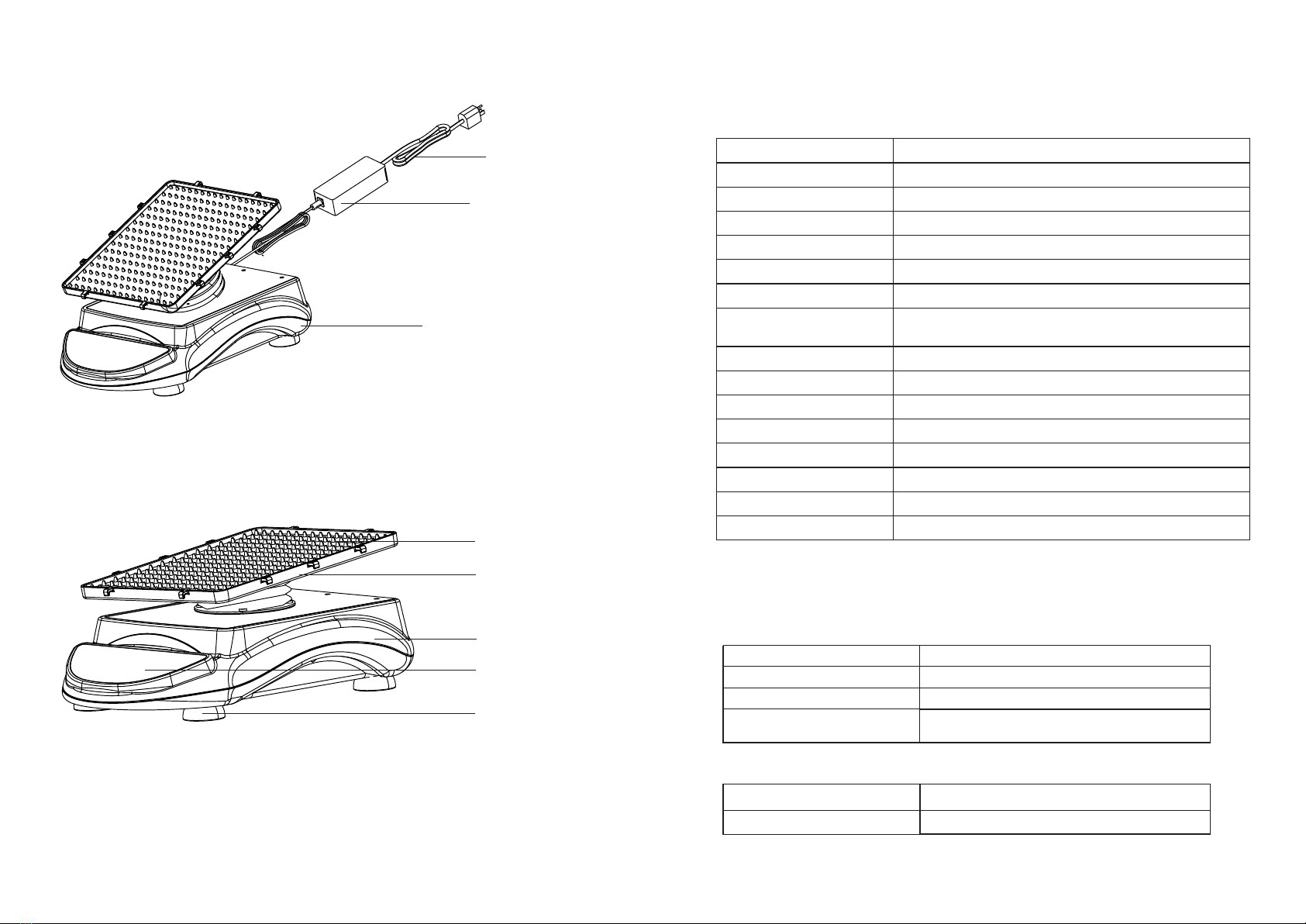

①

③④

⑤⑥

This Chapter covers introduction of the control panel and its operation.

1. Start/Stop button: Start or stop the instrument

2. RUN indicator light: The light is on when the instrument is running and off when the

instrument is in standby.

3. TIME display window: The window shows cumulative time (in continuous mode) or

remaining time (in timer mode). The range of time displayed is 0 to 99 hours and 59

minutes. The accuracy is 1 minute.

4. SPEED display window: The window shows set speed (when the instrument is in

standby) or current speed (when the instrument is running).

5. Set Time Buttons: UP/DOWN Arrow buttons are used to increase/ decrease the set

time of the instrument.

6. Set Speed Buttons: UP/DOWN Arrow buttons are used to increase/ decrease the set

speed of the instrument.

Section 3 Operation

3.1 Operations of the Control Panel

3.2 Settings

.

②

Section 3

Operation

3 1-3 2-

Speed Settings

Press the “ ” or “ ” arrow button below the SPEED display window. When the number

shown on the display window starts flashing, press “ ” or “ ” arrow button to increase

or decrease the speed value. Release the button when the speed shown on the display

window reaches the set value. The speed setting is finished after the number shown on the

display window has flashed twice.

Note: press the “ ” or “ ” arrow button for a longer time to accelerate the setting.

Run and Stop

1. Continuous Mode

Press “ ” button and the instrument will start running with the specified settings and the

RUN indicator light will be on. The TIME display window will show the cumulative time

and the SPEED display window will show the current speed. Press “ ” button again and

the instrument will slow down until it stops. The instrument will then be in standby and the

two display windows will show the set values.

2. Timer Mode

Press button the instrument will start running with the specified settings and the “ ”

RUN indicator light will be on. The TIME display window will show the remaining time and

the SPEED display window will show the current speed. Press button again and the“ ”

instrument will slow down until it stops. The instrument will then be in standby and the two

display windows will show the set values.

If the power supply is cut off suddenly while the instrument is in operation, the unit will

automatically run at the previously set parameter upon power restoration. The display

window will flash. Press any button to stop flashing.

Finish Operation

After the operation is finished, please press the power switch at the back right side the

instrument and put it into the “O” state. Unplug the instrument and store the instrument

according to the storage guide.

Alarm System

When the normal operation is obstructed or stopped by malfunctioning, the instrument

will stop running automatically within 2 minutes and the alarm will sound.

Power Recovery

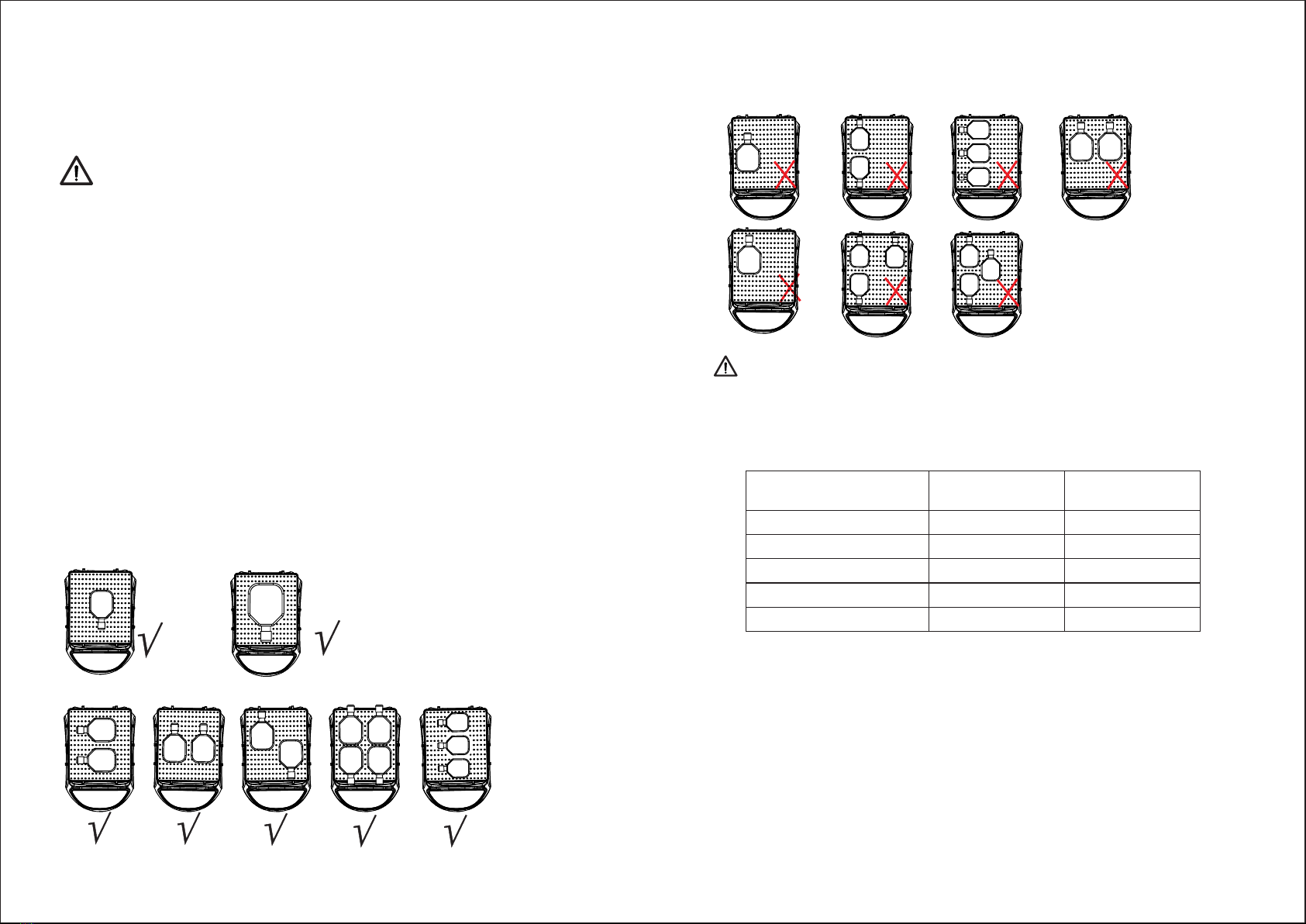

1. Connect all the components according to the figures shown on page 1-2 of this

manual. Use grounded power outlet.

2. Press the power switch "I" side and switch on the instrument.