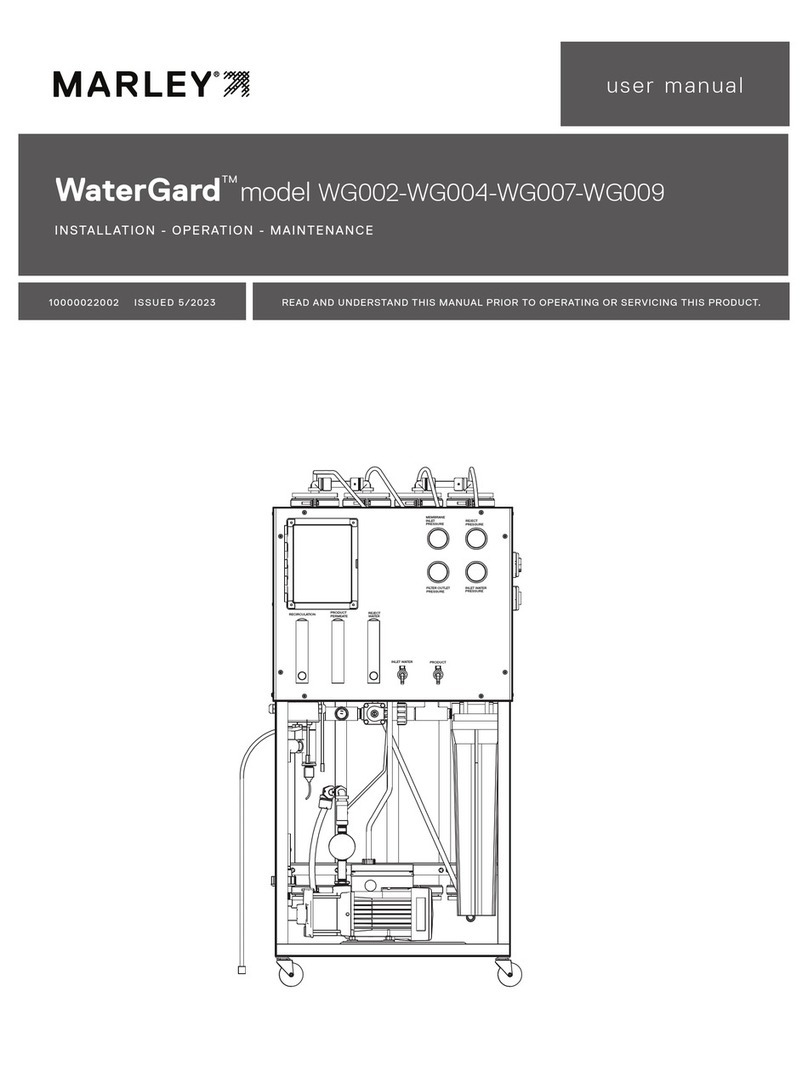

Netafim SCREENGUARD User manual

OPERATION, INSTALLATION & MAINTENANCE GUIDE

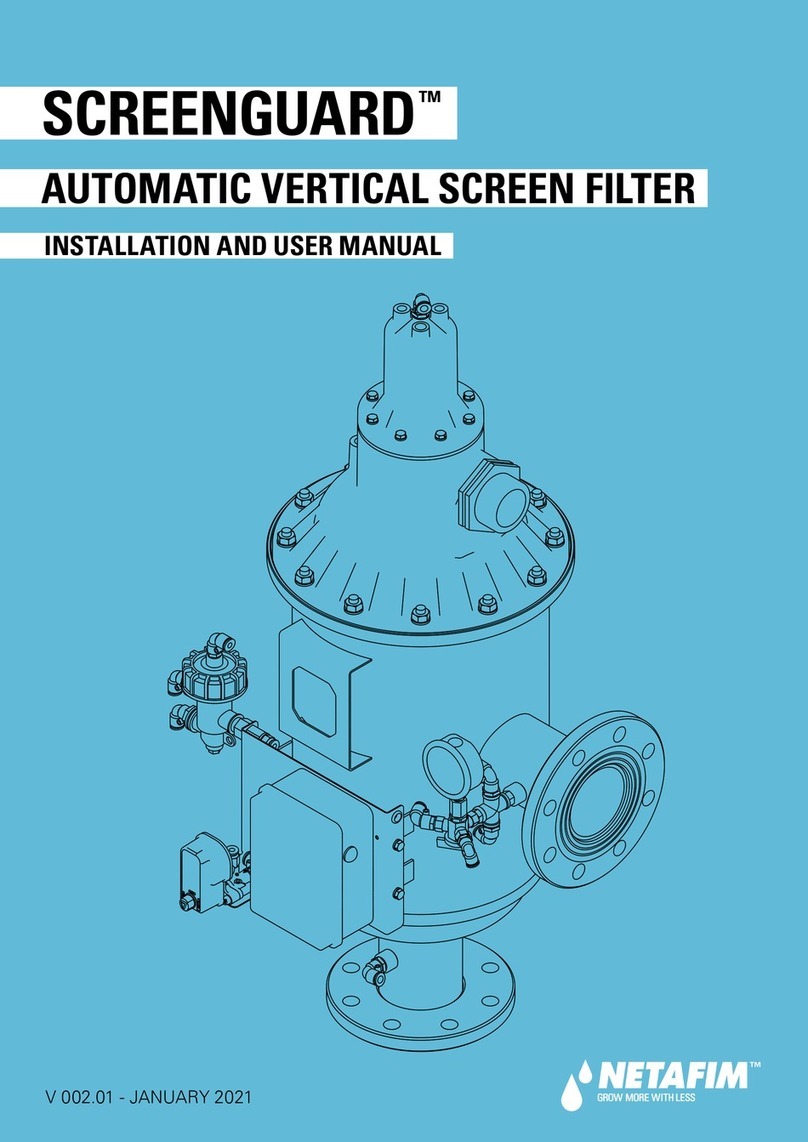

SCREENGUARD™ AUTOMATIC

SCREEN FILTERS

FILTRATION

2•SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION, INSTALLATION AND MAINTENANCE GUIDE •3

General Information.......................................................................................................4

Specifications.................................................................................................................4

Operations.......................................................................................................................6

Dimensions & Weight.................................................................................................... 7

Installation.......................................................................................................................8

Maintenance

Battery Removal & Replacement................................................................9

Control Card Removal & Replacement.....................................................10

Solenoid Removal & Replacement ...........................................................11

Hydraulic Piston Assembly & Replacement............................................12

Coarse Screen Removal & Replacement ................................................13

Fine Screen Assembly Removal & Replacement...................................14

Dirt Collector Removal & Replacement ...................................................15

Periodic Checks...........................................................................................16

Troubleshooting

Pressure Difference Between Inlet and Outlet ......................................17

Filter Flushing Cycle ....................................................................................17

Replacement Parts ......................................................................................................18

TABLE OF CONTENTS

4•SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

• Prior to installation or handling of the filter, read carefully the installation and operation instructions carefully.

• Confirm filter draining prior to service.

• Take precautions while lifting, transporting or installing the filter.

• Installation of the filter should be performed so as to avoid direct water splashing on any of the filter parts and

especially on the electronic control unit.

• Confirm that filter weight, when full, meets the support construction requirements.

• Prior to installation confirm that line pressure matches filter’s operational pressure.

• During installation, use standard flanges and connections only.

• Check that all filter flange bolts are properly secured.

• Please note, the filter enters a flushing mode automatically, without prior warning.

• Use original parts only when servicing the filter.

• NETAFIM can not accept responsibility for any changes or modifications to the equipment.

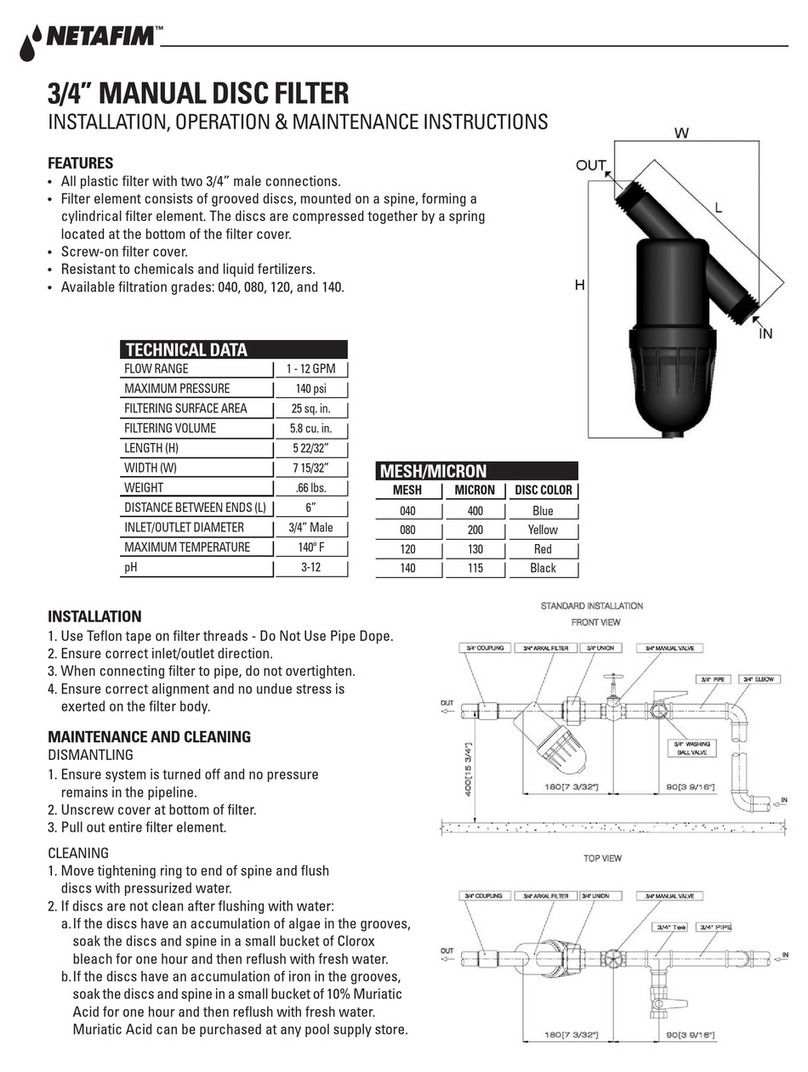

SPECIFICATIONS

GENERAL INFORMATION

• Minimum operating pressure: 30 psi

• Maximum Operating Pressure: 150 psi

• Maximum Water Temperature: 149˚ F (65˚ C)

• End Connections: Flanged

• Screen Mesh Sizes: 080, 120, 150, 200

• Sizes: 4”, 6”, 8” and 10”

• Control voltage: DC Latching

• Filter housing: baked epoxy, carbon steel coated

HEADLOSS (FLOW VS. PRESSURE)

1,000 2,000 2,5001,500450

0.14

14

1.4

FLOW RATE (GPM)

PRESSURE (psi)

10"

8"

6"

4"

SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION, INSTALLATION AND MAINTENANCE GUIDE •5

SPECIFICATIONS

FIGURE 1

1 Inlet

2 Coarse Screen

3 Fine Screen

4 Flushing Valve

5 Hydraulic Piston

6 Flushing Chamber

7 Dirt Collector

8 Suction Nozzle

9 Hydraulic Motor

10 Outlet

11 Electronic DP Unit

12 Control Unit

13 Solenoid Valve

14 Adapter 2”

KEY DESCRIPTION

AUTOMATIC SCREEN FILTERS

MESH / MICRON

MESH

MICRON

80

200

120

120

150

100

200

80

SPECIFICATIONS

SIZE

4”

6”

8“

10”

1,300 SQ. IN.

1,300 SQ. IN.

1,300 SQ. IN.

1,815 SQ. IN.

SCREEN AREA

132 GPM

132 GPM

132 GPM

396 GPM

BACKFLUSH

FLOW RATE

440 GPM

700 GPM

1,320 GPM

2,000 GPM

MAXIMUM

FLOW RATE

The ScreenGuard self-cleaning filter enables high quality filtration from 80-200 mesh from various types of fluid

sources such as sewage, reservoirs, rivers, lakes, and wells.

6•SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

OPERATIONS

FILTER OPERATIONS (FIGURE 1)

• Water enters the filter through the “Inlet” (1) and passes through the coarse screen (2) that functions as a “first stop”

for rough particles.

• Water then reaches the fine screen (3), which further purifies the flow by separating smaller particles from the water

As more water flows through, impurities build up on the fine screen. As impurities on the screen accumulate, a

pressure imbalance is built up between the internal section of the fine screen (3) and its external section.

• When the difference in pressure (DP) reaches the preset value in the electronic control unit (12), a series of events is

triggered while the water continues to flow to the user.

• The flushing valve (4) opens, pressure is released from the hydraulic piston (5) and water flows outside.

• Pressure in the hydraulic motor chamber (9) and the dirt collector (7) is significantly lowered, and the dirt collector

nozzles (8) begin a suction process.

• The water flows through the hydraulic motor (9) which rotates the dirt collector (7) around its axis.

• The pressure released from the piston (5) and the high pressure inside the filter cause linear movement of the dirt

collector. The combination of the linear movement and rotation significantly cleans the entire internal screen

(3) surface.

• The flushing cycle takes about 10 seconds. The flushing valve (4) closes at the end of the cycle and the increased

water pressure returns the hydraulic piston (5) to its initial position. The filter is now ready for the next flushing cycle,

with clean and filtered water flowing through the “Outlet” (10).

Note: At the back of the piston is an indicator that pops up when the piston reaches the end of its motion. This indicator

helps us to check whether the dirt collector, inside the filter, completed it’s motion.

ELECTRONIC CONTROL SYSTEM (FIGURE 1)

• The electronic system (12) initiates the cleaning process based on either time differential (DT) and / or pressure

indicator differential.

• The trigger closes a circuit and then triggers the electronic control unit after a delay of 15 seconds.

• The electronic control unit (12) controls the opening and the closing of the flushing valves (4) via the solenoid valve (13).

• The flushing cycle, which takes a total of about 10 seconds (can be adjusted by the operator), resumes its operation

whenever the time cycle ends or the difference in pressure reaches the preset pressure value set in the controller.

• If the difference in pressure remains unchanged after one cycle, another cycle will start after a delay of 15 seconds.

FIGURE 1

SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION, INSTALLATION AND MAINTENANCE GUIDE •7

DIMENSIONS & WEIGHT

L1

L

D D

X

H

D1

L1

L

H

D1

DXD

10” FILTER

4”, 6” AND 8” FILTERS

W1

W

W3

W2

W

DIMENSIONS

SIZE

4”

6”

8”

10”

L

76.02”

78.78”

86.26”

106.29”

L1

85.83”

88.58”

96.08”

125.2”

X

35.43”

35.43”

35.43”

43.31”

D1

10”

10”

12”

16”

H

21.44”

21.84”

22.81”

28.35”

W3

-

-

-

23.93”

W

12.79”

12.79”

12.79”

16.0”

W1

12.95”

12.95”

13.77”

-

W2

-

-

-

24.16”

D (IN/OUT)

4”

6”

8”

10”

WEIGHT & PACKAGING

SIZE

4”

6”

8”

10”

WEIGHT

340 LBS.

346 LBS.

412 LBS.

893 LBS.

PACKAGING

7.9’ L X 2.5’ W X 1.9’ H

7.9’ L X 2.5’ W X 1.9’ H

8.5’ L X 2.9’ W X 2.1’ H

11.1’ L X 3.3’ W X 2.4’ H

8•SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

INSTALLATION

FIGURE 2

INITIAL FILTER INSTALLATION

1. Remove the filter assembly from the wood platform.

2. Connect the filter assembly to the inlet line and outlet line.

3. Connect a drain pipe to the hydraulic flushing valve outlet

opening (at least 2.48” plastic pipe or 2” metal pipe and no

more than 16.4’ long) Confirm that water runs freely out of the

drainpipe.

4. Check that all connections are properly secured.

5. Check that all nuts and bolts on the filter periphery are properly

tightened and secured.

6. Connect the batteries located in the control unit box as

explained in “Initial Operation” (See Figure 3).

INITIAL OPERATION

1. Gradually open the inlet valve (make sure that the outlet valve,

if installed, is open).

2. Check the filter assembly and its connections for leaks. Perform

a flushing cycle manually by pushing the test button located on

the outside of the control box (See Figure 3).

3. Verify that the hydraulic piston fully extends during backflush.

4. Verify that the hydraulic flushing valve closes after 10 seconds.

5. When the filter is clean, verify that the differential pressure

between inlet and outlet does not exceed 1.48 psi.

6. Check that the differential pressure is set to 7 psi in the

controller (see ‘Controller’ section). FIGURE 3

NETAFIM BACKFLUSH CONTROLLER

1. Refer to the Netafim Backflush Controller’s installation and operation manual for installation instructions. This

can be found on the Netafim USA website (www.netafimusa.com) in the Literature Download area. Also refer to

the installation video located on the Netafim USA YouTube page (www.youtube.com/netafimusa)

2. The manual will provide information on setting the operation parameters, pressure differential settings, flush time

and other required configurations.

SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION, INSTALLATION AND MAINTENANCE GUIDE •9

BATTERY REMOVAL & REPLACEMENT

The 4 x 1.5V battery enables the electronic control unit’s operation. The battery

can last for 3000 flushing cycles, but should be replaced every six months. Use

ONLY ALKALINE type battery.

1. Remove the upper cover of the controller.

2. Disconnect and remove the used battery.

3. Connect a new battery according to the correct polarity. The controller

will perform a long ‘beep’ sound.

4. Close the upper cover.

5. Perform a flushing cycle by disconnecting the low pressure tube from

the differential pressure indicator (thereby closing the electrical circuit)

- reconnect it immediately as flushing starts.

6. Verify that the hydraulic flushing valve closes after 10 seconds.

7. Perform an additional flushing cycle manually by pushing the manual

button (M on the screen display). (See Figure 4)

WARNING

Take precautions while

operating the filter as the

filter may enter a flushing

mode automatically,

without prior warning.

M

FIGURE 4

INSTALLATION

MAINTENANCE

BACKFLUSH CONTROLLER CONNECTIONS

10 •SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

CONTROL CARD REMOVAL & REPLACEMENT (FIGURE 5)

1. Disconnect the controller from power (AC) or remove batteries (DC).

2. Remove upper and lower cover. If there are any outputs card connected to the controller disconnect them.

3. Unscrew 5 screws (Red Circles). Disconnect power wires (Both AC & DC model - Blue Square).

Disconnect DP sensor, Pressure sensor and external DP (If exists - Yellow Square).

4. Turn on back and separate the back cover:

5. For DC model only - unscrew and remove step-up card.

6. Unscrew the main card - 4 screws (Red circles). Remove the card.

7. Place the new card and go backwards through the same steps as described above:

• Fasten the 4 screws

• Place the Step-up cards and fasten the screw (DC MODEL ONLY)

• Join the two plastic parts (Front and back) and turn to front

• Connect DP sensor, Pressure sensor and external DP (If exists - Yellow square)

• Connect power cable (Blue Square)

• Fasten the 5 screws (Red Circles)

• Reconnect the output cards to the controller. Reconnect solenoids (If disconnected before)

• Return the upper and lower cover

• Connect to power

FIGURE 5

2. 3. 4.

5. 6.

MAINTENANCE

SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION, INSTALLATION AND MAINTENANCE GUIDE •11

MAINTENANCE

SOLENOID REMOVAL & REPLACEMENT (FIGURE 6)

The solenoid hydraulically controls the flushing valve’s operation.

1. Remove the upper cover, disconnect and remove the (4) 1.5V batteries.

2. Disconnect the solenoid control tubes.

3. Remove the fittings from the damaged solenoid.

4. Disconnect the electrical wiring from the control card terminals.

5. Remove the nut from the solenoid lower section.

6. Pull the solenoid out of the control assembly.

7. Insert a new solenoid into the control assembly.

8. Reinstall the nut on the solenoid lower section.

9. Install the fittings on the ports of the new solenoid.

10. Connect the 2 wires of the solenoid (black wire to ‘C’ port, red wire to ‘1’ port).

11. Connect the solenoid control tubes.

12. Connect the (4) 1.5V batteries according to the correct polarity and close the electronic control unit cover.

13. Perform a flushing cycle by disconnecting the low pressure tube from the differential pressure indicator

(closing of the electrical circuit) - reconnect it immediately as flushing starts.

14. Verify that the hydraulic flushing valve closes after 10 seconds.

15. Perform an additional flushing cycle manually by pushing the manual button (M on the screen display). (See Figure 4).

FIGURE 6

WARNING

Take precautions while

operating the filter as the

filter may enter a flushing

mode automatically,

without prior warning.

12 •SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

HYDRAULIC PISTON ASSEMBLY REMOVAL & REPLACEMENT (FIGURE 7)

1. The hydraulic piston enables the linear movement of the dirt collector.

2. Close the inlet and the outlet line valves.

3. Verify that the filter is drained prior to service.

4. Disconnect the control tube from the piston assembly’s upper section.

5. Screw the brass base out (clockwise) of the filter body and carefully remove the piston assembly.

6. Remove the O-ring from the current piston assembly.

7. Position the O-ring in the new piston assembly.

8. Lubricate the O-ring with silicon grease.

9. Carefully slide the new piston assembly into the filter housing.

10. Screw (counterclockwise) the brass base into the filter body and tighten it gently.

11. Connect the control tube to the piston assembly’s upper section.

12. Open the inlet and the outlet line valves.

13. Check for leaks.

14. Push the piston indicator (on the rear side of the piston) inside.

15. Perform a flushing cycle manually by pushing the manual button (M on the screen display). (See Figure 4).

16. Verify that the piston travels its complete path and that the indicator pops up.

17. Verify that the hydraulic flushing valve closes after 10 seconds.

FIGURE 7

WARNING

Take precautions while

operating the filter as the

filter may enter a flushing

mode automatically,

without prior warning.

MAINTENANCE

SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION, INSTALLATION AND MAINTENANCE GUIDE •13

MAINTENANCE

COARSE SCREEN REMOVAL & REPLACEMENT (FIGURE 8)

1. Close the inlet and the outlet line valves.

2. Verify that the filter is drained prior to service.

3. Remove the nuts and washers connecting the cover to the filter housing.

4. Remove the cover seal from the cover groove.

5. Pull out the damaged coarse screen out from the fine screen assembly using the gripping

handle.

6. Slide the new coarse screen into the fine screen assembly using the gripping handle.

7. Verify that the straight side of the cover seal fits into the groove located in the cover.

8. Put the cover on its place on the filter’s housing and install the nuts and washers

connecting the cover to the filter housing.

9. Open the inlet and outlet line valves.

10. Check for leaks.

11. Perform a flushing cycle manually by pushing manual button (M on the screen display).

(See Figure 4)

12. Verify that the hydraulic flushing valve closes after 10 seconds.

FIGURE 8

WARNING

Take precautions while

operating the filter as the

filter may enter a flushing

mode automatically,

without prior warning.

14 •SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

FINE SCREEN ASSEMBLY REMOVAL & REPLACEMENT (FIGURE 9)

1. Close the inlet and the outlet line valves.

2. Verify that the filter is drained prior to service.

3. Remove the nuts and washers connecting the cover to the filter housing.

4. Remove the cover from the filter’s housing and remove the cover seal from the cover groove.

5. Pull out the coarse screen from the fine screen assembly using the gripping handle.

6. Pull the fine screen assembly out of the filter housing assembly with the dirt collector.

7. Remove both O-rings (445) from the current fine screen assembly.

8. Unscrew (clockwise - cw) the hydraulic motor from the dirt collector.

9. Unscrew (counterclockwise -ccw) the fine screen handle section from the fine screen, loosen using screen wrenches.

10. Carefully pull the dirt collector out of the fine screen assembly.

11. Unscrew (ccw) the fine screen damaged sections and replaced them with new sections.

12. Slide the dirt collector into the fine screen, through the dirt collector bearing.

13. Position both O-rings (445) into the new fine screen assembly, if required replace them.

14. Lubricate the O-ring (445) with silicon grease.

15. Screw (cw) the fine screen handle section to upper screen section; make sure the dirt collector axis passes through the screen

bearing. Tighten using screen wrenches.

16. Screw (ccw) the hydraulic motor to the dirt collector.

17. Slide the new fine screen assembly into the filter housing assembly.

18. Slide the coarse screen into the fine screen assembly.

19. Verify that the straight side of the cover seal fits into the groove located in the cover.

20. Put the cover on its place on the filter’s housing and Install the nuts and washers connecting the cover to the filter housing.

21. Open the inlet and the outlet line valves.

22. Check for leaks.

23. Perform a flushing cycle manually by pushing the manual button (M on the screen display). (See Figure 4).

24. Verify that the hydraulic flushing valve closes after 10 seconds.

FIGURE 9

WARNING

Take precautions while

operating the filter as the

filter may enter a flushing

mode automatically,

without prior warning.

MAINTENANCE

SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION, INSTALLATION AND MAINTENANCE GUIDE •15

MAINTENANCE

DIRT COLLECTOR REMOVAL & REPLACEMENT (FIGURE 10)

1. Close the inlet and the outlet line valves.

2. Verify that the filter is drained prior to service.

3. Remove the nuts and washers connecting the cover to the filter housing.

4. Remove the cover from the filter’s housing and remove the cover seal from the cover groove.

5. Pull out the coarse screen from the fine screen assembly using the gripping handle.

6. Pull the fine screen assembly out of the filter housing assembly with the dirt collector.

7. Unscrew (clockwise - cw) the hydraulic motor from the dirt collector.

8. Unscrew (counterclockwise -ccw) the fine screen handle section from the fine screen, loosen using screen wrenches.

9. Carefully pull the dirt collector out of the fine screen assembly.

10. Slide the new dirt collector into the fine screen, through the dirt collector bearing.

11. Screw (cw) the fine screen handle section to upper screen section; make sure the dirt collector axis passes through the screen

bearing. Tighten using screen wrenches.

12. Screw (ccw) the hydraulic motor to the dirt collector.

13. Slide the fine screen assembly into the filter housing assembly.

14. Slide the coarse screen into the fine screen assembly.

15. Verify that the straight side of the cover seal fits into the groove located in the cover.

16. Put the cover on its place on the filter’s housing and Install the nuts and washers connecting the cover to the filter housing.

17. Open the inlet and the outlet line valves.

18. Check for leaks.

19. Perform a flushing cycle manually by pushing the manual button (M on the screen display). (See Figure 4).

20. Verify that the hydraulic flushing valve closes after 10 seconds.

FIGURE 10

WARNING

Take precautions while

operating the filter as the

filter may enter a flushing

mode automatically,

without prior warning.

16 •SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

MAINTENANCE

PERIODIC CHECKS

Perform yearly or periodical checks at the beginning of the season, according to the following:

1. Replace the (4) 1.5V batteries at the beginning of every season or every six months;

refer to ‘Battery Removal & Replacement’.

2. Check the condition of the coarse screen. If damaged, replace according to ‘Coarse Screen Removal & Replacement’.

3. Check the condition of the fine screen assembly. If damaged, replace according to ‘Fine Screen Assembly Removal &

Replacement’.

4. Check the condition of the dirt collector bearing and screen bearing. If any of the bearings have become misshaped, (oval),

replace with a new one.

5. Check the mechanical condition of the hydraulic piston assembly. Verify piston’s free movement. If damaged or deteriorated,

replace according to ‘Hydraulic Piston Assembly Removal & Replacement’.

6. Check the dirt collector suction nozzles height (see table). If damaged, replace according to ‘Dirt Collector Removal &

Replacement’.

7. Check the condition of the controller while operating with running water.

8. Check the filter housing for paint damage or corrosion. If required, clean the area with sandpaper and apply a thin layer

of basic + epoxy paint.

9. Check for leaks.

FIGURE 11

NOZZLE HEIGHT

TYPE

2.99”

HEIGHT

All Filters

FIGURE 12

SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION, INSTALLATION AND MAINTENANCE GUIDE •17

TROUBLESHOOTING

SYMPTOMCHECK SOLUTIONS

Filter flushing cycle

does not stop

PROBLEM

Check condition of battery and

solenoid by connecting the

solenoid wires directly to the

battery.

If the distributor unit aperture clogged, clean it.

If the distributor unit aperture is not clogged

and the flushing valves do not flush, disconnect

the control tube from the actuator’s lower

section and verify water pressure.

Flushing does not

stop

If there is no water pressure - check the

control tube for obstructions

If there is water pressure - replace the

mechanical actuator

SYMPTOMCHECK SOLUTIONS

Flushing cycle

doesn’t start

Pressure difference

between inlet and

outlet - above 7 psi

PROBLEM

Flushing cycle

starts

Check the differential pressure

indicator adjustment.

Verify that the line pressure

matches the filter’s operational

pressure.

Perform an additional flushing

cycle manually by pushing the test

button located on the outside of

the control box. (See Figure 3).

Disconnect the control tube from the flushing

valve's lower section. Perform a flushing cycle

manually, by operating the handle located on

the solenoid.

Check the hydraulic flushing valve for

obstruction and replace if required.

If Control Water is present, the solenoid is faulty

and should be replaced. If no Control Water is

present, check the distributor unit or the control

tube for obstructions.

Water doesn’t

come out of the

control tube

Water comes out of

the control tube

Check the hydraulic flushing valve for

obstruction and replace if required.

Check battery condition. Replace bad batteries.

If battery is okay, check the electrical

connections on the control card and the

solenoid electrical connection at the

differential pressure indicator.

If connections are not okay, connect properly.

If connections are okay, short the differential

pressure indicator wires on the control card.

If the flushing cycle starts, replace the

differential pressure indicator.

If the flushing cycle doesn’t start - See A.

Check solenoid operation by

connecting the wires

directly to the battery.

Solenoid clicks and

flushing cycle

starts

Solenoid clicks and

flushing cycle does

not start

Solenoid doesn't

click at all (not

operating)

Replace the control card.

Check inlet and outlet line pressures.

Pressure reading above 15 psi - faulty solenoid.

Pressure reading below 15 psi - the filter does

not comply with the system operating

requirements.

Close the outlet valve and check that

differential pressure between inlet and outlet of

the filter is zero.

Perform a flushing cycle manually by operating

the handle (turn clockwise 90o) located on the

solenoid and open the outlet valve.

Differential pressure nullified - the filter was

badly clogged.

Differential pressure remains the same - See B.

Replace the solenoid.

A

BDisassemble the filter and check:

1. Dirt collector rotates freely

2. Upper bearing and screen

bearing are not deformed

(oval in shape)

Replace the defective part and/or release the

jammed part.

Reassemble the filter and operate the system.

Filter found serviceable - the problem was not

solved during a regular service check, call

technician.

18 •SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

REPLACEMENT PARTS

1

234

5

67

9

10

11

12

13

14

15

16

17

8.3 8.1

8.2

9.1

9.2

8.2.2

8.2.3

10.1

11.1

12.1

14.1

19.2

8.2.1

18

19

8.1

20

NOTE: Substitute *** with desired mesh.

Filter Body

Filter Cover

Cover O-Ring

Stud 1/2” SS304

Washer M12 SS304

Nut 1/2“ Galvanized

Coarse Screen for 4”

Coarse Screen for 6“

Coarse Screen for 8”

Screen O-Ring

Upper Screen Adapter

Upper Screen Adapter Body

Screen Wheel

Dirt Collector Screen Bearing

Screen Only 4“ to 8”

Flushing Chamber

Flushing Chamber Body

Dirt Collector Bearing

Dirt Collector Assembly

Suction Nozzle Saddle

Hydraulic Motor

Head Collector Bearing

Hydraulic Piston

Hydraulic Piston O-Ring

Backflush Valve Galit

Repair Kit for Backflush Valve

Short Distributor

Short Distributor O-Ring

Pressure Gauge Set

Plug 1/4“ Plastic

Male Branch Tee 1/4”

Male Elbow 1/8“

Netafim Backflush Controller DCL

Aquative DCL with 1 Bracket

BSP to NPT Adapter Coupling 2”

Item Number Model Number DescriptionKey

1

2

3

4

5

6

7

8.1

8.2

8.2.1

8.2.2

8.2.3

8.3

9

9.1

9.2

10

10.1

11

11.1

12

12.1

13

-

14

14.1

15

16

17

18

19

19.2

20

-

-

72000-009590

72000-018400

72000-008511

72000-008495

72000-104500

72000-104520

72000-018498

72000-016940

72000-092050

-

72000-018530

72000-018510

-

72000-000310

-

72000-000320

72000-018561

72000-018300

72000-018960

72000-018582

72000-018900

72000-016960

72000-015520

-

72000-018850

72000-016905

72000-017350

72000-008545

72000-019240

72000-019250

00105-006250

35500-002020

-

Not Sold Separately

Not Sold Separately

79COVERORING

27APBOLT

79WSHRM12SS304468

79ASFNUT12GALV468

79ASFCOARSESCR4

79ASFCOARSESCR6

27APCOARSCRN

79ASFSCRORING468

79ASFUPRSCRADTR468

79ASFUPRSCRADBD468

79ASFSCRWHEEL468

79ASFDCOLLSCBRG468

79ASFSCRONLY468***

79ASFFLUSHCHAM468

79BDFLUSHCHAM468

79ASFDCOLLBRNG468

79ASFDCOLL468

79ASFSCTNOZSADL468

79ASFHYDMOTOR468

79ASFHDCOLLBRNG468

79ASFHYDPISTON468

79ASFHYDPSTORNG468

79ASFBACKFLUSHVLV

61GALIL2RKIT

79ASFSHORTDIST468

79ORNGSHORTDIST468

79ASFPRESSGAUGE

79ASFPLG46810

79ASFBRANCHT14468

79ASFMALEELL18468

31NBCDCL2

61AQTVDCL1

79ASF2BSPNPTADTR

SCREENGUARD AUTOMATIC SCREEN FILTER PARTS

4”, 6” and 8“ Sizes

SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION, INSTALLATION AND MAINTENANCE GUIDE •19

REPLACEMENT PARTS

1

2 3

5

67

9

10

11

12 13 14

15

16

17

8.1

8.2 9.1 9.2

16.1

16.2

18 19

4.1

4.2

21.2

21

22

23

14.1

20

9.8

9.5

9.7

8.4 9.6

9.3 9.4

8.38.1

NOTE: Substitute *** with desired mesh.

Filter Body

Filter Cover

Cover O-Ring

Stud 3/4” NC 73 SS304

Stud 3/4” NC130 SS304

Washer M20 SS304

Nut 3/4“ Galvanized

Coarse Screen for 10”

Service Cover Gasket

Coarse Screen 10“

Screen Wheel

Dirt Collector Screen Bearing

Dirt Collector Assembly

Dirt Collector Upper Plug

Dirt Collector Shaft

Dirt Collector Middle Plug

Dirt Collector Shaft Tightening Nut

Flat Head Screw SS304

Oval Head Screw SS304

Suction Nozzle

Dirt Collector Lower Plug

Hydraulic Motor

Dirt Collector Head Bearing

Stud 5/16” SS304

Nut 5/16” Brass

Hydraulic Piston

Hydraulic Piston O-Ring

Backflush Valve Galit

Repair Kit for Backflush Valve

Double Distributor

Accelerator Pilot O-Ring

Pilot 25300

Pressure Gauge Set

Plug 1/4“ Plastic

Male Branch Tee 1/4”

Male Elbow 1/8“

Netafim Backflush Controller DCL

Aquative DCL with 1 Bracket

BSP to NPT Adapter Coupling 2”

O-Ring, BSP to NPT Adapter Coupling 2”

Item Number Model Number DescriptionKey

1

2

3

4.1

4.2

5

6

7

8.1

8.2

8.3

8.4

9

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

10

11

12

13

14

14.1

15

-

16

16.1

16.2

17

18

19

20

21

21.2

22

23

-

-

72000-009595

72000-018398

72000-018396

72000-008509

72000-008501

72000-105000

72000-016945

-

72000-018520

72000-018567

72000-027987

72000-010582

72000-018593

72000-017414

72000-018584

72000-008558

72000-008557

72000-018329

72000-107053

72000-018924

72000-018595

72000-018402

72000-008502

72000-018350

72000-016965

72000-015520

-

72000-090250

72000-016905

72000-007040

72000-017350

72000-008545

72000-019240

72000-019250

00105-006250

35500-002020

-

-

Not Sold Separately

Not Sold Separately

79COVERORING10

79STUD3473SS30410

79STUD34130SS30410

79WSHRM20SS30410

79ASFNUT34GALV10

79ASFCOARSESCR10

79SCGASKET10

79ASFSCRONLY10-***

79ASFSCRWHEEL10

79ASFDCOLLSCRBRG10

79ASFDCOLL10

79ASFDCOLLUPRPLG10

79ASFDCOLLSHFT10

79ASFDCOLLMDLPLG10

79ASFDCOLLSHFTNT10

79ATCHSCRW34FLT10

79ATCHSCRW34OVL10

79ASFSCTNOZ10

79ASFDCOLLPLUGLWR

79ASFHYDMOTOR10

79ASFDCOLLHDBRNG10

79STUD51629SS30410

79NUT516NCBRSS10

79ASFHYDPISTON10

79ASFHYDPSTORNG10

79ASFBACKFLUSHVLV

61GALIL2RKIT

79ASFDOUBLEDIST10

79ASFACCORING10

61PIL25300

79ASFPRESSGAUGE

79ASFPLG46810

79ASFBRANCHT14468

79ASFMALEELL18468

31NBCDCL2

61AQTVDCL1

79ASF2BSPNPTADTR

79ASF2BSPNPTADORNG

SCREENGUARD AUTOMATIC SCREEN FILTER PARTS

10” Size

20 •SCREENGUARD AUTOMATIC SCREEN FILTERS OPERATION INSTALLATION AND MAINTENANCE GUIDE

NETAFIM USA

5470 E. Home Ave.

Fresno, CA 93727

CS 888 638 2346

www.netafimusa.com

SGOPS 01/18

REPLACEMENT PARTS

Actuator Assy (All Internal Components)

Shaft

Sealing Coupling Nut

U-Lock

Seal Disc

Body

Operator Body

ID Plate

O-Ring #2-227, Buna-N-Rubber

O-Ring, #6-075, Buna-N Rubber

Small Disc

Diaphragm

Large Disc

Large Disc Bolt

Diaphragm Spring

Bonnet

Bonnet Bolt

Bonnet Bolt Nut

Washer

Seal

Cone

Nut

Item Number Model Number DescriptionKey

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

-

-

71680-017150

71680-017160

71680-015620

-

-

-

71680-014350

-

-

71680-007430

-

-

71680-008000

71680-007850

-

-

-

71680-003200

71680-017050

71680-017070

61GALIL2RKIT

-

-

-

61GALILSDRF2

-

-

-

61FG2980R

-

-

61DIA298

-

-

61SP2

61GALILBON2

-

-

-

61FG2RS

61GALILCONERF2

61GALILLNRF2

SCREENGUARD BACKFLUSH VALVE PARTS

NOTE: Parts with Item Number and/or Model Number listed are stock and available for purchase.

All other parts are for identification purposes only.

1

2

3

5

6

7

9

9

10

11

12

13

14

15

16

17

18

19

21

20

8

4

Other manuals for SCREENGUARD

1

Table of contents

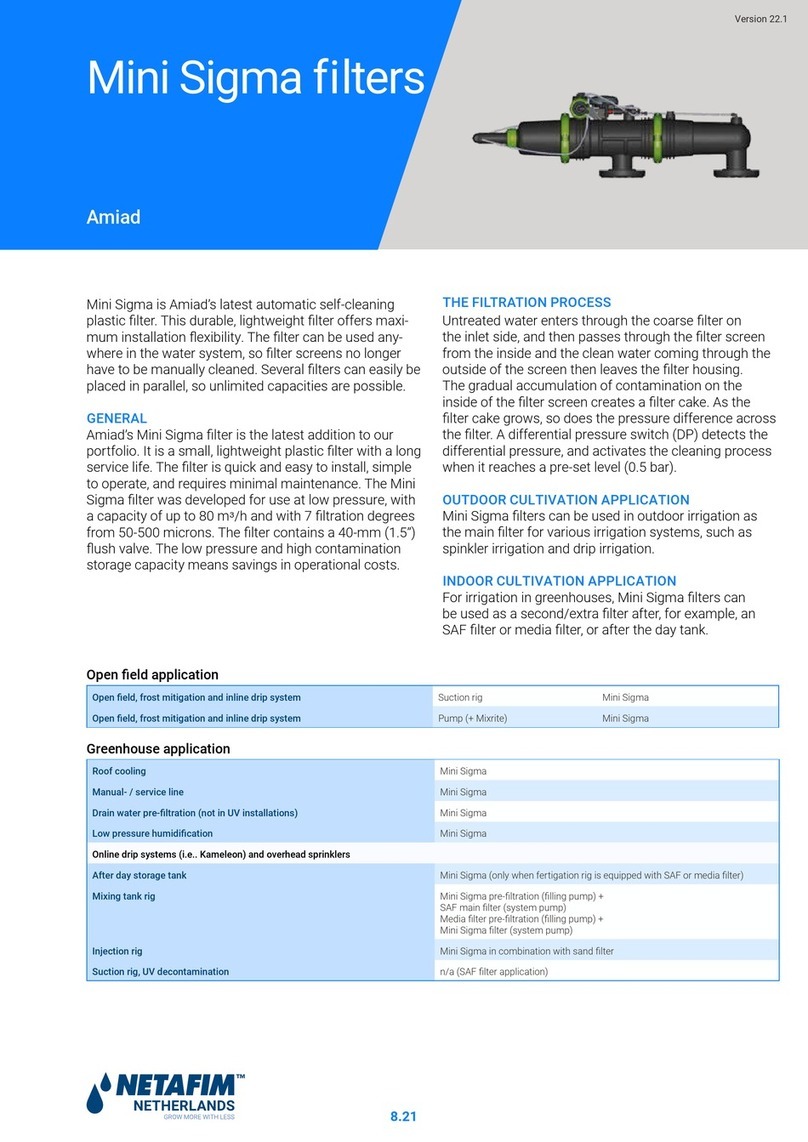

Other Netafim Water Filtration System manuals

Netafim

Netafim Apollo Instruction Manual

Netafim

Netafim Amiad Mini Sigma 2 1200 User manual

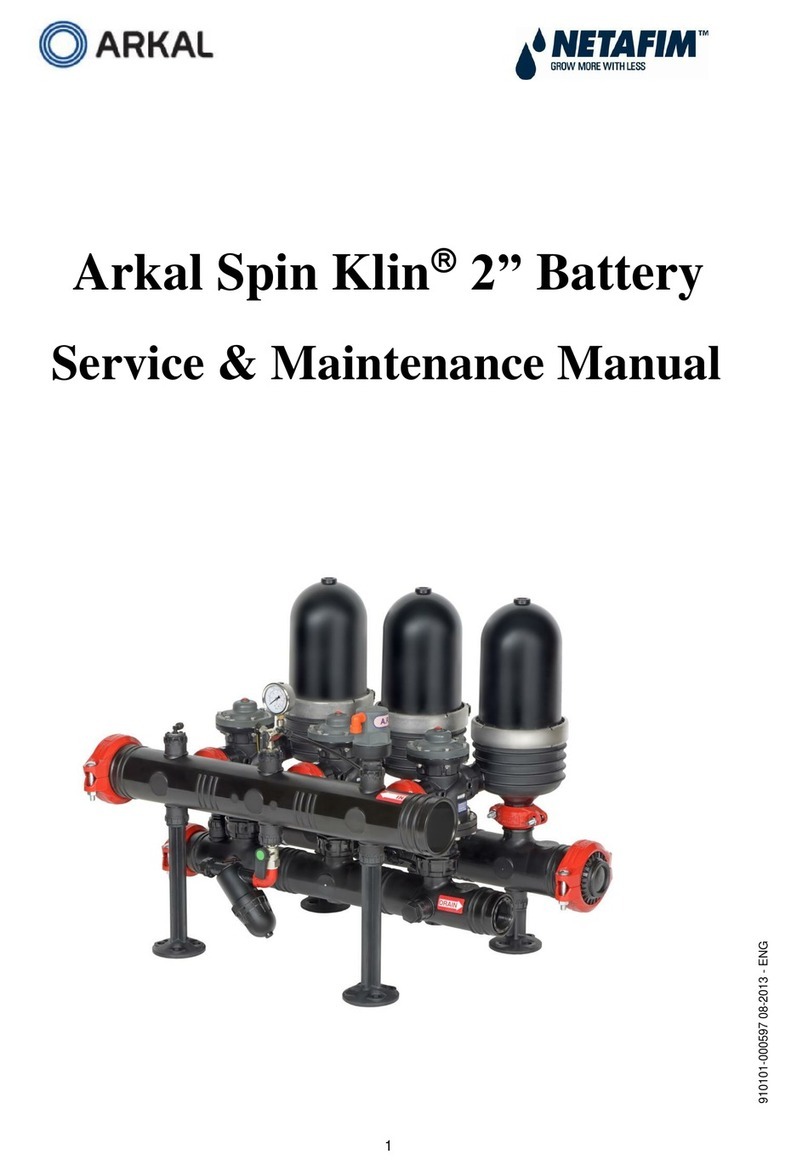

Netafim

Netafim Arkal 3" Spin-Klin Battery User manual

Netafim

Netafim AlphaDisc Series User manual

Netafim

Netafim 25AP46 Series Guide

Netafim

Netafim SCREENGUARD User manual

Netafim

Netafim Arkal 3" Spin-Klin Battery Installation and operating instructions

Netafim

Netafim SANDSTORM User manual

Netafim

Netafim APOLLO DISC-KLEEN Instruction Manual

Netafim

Netafim Arkal 2" Spin-Klin Compact Stand Alone... User manual