Neles B1C K Operating and maintenance manual

6 B 72 en • 9/2015

HAND WHEEL OPERATOR

For cylinder actuators

Types B1C_K/L/R and B1C_RK/RL/RR

Installation, Maintenance and

Operating Instructions

26 B 72 en

Table of Contents

1 GENERAL .............................................................. 3

2 SAFETY PRECAUTIONS ....................................... 3

3 B1C actuators, sizes 9 to 25 ................................ 3

3.1 B1C_K/L/R actuator ............................................. 3

4 Maintenance ........................................................ 3

5 Valve close and open position adjustment ...... 4

6 B1C actuators, sizes 32 to 50 .............................. 4

6.1 B1C_RK/RL/RR actuator ...................................... 4

7 Maintenance ........................................................ 5

8 Valve close and open position adjustment ...... 5

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and operation of the cylinder unit.

If you require additional assistance, please contact the manufacturer or manufacturer's representative.

Addresses and phone numbers are printed on the back cover.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

6 B 72 en 3

1 GENERAL

These manual hand wheel operators are designed for

Metso B1C-actuators. Hand wheel operator is intended to

be used for operating the pneumatic actuator in case of

supply power (air) or signal (air, electric) failure takes place.

These instructions contains the information needed for

operating the hand wheel operator, additional information

on B1-actuators are available from the instructions on

installation, operation and maintenance of the model in

question. See the IMO 6BC71en.

Manual hand wheel operator can be recognized from type

codes as follows: letter K and RK in type code is for hand

wheel on cylinder head, letter L and RL means that hand

wheel is installed on the bottom of the housing and R and

RR means that hand wheel is on both cylinder head and

bottom of the housing.

2 SAFETY PRECAUTIONS

3 B1C actuators, sizes 9 to 25

3.1 B1C_K/L/R actuator

The B1C_K actuator is otherwise like the B1C except that it

can be operated manually to bring the piston to lower posi-

tion in case there is no air supply.

The B1C actuator can be changed into a B1C_K by replacing

the cylinder end (44) accordingly and adding parts (33a,

50a to 56a), see Fig. 1.

The B1C_L actuator is otherwise like the B1C except that it

can be operated manually to bring the piston to upper

position in case there is no air supply.

The B1C actuator can be changed into a B1C_L by replacing

the housing (1) accordingly and adding parts (50b to 56b),

see Fig. 2.

The B1C_R actuator is otherwise like the B1C except that it

can be operated manually to bring the piston either to

upper or lower position in case there is no air supply.

The B1C actuator can be changed into a B1C_R by replacing

the cylinder end (44) and housing (1) accordingly and add-

ing parts (33a,50a to 56b), see Fig. 1 and 2.

4 Maintenance

If air escapes between the spindle (50a) and spindle nut

(51a), check the O-ring (54a) and replace it if necessary. Also

check the condition of the cylindrical roller (56a). See Fig. 1

and 2. Other maintenance as described for the B1C actua-

tor, see the IMO 6BC71en and the section 4.

CAUTION:

Before operating the hand wheel make sure it is per-

mitted to manually operate the valve (without disturb-

ing the process).

CAUTION:

Air pressure must always be released before operating

manual hand wheel operator!

CAUTION:

Be careful when adjusting actuator travel stops. The

spindle nut (51) may come out if turned too much. If

the actuator is pressurized it can cause uncontrolled

pressure release which may result in damage or per-

sonal injury.

NOTE:

There is some air bleed trough the spindle thread when

the spindle (50a) with the O-ring (54a) is positioned inside

the cylinder. I.e. when the valve has been manually oper-

ated to open position during compressed air loss and

then the air pressure is restored. To stop the leakage oper-

ate the manual override to non-operated position. See

Fig. 1 and 2

NOTE:

Hand wheel operator is not correct device for safety lock

up of valve.

Locking device, code Q or W, is intended to be used for

safety lock up function during service operation. see IMO

6B70.

CAUTION:

Air pressure must always be released before operating

or servicing manual hand wheel operator!

Fig. 1 B1C_K_ actuator

Parts list for Fig. 1:

Part Quantity Name

33a 1 O-ring

44 1 Cylinder end

50a 1 Spindle

51a 1 Spindle nut (use as a limit screw)

52a 1 Hand wheel

53a 1 Lock nut

54a 1 O-ring

55a 1 Spring pin

56a 1 Cylindrical roller

46 B 72 en

5 Valve close and open position

adjustment

In the B1C_K actuator, unlike in the B1C, the upper valve

position limit is adjusted with the spindle nut (51a) secured

with the lock nut (53a). During adjusting, the spindle (50a)

must be in the extreme outer position. Clockwise rotation

open.

In the B1C_L actuator, unlike in the B1C, the lower valve

position limit is adjusted with the spindle nut (51b) secured

with the lock nut (53b). During adjusting, the spindle (50b)

must be in the extreme outer position. Clockwise rotation

to close.

In the B1C_R actuator, unlike in the B1C, the upper and

lower valve position limit is adjusted with the spindle nut

(51a, 51b) secured with the lock nut (53a, 53b). During

adjusting, the spindle (50a, 50b) must be in the extreme

outer position.

6 B1C actuators, sizes 32 to 75

6.1 B1C_RK/RL/RR actuator

The B1C_RK actuator is otherwise like the B1C except that

it can be operated manually to bring the piston to lower

position in case there is no air supply.

The B1C actuator can be changed into a B1C_RK by replac-

ing the cylinder end (44) accordingly and adding parts

(306…330), see Fig. 4.

The B1C_RL actuator is otherwise like the B1C except that

it can be operated manually to bring the piston to upper

position in case there is no air supply.

The B1C actuator can be changed into a B1C_RL by replac-

ing the housing (1) accordingly and adding parts

(306…330) see Fig. 5.

The B1C_RR actuator is otherwise like the B1C except that

it can be operated manually to bring the piston either to

upper or lower position in case there is no air supply.

The B1C actuator can be changed into a B1C_RR by replac-

ing the cylinder end (44) and housing (1) accordingly and

adding parts (306…330), see Fig. 4 and 5.

The manual gear is disengaged when the handwheel is

turned counter clockwise to the extreme position:

B1CRRU32: 377 turns / 90º operation

B1CRRU40: 470 turns / 90º operation

B1CRRU50: 598 turns / 90º operation

B1CRRU60: 598 turns / 90º operation

B1CRRU75: 598 turns / 90º operation

Fig. 2 B1C_LU_ actuator

Parts list for Fig. 2:

Part Quantity Name

1 1 Housing

50b 1 Spindle

51b 1 Spindle nut (Use as a limit screw)

52b 1 Hand wheel

53b 1 Lock nut

54b 1 O-ring

55b 1 Spring pin

56b 1 Cylindrical roller

NOTE:

There is some air bleed trough the spindle thread and the

relief valve (58) when the sealing slide (15) with the Orings

(16) is positioned inside the cylinder. I.e. when the valve

has been manually operated to open position during

compressed air loss and then the air pressure is restored.

To stop the leakage operate the manual override to closed

position. See Fig. 3

Fig. 3 Manual overdrive

6 B 72 en 5

7 Maintenance

The manual override requires no regular maintenance.

Grease can be added to the gear through the hole of the

outermost fitting screw, if needed.

Other maintenance as described for the B1C actuator, see

the IMO 6BC71en and the section 4.

8 Valve close and open position

adjustment

In the B1C_RK actuator, the close position limit of valve is

adjusted with the handwheel (309), secured with screw

(319) and locked with the hex nut (320).

B1C_RK_: Counterclockwise rotation of the handwheel

opens the valve.

In the B1C_RL actuator, the open position limit of valve is

adjusted with the handwheel (321), secured with screw

(323) and locked with the hex nut (324).

B1C_RL: Clockwise rotation of the handwheel closes the

valve.

In the B1C_RR actuator, see function from the texts above.

CAUTION:

Air pressure must always be released before operating

or servicing manual hand wheel operator!

Fig. 4 B1C_RK

Parts list for Fig. 5:

Part Quantity Name

306 1 Manual overdrive

307 1 Cylinder end

308 1 Extension shaft

309 1 Handwheel

310 1 Support bracket

311 1 Hex screw

312 1 Bearing

313 1 Pin

314 1 Pin

319 1 Hex screw

320 1 Hex nut

Fig. 5 B1C_RL

NOTE:

Turn the handwheel back to the starting position, before

applying supply pressure to the actuator again.

Parts list for Fig. 6:

Part Quantity Name

1 1 Housing

305 1 Manual overdrive

310 1 Support bracket

316 1 Fitting plate (size 20 only)

317 1 Socket screw (size 20 only)

321 1 Handwheel

322 1 Pin

323 1 Hex screw

324 1 Hex nut

66 B 72 en

Metso Flow Control Inc.

Europe, Vanha Porvoontie 229, P.O. Box 304, FI-01301 Vantaa, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, M A 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

South America, Av. Independéncia, 2500-Iporanga, 18087-101, Sorocaba-São Paulo, Brazil. Tel. +55 15 2102 9700. Fax +55 15 2102 9748

Asia Pacic, Haw Par Centre #06-01, 180 Clemenceau Avenue, Singapore 239922. Tel. +65 6511 1011. Fax +65 6250 0830

China, 11/F, China Youth Plaza, No.19 North Rd of East 3rd Ring Rd, Chaoyang District, Beijing 100020, China. Tel. +86 10 6566 6600. Fax +86 10 6566 2583.

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/valves

This manual suits for next models

5

Table of contents

Other Neles Controllers manuals

Popular Controllers manuals by other brands

Chamberlain

Chamberlain CB124EV instructions

Siemens

Siemens EM 300 operating instructions

Precision Digital Corporation

Precision Digital Corporation ConsoliDator PD980-8K9-15 instruction manual

Toshiba

Toshiba V Series user manual

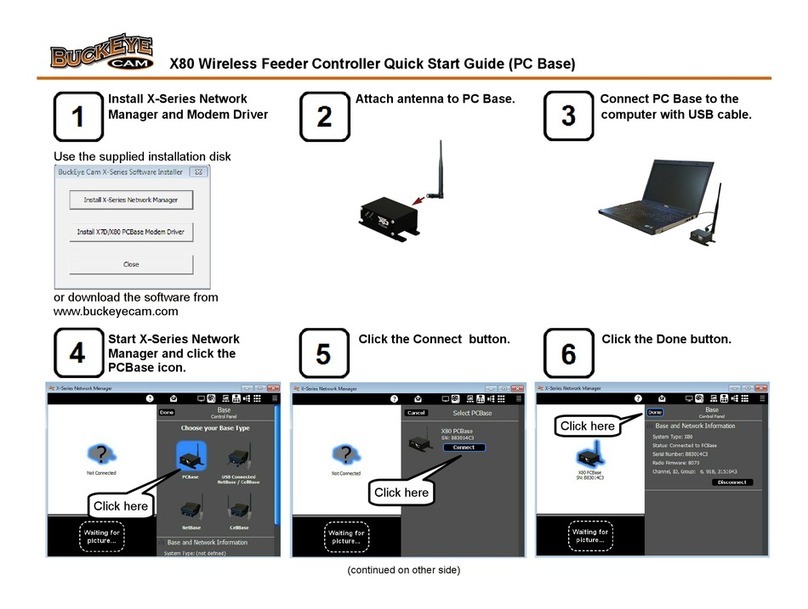

BuckEye Cam

BuckEye Cam X80 quick start guide

LenelS2

LenelS2 LNL-X4420 quick reference