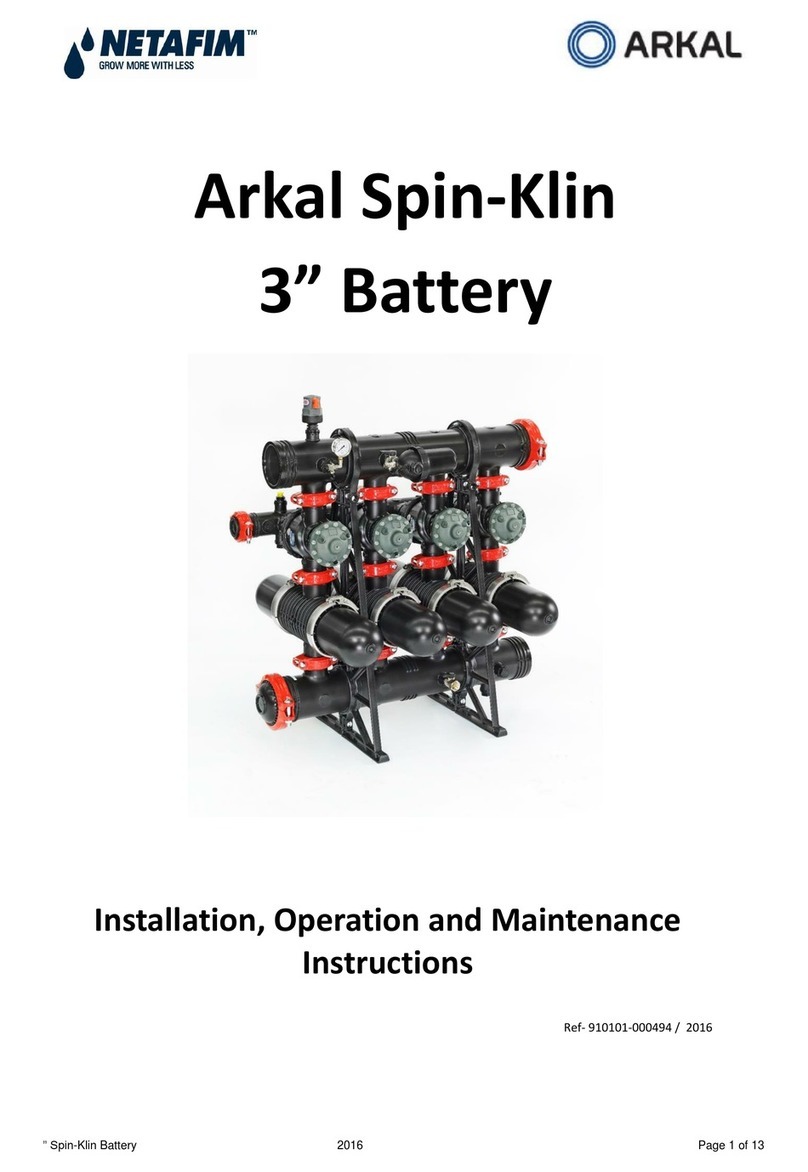

Netafim Arkal 3" Spin-Klin Battery User manual

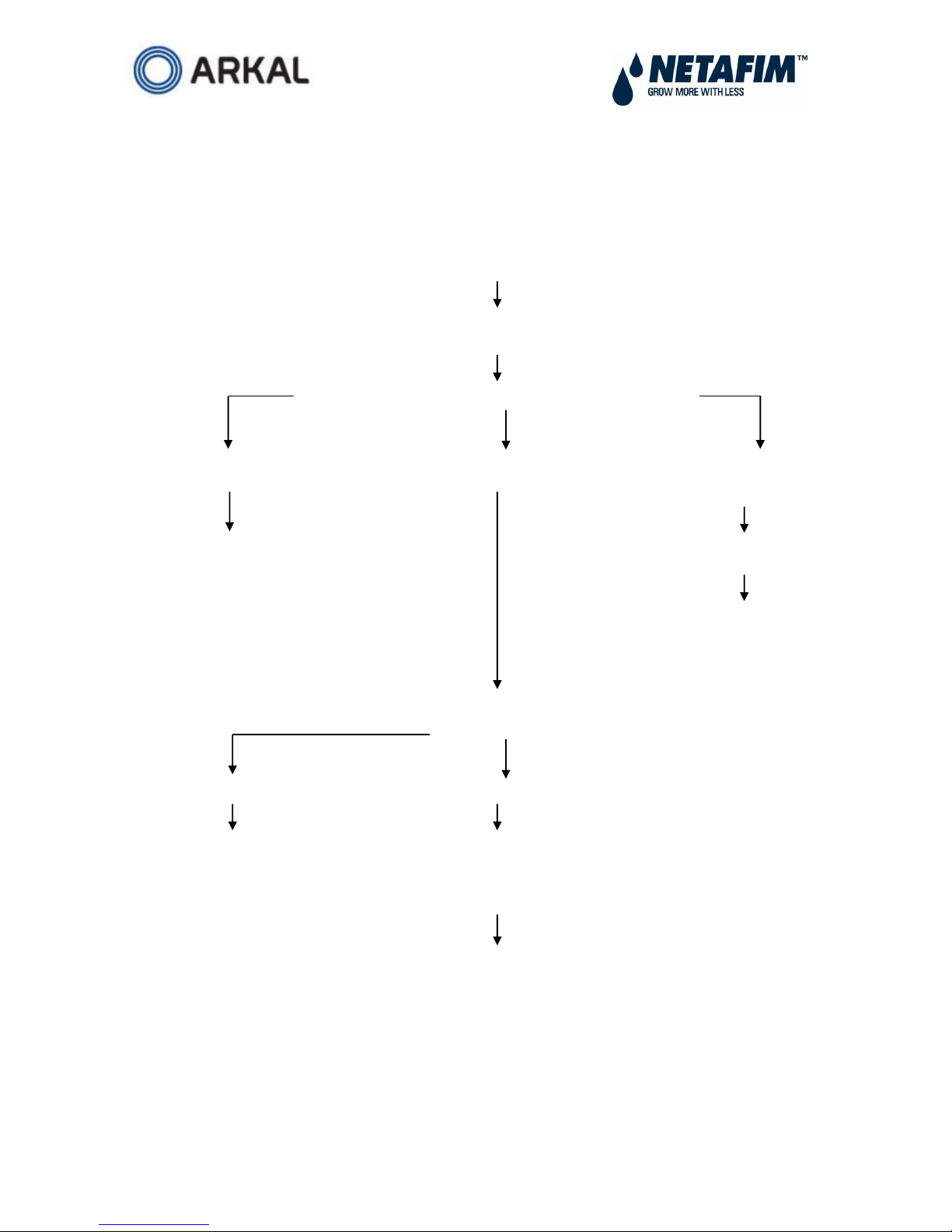

Other manuals for Arkal 3" Spin-Klin Battery

1

Other Netafim Water Filtration System manuals

Netafim

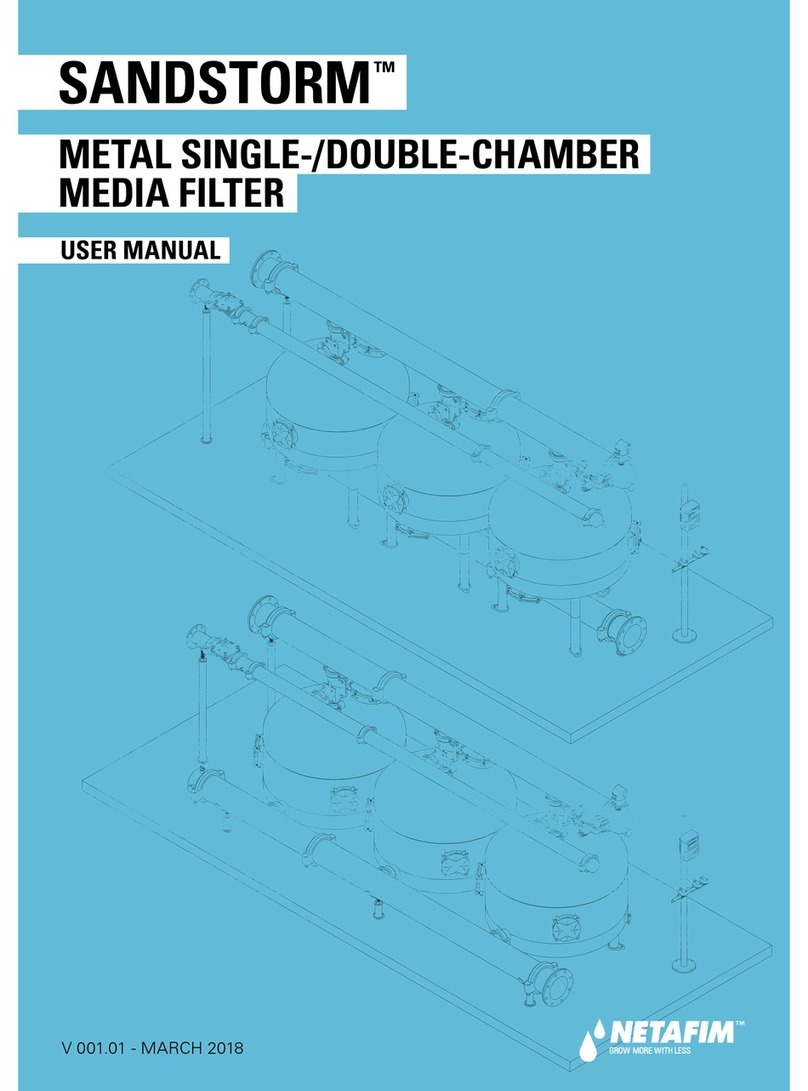

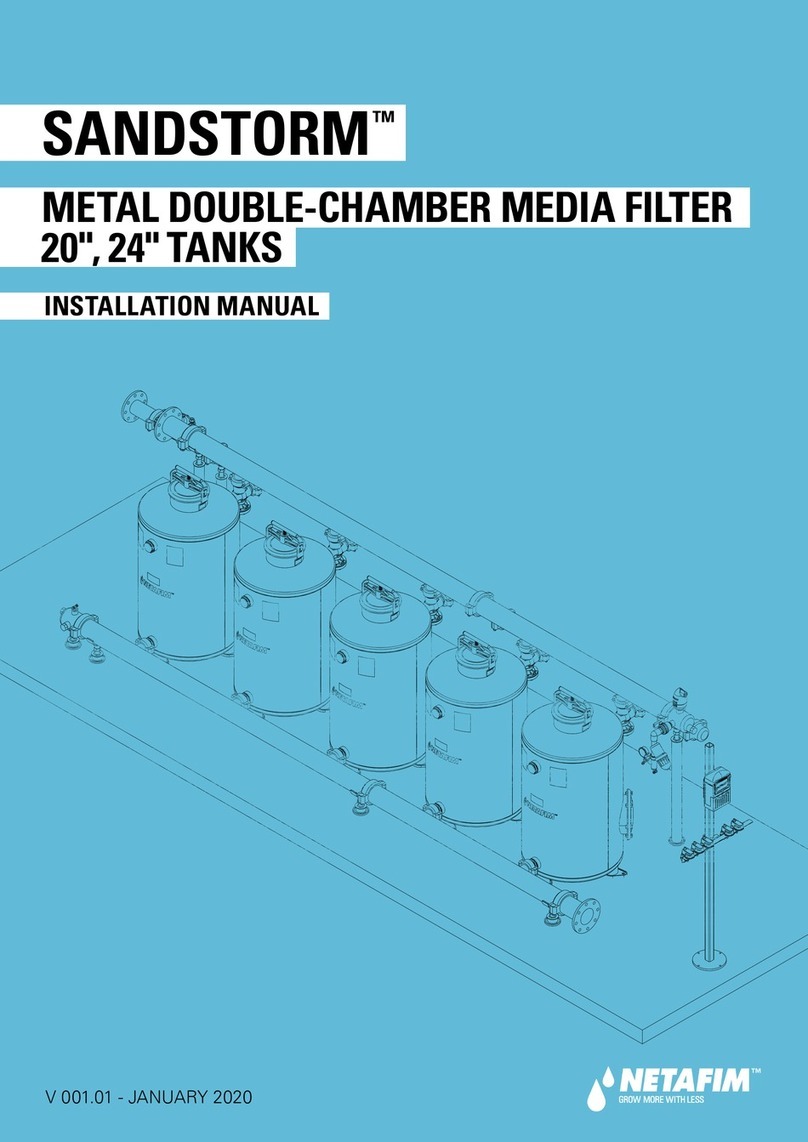

Netafim SANDSTORM User manual

Netafim

Netafim Apollo Instruction Manual

Netafim

Netafim Arkal 3" Spin-Klin Battery Installation and operating instructions

Netafim

Netafim SANDSTORM User manual

Netafim

Netafim AlphaDisc Series User manual

Netafim

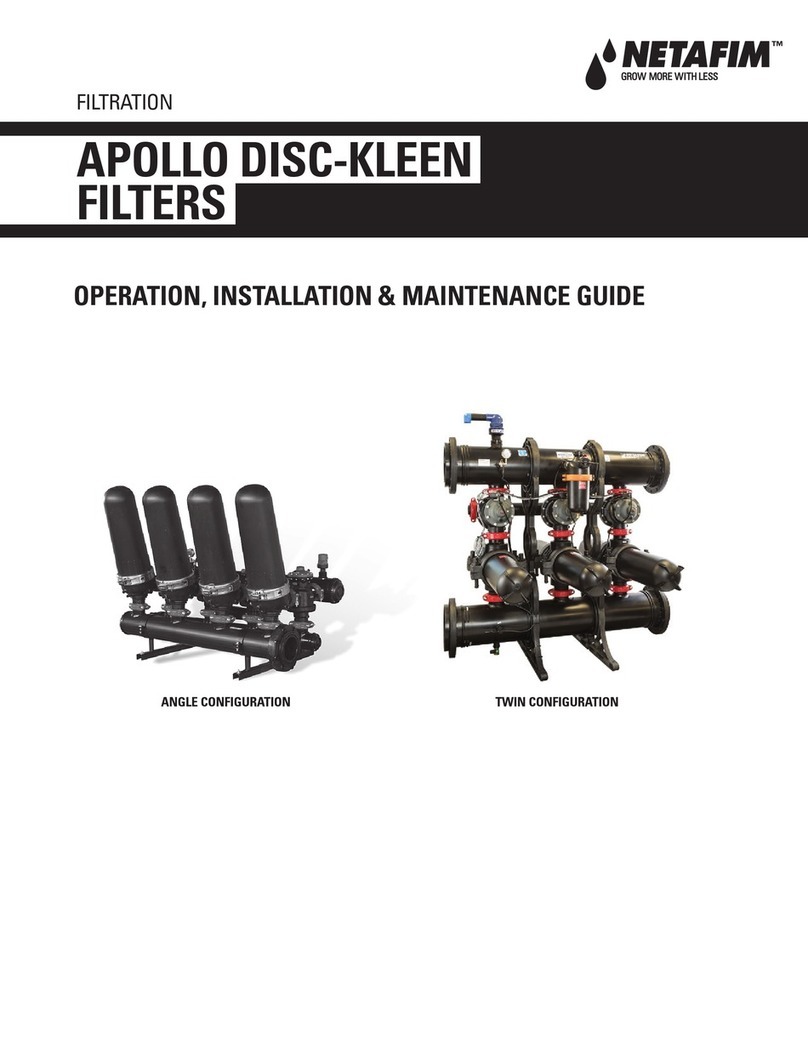

Netafim APOLLO DISC-KLEEN Instruction Manual

Netafim

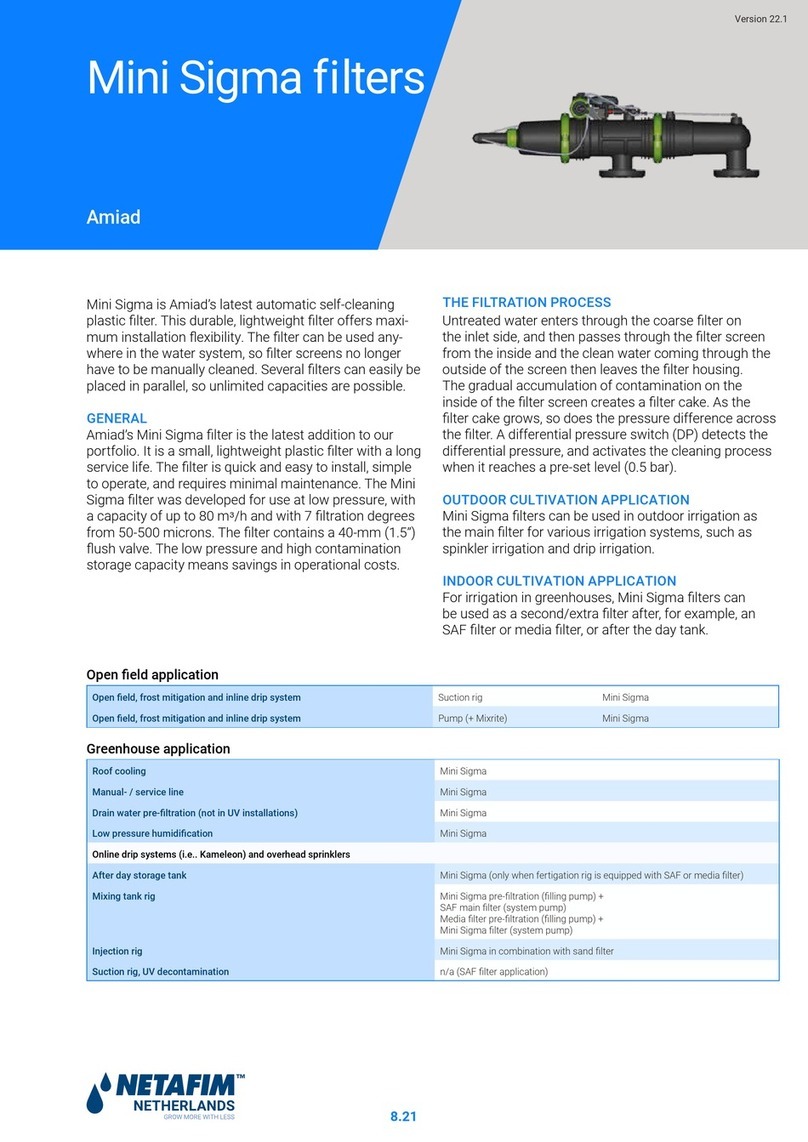

Netafim SCREENGUARD User manual

Netafim

Netafim Arkal 2" Spin-Klin Compact Stand Alone... User manual

Netafim

Netafim SANDSTORM User manual

Netafim

Netafim SCREENGUARD User manual

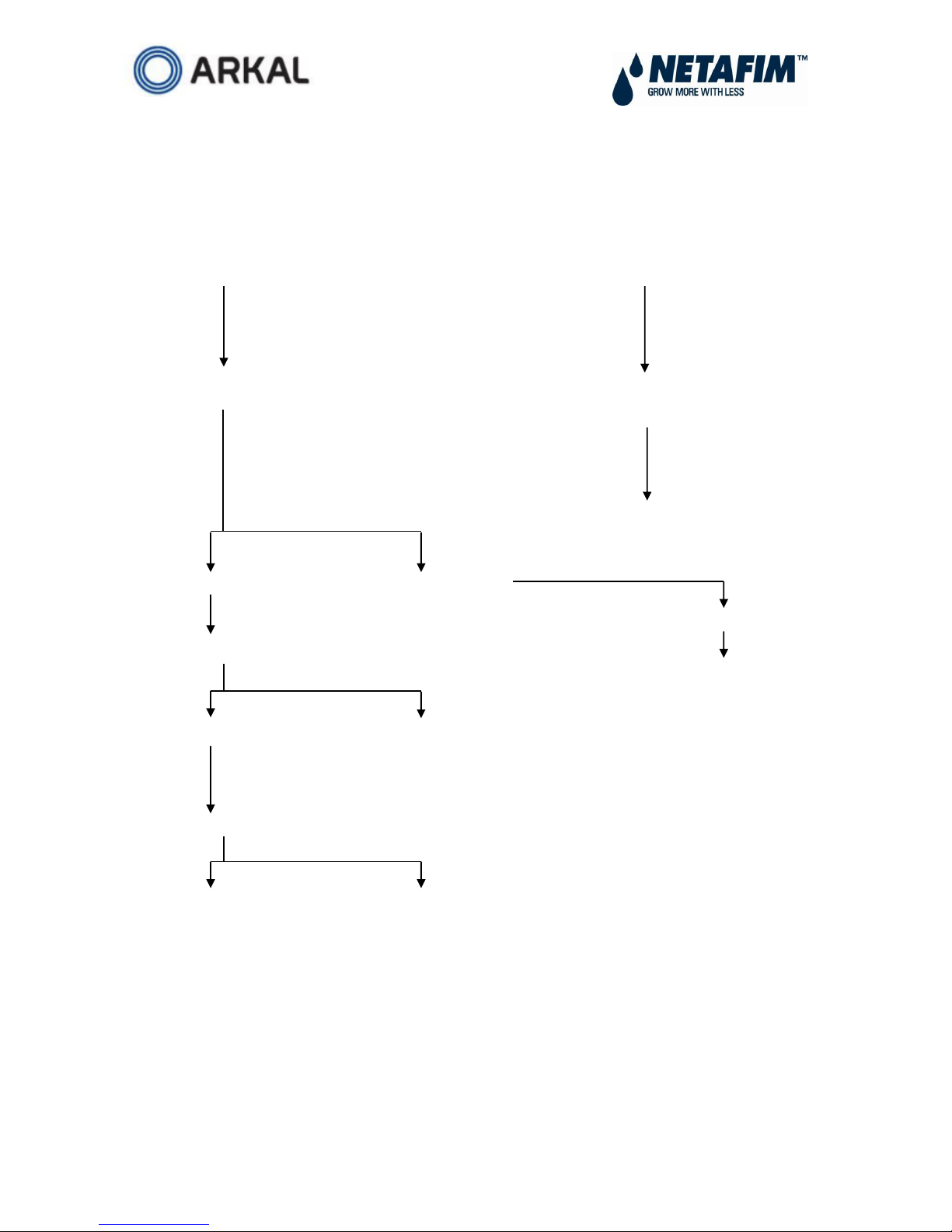

Popular Water Filtration System manuals by other brands

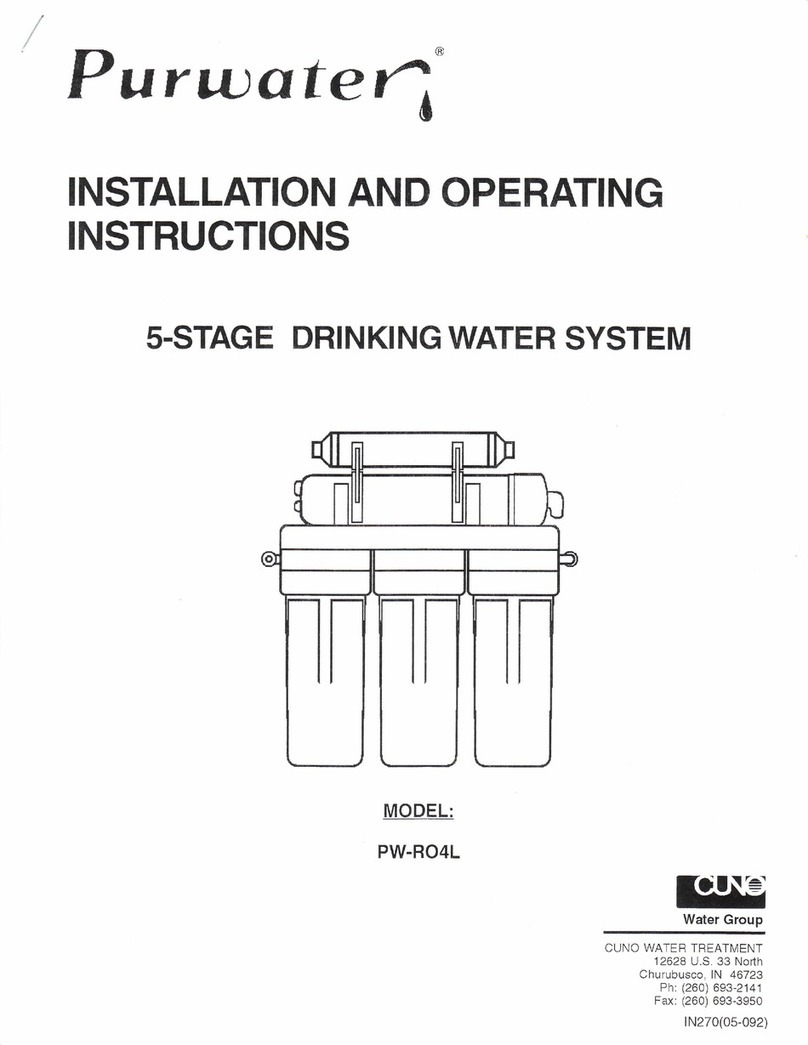

Purwater

Purwater PW-RO4L Installation and operating instructions

Spear & Jackson

Spear & Jackson BoilerMag XC BMXC22 Installation & maintenance

3M

3M CFS101BWF Installation and operating instructions

Antunes

Antunes VZN-441 owner's manual

Pentair

Pentair INTELLICHLOR COMSYS-16 installation guide

Sicce

Sicce GREEN RESET 25 instructions