Hoefer SE 260 User manual

Other Hoefer Laboratory Equipment manuals

Hoefer

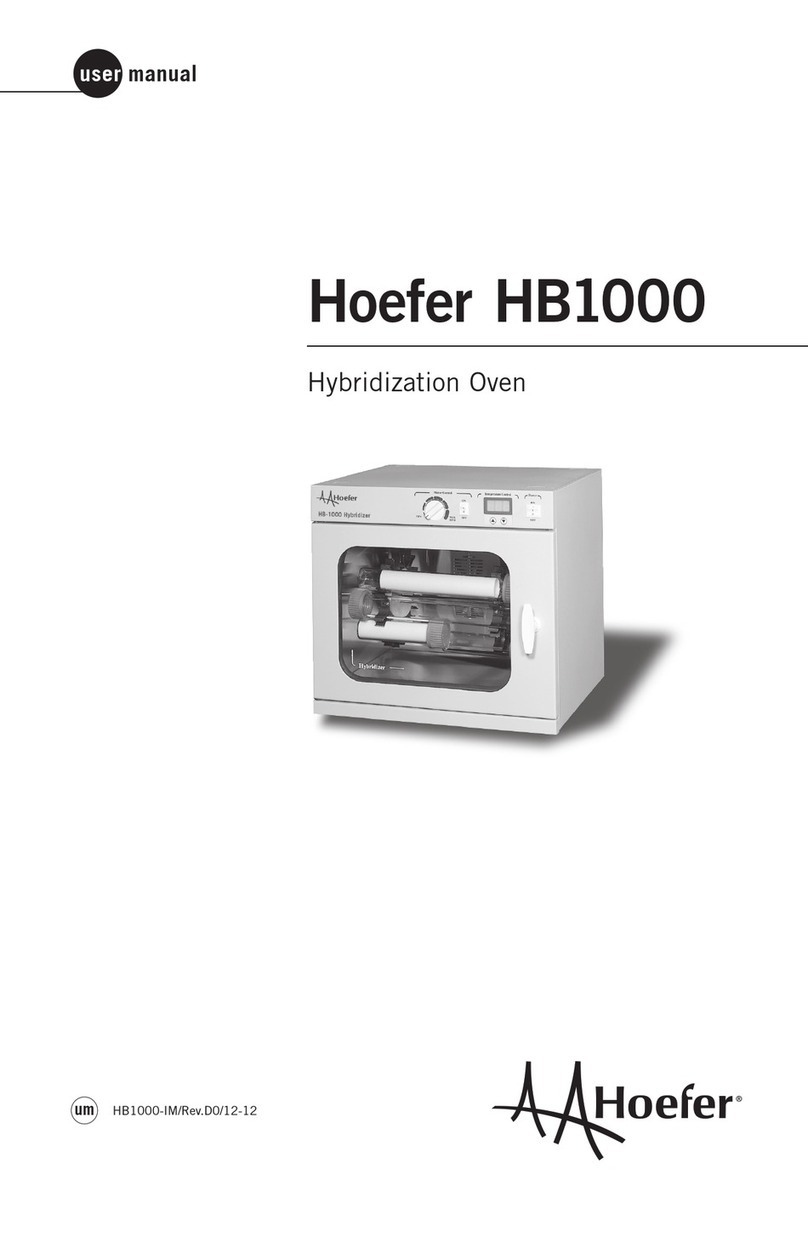

Hoefer HB1000 User manual

Hoefer

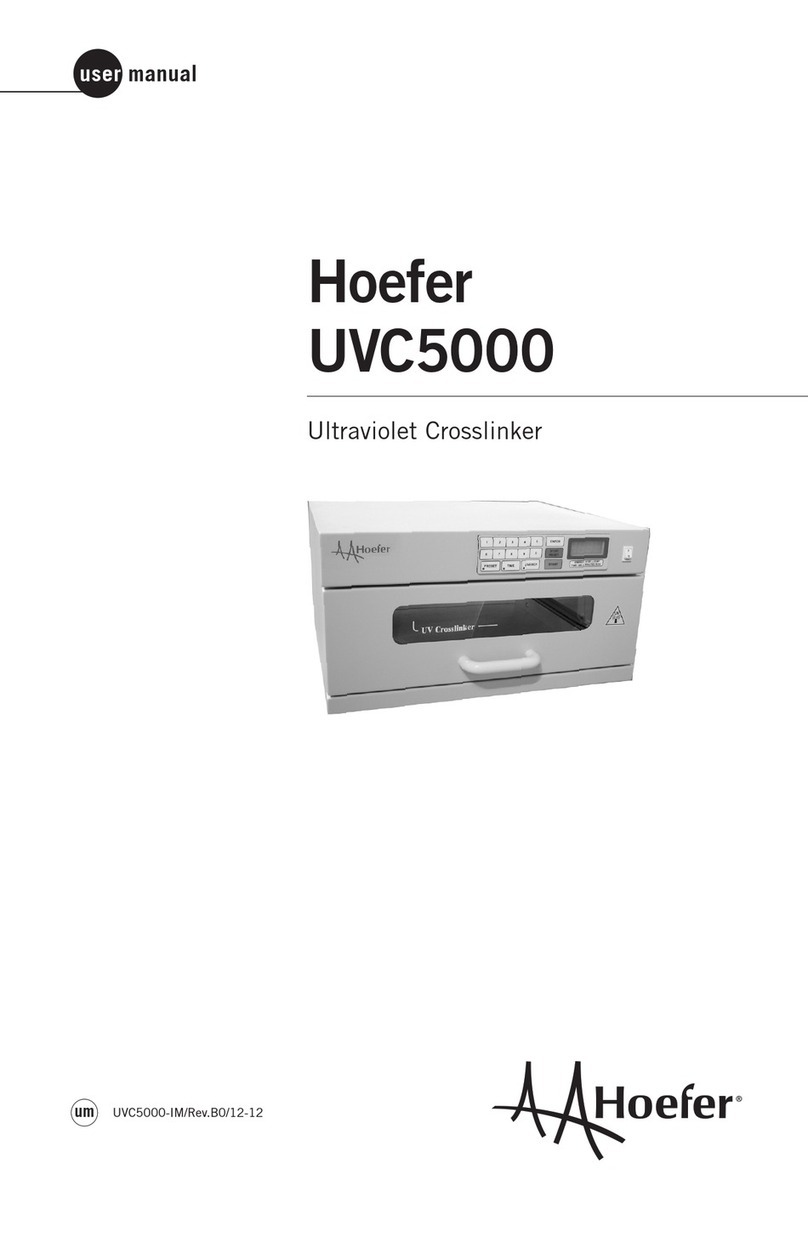

Hoefer UVC5000 User manual

Hoefer

Hoefer TE 70 User manual

Hoefer

Hoefer MacroVue UV-25 User manual

Hoefer

Hoefer TE 22 User manual

Hoefer

Hoefer SG500 User manual

Hoefer

Hoefer SE 400 User manual

Hoefer

Hoefer HE99X User manual

Hoefer

Hoefer TE70X User manual

Hoefer

Hoefer SG15 User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual