Nemalux LS Series User manual

TEMPORARY LIGHTING STRING

Intended for temporary lighting requirements in industrial, marine and hazardous locations, the LS

light stringer is rated for indoor and outdoor use. With a protection level of IP66 / NEMA4X the

versatile LS oers a lightweight solution for surface and hook mount applications during construc-

tion, operation and maintenance.

Conforms to: UL 844, UL 1088, CAN/ULC-S1088, UL 1598, UL 1598A:

CSA 22.2 No. 137

Hazardous Location Certication:

Class I, Division 2, Groups ABCD, T5;

Class II, Division 1, Groups EFG, T5;

Class III;

Class I, Zone 2, Groups IIC;

Class I, Zone 20, Groups IIIC

Housing: Copper-free Case Aluminum & Borosilicate Glass

Rated Voltage: 120 VAC , 50/60 Hz

Rated Power: 19.5W per module

Connections: Standard: Black: Line | White: Neutral | Green: Ground

Temperature Range: -50° C to +70° C

Ingress Protection: IP66/67 | Suitable for Wet Locations. Marine Outside type (Salt water).

rev. A-20

APPLICATION

TM

Nemalux

I N DUSTRIAL

LS Series

1-6

MADE IN CANADA

Installation Spec Sheet Webpage

PRE-ASSEMBLED TEMPORARY STRING LIGHTS

Refer to alternate instructions for LS-KIT

STEP 1:

Inspect shipping package and contents to ensure no

damage has occurred during shipping.

This product must be wired, installed, and maintained by a qualied electrician.

Refer to CEC/NEC codes and follow all local standards applicable to the area of installation

Make electrical connections in a Listed/Recognized junction box (Not Provided) or Listed/Recognized

connector approved for a minimum of 120VAC/8A. If the temporary lighting string will be connected

inside a classied (hazardous) zone, connector must be rated for the hazardous Class and Division/Zone

where the connection is made.

If the temporary lighting string will be installed in a wet location, the junction box or connector used

must be Listed/Recognized for use in Wet Locations.

WARNING

CAUTION: To avoid risk of re, explosion, or electric shock,

this product should be installed, inspected, and maintained

by a qualied electrician in accordance with all applicable

codes. Supply connector must be rated for location and

zone of use.

ATTENTION: Pour réduire le risque d'inammation des

atmosphères dangereuses et a n déviter les chocs

électriques, ce produit doit être installé, inspecté, et entre-

tenu par un électricien qualié conformément à tous les

codes applicables. Le connecteur d'alimentation doit être

adapté à l'emplacement et à la zone d'utilisation.

WARNING

NOTE: For use only on GFCI protected circuits when installed

with connector or plug.

VEUILLEZ NOTER: Utiliser seulement sur des prises protégées

de disjoncteur-detecteur de fuite a la terre

WARNING

CAUTION – To reduce the risk of electric shock do not

connect or disconnect when wet.

ATTENTION: Pour reduire les dangers de shoc électrique, ne

pas brancher ou debrancher une fois mouillé.

WARNING

CAUTION: To reduce the risk of ignition of hazardous

atmospheres, disconnect the luminaire from the supply

circuit before opening. Keep tightly closed when in opera-

tion.

ATTENTION: Pour réduire le risque d' inammation des

atmosphères dangereuses, débranchez le luminaire du

circuit électrique avant d'ouvrir. Conserver hermétiquement

fermé lorsqu'il est en fonctionnement.

TM

Nemalux

I N DUSTRIAL

LS Series

rev. A-20

2-6

MADE IN CANADA

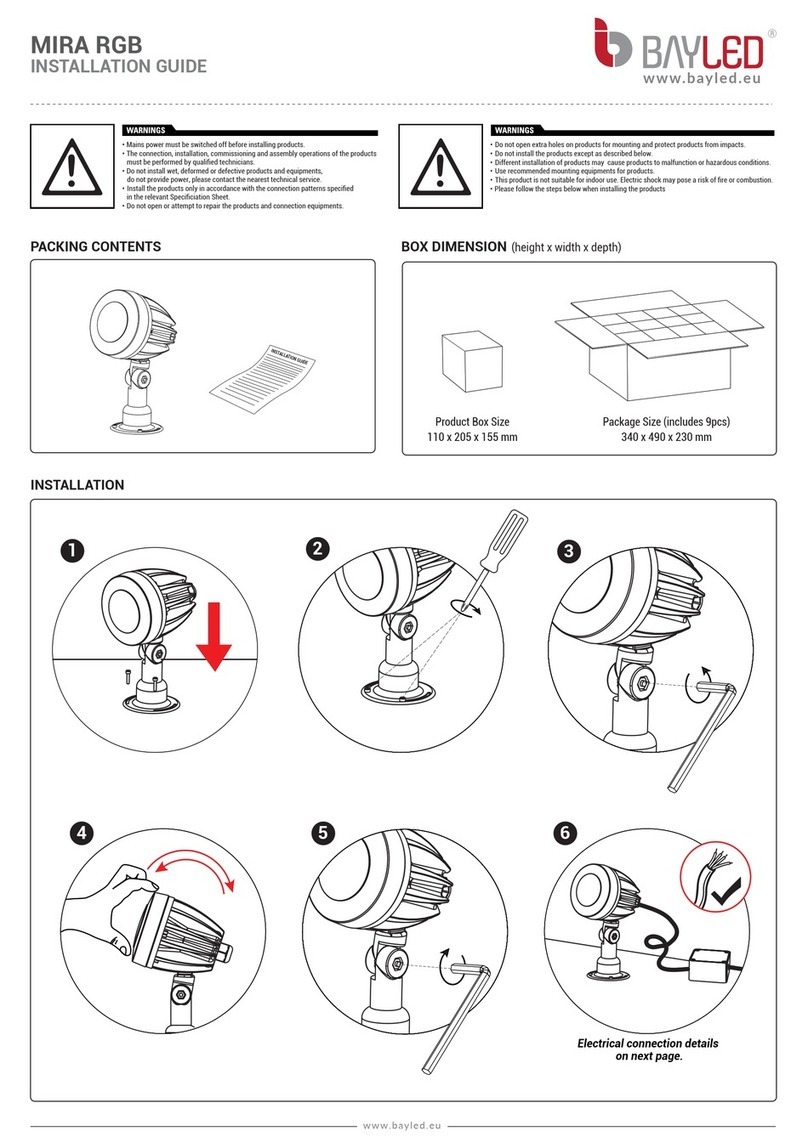

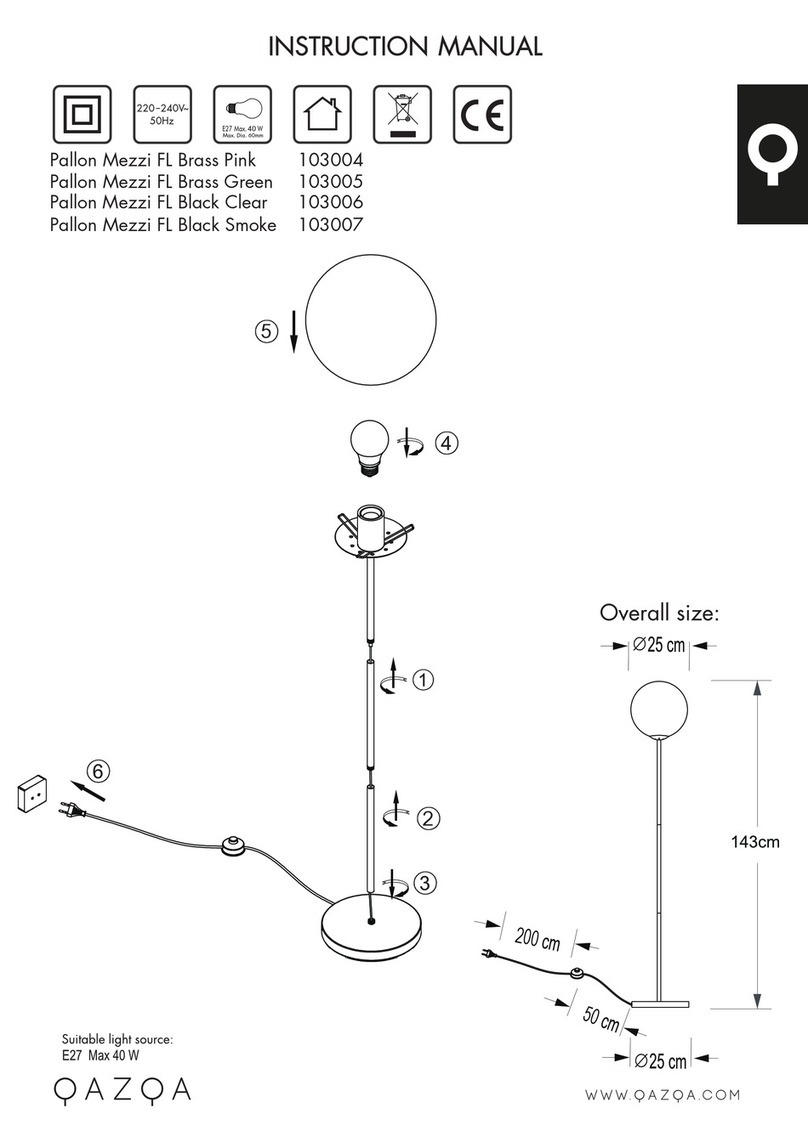

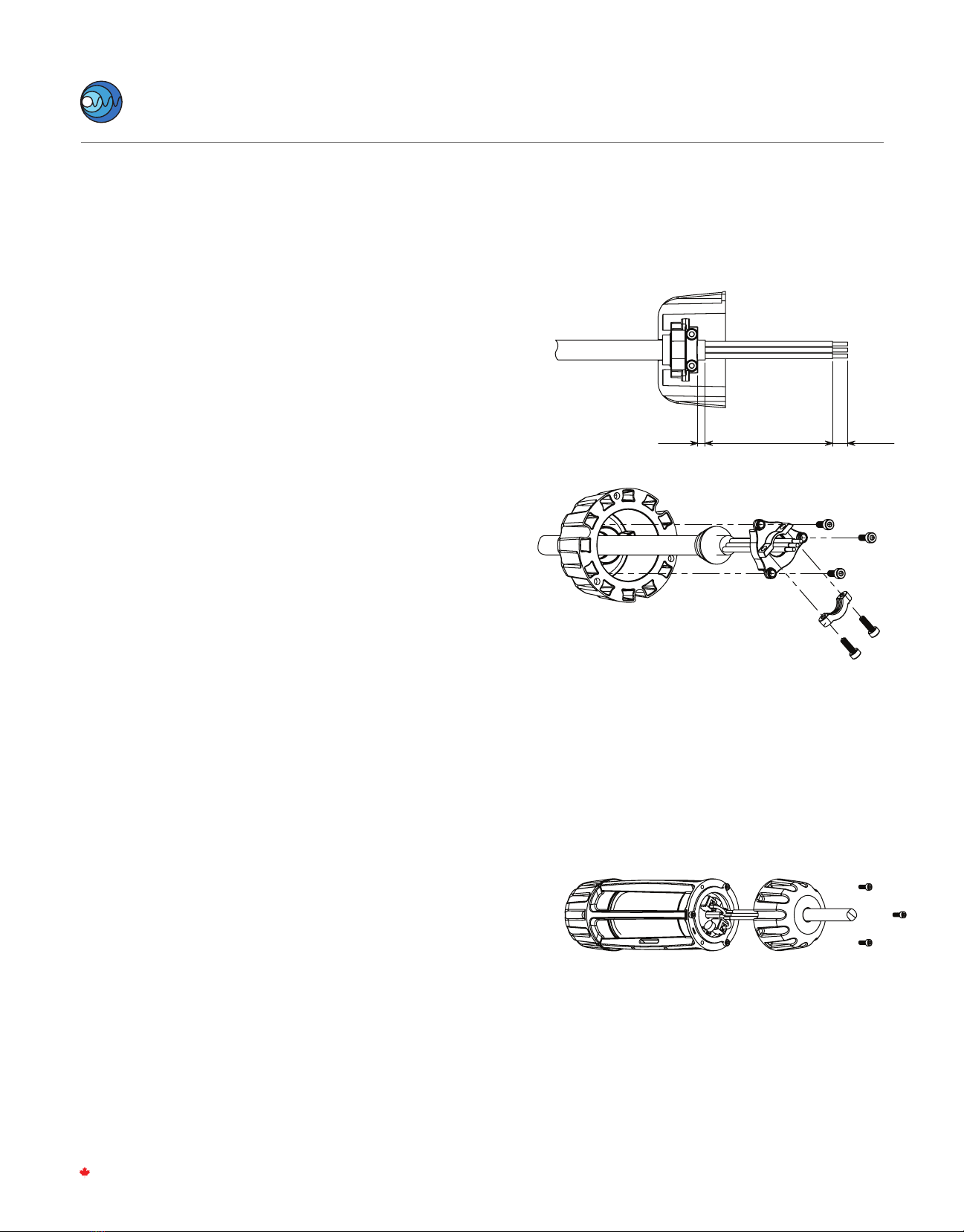

STEP 2 (Optional):

Attach Surface mount accessory using supplied M4

screws (2). Torque fasteners to 20 in-lbs (2.3 N-m) or

use Strap/Stainless Steel Clamp to fasten xture to

desired location.

STEP 3:

If not ordered with pre-installed connector, install

suitable UL/CSA Listed or Recognized connector for

the environment and zone where the electrical

connection will be made or connect wiring lead to a

Listed junction box suitable for the environment and

zone of use. Ordinary location plugs may be used

only if the electrical connection to power is made

outside of all hazardous environments or classied

zones. Where connections to electrical power will be

made inside hazardous classied zones, only UL/CSA

Listed or Recognized connectors rated for the

environment, Class/Division or Zone, temperature,

and hazardous gas or dust group present may be

used.

STEP 4:

For raised installations, attach light stringer to xed

infrastructure (handrail, exposed beams, pipe rack,

etc.) in desired location with adjustable strapping,

hook, or surface mount bracket accessories. Cam

buckle straps, stainless steel mounting clamps, hook

and surface mounts are available separately.

NOTE:

For replacement of damaged Cord, refer to Assembly of

LS-KIT into Approved Temporary String Light instruc-

tions on page 3-4.

STEP 5:

Plug-in or energize circuit.

INSTALLATION (CONT.)

2

1

STAINLESS STEEL STRAP ACCESSORIES

ARE AVAILABLE IF REQUIRED

TM

Nemalux

I N DUSTRIAL

LS Series

rev. A-20

3-6

MADE IN CANADA

Step 2

STEP 1:

Inspect shipping package and contents to ensure no

damage has occurred during shipping.

ASSEMBLY OF LS-KIT INTO APPROVED TEMPORARY STRING LIGHT

Refer to alternate instructions for Pre-assembled Temporary String Lights

This product must be wired, installed, and maintained by a qualied electrician.

Refer to CEC/NEC codes and follow all local standards applicable to the area of installation

Make electrical connections in a Listed or Recognized junction box (Not Provided) or Listed/Recognized

connector approved for a minimum of 120VAC/8A. If the temporary lighting string will be connected

inside of a classied (hazardous) zone, connector must be rated for the hazardous Class and

Division/Zone where the connection is made.

TM

Nemalux

I N DUSTRIAL

LS Series

rev. A-20

4-6

MADE IN CANADA

WARNING

CAUTION: To avoid risk of re, explosion, or electric shock,

this product should be installed, inspected, and maintained

by a qualied electrician in accordance with all applicable

codes. Supply connector must be rated for location and

zone of use.

ATTENTION: Pour réduire le risque d'inammation des

atmosphères dangereuses et a n déviter les chocs

électriques, ce produit doit être installé, inspecté, et entre-

tenu par un électricien qualié conformément à tous les

codes applicables. Le connecteur d'alimentation doit être

adapté à l'emplacement et à la zone d'utilisation.

WARNING

NOTE: For use only on GFCI protected circuits when installed

with connector or plug.

VEUILLEZ NOTER: Utiliser seulement sur des prises protégées

de disjoncteur-detecteur de fuite a la terre

WARNING

CAUTION – To reduce the risk of electric shock do not

connect or disconnect when wet.

ATTENTION: Pour reduire les dangers de shoc électrique, ne

pas brancher ou debrancher une fois mouillé.

WARNING

CAUTION: To reduce the risk of ignition of hazardous

atmospheres, disconnect the luminaire from the supply

circuit before opening. Keep tightly closed when in opera-

tion.

ATTENTION: Pour réduire le risque d' inammation des

atmosphères dangereuses, débranchez le luminaire du

circuit électrique avant d'ouvrir. Conserver hermétiquement

fermé lorsqu'il est en fonctionnement.

STEP 2:

Strip 95mm (3.75in) of cable jacket, and trim back any

ller. Strip conductor insulation 10mm (0.39in) from

ends. Feed wire through end cap, rubber gland, and

gland cap. Install cord clamp and tighten to 20 in-lbs

(2.3 N-m) so that cable jacket protrudes 5mm past

the end of the cord clamp.

Slide together end cap, rubber gland, and gland cap

assembly, before fastening with three M4 socket

head cap screws torqued to 20 in-lbs (2.3 N-m).

NOTE:

Electrical cord used must be 14 Gauge/3 Conductor

SOOW with an outer diameter between 13mm [0.51”]

and 14.2mm [0.56”]. SOOW cord must be rated for

600V/90˚C or higher.

Maximum string length must not exceed 300 ft.

Maximum number of lighting modules must not exceed

30 units on a single string.

STEP 3:

Connect each conductor into appropriate connectors

STEP 4:

Wrap excess conductor inside cap and gently rotate to

compress wires (without pinching them) till the assem-

bly holes align with the core and internal wires are not

strained or pinched.

Attach End Cap Assembly to the core with the supplied

M4 socket head cap screws (3) with M4 hex driver

torque to 2.3 N-m (20 in-lbs).

STEP 5:

Repeat steps 2-4 for other side of module.

INSTALLATION (CONT.)

TM

Nemalux

I N DUSTRIAL

LS Series

rev. A-20

5-6

MADE IN CANADA

Step 4

Step 2

85mm 10mm

5mm

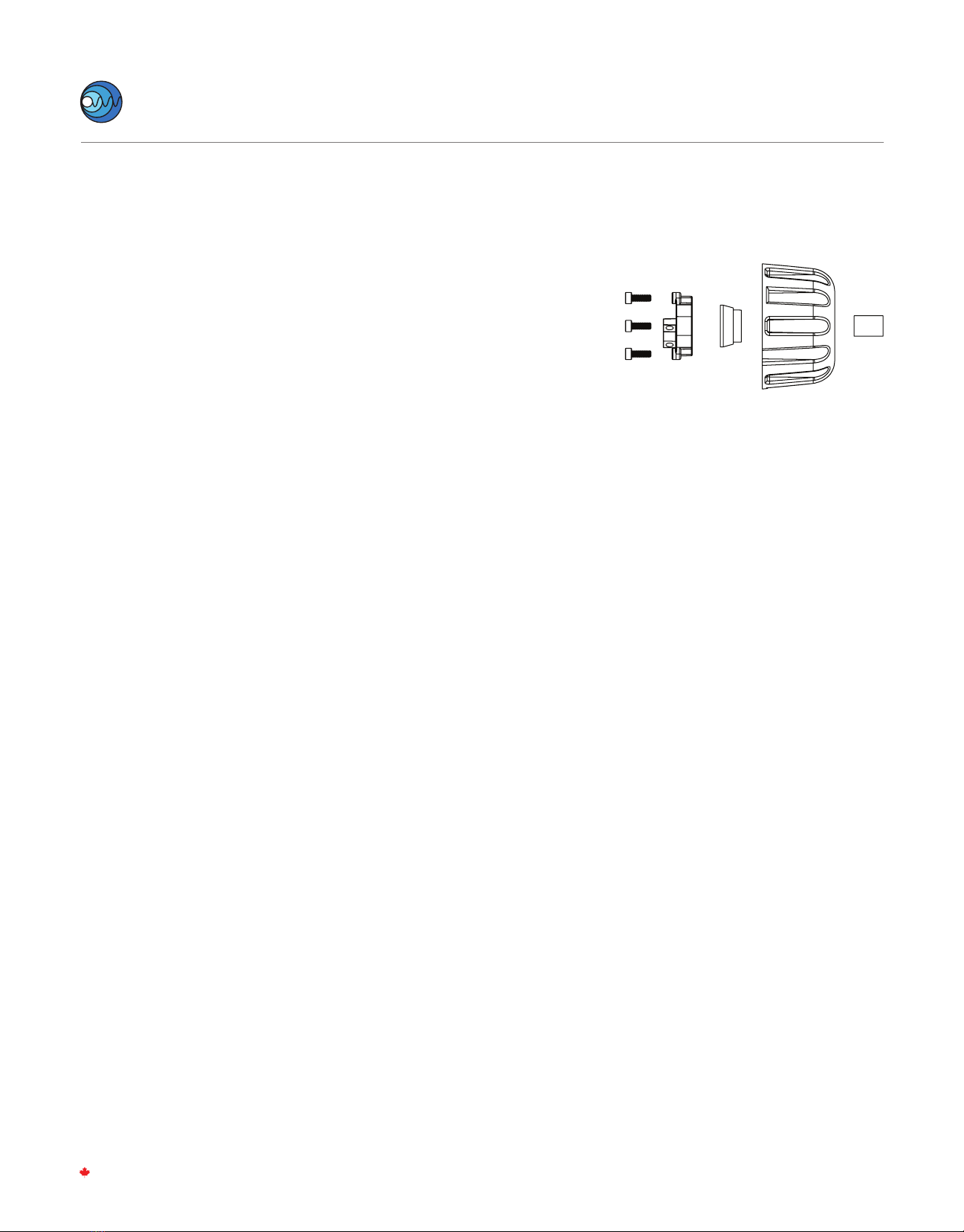

STEP 6:

To Maintain ingress protection the nal module must

have the blank end plugged. On the end module,

assemble the cord clamp and gland cap together using

two M4 fasteners and Torque to 20 in-lbs (2.3 N-m).

Install rubber Gland, Gland Cap assembly, and cylindri-

cal plug into the un-wired end-cap and torque M4

fasteners to 20 in-lbs (2.3 N-m) to secure in place and

compress gland seal around the cylindrical plug.

Attach End Cap Assembly to the core with the supplied

M4 socket head cap screws (3) with M4 hex driver

torque to 2.3 N-m (20 in-lbs).

STEP 7:

Attach mounting accessory if used (refer to Step 2 in LS

installation).

STEP 8:

Install suitable UL/CSA Listed or Recognized connector

for the environment and zone where the electrical

connection will be made or connect wiring lead to a

listed junction box suitable for the environment and

zone of use. Ordinary location plugs may be used only if

the electrical connection to power is made outside of

all hazardous environments or classied zones. Where

connections to electrical power will be made inside

hazardous classied zones, only UL/CSA Listed or

Recognized connectors rated for the environment,

Class/Division or Zone, temperature, and hazardous gas

or dust group present may be used.

STEP 9:

For raised installations, attach light stringer to xed

infrastructure (handrail, exposed beams, pipe rack, etc.)

in desired location with adjustable strapping, hook, or

surface mount bracket accessories.

Cam buckle straps, stainless steel mounting clamps,

hook and surface mounts are available separately.

INSTALLATION (CONT.)

Step 6

TM

Nemalux

I N DUSTRIAL

LS Series

rev. A-20

5-6

MADE IN CANADA

Other Nemalux Lighting Equipment manuals