Nemalux MR3 User manual

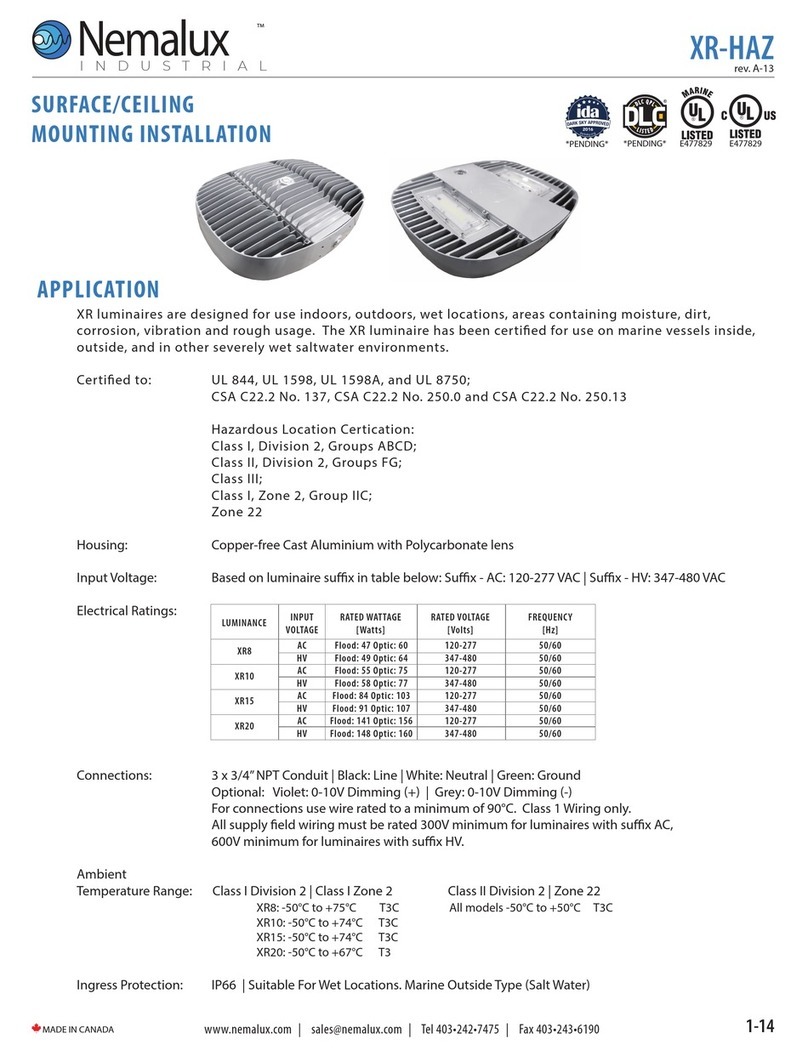

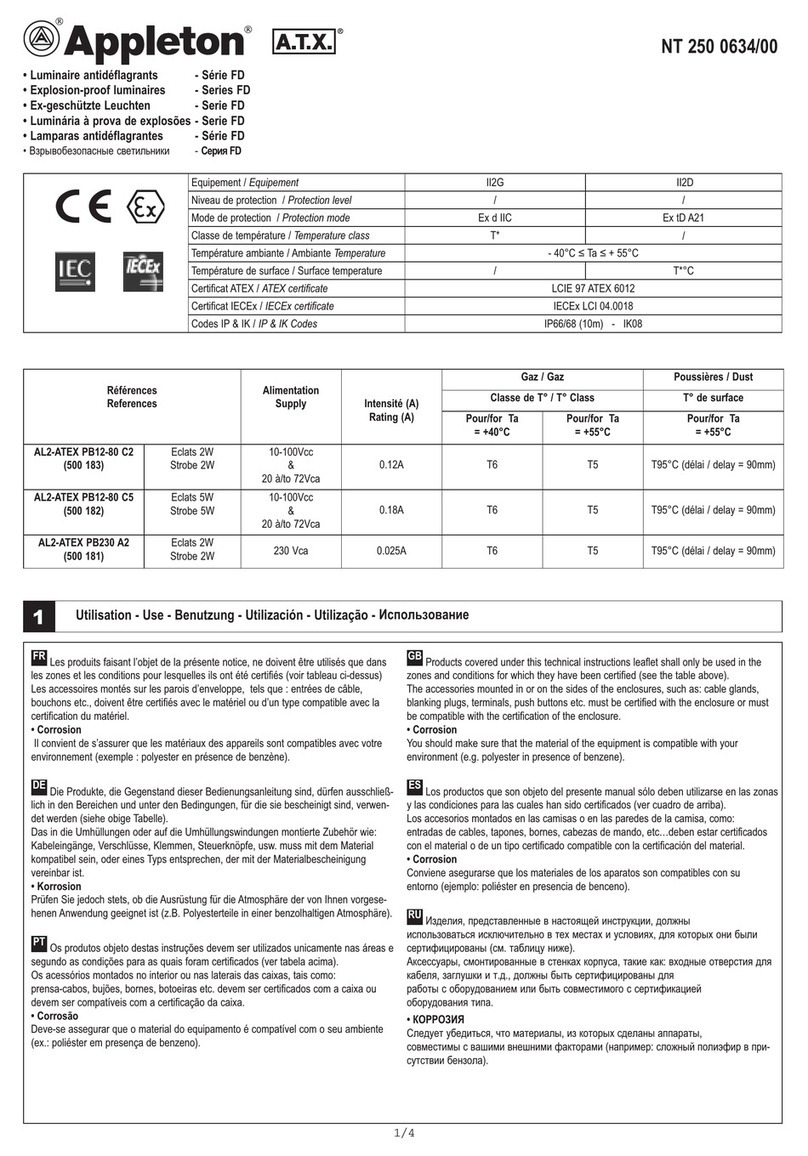

MR3 & MR6 Luminaires are suitable for use in the following areas as dened by the National

Electrical Code (NEC) and the Canadian Electrical Code (CEC):

Certied to: UL 1598, UL 1598A and UL 8750

CSA C22.2 NO. 250.0 and CSA C22.2 NO 250.13;

MR3 & MR6 luminaires are designed for use indoors, outdoors, wet locations, and areas containing

moisture, dirt, corrosion, vibration, and rough usage. The MR luminaire is also certied for use as a

marine, outside type (saltwater) non-recessed luminaire.

Housing: Copper-free Cast Aluminium with Polycarbonate lens

Voltage: AC: 120-277 VAC | HV: 347: 347 VAC 50/60Hz

Rated Current: MR3: 0.25A@120 VAC | 0.10A@347 VAC

MR6: 0.50A@120 VAC | 0.20A@347 VAC

Connections: 3/4” NPT Conduit | Black: Line | White: Neutral | Green: Ground

All eld wiring supply conductors shall be rated 90°C minimum and rated for

supply voltage (300V AC Models, 600V HV models). Class 1 Wiring Only.

Temperature Range: -40° C to +55° C

Ingress Protection: IP66 and IP67 rated for surface/suspension mount, yoke mount, pendant hook,

and conduit connected installations only. | Suitable For Wet Locations. Marine

Outside Type (Salt Water).

APPLICATION

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

1-4

MADE IN CANADA

INSTALLATION INSTRUCTIONS

E477827

E477827

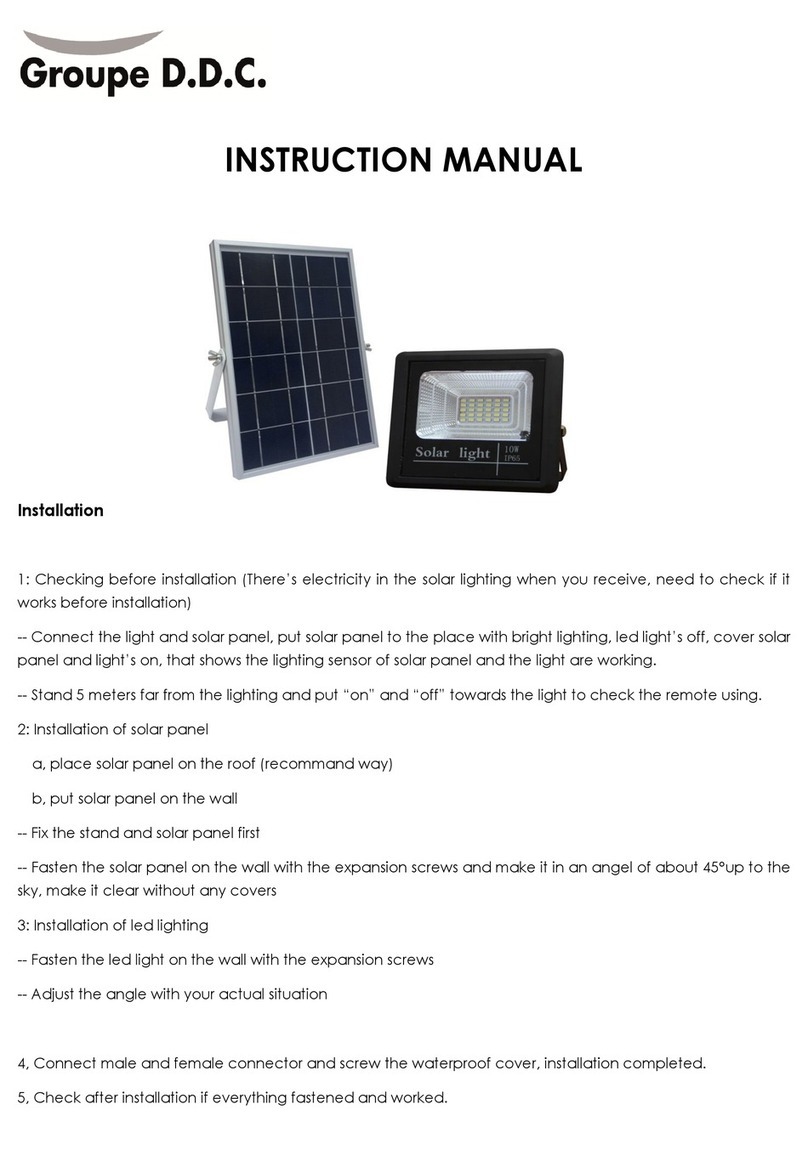

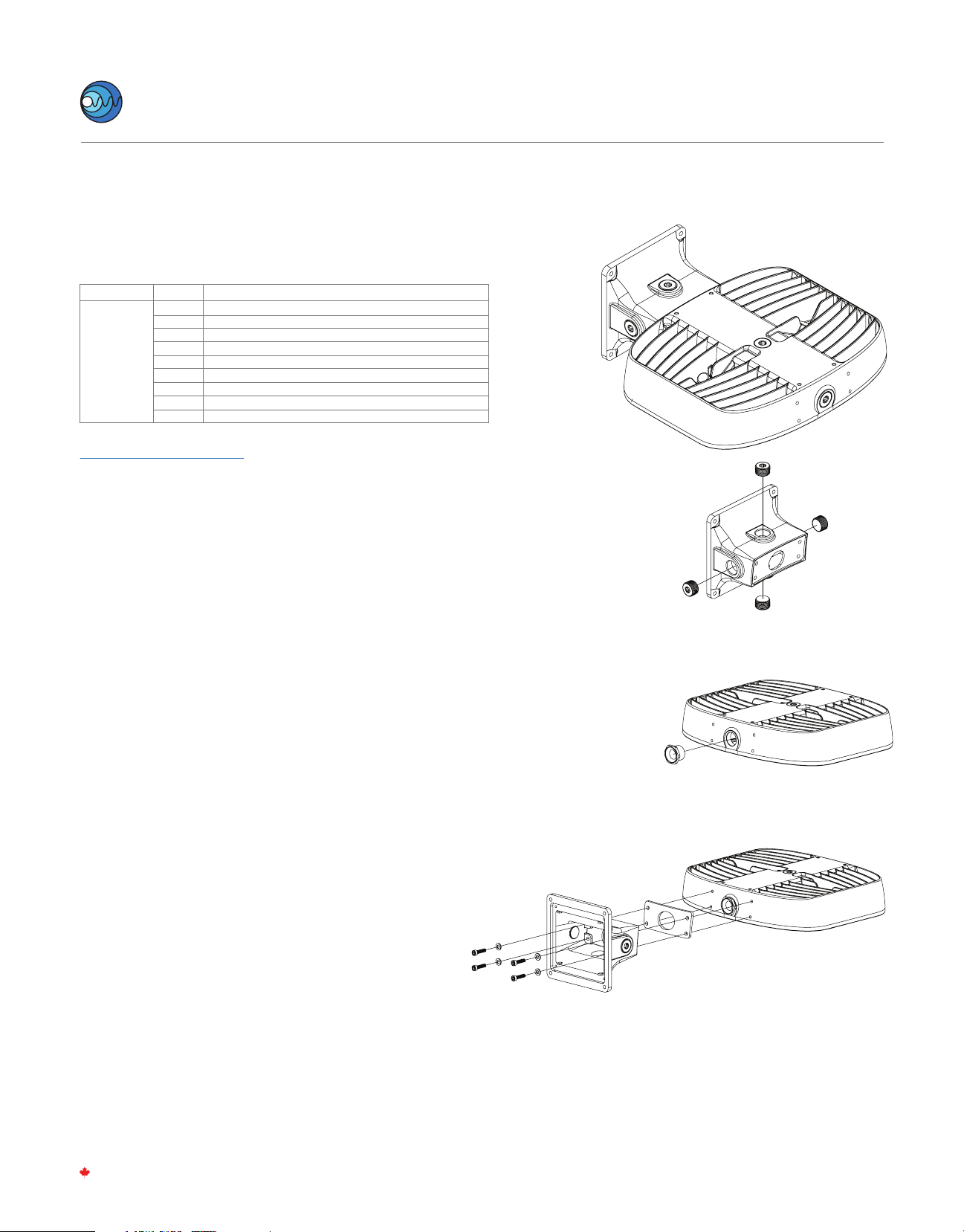

STEP 1:

Inspect shipping package and contents to

ensure no damage has occurred during

shipping.

STEP 2:

Install included Surface/Suspension Mount

Brackets. See diagram for orientation of

brackets for each version.

Install with included M6 bolts and washers to

7 N-m (62 in-lbs).

STEP 3:

- For surface mounting conguration, mount

xture to desired locations with 4x 1/4-20 OR

M6 Screws or Bolts.

- For suspension mounting conguration,

connect 4x anchors to points shown

2 x

7mm

10mm

SURFACE MOUNTING CONFIGURATION

SUSPENSION MOUNTING CONFIGURATION

SURFACE MOUNTING CONFIGURATION SUSPENSION MOUNTING CONFIGURATION

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

2-4

MADE IN CANADA

INSTALLATION INSTRUCTIONS

(Brackets are Ordered Separately)

Refer to alternate instructions if using Wall, Pole, Yoke, Conduit or Hook Mount

WARNING

To reduce the risk of electric shock, disconnect the luminaire

from the supply circuit before opening for installation and

servicing. Keep tightly closed when in operation.

WARNING

To avoid the risk of re, explosion, or electric shock, this

product should be installed, inspected, and maintained

by a qualied electrician only, in accordance with all

applicable electrical codes.

MR-SM – SURFACE MOUNT INSTALLATION

Ordered Separately

STEP 4:

To begin wiring, remove power supply lid by

loosening six (6) M4 captive screws using a 3mm hex

driver.

Allow the captive fasteners to remain in the lid for

ease of re-installation.

The lid is secured with a retention cable.

STEP 5:

Supply connection to be made through one of 3

3/4-14 NPT entries on the luminaire. If using

Surface, Suspension or Yoke conguration, install

appropriate Listed 3/4” NPT cable gland for cable

size and be sure to follow all applicable local

electrical codes for the specic hazardous locations.

Torque cable gland base to manufacturer's

recommended specication. All unused entries

must be plugged with a NPT plug (two provided).

OR

Install Direct Rigid Conduit as per local electrical

code. For direct rigid conduit installation, torque

hand tight plus 2 to 3 turns

NOTE:

To aid in assembly and protection against ingress

use of a petrolatum or soap thickened mineral oil

based thread lubricant/sealant is necessary.

STEP 6:

Feed wire into Power Supply cavity.

Strip 100mm (4”) of cable casing and strip

conductors 8mm (0.32”).

NOTE:

If using cable, terminate the supply end in a suitable

Listed metal junction box using a suitable Listed

tting approved for installation location as required.

All eld wiring supply conductors shall be rated 90°C

minimum and rated for supply voltage (300V AC

Models, 600V HV models).

4”

100mm

0.32”

8 mm

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

3-4

MADE IN CANADA

STEP 7:

Make wiring connections from branch circuit

conductors to factory provided lead wires. Refer to

NEC/CEC codes and follow all applicable local

standards.

The MR luminaire is suitable for daisy-chain wiring of

multiple luminaires on a single circuit. Input supply

wiring through one NPT hub as described in Step 5

above. Feed input wiring into the luminaire and

connect to LED driver supply wires using the wiring

connectors provided. Connect output wiring using the

same wiring connectors. Feed output wiring through

the remaining NPT hub as described in Step 5 above.

For dimming, connect 18AWG or larger conductors to

dimming connection points.

STEP 8:

Close Power Supply Cavity Lid.

A. Re-install the power supply lid using six (6)

Captive M4 screws.

B. Tighten M4 Captive screws to 2 Nm (17in-lbs)

Line - Black

Neutral - White

Ground - Green

Red (+)

Blue ( - )

Violet (+)

Grey (-) 0-10V

Dimming

Control

LED

Module

LED

Driver

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

4-4

MADE IN CANADA

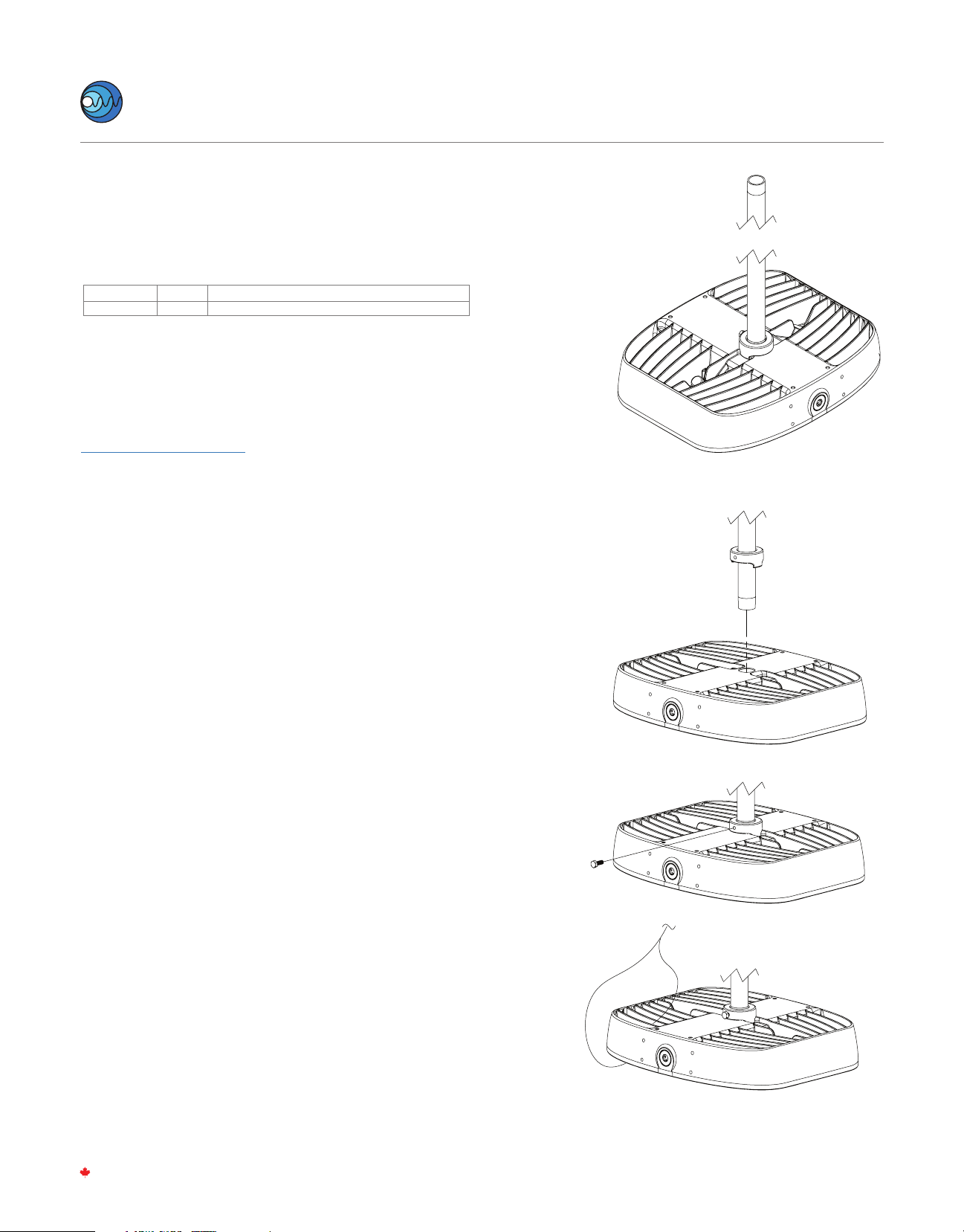

STEP 1:

Inspect shipping package and contents to

ensure no damage has occurred during

shipping.

STEP 2:

Install the provided plastic 3/4”bushing.

STEP 3:

Install Pole Mount and gasket with adhesive

side applied to mount and included M6 bolts

and washers.

Torque to 7 N-m (62 in-lbs)

STEP 4:

Thread xture assembly onto 1.5” NPT pole.

STEP 5:

Insert and tension M6 set screw to pole to lock

rotation.

Torque to 5 N-m or 44 in-lbs.

STEP 6:

Resume installation instructions provided

with xture. (STEP 4) Set Screw

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

1-1

MADE IN CANADA

MR-PM – POLE MOUNT INSTALLATION (Ordered Separately)

Refer to alternate instructions if using Wall, Yoke, Conduit or Hook Mount

INSTALLATION STEPS

This MR-PM kit is intended for use with UL Listed MR luminaire as

marked on the luminaire nameplate.

Accessory Package Contents

MR-PM

PART NAMEQTY

1

1

4

4

1

1

POLE MOUNT

POLE MOUNT GASKET

M6 X 25mm HEX HEAD CAP SCREW

M6 FLAT WASHER

M6 X 16mm HEX HEAD CAP SCREW

3/4 NPT THREADED SMOOTH BORE BUSHING

STEP 1:

Inspect shipping package and contents to ensure no

damage has occurred during shipping.

STEP 2:

Install provided 3/4 NPT conduit plugs in desired

locations. To maintain ingress rating all NPT entries

not used for wiring connections are required to be

plugged. Torque to 10 Nm (88 in-lbs)

NOTE:

To aid in assembly and protection against ingress use

of a petrolatum or soap thickened mineral oil based

thread lubricant/sealant is necessary.

STEP 3:

Install provided 3/4”NPT plastic bushing.

STEP 4:

Install Wall Mount main body with included M6 bolts

and washers and adhesive backed gasket. Apply

gasket to mount with adhisive backed side. Torque to

7 N-m (62 in-lbs)

STEP 5:

Install Back Cover Plate with 4x M4 Flat head screws

and adhesive backed gasket. Apply gasket with

adhesive side applied to mount main body.

Torque to 2 N-m (17 in-lbs)

MR-WM – WALL MOUNT INSTALLATION (Ordered Separately)

Refer to alternate instructions if using Pole, Yoke, Conduit or Hook Mount

This MR-WM kit is intended for use with UL Listed MR luminaire as

marked on the luminaire nameplate.

Accessory Package Contents

MR-WM

PART NAME

QTY

1

1

1

1

4

4

4

3

1

WALL MOUNT

WALL MOUNT PLATE

WALL MOUNT PLATE SIDE GASKET

WALL MOUNT GASKET

6 x 25mm SOCKET HEAD CAP SCREW

M4x 10mm FLAT HEAD SOCKET CAP SCREW

M6 FLAT WASHER

3/4 NPT HEX CAP PLUG

3/4 NPT THREADED SMOOTH BORE BUSHING

INSTALLATION STEPS

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

1-2

MADE IN CANADA

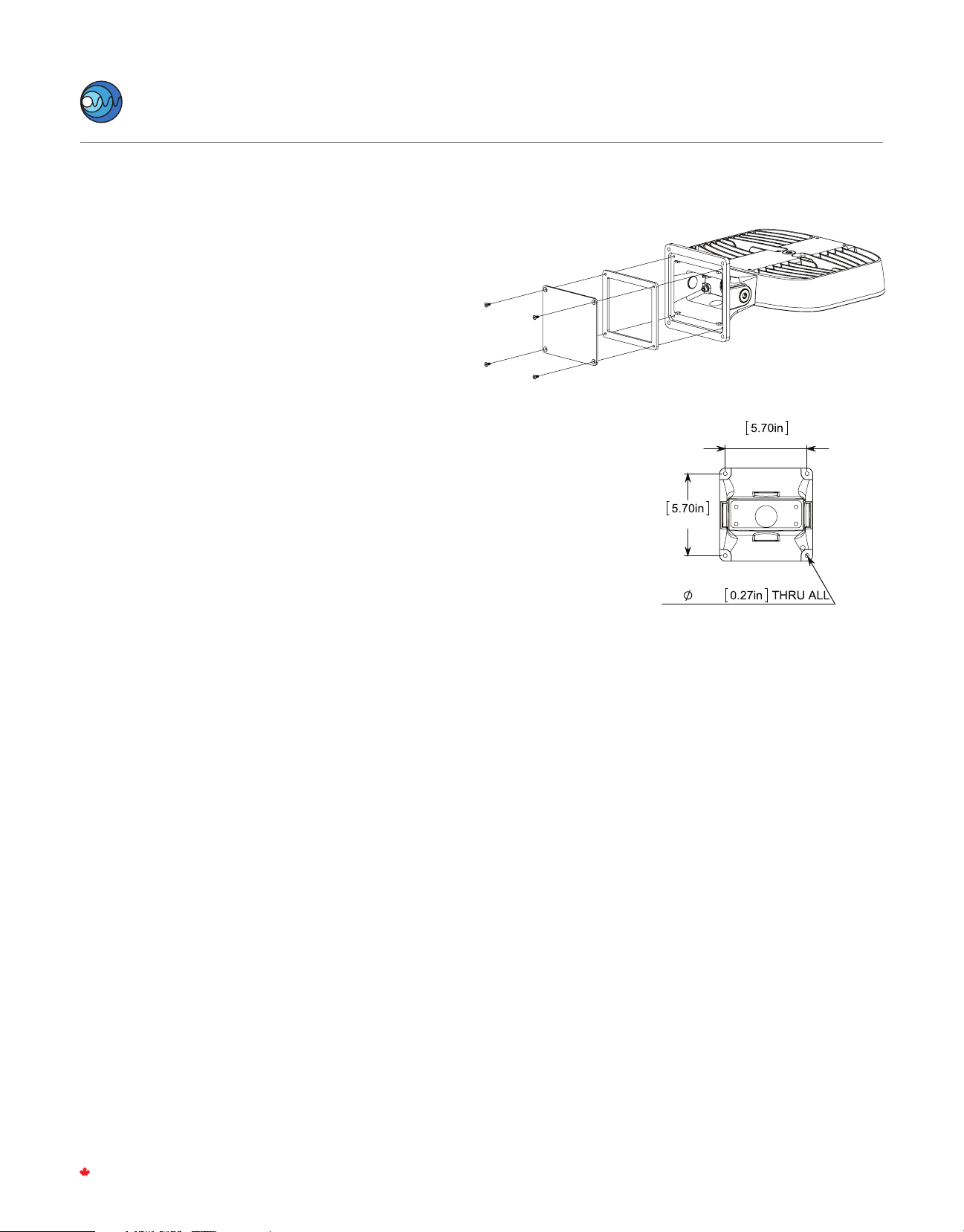

MR-WM – WALL MOUNT INSTALLATION (Ordered Separately)

STEP 5:

Install Back Cover Plate with 4x M4 Flat head screws

and adhesive backed gasket. Apply gasket with

adhesive side applied to mount main body.

Torque to 2 N-m (17 in-lbs)

STEP 6:

Mount xture assembly to desired location using

4x 1/4-20 OR M6 Screws or Bolts.

STEP 7:

Install appropriate Listed 3/4”NPT cable gland for cable

size to desired entry location and be sure to follow all

applicable local electrical codes for the specic hazardous

locations. Torque cable gland base and dome nut to

manufacturer's recommended specication. OR Install

Direct Rigid Conduit as per local electrical code. For direct

rigid conduit installation, torque hand tight plus 2 to 3

turns.

NOTE:

To aid in assembly and protection against ingress use

of a petrolatum or soap thickened mineral oil based

thread lubricant/sealant is necessary.

STEP 8:

Resume installation instructions provided with xture.

(STEP 4)

145mm

145mm

4 x

7mm

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

2-2

MADE IN CANADA

STEP 1:

Inspect shipping package and contents to

ensure no damage has occurred during

shipping.

STEP 2:

Assemble Yoke mount with carriage bolts on

inside and with washers and nuts.

Note:

By alternating the rotation mounting hole you

can determine either an upward swing or

downward swing.

STEP 3:

Install Yoke Mount with included M6 bolts

and washers to MR Head.

Torque to 7 N-m (62 in-lbs)

STEP 4:

Mount xture assembly to desired location

2-4x 1/4-20 OR M6 Screws or Bolts.

STEP 5:

Adjust and Aim xture to desired position. Torque

hardware nuts to 9 N-m (80 in-lbs).

STEP 6:

Resume installation instructions provided

with xture. (STEP 4)

43mm

4 x

7mm

72mm

2.83in

51mm

60 deg

MR-YM – YOKE MOUNT INSTALLATION (Ordered Separately)

Refer to alternate instructions if using Pole, Wall, Conduit or Hook Mount

This MR-YM kit is intended for use with UL Listed MR luminaire as

marked on the luminaire nameplate.

Accessory Package Contents

INSTALLATION STEPS

MR-YM

PART NAME

QTY

1

1

4

4

4

YOKE MOUNT A

YOKE MOUNT B

1/4-20 HEX NUT

1/4" FLAT WASHER

1/4-20 x 0.5in CARRIAGE BOLT

90° Upward

swing

90° Downward

swing

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

1-1

MADE IN CANADA

MR-YK – HIGH VIBRATION YOKE INSTALLATION (Ordered Separately)

Refer to alternate instructions if using Conduit, Hook, Pole, Wall Mount, or Yoke Mount

STEP 1.

Inspect shipping package and contents to ensure no damage has

occurred during shipping. Discard surface/ceiling mounting bracket

provided with MR luminaire.

STEP 2.

Mount MR high vibration yoke to mounting surface using a minimum

of 4x ¼-20 or M6 fasteners (not provided).

STEP 3.

Install suitable wiring system to the conduit opening per CEC/NEC

requirements for the speci-c location of install.

NOTE:

To aid in assembly and protection against ingress use of a petrolatum or soap

thickened mineral oil based thread lubricant/sealant is necessary.

Un-used conduit opening must be plugged to maintain the integrity of the

enclosure.

STEP 4.

Mount MR Cheek Plates to sides of MR luminaire using 4x M6 at head

cap screws per side. Thread one cheek plate over installed wiring

during assembly. Torque fasteners to 5 Nm (45 in-lbs).

STEP 5.

Thread installed wiring through opening in MR high vibration yoke

mount and install MR luminaire into yoke. The raised circular bosses on

the MR cheek plates should register inside of the large circular holes on

the MR high vibration yoke mount arms. Rotate luminaire to aim in the

desired direction and fasten in place using 2x M6 socket head cap

screws and at washers per side. Torque fasteners to 5 Nm (45 in-lbs).

STEP 6.

Resume installation instructions provided with luminaire. (STEP 4 in MR

Installation Instructions provided with Luminaire)

Step 4

Step 2

This MR-YK kit is intended for use with UL Listed MR luminaire as

marked on the luminaire nameplate.

Accessory Package Contents

INSTALLATION STEPS

MR-YK

PART NAME

QTY

1

2

8

4

4

MR HIGH VIBRATION YOKE

CHEEK PLATE

M6 x 1 x 25mm SOCKET FLAT HEAD CAP SCREW

M6 FLAT WASHER

M6 x 1 x 16mm SOCKET HEAD CAP SCREW

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

1-1

MADE IN CANADA

WARNING:

The MR Head must not face upwards

by any degree beyond the vertical

position for Class II, Division 2, Zone 22,

and Class III hazardous locations.

LIGHT BEAM

HORIZON

4.3in

3.8in

108mm

95mm

2.3in

59mm

10 x

7mm

0.3in

THRU ALL

8.0in

203mm

3.1in

80mm

MR-CC –

CONDUIT CONNECTION

(Ordered Separately)

Refer to alternate instructions if using Pole, Wall, Yoke or Hook Mount

STEP 1.

Inspect shipping package and contents to ensure no damage has

occurred during shipping. Discard surface/ceiling mounting bracket

provided with MR luminaire.

STEP 2.

Slide anti-rotation lock onto suitably mounted hanging conduit and

install luminaire onto ¾”conduit. Slide anti-rotation lock into place

and tighten set screw to lock unit in place. Tighten the anti-rotation

lock set screw to 5 N-m (44 in-lbs). Fixed Rigid Metal Conduit must

be suitably mounted to prevent rotation.

NOTE:

To aid in assembly and protection against ingress use of a petrolatum or

soap thickened mineral oil based thread lubricant/sealant is necessary.

Un-used conduit opening must be plugged to maintain the integrity of the

enclosure.

STEP 3.

Install Secondary Safety Cable by looping appropriate steel cable or

chain through the outer band of the unit and fastening a closed

loop. Secondary safety hardware must be rated for a minimum of

50lbs.

Install remaining loop of secondary safety chain or steel cable to

suitable mounting location and fasten securely. Secondary safety

hardware must be rated for 50lbs.

STEP 4.

Resume installation instructions provided with Fixture. (STEP 4)

This MR-CC kit is intended for use with UL Listed MR luminaire as

marked on the luminaire nameplate.

Accessory Package Contents

INSTALLATION STEPS

MR-CC

PART NAMEQTY

1ANTI-ROTATION BRACKET ASSEMBLY

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

1-1

MADE IN CANADA

Step 2

Step 3

INSTALLATION STEPS

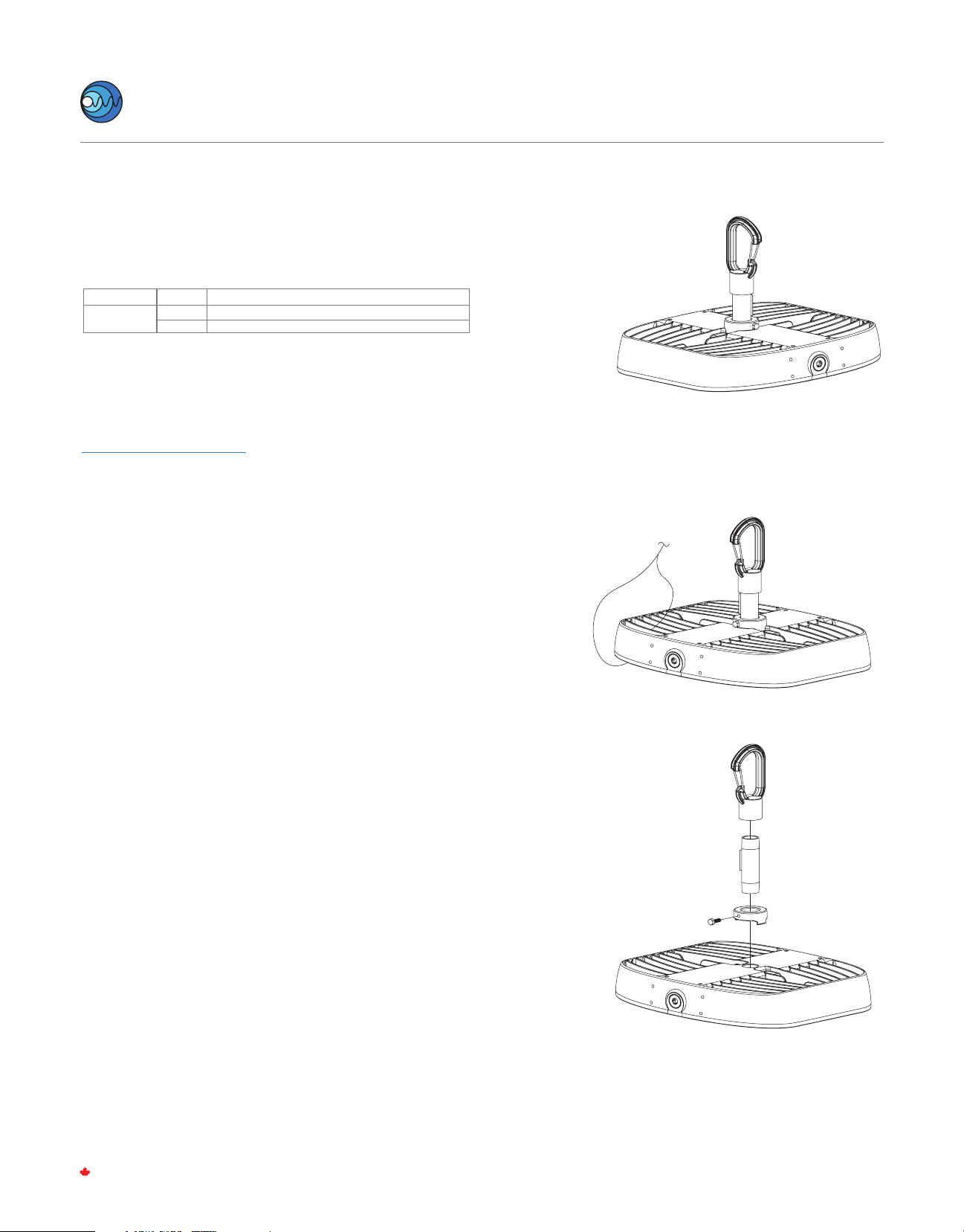

MR-HK –

HOOK PENDANT INSTALLATION

(Ordered Separately)

Refer to alternate instructions if using Pole, Wall, Yoke or Conduit Mount

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

1-1

MADE IN CANADA

Step 3

STEP 1.

Inspect shipping package and contents to ensure no damage has

occurred during shipping. Discard surface/ceiling mounting bracket

provided with MR luminaire.

STEP 2.

It is recommended to install Secondary Safety Cable by looping

appropriate steel cable or chain through the outer band of the unit and

fastening a closed loop. Secondary safety hardware must be rated for a

minimum of 50lbs. Secondary safety cables made from stainless steel

aircraft cable are available upon request.

STEP 3.

Slide anti-rotation lock onto suspension hook assembly and install hook

assembly into ¾ NPT threaded entry. Tighten to hand tight plus 1 to 2

turns. Slide anti-rotation lock into place and tighten set screw to lock

unit in place.

NOTE:

To aid in assembly and protection against ingress use of a petrolatum or soap

thickened mineral oil based thread lubricant/sealant is necessary.

Un-used conduit opening must be plugged to maintain the integrity of the

enclosure.

STEP 4.

Latch hook onto eye-bolt or other xed mounting loop. Mounting point

must be rated for a minimum of 50lbs.

STEP 5.

Install remaining loop of secondary safety chain or steel cable to

suitable mounting location and fasten securely.

STEP 6.

Resume installation instructions provided with Fixture. (STEP 4)

Step 2

This MR-HK kit is intended for use with UL Listed MR luminaire as

marked on the luminaire nameplate.

Accessory Package Contents

MR-HK

PART NAME

QTY

1

1

PENDANT HOOK ASSEMBLY

ANTI-ROTATION ASSEMBLY

STEP 1.

Remove the bottom-left pre-installed M6 x 16mm Hex Cap Screw.

STEP 2.

Install bracket on MR luminaire as shown using supplied M6 x 20mm

Hex Cap Screw. Torque M6 x 20mm Hex Cap Screw to 40 in-lbs (4.5

Nm). It is strongly recommended that a medium or high strength

thread-locker be used when installing the bracket. For units using

surface or suspension mounting, install safety kit hardware on top of

the surface mount or suspension mount brackets in the same location

as shown.

STEP 3.

Attach stainless steel chain to safety kit bracket using stainless steel

oval shaped threaded connecting link.

STEP 4.

Attach loose end of chain. Secondary safety mounting point must be

suitable for supporting a minimum of 50lbs:

- Attach loose end of stainless steel chain to xed eye-bolt (not

supplied) using the second stainless steel oval shaped thread-

ed connecting link.

- Alternate attachment method: Wrap loose end of chain

around xed beam or other immovable support and create a

closed loop using the second stainless steel oval shaped

threaded connecting link. Supporting beam or structure must

form a closed loop to prevent the secondary safety chain from

slipping o or becoming unhooked.

MR-SK-##

PART NAMEQTY

1

1

1

2

1

Secondary Safety Bracket

M6 Flat Washer

M6 x 20mm Hex Cap Screw

Oval Shaped Threaded Connecting Link

Stainless Steel Chain, 1/8”Trade Size

MR-SK-## – SECONDARY SAFETY KIT (Ordered Separately)

This MR-K-## kit is intended for use with UL Listed MR luminaire as

marked on the luminaire nameplate.

Accessory Package Contents

INSTALLATION STEPS

Step 2

Step 1

1

2

3

M6 SCREW

TM

Nemalux

I N DUSTRIAL

MR-GEN

rev. A-15

1-1

MADE IN CANADA

This manual suits for next models

2

Table of contents

Other Nemalux Lantern manuals