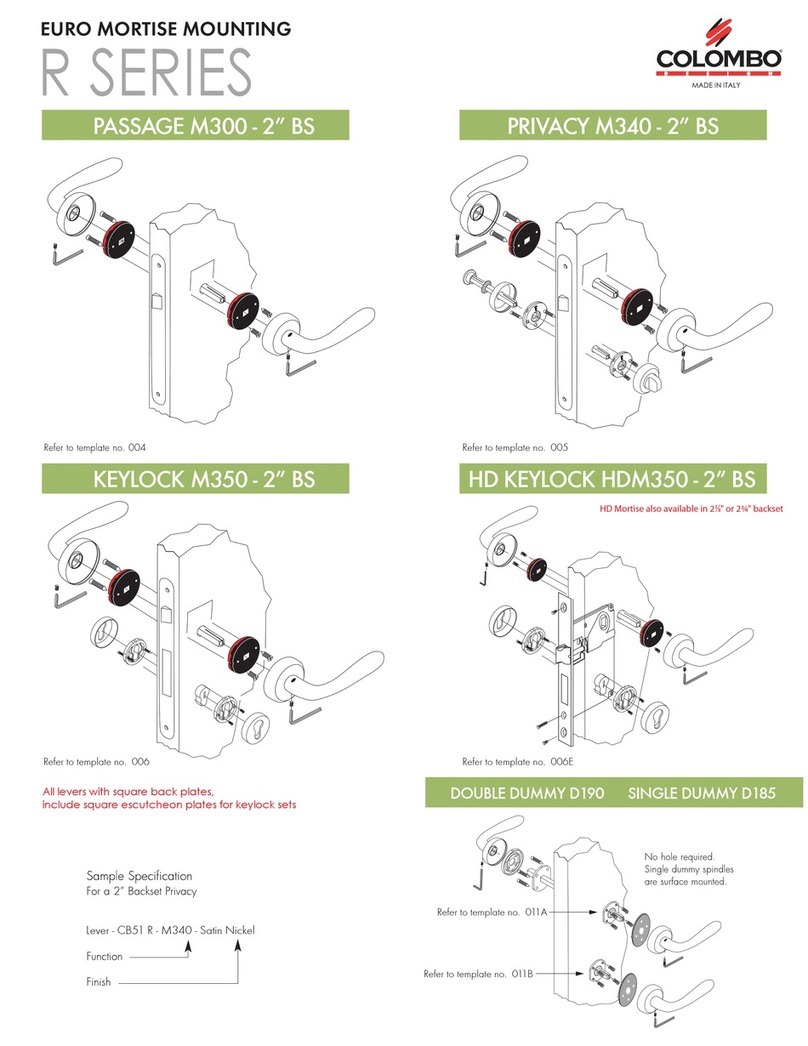

7. SETTING THE DIP-SWITCHES – Selecting the stroke and setting the

operating mode.

The programming dip-switches are located under the cap on the side of the hook. The

selection is made using a small screwdriver or tweezers.

Dip-switch n. 1

This dip-switch is used to set two different strokes of the hook: 18 or 36

mm. The selection is determined by the type of application. The hook

must completely free the bolt of the sliding accessory by at least 3-5 mm.

The dip-switch:

- when placed in the ON position, sets the stroke to 18 mm:

- when placed in the OFF position, sets the stroke to 36 mm.

Dip-switch n. 2

This is the dip-switch that allows the user to select the operating mode:

“with actuator” or “ free” (without actuator). This dip-switch:

when placed in the OFF position, the OPEN / CLOSE movement of

the hook occurs according to the polarity of the power supply

between wire1 and wire2: wire1 +24V → CLOSE, wire1 -24V

→ OPEN.

This mode is useful during assembly or testing when there’s no

communication with the actuators; it’s also useful for performing a

test in the event of accidental fault or lack of operation.

8

when placed in the ON position, it dialogues with the chain

actuator according to the operating logic sequence.

In this case the lock moves only when the chain of the actuator

has re-entered completely.

It’s advisable to select the stroke and operating mode before installation and

ensure that the dip-switches are always accessible.

Stroke 18 mm. The key of the dip-switch should be moved to the ON position towards the

power supply cable.

Stroke 36 mm. The key of the dip-switch should be moved to the OFF position opposite

the power supply cable.

The factory settings are the following: dip1 = ON, dip2 = OFF.

8. ASSEMBLY INSTRUCTIONS

These instructions are intended for technical and specialized personnel, therefore

basic safety and working techniques are not discussed.

All operations for preparation, assembly and electrical connection must be carried out by

technical and specialized personnel; this will guarantee optimum performance and proper

operation of the electromechanical lock. First check that these fundamental conditions are met:

The performance of the electromechanical lock must be sufficient to move the

sliding accessory without any obstruction whatsoever; the limits specified in the

product’s technical data table (page 5) must not be exceeded.

Check that the electric power supply used corresponds to that specified on the

“technical data” label attached to the machine and provided in the previous chapter.

Check that the electromechanical lock has not been damaged during transport,

first by visual inspection and then by powering it in one direction and the other.

Once the lock is installed, check that the latching hook of the pawl of the sliding

accessory is completely latched when the lock is closed and that after opening it’s

completely unlatched so as to allow the window or door to open without any

obstruction.

with actuator

without actuator

9

8.1. Preparation of actuator for assembly

Before starting assembly of the actuator, prepare the following material for completion,

equipments and tools.

For fixing onto metal window frames: M5 threaded inserts (6 pieces), M5x12 flat headed

metric screws (6 pieces).

For fixing onto wooden window frames: self threading screws for wood Ø4.5 (6 pieces).

For fixing onto PVC window frames: self threading screws for metal Ø4.8 (6 pieces).

Equipment and tools: measuring tape, pencil, drill/screwdriver, set of drill heads for metal,

insert for screwing in, electricians pliers, screwdrivers.

8.2. Installation

Improper use of the mechanisms may result in personal injury or damage to

property.

A correct assembly of this device must be studied beforehand while processing the window or

door, so that mechanical processing on machining tools, such as milling and drilling, is still

possible. Nevertheless, in case of assembly on a finished door or window frame, an expert

technician may be capable of applying the device as long as he has the necessary equipment.

First of all the type of installation, recessed or external, must be chosen; in any case the

material for completion listed above must be prepared.

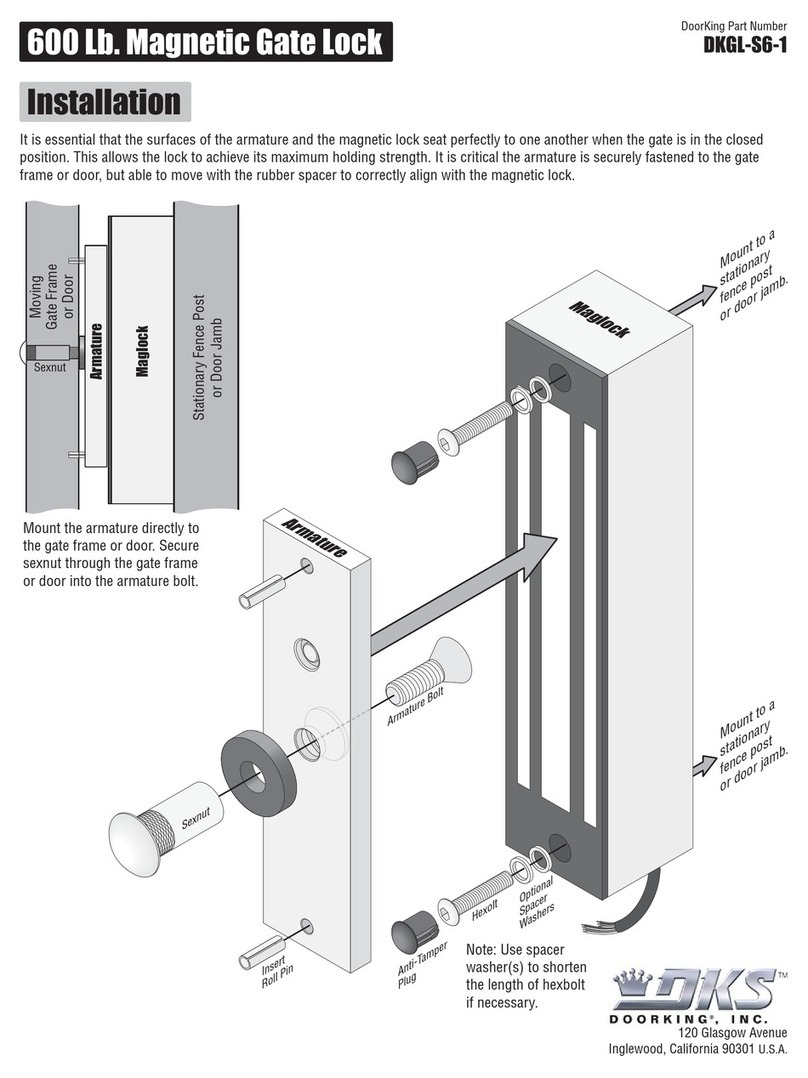

8.2.1 Milling of the seats for recessed assembly

Determine the plan outline of the electromechanical lock that corresponds with a bolt of

the sliding accessory to be moved, and mark it with a pencil. The plan measurements for

the milling are 335x27 mm; (see drawing below).

Once the outline has been marked, mill the window frame with a minimum depth of 24

mm; a Ø4 mm milling cutter is recommended. Use a drill bit with a diameter

corresponding to the selected clamping screws to drill holes in the two points marked for

fastening the device.

Clean the edges with a shaver or using a fine-grit file to eliminate any burr that could

obstruct or ruin the cables during assembly of the devices.

Check - by overlapping them - that the electromechanical lock is positioned correctly and

the hook (in the closed position) is aligned with the pawl of the closed sliding accessory.

Check that the electrical cable path is free of obstacles, otherwise eliminate them.

Now the window frame can be assembled.

10

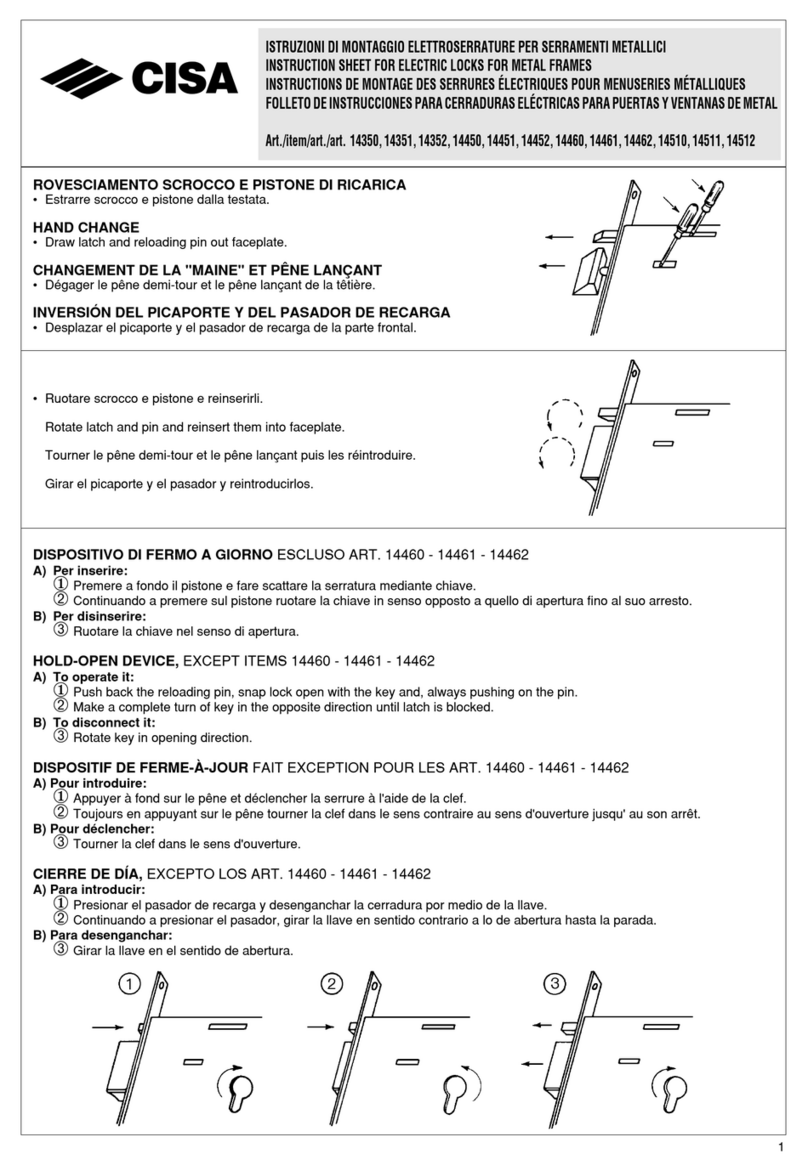

8.2.2 Recessed assembly

Assemble the actuator in the recessed hole made previously on the window frame, taking

care not to damage the cable.

Fix the screws that secure the actuator.

Make the electrical connections following the instructions and diagram provided below in

Chapter 9. “Electrical connection”.

Complete the path of the cables and finish making the electrical connections.

Perform a final test and verify that the device operates correctly on the window frame,

moving the pawl of the sliding accessory sideways.

Power the device and move the pawl to the Open position; the hook of the actuator must

slide towards the center of the machine.

Close the sash of the window or door.

8.2.3 Drilling for external assembly

Determine the drilling points for the linear actuator (the metal one) that corresponds with a

bolt of the sliding accessory to be moved, and mark it with a pencil. The measurements

are provided in the drawing below.

Drill the window frame in the points marked with the diameters indicated in the drawings

and clean the edges of any burr.

Check (by overlapping them) that the actuator is positioned correctly and the hook (in the

closed position) is aligned with the pawl of the closed sliding accessory.

Check that the electrical cable path is free of obstacles; otherwise eliminate them.

Now the window frame can be assembled.

8.2.4 External assembly

Check that the cable path has been prepared beforehand and all the holes have been drilled.

Position the actuator on the window frame and secure it with the screws provided.

Make the electrical connections following the instructions and diagram provided below in

Chapter 9. “Electrical connection”.

Complete the path of the cables and finish making the electrical connections.

Perform a final test and verify that the device operates correctly on the window frame,

moving the pawl of the sliding accessory sideways.

Power the device and move the pawl to the Open position; the hook of the actuator must

slide towards the center of the machine.

Close the sash of the window or door.

The device requires a voltage of 24V .

Higher voltage may destroy the motor.

The device requires a voltage of 24V .

Higher voltage may destroy the motor.

11

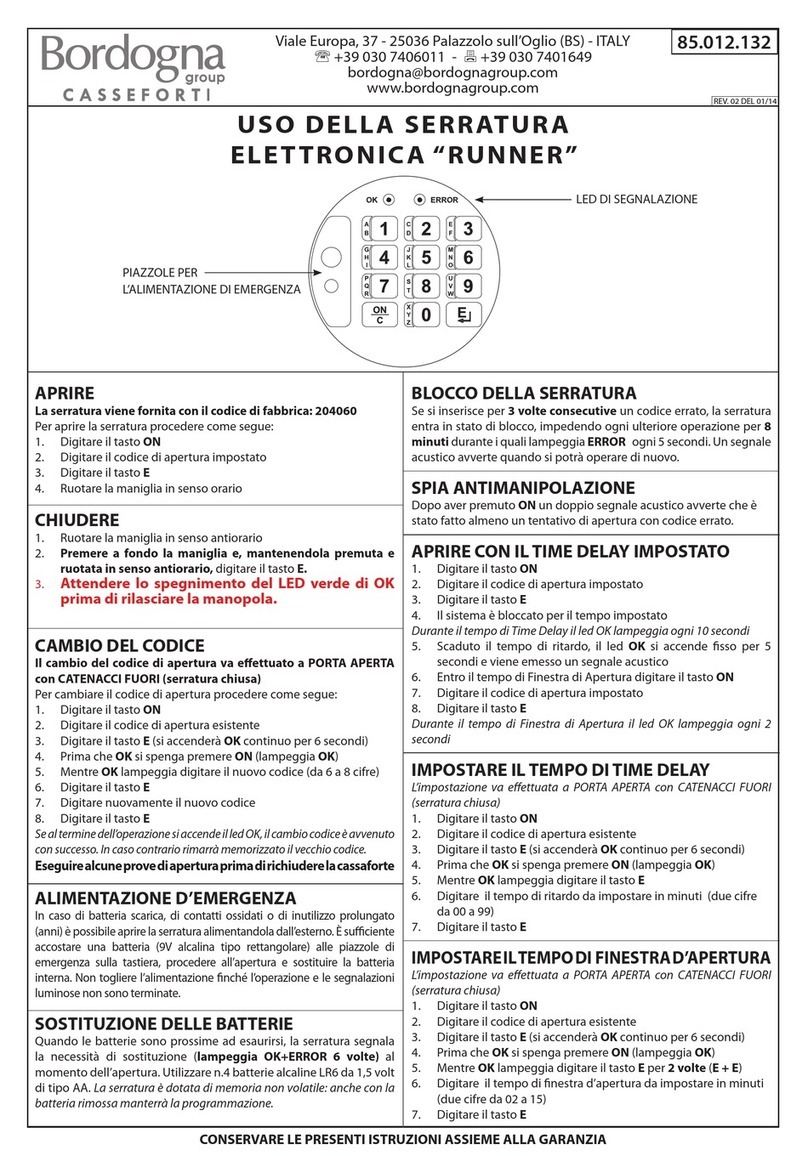

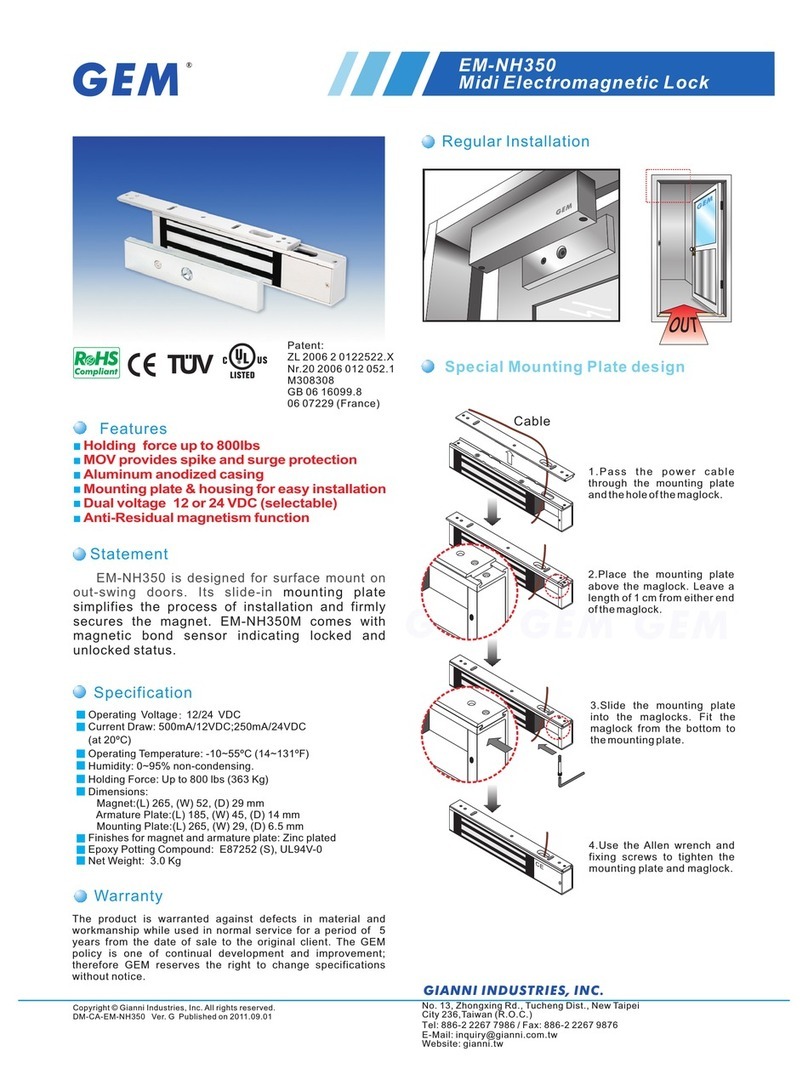

9. ELECTRICAL CONNECTION

The device is equipped with power supply cables constructed in compliance with current safety

standards, restrictions for protection against radio interference and according to that required

by standard EN 12101-2 – Smoke and heat exhaust ventilators. Warning if the cables require

extension:

- Use the same type of cable (cable with sheath and core in silicone).

- Prepare the correct cross-section of the cables.

- To avoid connection errors, use the same coloring of the wires.

For wiring and electrical connections see following diagrams:

Connection of a B-LOCK to a chain actuator

Connection of a B-LOCK to more chain actuators

10. START-UP OPERATIONS

- In order to prevent damage, do not apply the 24V power supply voltage to the

system before having performed the start-up.

- Strictly following the work steps below will guarantee a problem-free installation.

10.1. With actuator

The connections between chain actuator and K-LOCK have been made and the

operation has already been bench tested; when opening the K-LOCK opens, goes

to 18 or 36 mm (the hook moves towards the outside of the machine) and then the

chain of the actuator comes out. When closing, first the chain of the actuator re-

enters completely and then the K-LOCK goes to 0 (the hook moves towards the

center of the machine towards the power supply cable).

Caution: First the RESET procedure indicated in the instructions of the INKA

356 actuator should be executed.

Keep the window unhooked from the chain.

If necessary, operate on dip-switch 1 to correct the stroke; (see Chapter 7. “Setting

the dip-switches”).

ACTUATOR

ACTUATOR

ACTUATOR

24V

24V

12

Supply power [24V ] and move the hook into the opening stroke-end position (18

or 36), then cut off the power.

Hook up the window, i.e. check that the hook is inserted in the pawl of the sliding

accessory.

Supply power again and check operation of the assembly, which must be as seen

on the bench.

Repeat the complete cycle a second time.

Now if everything works perfectly, check that all the screws are tightened correctly

and the cables are orderly and well-protected.

10.2. Without actuator (test)

Ensure that the hook is inserted in the pawl of the sliding accessory and can move.

Select dip2=OFF and dip1 according to the desired stroke.

Supply the power supply voltage [24V ]: check the OPEN or CLOSE movement,

depending on the power supply orientation on wire 1. The movement must be

complete up to the stroke-end without obstacles.

11. MAINTENANCE OR CLEANING

In order to guarantee problem-free operation, the following operations must be carried out after

about 1000 opening cycles and at least once a year:

- Check all the screws to ensure that they are tight, except for the two that fix the hook which

must be loosened by ½ turn.

- Check that the wing is seated perfectly in the frame of the window; if necessary, adjust the

fastening.

- Check all parts for damage and wear. If necessary, replace the damaged parts.

12. EMERGENCY OPERATIONS OR MALFUNCTIONS

Strictly follow the instructions provided below.

Observe the safety standards referred to in this booklet.

12.1. Emergency operations

First set dip2 = OFF (free) and power the lock directly, moving the hook to the OPEN stroke-end

(18 or 36 mm).

12.2. Malfunctions of the device

Since the user cannot repair a defective lock safely or correctly, this is not allowed. Repairs

may only be carried out in the factory.

If the device is opened or tampered with, the warranty becomes null and void; therefore it’s

best to replace the device or have it repaired. If the mechanism is stuck, first check to see if

there is a power failure.

If problems arise during installation or operation of the device, it’s advisable to evaluate the

following possible causes of malfunction.

Problem Possible cause Resolution

The device does

not work.

Lack of electricity to the power

supply unit.

Check the presence of electricity

or the state of the automatic

circuit-breaker or safety switch.

13

The power supply unit does not

supply 24V .

Check that the power supply unit

and safety switch are operating

properly.

Connection cable not connected

or has a detached wire.

Check all the electrical

connections.

The device is

powered but does

not respond to

commands.

Probable breakage of an

electronic element or the motor.

Contact a qualified technician or

the manufacturer's service

center.

12.3. LED Light signals

If there are any problems during installation or operation, consult the possible causes listed below:

WITH RED LED

Number of

Flashes

Type of Error Possible Solution

1

Overload error:

The electromechanical lock has

detected an overcurrent in the

motor.

Check that there are no obstacles

preventing it from completing its stroke.

Check that it has been installed correctly.

2

Communication error:

Communication between the

electromechanical lock and

actuators is interrupted.

Check the condition of the connection

cables, and repeat the RESET procedure if

necessary.

3 Error in the actuators Check the error LED on the actuators.

7

Encoder error:

The internal encoder had a

counting error.

Repeat the RESET procedure.

8

Electric power supply error:

The power supply voltage is

outside the allowed range or

unstable.

Check the electrical contacts at the ends of

the lock's cable and ensure that the power

supply voltage is correct.

10

Memory error:

The internal memory write process

failed.

Repeat the RESET procedure.

11

Connection error:

A RESET procedure is being

started with several actuators that

are not compatible with one

another.

Check the type of actuators selected for the

system.

Repeat the RESET procedure.

WITH GREEN LED

LED Status

Meaning

STEADY-ON

Device powered correctly.

The device executed a chain re-entry stroke correctly, completing the

operation by writing to the memory, or is in motion.

FLASHING

Device powered correctly and at the opening stroke-end.

The number of flashes indicates the address number previously

assigned to the device during the RESET procedure.

14

WITH ORANGE LED

LED Status

Meaning

STEADY-ON

Duration < 0.5

seconds

Internal memory write process in progress.

STEADY-ON RESET Procedure in progress.

FLASHING

RESET Procedure finished correctly.

The number of flashes indicates the address assigned to the device in a

configuration with several devices.

13. ENVIRONMENTAL PROTECTION

Respect safety instructions

To disassemble the device from the frame, proceed as for the mounting (see pages from 10 to 13)

in the proper points, in reverse way.

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent

to a centre for ecological recycling as established from laws in force on recycling.

The device is mainly made from the following materials:

aluminium, zinc, iron, plastic of various type, cuprum,

silicon, silicone.

Dispose materials in conformity with local regulations about removal.

Disassemble the device using suitable tools and separate parts and destine them to disposal or

recycling.

14. CERTIFICATE OF GUARANTEE

The manufacturer will guarantee good function of the appliance. The manufacturer shall

undertake to replace defective parts due to poor quality materials or manufacturing defects in

accordance with article 1490 of the Civil Code.

The guarantee covers products and individual parts for 2 years from the date of purchase. The

latter is valid as long as the purchaser possesses proof of purchase and completion of all

agreed conditions of payment.

Guarantee of good function of appliances agreed by the manufacturer implies that the latter

undertakes to repair or replace free of charge and in the shortest period possible any parts that

break while under warranty.

The purchaser is not entitled to any reimbursement for eventual direct or indirect damage or

other expenses incurred. Attempt to repair by personnel unauthorised by the manufacture shall

render the warranty null and invalid.

The warranty does not cover fragile parts or parts subject to natural wear and tear or corrosion,

overload, however temporary etc. The manufacturer will accept no responsibility for eventual

damage incurred by erroneous assembly, manoeuvre or insertion, excessive stress or inexpert

use.

Repairs performed under guarantee are always "ex factory of the manufacturer". Respective

transport expenses (out/back) are the responsibility of the purchaser.

15

15. DICHIARAZIONE DI INCORPORAZIONE (per una quasi macchina) E

DICHIARAZIONE CE DI CONFORMITÀ / DECLARATION OF

INCORPORATION (for a partly completed machine) AND EC

DECLARATION OF CONFORMITY.

Con la presente il / Hereby the

Costruttore:

Manufacturer:

NEKOS S.r.l.

Via Capitoni 7/5- 36064 Mason Vicentino (Vicenza) - Italy

Tel +39 0424 411011 – Email [email protected]

dichiara sotto la propria responsabilità che i seguenti prodotti

declare under its own responsibility that the following products

Descrizione prodotto :

Product Designation:

Attuatore a cremagliera, lineare a stelo, elettroserratura, tubolare per tende

Rack and pinion drive, linear drive, electromechanical lock, tubular drive

Modello:

Type :

230 V: SKY450

–

SKY 650

NKL 450

24 V: SKY 650

K-LOCK – BK-LOCK

MR28

-

B

Anno di costruzione dal / Year of manufacturing from: 2017

Soddisfano gli applicabili requisiti essenziali della

Direttiva Macchine 2006/42/EC, Allegato I

Fulfil the essential requirements of the Machinery Directive 2006/42/EC, Annex I, Art. 1.1.2, 1.1.3, 1.1.5, 1.2.1,1.2.3,

1.2.6; 1.3.2, 1.3.4, 1.3.9, 1.5.1, 1.5.2, 1.5.6, 1.5.7, 1.5.8, 1.5.9, 1.5.10, 1.5.11, 1.7.1, 1.7.1.1, 1.7.3, 1.7.4.2, 1.7.4.3

La documentazione tecnica pertinente è compilata secondo l’Allegato VII, sezione B

The relevant technical documentation is compiled in accordance with Annex VII, Part B

La persona autorizzata a costituire la documentazione tecnica pertinente è:

The person authorised to compile the relevant technical documentation is: ing. Matteo Stefani – Nekos S.r.l.

Su richiesta adeguatamente motivata delle autorità nazionali, la documentazione tecnica dei citati prodotti sarà resa

disponibile, via e-mail, entro un tempo compatibile con la sua importanza.

In response to a reasoned request by the national authorities, we will provide, via e-mail, the relevant information on the

product listed above within an adequate period proportional to its importance.

Inoltre i succitati prodotti sono conformi alle disposizioni pertinenti delle seguenti Direttive:

Furthermore the products listed above complies with the provisions of followings Directives :

2014/30/EU Direttiva Compatibilità Elettromagnetica / ElectroMagnetic Compatibility Directive (EMCD)

2014/35/EU Direttiva Bassa Tensione / Low Voltage Directive (LVD)

2011/65/EU Direttiva sulla restrizione dell’uso di determinate sostanze pericolose nelle apparecchiature elettriche

ed elettroniche (Direttiva RoHS) / Restriction of the use of certain hazardous substances Directive (RoHS Directive)

e delle seguenti norme armonizzate e/o specifiche tecniche:

and of the following harmonised standards and/or technical specifications:

EN 60335

-

2

-

103;

EN 61000

-

6

-

3:2007 + A1:2011;

EN 61000

-

6

-

2:2005 + AC:2005

EN 60335-1:2012 + EN 60335-1/A11:2014; EN 50581:2012;

La messa in moto di una macchina completa che includa la quasi macchina sopra menzionata, da noi fornita, non è

permessa finché non sia accertato che l’installazione sia stata fatta secondo le specifiche e le indicazioni di installazione

contenute nel “Manuale d’istruzioni” fornito con la quasi-macchina, e che sia stata espletata e documentata, in apposito

protocollo, una procedura di accettazione da parte di un tecnico abilitato.

Commissioning of the complete machinery including the above mentioned drives delivered by us is not allowed until it is

ascertained that the installation of the complete machinery was performed in accordance with the specifications and the

operating and installation advice given in our Mounting Instructions, and that the acceptance procedure was duly carried out

and documented in an acceptance protocol by a specialist.

Questa dichiarazione è fatta dal costruttore / This is declared by the manufacturer :

NEKOS S.r.l. - Via Capitoni 7/5- 36064 Mason Vicentino (Vicenza) - Italy

Rappresentato da / Represented by :

Giuliano Galliazzo – A.D. Presidente / President CEO

Firma / Valid signature

Luogo e data / Place and date: Mason Vicentino 28/07/2017

16

NEKOS S.r.l.

I - 36064 - MASON VICENTINO (VI) - Via Capitoni, 7/5

Telefono (+39) 0424 411011 Fax (+39) 0424 411013

[email protected] - http://www.nekos.it

Table of contents

Other nekos Lock manuals