Netafim APOLLO DISC-KLEEN Instruction Manual

ANGLE CONFIGURATION TWIN CONFIGURATION

OPERATION, INSTALLATION & MAINTENANCE GUIDE

APOLLO DISC-KLEEN

FILTERS

FILTRATION

2•APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE

TABLE OF CONTENTS

Specifications.................................................................................................................3

Filter Dimensions............................................................................................................4

Water Quality & Maximum Flow Rates ......................................................................5

Filter Operation...............................................................................................................5

Installation.......................................................................................................................8

Filter Start-up................................................................................................................10

System Maintenance ..................................................................................................10

Troubleshooting............................................................................................................13

Replacement Parts ......................................................................................................15

APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE •3

Netafim congratulates you on purchasing the Apollo Disc-Kleen filter. All Netafim filters are easy to install, use and service and don’t

require special skills to operate. For operation and maintenance of the filter, please follow the instructions in this manual.

SPECIFICATIONS

STANDARD MODEL MAX.

OPERATING PRESSURE (psi)

HIGH PRESSURE MODEL MAX.

OPERATING PRESSURE (psi)

MINIMUM BACKFLUSH

PRESSURE (psi)

FILTRATION SURFACE

AREA (sq. in.)

BACKFLUSH FLOW

PER UNIT (GPM at 35 psi)

BACKFLUSH VOLUME PER

FLUSH CYCLE (GPM)

INLET/OUTLET MANIFOLD

CONNECTION (in.)

DRAIN MANIFOLD

CONNECTION (in.)

MINIMUM ALLOWABLE PH

4 UNIT

ANGLE

90

140

30

1,625

95

130

10 FL

4 GR

5

4 UNIT

TWIN

90

140

30

3,245

190

265

10 FL

4 GR

5

SPECIFICATIONS

3 UNIT

TWIN

90

140

30

2,435

190

210

10 FL

4 GR

5

3-1 UNIT

TWIN

90

140

30

1,625

190

210

10 FL

4 GR

5

5 UNIT

TWIN

90

140

30

4,055

190

340

10 FL

4 GR

5

8 UNIT

TWIN

90

140

30

6,485

190

550

10 FL

4 GR

5

6 UNIT

TWIN

90

140

30

4,865

190

420

10 FL

4 GR

5

7 UNIT

TWIN

90

140

30

5,675

190

500

10 FL

4 GR

5

HIGH PRESSURE MODEL

Dual command filter and orifice

plate on drain manifold

MANIFOLD CONNECTIONS

FL = Flanged and GR = Grooved

12

10

8

6

4

2

0

PRESSURE (psi)

FLOW RATE (GPM)

250 500 750 1,000 1,250 1,500 1,750 2,000 2,250 2,500 2,750 3,000 3,250 3,500

3

UNIT

4

UNIT

5

UNIT

6

UNIT

7

UNIT

8

UNIT

HEADLOSS VS. FLOW RATE

SOLENOID OPTIONS

TYPE

24VAC

12VDC

12VDCL

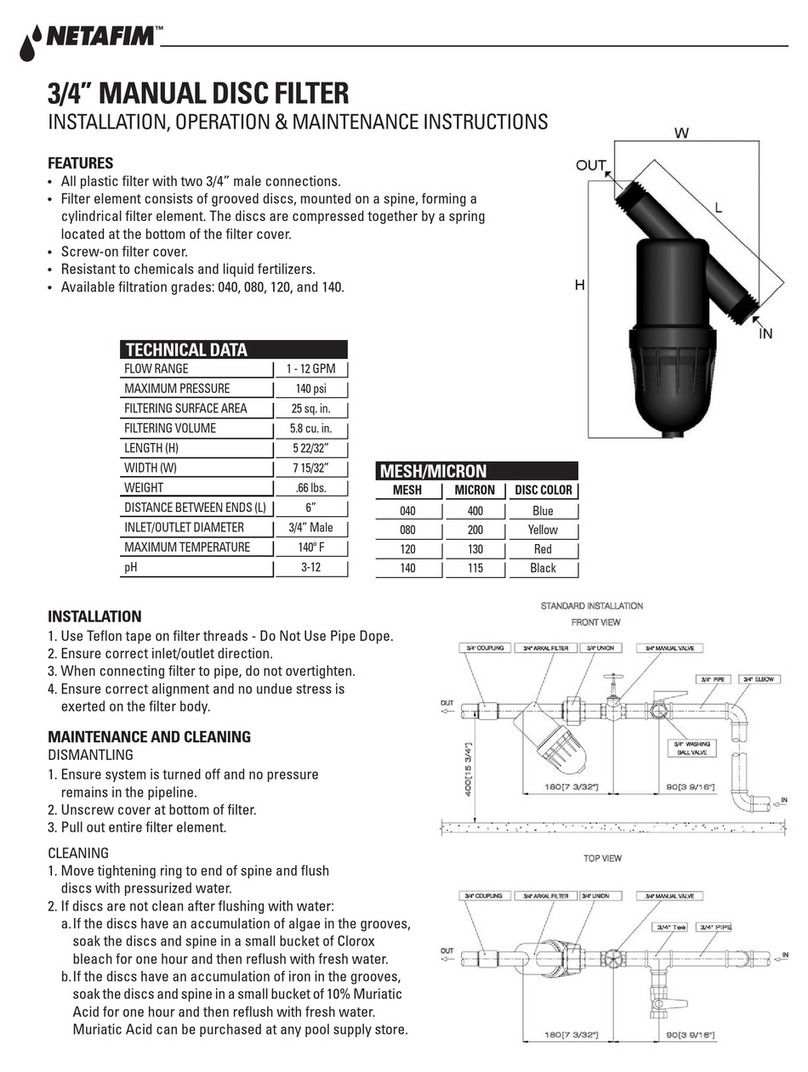

MESH AND MICRON

MESH MICRON

400

200

130

115

BLUE

YELLOW

RED

BLACK

40

80

120

140

COLOR

4•APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE

MATERIALS

•Manifold: High density

polypropylene

•Filter Body and Cover: High

density polypropylene

•Discs: Polypropylene

•Backflush Valve: Plastic with

reinforced polyamide

•O-Ring and Seals: Rubber

FILTER DIMENSIONS

4 UNIT ANGLE

3 UNIT TWIN

3-1 UNIT TWIN

4 UNIT TWIN

5 UNIT TWIN

6 UNIT TWIN

7 UNIT TWIN

8 UNIT TWIN

L

64 1/2”

68 9/32”

68 9/32”

87 15/16”

107 5/8”

127 5/16”

147”

166 11/16”

W

36 1/8”

60 9/32”

60 9/32”

60 9/32”

60 9/32”

60 9/32”

60 9/32”

60 9/32”

H

47 15/16”

71 9/32”

71 9/32”

71 9/32”

71 9/32”

74 25/32”

74 25/32”

74 25/32”

A

-

56 15/32”

56 15/32”

45 7/16”

45 7/16”

47 6/16”

47 6/16”

47 6/16”

B

8 1/4”

11 1/32”

11 1/32”

11 1/32”

11 1/32”

12 1/32”

12 1/32”

12 1/32”

C

-

29 29/32”

29 29/32”

29 29/32”

29 29/32”

29 29/32”

29 29/32”

29 29/32”

D

-

24 9/32”

24 9/32”

24 9/32”

24 9/32”

24 9/32”

24 9/32”

24 9/32”

E

-

43 31/32”

43 31/32”

63 31/32”

63 31/32”

63 31/32”

63 31/32”

63 31/32”

WEIGHT

510 LBS.

351 LBS.

235 LBS.

455 LBS.

1,254 LBS.

1,495 LBS.

1,750 LBS.

2,010 LBS.

DIMENSIONS AND WEIGHT

FILTER SIZE

All measurements are approximate. For specific dimensions refer to the CAD Design Details located on the Netafim USA website.

W

H

A

B

C

L

D

E

APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE •5

The discs are stacked on the spine. The discs are color-coded by mesh

size and are selected according to water filtration requirements. The spine

assembly has a spring compression unit and an internal piston which are

used to alternately compress and release the discs during filtering and

backflushing cycles.

FILTRATION MODE:

During the filtration process the discs are tightly compressed together by

the spring, forcing the water to flow through the grooves and traps the

debris.

BACKFLUSH MODE:

During backflush, the discs are separated by the releasing the inlet

hydraulic pressure. Multi-jet nozzles provide peripheral spray on the

loosened discs, causing them to spin, and release the retained solids,

which are flushed out through the drain.

WATER QUALITY

•Good Water Quality: Municipal water supply

or well water from a clean aquifer with no

sand, iron or manganese.

•Average Water Quality: Wells with small

amounts of sand (< 2 ppm) or clean surface

water which includes lakes, ponds,

reservoirs and canals.

•Poor Water Quality: Well water from a poor

quality aquifer (> 2 ppm) or surface water

in hot climates with increased biological

growth and no chemical treatment which

includes lakes, ponds, reservoirs and

canals.

•Very Poor Water Quality: Well water with

greater than 10 ppm of sand including

rivers, muddy canals, lakes and ponds with

severe run off deposits and raw municipal

wastewater.

•Greater than 3 ppm Sand or Silt: May

require a pre-filter such as a hydrocyclone.

Backflush

Water Inlet

Water flows from

outside to inside.

Water sprayed from

the inside to the outside.

To Drain

FILTRATION MODE BACKFLUSH MODE

Outlet

Inlet

WATER QUALITY & MAXIMUM FLOW RATES

FILTER OPERATION

SPINES PER FILTER

FILTER SIZE

4 UNIT ANGLE

3 UNIT TWIN

3-1 UNIT TWIN

4 UNIT TWIN

5 UNIT TWIN

6 UNIT TWIN

7 UNIT TWIN

8 UNIT TWIN

# OF SPINES

4

6

4

8

10

12

14

16

MAX. FLOW RATE (GPM)

WATER

QUALITY

GOOD

AVERAGE

POOR

VERY POOR

80 MESH

FLOW PER SPINE

198

183

156

132

120 MESH

183

171

144

117

140 MESH

171

156

132

105

Calculating Maximum Flow Rate (GPM) per Filter Unit:

Take the total # of Spines based on the filter size and multiple

that number by the Flow Per Spine based on the Water Quality

and Mesh.

6•APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE

BACKFLUSH VALVE:

The Backflush valve has two built-in chambers, the N.O. filter port and the N.C. drain

port. Each port has its own valve seat, but they share a common shaft and diaphragm.

The valve chambers are mutually integrated units. When one port is open, the other is

closed, permitting the backflush valve to perform two modes of operation:

FILTRATION MODE:

The valve permits flow from the inlet manifold through the filter, into the pipeline.

FLUSHING MODE:

The valve closes the inlet manifold and opens the drain port, causing reverse flow

through the filter, ejecting impurities via the drain port. The backflush valve is either

controlled by water pressure or a pneumatic source. Operation is initiated by an electric

solenoid with a manual override feature. A manual override knob is installed on the base

of all AC and DC continuous solenoids. During normal operation, the dot on the round

brass knob should be pointing towards the brass solenoid base (down). Turning this

knob 90 degrees to the left or right will activate the solenoid and put the valve/filter into

a backflush mode. Backflushing should be maintained for 20 seconds, then the knob

can be returned to the auto position for normal irrigation. For DC latching solenoids, the

manual override green lever is in a vertical position. Turning to the left 90 degrees will put

the valve/filter into a backflush mode.

FILTRATION PROCESS:

During the filtration process, the water flows through the inlet manifold reaching the

filters through the backflush valves. The filtered water flows through the outlet manifold

into the system.

Auto

COIL

OffOn

Auto

BASE

Manual

AC & DC CONTINUOUS

SOLENOID MANUAL

OVERRIDE

DC LATCHING SOLENOID

MANUAL OVERRIDE

Command Filter

4” Backflush Valve

4” Twin

Apollo Filter

IN

OUT

3

4

2

1

FILTERS 1, 2 & 3 ARE IN FILTRATION MODE

Air Release Vent

FILTER OPERATION

FLUSHING MODEFILTRATION MODE

APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE •7

BACKFLUSH PROCESS:

The backflush process begins with an electrical command from the backflush controller to the first

solenoid which is activated by the pressure differential gauge or by time.

The solenoid then sends a hydraulic command to the accelerator relay installed on the backflush

valve.

The accelerator relay opens causing the No. 1 valve to close the 4” inlet to the filter and open the

3” drain port. Filter No. 1 is now in a backflush position.

The spines in Filter No. 1 operate simultaneously, separating the compressed discs. Jets of clean

water supplied by the other filters are sprayed on an angle towards the discs causing them to spin

fast and free, flushing trapped solids and debris. The dirty water from this backflushed filter drains

out through the drain manifold.

Backflush time per filter is 20 seconds. When the time elapses, the backflush controller stops the

electric command to the solenoid. The spines return to the compressed state and the backflush

valve closes the drain port and opens for filtration.

The backflush process is repeated for all other filter units. Filters flush one at a time.

After all the filters have been backflushed, the system returns to filtration mode until the next

backflush cycle.

Air Release Vent

Command Filter

4” Backflush Valve

4” Twin

Apollo Filter

IN

OUT

DRAIN

3

4

2

1

FILTER 4 IS IN BACKFLUSH MODE

FILTER OPERATION

8•APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE

Air Release Vent

Filter

Backflush

Valve

Pressure Gauge

Command Filter

PLEASE NOTE:

•If the drain manifold is over 50’ in length, a 6” diameter drain pipe is

recommended. This will eliminate back pressure to the filter during the

backflush mode.

•If there is positive elevation of the drain manifold, the pressure required

for backflush will increase. For every 2.3 feet of elevation, an additional

1 psi must be added to the minimum downstream pressure of 30 psi.

INSTALLATION:

•Make sure that the inlet and outlet orientation is correct (shown by arrows on filter).

•Prior to start-up, check for any damage to the unit.

•Connect backflush drain manifold.

•Cover clamps need to be properly closed with safety pins secured.

•Verify the solenoids are correct as ordered before connecting the wires to the backflush controller.

DRAIN MANIFOLD INSTALLATION:

BACKFLUSH CONTROLLER ELECTRICAL WIRE HOOK-UP:

•Use 1/2” conduit and 16 gauge wire or larger from the controller

to the solenoids.

•C is common to all solenoids 24 VAC or 12 VDC. For the 12 VDCL

(latching), use positive or red lead.

•M is master valve – used with Pressure Sustaining Normally

Open or Electric valves to control the downstream flow.

•Terminals 1-8 for each solenoid for the “hot” lead.

•Seal the wire access holes to the controller.

SAFETY PRECAUTIONS:

Prior to Installation:

1. Take precautions while lifting, transporting or installing the filter.

2. Installation of the filter should be performed so as to avoid direct water

splashing on the electronic backflush controller.

3. Confirm that the filter weight, when full, meets the support construction

requirements.

4. Prior to installation confirm that line pressure matches filter’s operational

pressure.

5. During installation, use standard flanges and connections only.

6. Check that all filter flange bolts are properly secured.

7. Please note, the filter enters a flushing mode automatically, without prior

warning.

8. Use original parts only when servicing the filter.

9. Netafim cannot accept responsibility for any changes or modifications to the

equipment.

PLEASE NOTE:

Before opening the filter clamp, check that

there is no pressure in the filter. Open the 1”

brass ball valve found on the side of the filter

body to release any pressure in the filter.

INSTALLATION

DRAIN MANIFOLD

INST

ALLATION GUIDELINES

Minimum Battery

Pressure Downstream

Backflush Flow Rate

Drain Pipe Diameter

Topographic Elevation

30 psi

190 GPM

4”

0

APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE •9

BACKFLUSH CONTROLLER INSTALLATION:

•Refer to the controller’s handbook for installation instructions.

•Make sure that the voltage of both the solenoid unit and controller are correct.

•Set the backflush controller switch to “RUN”.

•Check that the PD hydraulic switch HIGH and LOW pressure lines are correctly connected to the appropriate

ports. The high pressure sensing port is found on the last backflush valve. The low pressure sensing port is found

on the downstream outlet manifold.

•Set the starting backflush point on the PD switch to: 5 psi differential when flushing at 30 psi

7 psi differential when flushing at 40 psi or greater

•Set the controller to a flush time of 20 seconds and a dwell time of 10 seconds. These settings may require

adjustment to conform to local water conditions. Typically, a 2 to 4 hour interval between backflushes is

recommended.

Backflush Controller

Flushing Time Between FlushingDwell

Vent. Vent. Vent.

123

Time or ∆ P 12

Time or ∆ P

Drain Drain Drain

Command

Water Filter

HP IN

LP

OUT

S

o

l

e

n

o

i

d

1

2

V

D

C

L

In

Com.

S

o

l

e

n

o

i

d

2

4

V

A

C

o

r

1

2

V

D

C

Vent

In

Out

4

”

T

w

i

n

A

p

o

l

l

o

F

i

l

t

e

r

LP

HP

M

u

r

p

h

y

∆

P

S

w

i

t

c

h

Vent

Feed

Command

Water

Command

to Valve

A

c

c

e

l

e

r

a

t

o

r

R

e

l

a

y

Command

from Solenoid

In Out

4

”

B

a

c

k

fl

u

s

h

V

a

l

v

e

Drain

Pressure

Comm

Vent

INSTALLATION

NOTE: Refer to Netafim USA’s YouTube Channel

for Backflush Controller Installation Video

10 •APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE

GENERAL REQUIREMENTS AND MAINTENANCE:

•Confirm there is 30 psi of pressure downstream of the filter during backflush.

•Check that the Pressure Differential (PD) Gauge returns to 0-2 psi after a

backflush.

•All vent tubes need to vent freely to atmosphere without any back pressure.

•To minimize damage to the backflush controller, always keep the door closed

and turn off the power when not using the controller for long periods of time.

SEASONAL MAINTENANCE:

•At the end of the irrigation season, just before shutdown, initiate a backflush

with the required pressure and turn off the water. This will ensure the discs

remain clean during the offseason.

•Manually clean the discs if needed – see detailed instructions on Page 11.

•In order to prevent the filter from becoming damaged under freezing

conditions, drain all the water from the filter and leave the drain valve open.

Disconnect the hydraulic tubes from the PD Gauge.

START-UP OPERATION:

•Flush out the main line upstream of the filter by opening

the blind flange connection of the inlet manifold. After

initial flushing, reassemble the blind flange.

•Turn the system on slowly to build up the pressure.

•Start the backflush cycle making sure that all system

components function correctly.

•Check that the PD gauge reads zero after a backflush

cycle.

IF FILTER LOADS UP DURING START-UP:

•Close the downstream (flow control) valve to increase

pressure downstream of the filter.

•Initiate backflush cycle until the discs are clean.

•Slowly reopen the downstream valve.

•If the pressure difference remains high, check and see if

the flow rate is too high. An excessive flow rate through

the filter causes excessive pressure loss.

FILTER START-UP

SYSTEM MAINTENANCE

WEEKLY CHECK

Inlet/Outlet Pressure

x

Backflush Controller

x

Leakage

x

Clean Command Filter

x

Solenoids

x

Downstream Pressure and Drain

x

Backflush Valves

x

MONTHLY CHECK - OPERATE BACKFLUSH

IN THE SYSTEM ACCORDING TO DP

METER AND CHECK:

NOTE: Refer to Netafim USA’s YouTube Channel

for Apollo Filter Start-Up Video

APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE •11

PLEASE NOTE:

•Make sure the system is not under

pressure.

•Before removing the cover you

may experience the vacuum

phenomenon which will make

removing the cover very difficult or

almost impossible.

•DO NOT insert any sharp tools or

objects in between the cover and

the body. You may damage the

hydraulic seal and the cover.

•In order to remove the cover easily,

you should drain the water from the

filter.

•You may drain the filter through the

drain valve located on the filter body.

Once the filter is empty, the cover

can then be removed safely and

easily.

DISC CLEANING INSTRUCTIONS:

•Use the clamp wrench to loosen the bolts.

•Slide the clamp down and off the filter.

•Remove the filter cover from the filter body.

•Unscrew the butterfly nut on the filtration element.

•Remove the tightening cylinders.

•Remove the discs. For convenience, we recommend using a plastic bag.

•Tie each disc set on a string and place them in a cleaning solution. Refer to

instructions on page 12 for recommended cleaning solutions based on water

deposits.

•Thoroughly wash the discs with fresh water and then reassemble the discs on

the spine.

•Check that the correct quantity of discs is assembled on the spine. When

the discs are pressed with two hands, the top disc should be level with the

imprinted white line on the outside of the spine.

•Replace the tightening cylinder and tighten the butterfly nut until it stops - do

not overtighten.

•Ensure the cover O-ring is in the correct position with the holes facing out.

•Place the filter cover on the filter body and secure it with a slight clockwise

rotation. Reposition the clamp onto the cover and tighten the bolts with the

clamp wrench.

SYSTEM MAINTENANCE

NOTE: Refer to Netafim USA’s YouTube Channel

for Apollo Disc Cleaning Video

12 •APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE

DISC CLEANING INSTRUCTIONS FOR WELL

WATER WITH MANGANESE, IRON OR CARBONATE

DEPOSITS:

STEP 1

•Make a 10% Hydrochloric Acid solution. Pour 1.8 gallons

of water into a container and add .80 gallons Hydrochloric

Acid (30-35%) to the water.

•Soak the discs in this solution making sure the discs are

loose and have good contact on both sides with the acid

solution. Do not put too many discs in at one time.

•Stir the discs in the solution a few times.

•Total soaking time is 1 to 3 hours. If the solution is no longer

cleaning the discs, replace it with a new mixture.

•Remove the discs and rinse well with water – there should

only be a pale sedimentation on the discs.

STEP 2

•After the discs have been rinsed with water, they must be

soaked in a 10% Peroxide solution to remove the organic

residue.

•Make a 10% Peroxide solution. Pour 1.8 gallons of water

into a container and add .80 gallons of Hydrogen Peroxide

(35%) or pour

2.1 gallons of water into the container and add .53 gallons of

Hydrogen Peroxide (50%) to the water.

•Soak the discs in this solution making sure the discs

are loose and have good contact on both sides with the

Peroxide solution. Do not put too many discs in at one time.

•Stir the discs in the solution a few times.

•Total soaking time is 1 to 3 hours. If the solution is no longer

cleaning the discs, replace it with a new mixture.

•Remove the discs and rinse well with water – there should

no longer be any residue between the grooves of the discs.

•Put the discs on the spine and spine assembly in the filter

bank.

•Flush the filter bank a few times to remove all chemicals.

DISC CLEANING INSTRUCTIONS FOR SURFACE

WATER WITH ORGANIC AND BIOLOGICAL RESIDUE:

STEP 1

•Make a 10% Peroxide solution. Pour 1.8 gallons of water into a

container and add .80 gallons of Hydrogen Peroxide (35%) or

pour 2.1 gallons of water into the container and add .53 gallons

of Hydrogen Peroxide (50%) to the water.

•Soak the discs in this solution making sure the discs are

loose and have good contact on both sides with the Peroxide

solution. Do not put too many discs in at one time.

•Stir the discs in the solution a few times.

•Total soaking time is 1 to 3 hours. If the solution is no longer

cleaning the discs, replace it with a new mixture.

•Remove the discs and rinse well with water – there should

only be a pale sedimentation on the discs.

STEP 2

•After the discs have been rinsed with water, they must be

soaked in a 10% Hydrochloric Acid solution to remove the

organic residue.

•Make a 10% Hydrochloric Acid solution. Pour 1.8 gallons of

water into a container and add .80 gallons Hydrochloric Acid

(30-35%) to the water.

•Soak the discs in this solution making sure the discs are loose

and have good contact on both sides with the acid solution.

Do not put too many discs in at one time.

•Stir the discs in the solution a few times.

•Total soaking time is 1 to 3 hours. If the solution is no longer

cleaning the discs, replace it with a new mixture.

•Remove the discs and rinse well with water – there should no

longer be any residue between the grooves of the discs.

•Put the discs on the spine and spine assembly in the filter

bank.

•Flush the filter bank a few times to remove all chemicals.

CAUTION: When blowing out with compressed air, make sure all parts are opened.

SYSTEM MAINTENANCE

NOTE: Refer to Netafim USA’s YouTube Channel

for Apollo Disc Cleaning Video

APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE •13

NO WATER GOING THROUGH THE FILTER:

•If the system has upstream and downstream valves around the filter, check to make sure they are open. Check that field valves are

open.

•At start-up, the backflush valves need a minimum 12 psi to start working. If air is trapped in the system, close the downstream butterfly

valve so that pressure builds up at the filter. Then, slowly open the butterfly valve to allow water to flow to the field.

•Verify that the manual override buttons on all the solenoids are in the correct position. For AC and DC continuous solenoids, the dot in

the round brass knob should be pointing towards the brass base of the solenoid, not towards the black square plastic solenoid coil.

For DC latching solenoids, the green lever should be vertical. See page 6 for illustrations. If all of the manual override buttons are in the

wrong position, water will not flow through the filter.

•Make sure all vent tubes are venting to atmosphere with no back pressure.

NO BACKFLUSH OPERATION:

Check the Upstream and Downstream Pressure

•The pressure downstream of the filter needs to be at least 30 psi during backflushing. The Pressure Sustaining Normally Open (PSNO)

Valve should be set to at least 30 psi during backflushing.

Check the Command Filter

•Make sure the command filter is clean. A clogged command filter does not provide command water to the solenoids and backflush

valves and the filter will not flush. Also, make sure the 2” ball valve in front of the command filter is open.

Check the Pressure Differential (PD) Gauge

•Make sure the PD gauge is not broken. The set point (the short needle) should be set at 5 psi. The long red needle indicates the

pressure differential at any given time. If the needle reads zero, then the discs are clean. As the red needle moves towards the shorter

(set point) needle, then the discs are getting dirty. When the two needles touch, the backflush controller will initiate a flush cycle.

•Test the PD gauge while the water is on - disconnect the hydraulic tube from the low pressure port of the gauge (the off center port).

Water will squirt out of the tube; you can bend the tube to temporarily stop the water. The long red needle should move quickly and

touch the short needle. When both needles touch for 15 consecutive seconds, a backflush cycle will start.

•If the backflush starts, then the PD gauge is working. If there is no flush, replace the PD gauge. Re-connect the hydraulic tube to the

PD gauge.

Check if the Filter Discs are Clogged

•To check if the filter discs are clogged, turn off the water and confirm there is no pressure in the system. Open up a filter cover and

inspect the discs. If all of the filters are completely clogged, the filter will not flush.

•Remove the discs and clean – refer to the Disc Cleaning Instructions on Page 11 and 12.

•Reassemble the discs on the spine and the filter cover, then tighten the clamp.

•Initiate a backflush with the backflush controller. If the filter still doesn’t flush, refer to the Check the Backflush Controller Section

below.

Check the Backflush Controller

•To test the backflush controller, initiate a backflush by pressing the black button (manual override).

•The solenoid should click and send the filter into flush mode. After 20 seconds, the solenoid should click again and end the backflush.

•If the solenoid clicks, then the solenoid is operating and the control panel is not. If the solenoid does not click, then the solenoid needs

to be replaced

•To test the solenoids: remove the wires of the solenoid from the terminal of the control panel and connect them directly to the power

source. For DC models, touch the wires. For AC models, connect the solenoid wires to the outlet transformer wires.

•If the backflush was not initiated, check wires to verify all connections are secure.

•Push the reset button on the front panel and initiate a backflush again.

•Flush a filter individually by turning the manual override of the solenoid 180 degrees. If that filter flushes, then the filter is working

hydraulically and the problem is electric.

TROUBLESHOOTING

NOTE: Refer to Netafim USA’s YouTube Channel

for Apollo Troubleshooting Guide Video

14 •APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE

•For AC backflush controllers, make sure the transformer is still functioning and replace if needed.

•The controller panel can malfunction if exposed to moist or dusty conditions, rust, or lightning. If you suspect

any of these causes, contact the backflush controller manufacturer for inspection and possible warranty or

repair. Or call Netafim USA Technical Support for assistance.

CONTINUOUS BACKFLUSHING:

Constant Water Flowing Out of the Drain Manifold

•If there is constant water going through the drain manifold, then one of the backflush valves is stuck in the flush

position. This can be caused by one of these three issues:

- There may be debris stuck in the drain port of the backflush valve which does not allow the valve to return

to the filtration position. Determine which valve is flushing all of the time. Turn the manual override of the

solenoid to flush and then return the knob to filtration. Make sure the knob is in exactly the correct position.

If the valve is still flushing, turn off the water.

- Remove the entire 4” drain manifold from the back of the backflush valves. Visually inspect the back side of

all valves to see if there is debris. Start to disassemble the backflush valve from the back by removing the

large plastic union. Put the large spring or large o-ring in a secure place. Remove the small bolt from the

stem, pull out the black round piece and remove any debris. Carefully reassemble the valve and attach the

drain manifold.

- The solenoid may be stuck and not returning to filtration mode. On the Backflush Controller, switch the

terminal wire (the wire connected to terminal 1 and 2 for example) from a stuck solenoid to a working

solenoid. If the problem moves with the solenoid that is stuck, then the problem

is in the solenoid. Disassemble the solenoid to clean any debris. If the problem persists, replace the solenoid

coil with a new one.

- The diaphragm of the backflush valve may be torn. To confirm, close the ball valve in front of the 2”

command filter. If water is still flushing from the drain manifold, the diaphragm may be torn. Turn off the

water and remove all of the bolts from the bonnet of the valve. Remove the diaphragm and inspect for tear.

Replace if necessary.

Filter Completes a Backflush Cycle, Stops and Backflushes Again:

•If the filter is constantly backflushing by going through a cycle, stopping for 1 minute and backflushing again,

look at the controller to see if the word “Alarm” is flashing. If it is, then the filter is probably clogged.

•The filter will get clogged for the following reasons:

- There was less than 30 psi on the downstream side of the filter during backflush.

- The water quality changed and became too dirty for the filter to keep up. (Check for severe algae bloom or

high silt load).

- The flow rate was increased by turning on an additional valve, so the filter cannot keep up with the

increased flow rate.

- The diameter of the drain pipe is too long or too small or it’s plumbed so that it elevates back into a reservoir.

All of these will create back pressure on the filter during the flush cycle and have a negative effect on the

quality of the flush. The drain pipe should be at least 4” diameter, not to exceed 50 feet long and free flow to

a drain pit. If the drain pipe needs to be longer than 50 feet, use a 6” pipe. There should not be a check valve

or gate valve on the drain pipe.

- Remove the discs from the spines and clean them manually. Refer to the Disc Cleaning Instructions on

Pages 11 and 12.

CHECK THE BACKFLUSH CONTROLLER (CON’T)

TROUBLESHOOTING

NOTE: Refer to Netafim USA’s YouTube Channel

for Apollo Troubleshooting Guide Video

APOLLO DISC-KLEEN FILTER OPERATIONS, MAINTENANCE AND TROUBLESHOOTING GUIDE •15

REPLACEMENT PARTS

NOTE: Substitute *** with desired mesh.

24

25 23

Pressure Gauge Assembly

2” Combination Air Vent

Extension for Combination Air Vent

Inlet Manifold

Blind Flange

7/8” Bolt for Blind Flange

7/8” Washer for Blind Flange

7/8” Nut for Blind Flange

2” Dual HP Command Filter

Gasket for Blind Flange

Apollo 4” Twin Filter

Apollo 3” Angle Filter

4” Victaulic Coupling

4“ Series 350 Plastic Backflush Valve

3” Series 350 Plastic Backflush Valve (Angle Filter Only)

24VAC Normally Closed Solenoid

1” Ball Valve

Outlet Manifold

Plastic Support Leg for 10” Inlet/Outlet Manifolds

Plastic Support Leg for 12” Inlet/Outlet Manifolds

1” Plug

1/2” Vacuum Breaker on Drain Manifold

4” Victaulic Cap

Drain Manifold

Mounting Bracket for Backflush Controller

Plastic Finger Filter

Plastic Elbow 8 mm x 1/8” M for Solenoid & Relay (Bag 10)

Plastic Male Branch Tee 8 mm x 1/4” x 8 mm (Bag 10)

Flange-Bolt Kit: 24 bolts, 24 nuts, 48 washers, 2 flanges

Adapter Kit: 24 bolts, 24 nuts, 48 washers, 1 drain manifold, 1 conn.

1/4” Plug (Bag 10)

8 mm Control Tube (50’ Roll)

Item Number Model Number Description Price EachKey

228.00

208.00

48.00

Call

830.00

23.00

2.40

9.10

489.00

41.00

6,222.00

3,350.00

62.00

1,308.00

821.00

201.00

65.00

Call

800.00

864.00

2.50

21.00

27.00

Call

113.00

17.00

45.70

57.80

1,988.00

786.00

8.80

9.00

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

-

-

-

-

-

70561-001660

-

-

00110-001520

-

-

-

70641-003640

00110-001521

-

-

70040-003100

71000-013440

71000-013360

70800-003260

76601-001400

-

-

-

75050-008500

70620-008360

78201-010100

-

70041-004000

71680-014170

76400-003410

76400-004505

00110-001540

00110-001550

76400-005410

40001-000382

25AP225403414

65ARIB2PP

25AP50480222

-

25APMODBLINDFLG-P

25AP50402139

25AP50409017

25AP50408017

25A30-120

25APMODGASKET

25AP14461***

25AP13761***

44VIC04

61BFG4GPGB-DM

61BFG3PB

61BBC-024

62SBV100F

-

25AP22531001

25AP22531210

595177100

25AP22530512

44VICCP04

-

25AP22541230

61SF25P

55P4694802-B

55P4714804-B

25APMODKITFLNG

25APMODKIT5-8

55P1210400-B

15CONT8C50

APOLLO DISC-KLEEN FILTER BATTERY PARTS

Model Numbers 26ASK*PP or 26ASK*PPB and the NEW Modular Apollo 26SK*PB

Model Numbers will be different based on filter configurations.

REPLACEMENT PARTS

NETAFIM USA

5470 E. Home Ave.

Fresno, CA 93727

CS 888 638 2346

www.netafimusa.com

APOPS 10/17

NOTE: Substitute *** with desired mesh.

3” Angle Body

1/4” x 1/2” Ball Valve

Gauge Port Seal

Gauge Port Nut

Cover Gasket

Clamp - Polymeric Complete

Spine Seat O-Ring

Ring Set Only

Spine Assembly without Rings

Filter Cover

Butterfly Nut Wrench

Wrench for Polymeric Clamp Bolts

Item Number Model Number Description Price EachKey

361.00

34.00

8.40

5.90

25.00

263.00

7.20

358.00

1,534.00

421.00

47.00

6.60

1

2

3

4

5

6

7

8

9

10

11

12

70620-003384

70620-003865

70620-005100

70620-005200

70620-004300

70620-019450

70620-004146

-

70620-007414

70620-002162

70620-007900

70620-019460

25AP22371011

25AP50540212

25AP50060004

25AP25110103

25AP534341

25AP70019003658

25AP50022355

25AP20334-***

25AP21991040LC

25AP25010602

25AP50760028

25APLCLPWRENCH

APOLLO DISC-KLEEN FILTER PARTS

Angle Filter

4” Twin Body

3/4” Ball Valve

O-Ring for 3/4” Ball Valve

Gauge Port Seal

Gauge Port Nut

Cover Gasket

Clamp - Polymeric Complete

Spine Seat O-Ring

Ring Set Only

Spine Assembly without Rings

Filter Cover

Wrench for Polymeric Clamp Bolts

Butterfly Nut Wrench

Item Number Model Number Description Price EachKey

709.00

32.00

6.20

8.40

5.90

25.00

263.00

7.20

358.00

1,534.00

421.00

6.60

47.00

1

2

3

4

5

6

7

8

9

10

11

12

13

70620-003432

76000-002400

70620-007065

70620-005100

70620-005200

70620-004300

70620-019450

70620-004146

-

70620-007414

70620-002162

70620-019460

70620-007900

25AP22000402

25AP50540112

25AP50032311

25AP50060004

25AP25110103

25AP534341

25AP700190003658

25AP50022355

25AP20334-***

25AP21991040LC

25AP25010602

25APLCLPWRENCH

25AP50760028

APOLLO DISC-KLEEN FILTER PARTS

Twin Filter 11

9

10

11

10

9

12

13

11

12

Table of contents

Other Netafim Water Filtration System manuals

Netafim

Netafim AlphaDisc Series User manual

Netafim

Netafim SANDSTORM User manual

Netafim

Netafim 25AP46 Series Guide

Netafim

Netafim SANDSTORM User manual

Netafim

Netafim Arkal 3" Spin-Klin Battery Installation and operating instructions

Netafim

Netafim Arkal 3" Spin-Klin Battery User manual

Netafim

Netafim SCREENGUARD User manual

Netafim

Netafim SANDSTORM User manual

Netafim

Netafim Amiad Mini Sigma 2 1200 User manual

Netafim

Netafim Apollo Instruction Manual