Netafim SANDSTORM User manual

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

MTL SNG 480308 S D08 BFC DC SOL DC NGR.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

MTL SNG 480308 S D08 BFC DC SOL DC

NGR

13/02/2017

Barga

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

A-26577-220817

MTL DBL 480308 S for manual isometric wireframe.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

MTL DBL 480308 S D08 BFC DC SOL DC

NGR

13/02/2017

Tamir Itai

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

V 001.01 - MARCH 2018

USER MANUAL

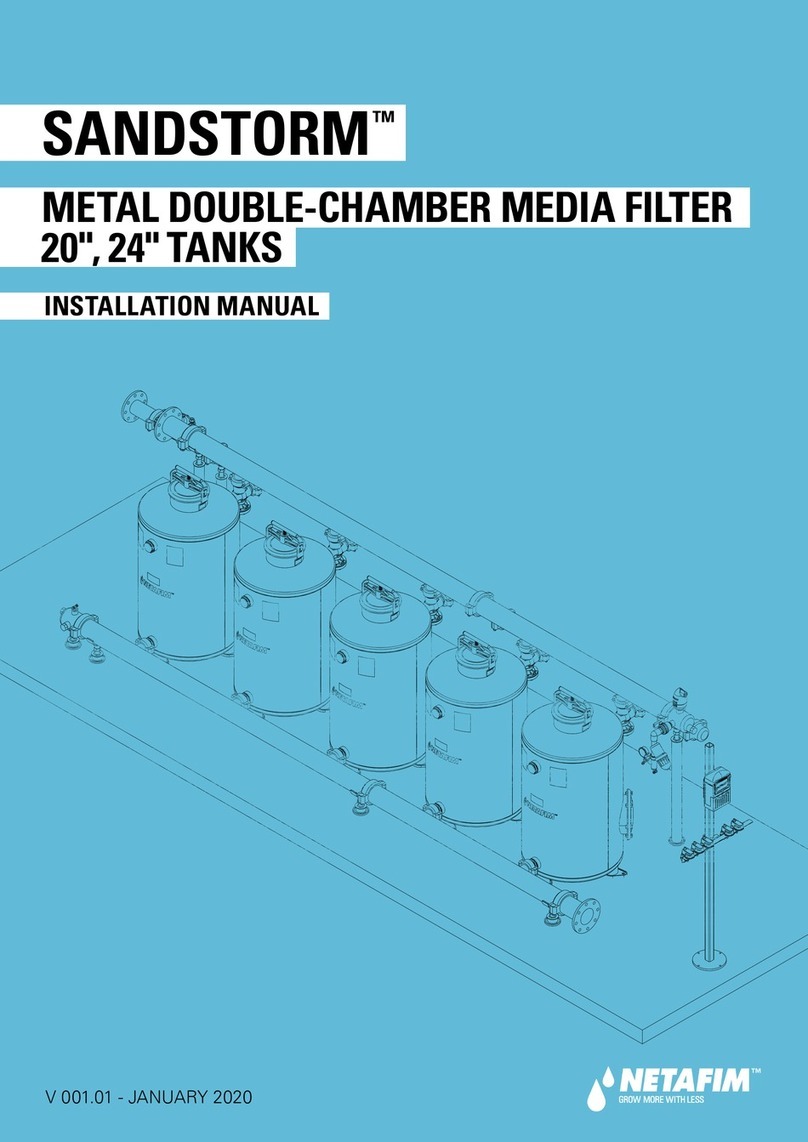

SANDSTORM

™

METAL SINGLE-/DOUBLE-CHAMBER

MEDIA FILTER

© COPYRIGHT 2018, NETAFIM™

NO PARTS OF THIS PUBLICATION MAY BE REPRODUCED, STORED IN AN AUTOMATED DATA FILE OR MADE PUBLIC IN

ANY FORM OR BY ANY MEANS, WHETHER ELECTRONIC, MECHANICAL, BY PHOTOCOPYING, RECORDING OR IN ANY

OTHER MANNER WITHOUT PRIOR WRITTEN PERMISSION OF THE PUBLISHER.

ALTHOUGH NETAFIM™TAKES THE GREATEST POSSIBLE CARE IN DESIGNING AND PRODUCING BOTH ITS PRODUCTS

AND THE ASSOCIATED DOCUMENTATION, THEY MAY STILL INCLUDE FAULTS.

NETAFIM™WILL NOT ACCEPT RESPONSIBILITY FOR DAMAGE RESULTING FROM THE USE OF NETAFIM'S PRODUCTS

OR THE USE OF THIS MANUAL.

NETAFIM™RESERVES THE RIGHT TO MAKE CHANGES AND IMPROVEMENTS TO ITS PRODUCTS AND/OR THE

ASSOCIATED DOCUMENTATION WITHOUT PRIOR NOTICE.

FOREIGN LANGUAGES

In the event that you are reading this manual in a language other than the English language, you

acknowledge and agree that the English language version shall prevail in case of inconsistency or

contradiction in interpretation or translation.

CONTENTS

Introduction

Aim of this manual

Safety instructions

Tools required for maintenance and troubleshooting

Flange connection

Filtration system components and structure - single-chamber

Filtration system components and structure - double-chamber

Initial operation and adjustment

Maintenance

Once a week

Once every three months

At the end of the irrigation season

At the beginning of the next irrigation season

Algae and bacterial growth control

Replacing the media

Replacing the batteries in the BackFlush controller

Paint retouching of the tanks and manifolds

Cleaning the secondary filter

Troubleshooting

If the pressure difference across the filtration system is over 0.7 bar (10.15 PSI)

and the flushing cycle does not reduce it

If the flushing cycle does not start but the controller is initiating the flushing signal

and the solenoids are reacting (“clicking”)

If the media is running out through the backwash manifold during backwash

If media is running out through the outlet manifold during filtration

Replacement parts

Tanks - single-chamber

Tanks - double-chamber

Manifold sections

Manifolds accessories

Grooved couplings

Support legs

Control kit

Backwash 3-way hydraulic valve 2"

Backwash 3-way hydraulic valve 3"

Backwash 3-way hydraulic valve 4"

Backwash flow-control valve

BackFlush controller

DC actuator valve

Air Valve

Inlet adaptor pipe

Secondary filter

Warranty

4

4

5

5

6

7

8

10

10

11

12

13

14

15

16

16

18

18

18

19

20

22

24

25

25

26

27

28

30

32

34

35

35

35

36

36

37

4 SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL

Aim of this manual

The aim of this manual is to provide the user with general instructions for operation, maintenance and

troubleshooting of any configuration of the SandStorm™ metal single- or double-chamber media filtration

system.

All system components are shipped to the site packed in pallets and boxes with installation drawings, user

manual, and a packing list.

NOTE

This manual describes the operation, maintenance and troubleshooting processes of a generic

SandStorm™ filtration system and must be used in unison with the drawings supplied with the system.

Safety instructions

Before handling any part of the system, carefully read the instructions and act accordingly.

NOTE

The maximum working pressure of the filtration system is 8 bar (116 PSI). Make sure the pressure

at the inlet of the filtration system is not higher. (For filtration systems made to order, see the

maximum working pressure in the Product Order).

Check and make sure the pumps and valves do not exceed the tolerances of the system and match the

requirements of the system pressure and flow-rate specifications (see the documentation supplied with

the system).

WARNING

Do not perform maintenance operations or open filter ports before the pressure in the system is

fully released. For draining purposes, open any valve downstream from the filtration system until

the pressure is fully released. Check the pressure gauge to be sure it is at 0 before proceeding.

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

MTL SNG 480308 S with drainning valve.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

MTL SNG 480308 S D08 BFC DC SOL DC

NGR

13/02/2017

Barga

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

TIP

If a valve downstream from the filtration system is not available

for pressure release, you can install a manual valve on the lower

2" socket of the outlet manifold end-cap.

Electrical connections and wiring must be done by an authorized electrician only.

Be sure that prior to any maintenance procedures, all electrical connections to the system are unplugged

(AC controller, pumps, etc.).

Do not apply excessive force or pressure on the filtration system components.

Work only with proper and standard tools.

Use only original parts supplied/approved by Netafim™.

INTRODUCTION

SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL 5

INTRODUCTION

Handling sodium hypochlorite (NaClO) or hydrogen peroxide (H2O2)

WARNING

Sodium hypochlorite (NaClO) and hydrogen peroxide (H

2

O

2

) are dangerous toxic and corrosive

chemicals. All application regulations and safety rules must be observed. Store and handle them

according to safety regulations.

Before handling

sodium hypochlorite (NaClO)

or

hydrogen peroxide (H

2

O

2

)

, carefully read all the

specific safety, health protection and first aid information and instructions.

Be sure you have all

required first aid at the site, as instructed

.

Concentrated liquid sodium hypochlorite (NaClO) or hydrogen peroxide (H2O2) can damage exposed

metal (especially threads that are exposed to water). Be careful when applying them and avoid the

spillage of any of the liquid onto exposed metal parts. Should any of the liquid come into contact

with metal parts, immediately wash thoroughly with fresh water.

Tools required for maintenance and troubleshooting

•No special tools are needed. A standard toolkit is adequate.

•To connect grooved couplings: The following wrenches are required:

Grooved coupling size Bolt and nut size

(mm)

Wrench size

(mm)

inch mm

250 M10 17

380 M12 19

4100 M12 19

6150 M16 24

8200 M20 30

10 250 M22 34

•To connect flanges: The following wrenches are required:

Flange size Bolt and nut size Wrench size

up to 8" 5/8" 15/16"

10" to 14" 7/8" 1.1/ 8 "

Flange connection

In most cases, the filtration system manifolds are connected to the main line with flanges.

ATTENTION

When connecting flange pipe connectors, do not forget to place the rubber gasket in place.

6 SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL

INTRODUCTION

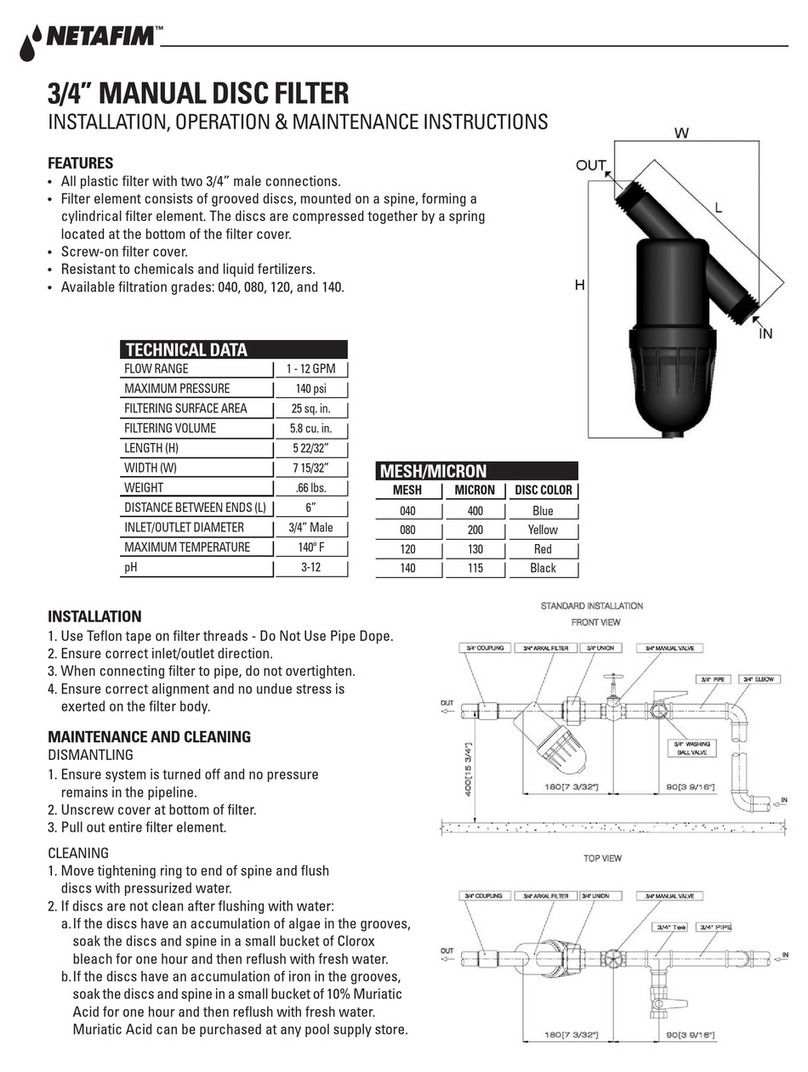

Filtration system components and structure

Single-chamber media filtration system

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

MTL SNG 480308 S D08 BFC DC SOL DC NGR.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

MTL SNG 480308 S D08 BFC DC SOL DC

NGR

13/02/2017

Barga

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

Media filter tank

Backwash 3-way hydraulic valves

Backwash

flow-control valve

Filtration system

control kit

Air valve

Inlet manifold

Outlet manifold

Backwash manifold

Grooved coupling

Manifold support legs

Inlet flange adaptor

Outlet

flange adaptor

Backwash

flange adaptor

Location of the tank ports

1Filling port

2Side service port

3Bottom service port

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

P-53531-140317

48'' SINGLE CHAMBER MEDIA FILTER.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

48'' SINGLE CHAMBER MEDIA FILTER

ASSEMBLY V170228

06/06/2017

Tamir Itai

Material <not

specified>

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

1

2

2

3

SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL 7

INTRODUCTION

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

A-26577-220817

MTL DBL 480308 S for manual isometric color.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

MTL DBL 480308 S D08 BFC DC SOL DC

NGR

13/02/2017

Tamir Itai

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

Media filter tank

Backwash 3-way hydraulic valves

Backwash

flow-control valve

Filtration system

control kit

Air valve

Inlet manifold

Outlet manifold

Backwash manifold

Grooved coupling

Manifold support legs

Inlet flange adaptor

Outlet

flange adaptor

Backwash

flange adaptor

Location of the tank ports

1Filling port

2Side service port

3Bottom service port

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

P-51603-080117

48inch Gravel filter 2.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

48inch Gravel filter

16/01/2017

Tamir Itai

Material <not

specified>

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

1

22

3

Filtration system components and structure

Double-chamber media filtration system

8 SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL

INITIAL OPERATION AND ADJUSTMENT

DP ACTUAL

DP SET

FLUSH

TIME

FLUSH

MODE

BARSec Hours

MANUAL

ENTER

The actual DP value.

Available only when the built-in

electronic DP sensor is used.

The DP set-point.

Available only when the built-in

electronic DP sensor is used.

The desired

flushing time

per station. The desired flushing mode.

Contains either the flushing

interval or, when the flushing

is triggered by DP only, the

letters “DP.”

1.

Set the BackFlush controller:

The controller is equipped with an LCD display and 4 keys, as displayed below. When the unit is left

untouched for a minute, the display switches off and a beep is heard every 20 seconds to indicate it is

working.

Holding down any of the keys for a few seconds will bring the screen back to life.

The screen consists of several fields. Some of them are editable and some of them are not.

To enter the EDIT MODE, press the key. The EDIT MODE is indicated by blinking of the currently

editable field.

Each time you press the key, the next editable field becomes active and starts blinking.

Use the and keys to change the value in the active field.

Press the key again to set the selected value for the current field and move to the next editable field.

To return to a previous field during the process of passing through the editable fields, press the key

repeatedly until you get back to the FLUSH TIME field, and there are blinking fields. You can then begin

the process again.

Configuration

Parameter Definition Action

Main valve

(sustaining valve)

The pre-dwell delay between the main valve

opening and the opening of station 1

Select:

YES

if exists

Enter:

20 sec

Dwell time

The backwashing delay between stations Enter:

10 sec

DP delay

The delay during which the DP sensor reading

is expected to remain stable before reaction

Enter:

10 sec

Looping limit

The number of consecutive flushing cycles

triggered by the DP sensor before deciding

that there is an endless looping problem

Enter:

3

Alarm

Allocates one output for alarm activation Select:

YES

Delay valve

Allocates one output for delay-valve activation Select:

YES

if exists

(continued on the next page)

SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL 9

INITIAL OPERATION AND ADJUSTMENT

Parameter Definition Action

View outputs

This is a special mode that enables the user to

review the list of outputs and their allocations.

The output number is displayed in the bottom

left corner and its allocated function appears in

large letters in the center of the screen

Use the

key to toggle between

NO and YES and confirm by

pressing

the key

. Keep using

the

key to review the list

Pressure units

Select the units to be used for pressure

measurement

Select:

BAR

or

PSI

Calibration

Zero calibration of the built-in electronic DP

sensor.

Disconnect the sensor ports from

the command tube and open them

to atmospheric pressure;

then select calibration:

YES

Version display

Displays the controller's software version-

number.

No action required.

Press the key twice to

proceed.

Flush time

The desired flushing time per station. Enter:

100 sec

DP set-point

The pressure difference between the filter’s

inlet and outlet that initiates a flushing cycle.

Enter:

0.7 bar

or

10 PSI

Flush mode

The flushing interval or, when the flushing is

triggered by DP only, the letters “DP.”

Enter:

3 hours

(For full instructions, see the BackFlush controller manual).

NOTE

If the filtration system was not ordered with a BackFlush controller and is used with an existing

irrigation system controller, see your irrigation controller user manual for instructions.

2.

Turn on the water and start irrigation.

3.

As soon as the system is pressurized and stable, start a manual backwashing cycle by pressing the

key. The icon will appear on the display (to manually terminate a backwashing cycle in progress,

press the same key).

4.

After completion of a full backwashing cycle, check that the filtration system DP is within the operational

range (0.15-0.4 bar/2.2-5.8 PSI, depending on the flow rate). Toggle the control kit 3-way ball valve and

note the filtration system inlet and outlet pressure. Subtract the outlet pressure from the inlet pressure.

The result is the filtration system DP.

5.

Check all the filtration system connections for water leaks – re-fit, re-connect and re-secure if necessary.

6.

Check all the command tube connections for leaks – re-fit, re-connect, and re-secure if necessary.

7.

Check that the backwashing cycle is performed in the correct order and that all the filters in the system

are backwashed in sequence.

8.

Check the secondary filter (if installed) for the presence of gravel.

NOTE

If a secondary filter is not installed, disconnect the main line pipe downstream from the filtration

system, let the water flow to the ground and visually check for the presence of gravel.

If gravel is present, see Troubleshooting, page 17.

ATTENTION

Steps

2

to

8

above should be performed whenever the operation of the filtration system is resumed

after being idle (i.e., after seasonal shutdown, maintenance or troubleshooting operations).

Configuration (continued)

10 SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL

MAINTENANCE

NOTE

It is highly recommended to keep track of the filtration system pressure regime. Make a dated list

of all maintenance activities with system pressure data.

Once a week

While the system is working:

1.

Start a manual backwashing cycle by pressing the key (the icon will appear on the display) and

check that the backwashing happens in sequence according to your backwash controller setup (to

manually terminate a backwashing cycle in progress, press the same key).

2.

Check that during the last 10 seconds of the backwash of every filter, the water from the backwash

manifold runs out freely and clean.

3.

After completion of a full backwashing cycle, check that the filtration system DP is within the

operational range (0.15-0.4 bar/2.2-5.8 PSI, depending on the flow rate). Toggle the control assembly

3-way ball valve and note the filtration system inlet and outlet pressure. Subtract the outlet pressure

from the inlet pressure. The result is the filtration system DP.

4.

Check the control assembly filter and clean it (blockage of this filter will cause a malfunction of the

backwashing process).

5.

Check for leaks from connections and fittings - re-fit, re-connect and re-secure if necessary.

6.

Open the secondary screen filter (if installed) and check its condition - if necessary, take out the filtration

element and clean it with high pressure water. Put the filtration element back in place and close the

filter.

7.

Check the filtration system visually for any damage to the paint. If the protective coating of the tanks

and/or manifolds is damaged, see Paint retouching of the tanks and manifolds, page 16.

For further assistance, contact your local Netafim™ representative.

Once every three months

While the system is working:

1.

Perform steps 1 - 5 as described in the weekly maintenance section above.

2.

Release the pressure from the filtration system. Open any valve downstream from the filtration system

or the manual valve (if installed) on the outlet manifold end-cap until the pressure is fully released.

Check the pressure gauge to be sure it is at 0 before proceeding.

3.

Empty all the water from the filtration system. Open any valve downstream from the filtration system or

the manual valve (if installed) on the outlet manifold end-cap.

4.

Open the filling port (top port) of all the tanks.

TIP

To speed up emptying the water from the filtration system,

you can temporarily dismantle the outlet manifold end-cap.

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

MTL SNG 480508 S D08.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

MTL SNG 480508 S D08 BFC DC SOL DC

NGR

13/02/2017

Barga

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL 11

MAINTENANCE

5.

Visually check the filtration system (externally and inside the tanks, with the aid of a flashlight) for

any damage to the paint. If the protective coating of the tanks and/or manifolds is damaged, see Paint

retouching of the tanks and manifolds, page 16.

6.

Check the level of media inside the filters.

•If the level is lower than the media level marker on the filter tank - add media.

•If the level is higher than the media level marker on the filter tank - remove media.

7.

Manually stir the media inside the tank and check for media solidification.

•If the media has solidified, crumble it with high pressure water.

WARNING

Do not use tools (such as a shovel) to crumble the media, as this could damage the elements inside

the tank.

8.

Open the secondary screen filter (if installed) and check its condition - if necessary, remove the filtration

element and clean it with high pressure water. Put the filtration element back in place and close the

filter.

For further assistance, contact your local Netafim™ representative.

At the end of the irrigation season

ATTENTION

Never leave the filtration system unclean for the winter season.

1.

During the last irrigation cycle of the season: Check the filtration system inlet and outlet pressure and

make sure that they and the DP (Delta pressure) fit the system benchmark data.

2.

Perform all actions as described in the weekly maintenance section, page 10.

3.

Check that the backwashing parameters in the controller are correct. If not, enter the correct data.

4.

Close the water inlet to the filtration system.

5.

Perform steps 2 - 4 as described in the quarterly maintenance section, page 10.

6.

Check the level of media inside the filters.

•If the level is lower than the media level marker on the filter tank - add media.

•If the level is higher than the media level marker on the filter tank - remove media.

7.

Open the secondary screen filter (if installed) and check for gravel. If there is gravel, empty the tank that

is losing media and replace the damaged under-drain diffuser/s ("flute/s" or "mushroom/s")

(see Replacing a damaged under-drain diffuser part, page 18).

8.

Perform chemical cleaning of the media (see Algae and bacterial growth control, page 13).

9.

Turn off the water.

10.

Open the secondary screen filter (if installed), remove the screen, clean it and store it in a dry and safe

place with all the filter covers and handles.

•For manual filters: Make sure that the cover gaskets are dry before storage.

•For automatic or semi-automatic filters: Open the filter and check all the inner elements.

11.

Lubricate all the screws and bolts of the system. In particular, carefully oil the screws of the shutter

units in the gravel filter and the secondary screen filter (if it is a manual filter).

12 SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL

MAINTENANCE

12.

Open all gravel-filter covers, drain all the water out of the filtration system (preferably by removing the

outlet manifold end-cap). When the filters are completely drained, close the filling ports.

13.

Disconnect the electricity source of the backwash controller (for battery-operated controllers – remove

the batteries).

For further assistance, contact your local Netafim™ representative.

At the beginning of the next irrigation season

1.

Check all covers, gaskets and screen/s that were stored at the end of the previous season. Clean them

and wash with fresh water.

2.

Check the level of media inside the filters.

•If the level is lower than the media level marker on the filter tank - add media.

•If the level is higher than the media level marker on the filter tank - remove media.

3.

Install the screen and cover of the secondary screen filter.

4.

Connect the electricity source to the controller (for battery-operated controllers – replace the old

batteries with new ones) and perform a manual backwash – be sure that the controller sends signals in

sequence to the solenoids valves and that the solenoids are reacting.

5.

Clean the screen filter in the control assembly with fresh water.

6.

Lubricate all the screws and bolts of the system. In particular, carefully oil the screws of the port covers

in the gravel filter and the secondary screen filter cover.

7.

Perform chemical cleaning of the media (see Algae and bacterial growth control, page 13).

8.

Run according to the irrigation program.

For further assistance, contact your local Netafim™ representative.

SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL 13

MAINTENANCE

Algae and bacterial growth control

WARNING

Sodium hypochlorite (NaClO) and hydrogen peroxide (H

2

O

2

) are dangerous toxic and corrosive

chemicals. All application regulations and safety rules must be observed. Store and handle them

according to safety regulations.

Before handling

sodium hypochlorite (NaClO)

or

hydrogen peroxide (H

2

O

2

)

, carefully read all the

specific safety, health protection and first aid information and instructions.

Be sure you have all

required first aid at the site, as instructed

.

Concentrated liquid sodium hypochlorite (NaClO) or hydrogen peroxide (H2O2) can damage exposed

metal (especially threads that are exposed to water). Be careful when applying them and avoid the

spillage of any of the liquid onto exposed metal parts. Should any of the liquid come into contact

with metal parts, immediately wash thoroughly with fresh water.

1.

Perform 1 or 2 manual backwashes of the system (as needed), using the manual option in the controller.

2.

Release the pressure from the filtration system. Open any valve downstream from the filtration system

or the manual valve (if installed) on the outlet manifold end-cap, until the pressure is fully released.

Check the pressure gauge to be sure it is at 0 before proceeding. Do not drain the system.

3.

Open the top service ports of all the tanks.

4.

Make sure that the tanks remain two-thirds full with water. This is essential for the success of the

chemical treatment.

5.

Pour the required quantity of sodium hypochlorite (NaClO) or hydrogen peroxide (H2O2) into each tank

according to the table below.

Tank

diameter

(inch)

Quantity of sodium hypochlorite (NaClO) (liter) Quantity of hydrogen peroxide (H

2

O

2

) (liter)

Domestic liquid

3% concentration

Technical liquid

10% concentration

Technical liquid

30% concentration

12 0.7 0.25 0.15

16 0.8 0.3 0.15

20 1.1 0.4 0.2

24 1.5 0.5 0.2

30 3.0 1.0 0.3

36 5.0 1.5 0.5

48 10.0 3.0 1.5

6.

Gently stir the media inside each tank with a wooden stick.

WARNING

Take care not to damage the tank under-drain diffuser/s ("flutes" or "mushrooms").

7.

Wait at least 3 hours for the chemical contact time.

8.

Close the top service ports of all the tanks.

9.

Pressurize the system.

10.

Perform 1 or 2 manual backwashes of the system (as needed), using the manual option in the controller.

For further assistance, contact your local Netafim™ representative.

14 SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL

MAINTENANCE

Replacing the media

WARNING

Do not perform maintenance operations or open filter ports before the pressure in the system is

fully released. For draining purposes, open any valve downstream from the filtration system until

the pressure is fully released. Check the pressure gauge to be sure it is at 0 before proceeding.

The sand media usually requires replacement every 3 to 5 years, depending on water quality and how

much the system operates.

1.

Close all the valves, open the top and bottom service ports of all the tanks and remove their covers.

2.

Drain and flush all the media from the tank.

CAUTION

Do not use tools to help remove the media - under-drain diffusers ("flutes" or "mushrooms") could

be damaged.

TIP

If the sand media is solidified inside the tank and does not pour out of the bottom service port by

itself, you can crumble it with pressurized water through the bottom service port.

3.

Rinse and clean the inside of the tank.

4.

Visually check (with the aid of a flashlight) the inside of all the tanks, through the filling port, for

damaged, missing or unsecured under-drain diffusers ("flutes" or "mushrooms"). Replace, re-fit, re-

connect and re-secure if necessary (See tank replacement parts: single-chamber - page 20, double-

chamber - page 22).

5.

Make sure that the bottom service port and its gasket are clear of any remaining gravel particles and

close the bottom service port.

ATTENTION

Single-chamber only

Before filling the tanks with media, Fill each tank with water up to a third of its height with a hose

through the filling port before media filling to prevent damage to the under-drain diffusers when

pouring the media.

6.

Fill the tanks with media through the filling port. Fill each tank up to the media level marker on the filter tank.

*Crushed basalt.

Tank diameter

(inch)

Sand quantity*

kg lbs

12 60 132

16 90 198

20 120 265

24 180 397

30 240 529

36 360 794

48 575 1768

Tank diameter

(inch)

Sand quantity*

kg lbs

30 270 595

36 350 770

48 675 1490

Single-chamber Double-chamber

7.

Flatten the surface of the media.

SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL 15

MAINTENANCE

8.

Make sure that the filling port and its gasket are clear of any remaining gravel particles and clos the

filling port.

9.

Turn on the water and start irrigation.

10.

As soon as the system is pressurized and stable, start a manual backwashing cycle by pressing the

key (the icon will appear on the display) and check that the backwashing happens in sequence

according to your backwash controller setup (to manually terminate a backwashing cycle in progress,

press the same key).

11.

Readjust the backwash flow-control valve:

•If a manual backwash flow-control valve is installed, throttle the valve to reduce the flow until the

media stops running out.

•If a hydraulic backwash flow-control valve is installed, the valve is factory pre-set to the required

flow rate.

In the rare case that the backwash flow-control valve requires fine-tuning:

a.

Release the pilot lock-nut.

b.

Gently rotate the pilot calibration bolt counterclockwise with a wrench to reduce the flow until the

media stops running out.

c.

Retighten the pilot lock-nut.

For further assistance, contact your local Netafim™ representative.

Replacing the batteries in the BackFlush controller

For controllers powered by 4 x 1.5v D-size batteries (6v DC)

ATTENTION

•Match the poles to the markings inside the battery housing.

•Always replace the whole set of 4 batteries at once.

1.

Remove the upper cover.

2.

Pull out the battery housing

.

3.

Remove the used batteries from the battery

housing

.

4.

Insert new batteries.

5.

Push the battery housing back in.

6.

Put the upper cover back in place.

1 2

16 SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL

MAINTENANCE

Paint retouching of the tanks and manifolds

WARNING

If the protective coating (inside and outside) of the tanks and manifolds is damaged and the bare

metal is exposed, it will rust in contact with irrigation water and chemicals. If neglected, this will

lead to a leak.

A tin of polyester protective repair paint (color: RAL 5010) is supplied with the system.

Any damage to the protective coating of the tanks and manifolds must be repaired as soon as possible.

1.

Sand the damaged area or spot with sandpaper and clean it with a wire brush.

2.

Apply the protective paint.

3.

Let the paint completely dry for at least 24 hours before exposing the mended spot to water.

For further assistance, contact your local Netafim™ representative.

Cleaning the secondary filter

At the end of the irrigation season and during the irrigation season, at the frequency required by the

irrigation water quality.

Remove the filtration element from the filter casing and clean it according to the instructions in the filter

user manual.

SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL 17

TROUBLESHOOTING

WARNING

Do not perform maintenance operations or open filter ports before the pressure in the system is

fully released. For draining purposes, open any valve downstream from the filtration system until

the pressure is fully released. Check the pressure gauge to be sure it is at 0 before proceeding.

Alternatively, you can open the valve installed on the outlet manifold end-cap - if installed.

If the pressure difference across the filtration system is over 0.7 bar (10.15 PSI) and the

flushing cycle does not reduce it:

1.

Check the system flow rate to see if the flow rate corresponds with the benchmark data, to make sure

that the system flow rate is not too high.

2.

If the pressure differential is not caused by a high flow rate, perform the following steps.

3.

Adjust the flow-control valve if necessary.

4.

Make sure that the water from the backwash manifold is running free.

5.

Check the duration of backwash and make sure the water that drains in the last 10 seconds of flushing

is clean.

If the water is dirty at the end of the flushing – increase the duration of flushing – if required, increase

the backwash duration and perform 3 consecutive flushing cycles.

If the flushing cycle does not start but the controller is initiating the flushing signal and

the solenoids are reacting (“clicking”):

1.

Check the command filter in the control head. Clean it if necessary and perform manual flushing.

2.

Check for clogging inside the solenoid valves - clean if possible or replace with a new solenoid.

3.

Check for clogging of the hydraulic control tubes - open the clogs and clean if necessary.

4.

Check for a ruptured or defective hydraulic control tube - replace if necessary.

If the media is running out through the backwash manifold during backwash:

1.

Adjust the backwash flow-control valve on the backwash manifold.

•If a manual backwash flow-control valve is installed, throttle the valve to reduce the flow until the

media stops running out.

•If a hydraulic backwash flow-control valve is installed, the valve is factory pre-set to the required

flow rate.

In the rare case that the backwash flow-control valve requires fine-tuning:

a.

Release the pilot lock-nut.

b.

Gently rotate the pilot calibration bolt counterclockwise with a wrench to reduce the flow until the

media stops running out.

c.

Retighten the pilot lock-nut.

2.

Check the level of media inside the filters.

•If the level is lower than the media level marker on the filter tank - add media.

•If the level is higher than the media level marker on the filter tank - remove media.

18 SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL

TROUBLESHOOTING

If media is running out through the outlet manifold during filtration:

Replacing a damaged under-drain diffuser part ("flute" or "mushroom"):

1.

Release the pressure and drain the filtration system. Open any valve downstream from the filtration

system or the manual valve (if installed) on the outlet manifold end-cap, until the pressure is fully

released. Check the pressure gauge to make sure it is at 0 before proceeding.

2.

Empty the water from the filtration system.

TIP

To speed up emptying the water from the filtration system,

you can temporarily dismantle the outlet manifold end-cap.

3.

Open the top service ports of all the tanks.

4.

Gently remove the media from all the tanks.

WARNING

Do not use tools (such as a shovel) to remove the media, as this could damage the tank under-drain

diffusers ("flutes" or "mushrooms").

5.

Clean any media remaining on the under-drain diffuser with pressurized water (with a hose, through the

top service ports).

6.

Visually identify the damaged under-drain diffuser part/s ("flute/s" or "mushroom/s") with the aid of a

flashlight.

ATTENTION

There may be more than one tank losing gravel.

ATTENTION

Screw, unscrew and fasten the under-drain diffuser parts by hand only. Do not use tools, as this

could damage the under-drain diffusers ("flutes" or "mushrooms").

7.

Manually unscrew the damaged under-drain diffuser part.

8.

Check the integrity of the following parts and replace them it if necessary:

•Single-chamber tank - the plastic washer (yellow).

•Double-chamber tank - the rubber gasket.

WARNING

A damaged rubber gasket may be difficult to pull out. Do not use a screwdriver (or any metal tool)

to remove it, as this could damage the tank protective coating.

9.

Replace the damaged under-drain diffuser part ("flute" or "mushroom") with a new one.

ATTENTION

Do not forget to put the following parts back in place:

•Single-chamber tank - the plastic washer (yellow).

•Double-chamber tank - the rubber gasket.

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

MTL SNG 480508 S D08.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

MTL SNG 480508 S D08 BFC DC SOL DC

NGR

13/02/2017

Barga

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL 19

TROUBLESHOOTING

ATTENTION

Single-chamber only

Before filling the tanks with media, fill each tank with water up to a third of its height with a hose

through the filling port before media filling.

10.

Fill the tanks with media through the filling port. Fill each tank up to the media level marker on the filter tank.

*Crushed basalt.

Tank diameter

(inch)

Sand quantity*

kg lbs

12 60 132

16 90 198

20 120 265

24 180 397

30 240 529

36 360 794

48 575 1768

Tank diameter

(inch)

Sand quantity*

kg lbs

30 270 595

36 350 770

48 675 1490

Single-chamber Double-chamber

11.

Flatten the surface of the media.

12.

Make sure that the filling port and its gasket are clear of any remaining gravel particles and close the

filling port.

13.

Turn on the water and start irrigation.

(See tank replacement parts: single-chamber - page 20, double-chamber - page 22).

For further assistance, contact your local Netafim™ representative.

20 SANDSTORM

™

SINGLE-/DOUBLE-CHAMBER USER MANUAL

REV.

DESCRIPTION

DATE

APPROVED

ITEM

NO.

Part Name

Manufacturer's

Name

Material type

Material Grade

QTY.

1

48'' UNDER CAMBER SINGLE

1

2

48'' BODY SHEET SINGLE

1

3

48'' TOP CAMBER SINGLE

1

4

10'' COVER GASKET

2

5

10'' IRON COVER

2

6

hex bolt gradeab_iso(ISO 4014 -

M12 x 50 x 30-S)

24

7

hex nut gradec_iso(Hexagon

Nut ISO - 4034 - M12 - S)

26

8

8'' COVER GASKET

3

9

8'' CAST IRON COVER

3

10

PVC T

1

11

PVC pipe PN25-48''

2

12

underdrain bolt M12

2

13

spring washer M12

2

14

tank leg O-ring

6

15

flute internal core MxM

22

16

flute internal core MxF

38

17

flute washer

31

18

PVC blind cap

2

19

underdrain washer plate

underdrain washer plate

2

20

extension leg column

3

21

extension leg O-ring

6

22

tank leg base

3

23

tank leg rubber shoe

3

24

SC underdrain mushroom

31

25

SC underdrain mushroom core

9

26

NUT HOLDER(Default)

26

27

10''X70XTOP PIPE

2

28

8''X60X48'' PIPE(6)

3

29

MEDIA FILTER OUTLET PIPE 4''X200

1

30

lifting ear

4

31

WATER SPREADER

1

32

48'' INLET PIPE 4'' SINGLE

1

33

diffuser segment blind

56

34

diffuser segment slotted

102

Drawing No.

QA

Project:

A-28097-220118

48'' SINGLE CHAMBER open body.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

t21734

48'' SINGLE CHAMBER MEDIA FILTER

ASSEMBLY V170406

22 Jan 2018

22 Jan 2018

t21734

Subject:

Checked By

Part Name:

Material:

1:15

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

-

Rev.

N125052/1

Quantity:

1

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

Filtration

REPLACEMENT PARTS

Tanks 30, 36, 48"

Tanks - single-chamber

REV.

DESCRIPTION

DATE

APPROVED

Drawing No.

QA

Project:

48 single exploded.slddrw

File Name:

General Tolerance According to ISO 2768-f

LINEAR DIMENSIONS

ANGULAR DIMENSIONS

Permissible deviations in mm for ranges in nominal lengths

Permissible deviations in degrees and minutes

for ranges in nominal lengths

3-D Proj.

Part No.

Scale:

Sheet Size:

A3

Drawn By

Designed By

Subject:

Checked By

Part Name:

Material:

1:50

Finish:

Sheet:

Of:

1 1

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

NETAFIM. ANY REPRODUCTION IN PART

OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF NETAFIM IS PROHIBITED

Rev.

/1

Quantity:

±1°

±0.05

≥ 0.5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

≤ 10

> 400

> 120

≤ 400

> 50

≤ 120

> 10

≤ 50

±0°30'

±0°20'

±0°10'

±0°5'

±0.15

±0.1

±0.05

±0.2

±0.3

-

±0.5

1

3

4

3

5

6

11

12

13141211

11

12

14

13

9

10

15

15

16

17

14

13

10

9

15

15

16

17

2

12

11

12

11

7

8

Other manuals for SANDSTORM

2

Table of contents

Other Netafim Water Filtration System manuals

Netafim

Netafim SANDSTORM User manual

Netafim

Netafim AlphaDisc Series User manual

Netafim

Netafim SCREENGUARD User manual

Netafim

Netafim SCREENGUARD SG V 2 User manual

Netafim

Netafim APOLLO DISC-KLEEN Instruction Manual

Netafim

Netafim Amiad Mini Sigma 2 1200 User manual

Netafim

Netafim Arkal 2" Spin-Klin Compact Stand Alone... User manual

Netafim

Netafim 25AP46 Series Guide

Netafim

Netafim Arkal 3" Spin-Klin Battery User manual

Netafim

Netafim Apollo Instruction Manual