1 General information

Before installing the NVV read these instructions carefully. It is the basis

for any action when dealing with the NVV, and may be used for training

purposes. The instructions should be subsequently stored at the operation

site.

The target group for these instructions is technical staff, who have basic

knowledge in pneumatics and mechanics.

Only complying technical staff may work on the NVV.

The NVV may only be installed, put into operation, maintained, troubleshot

and disassembled by persons authorised by the operator.

This documentation is protected by copyright.

Netter

Vibration reserves all rights such as translations, reprinting and re-

production of the instructions, as well as parts thereof.

All technical information, data and instructions for installation, operation

and maintenance in these instructions are based on the latest information

available at the time of printing and take our past experience to the best of

our knowledge into account.

No claims can be derived from the information, illustrations and descrip-

tions in these operating instructions.

The manufacturer does not assume liability for damages resulting from:

•failure to observe the instructions,

•improper use,

•unauthorised repairs,

•technical modifications,

•use of non-permissible spare parts.

Translations are made to the best of our knowledge.

Netter

Vibration does not assume liability for translation errors, even if the

translation was made by us or on our behalf. Only the original German text

remains binding.

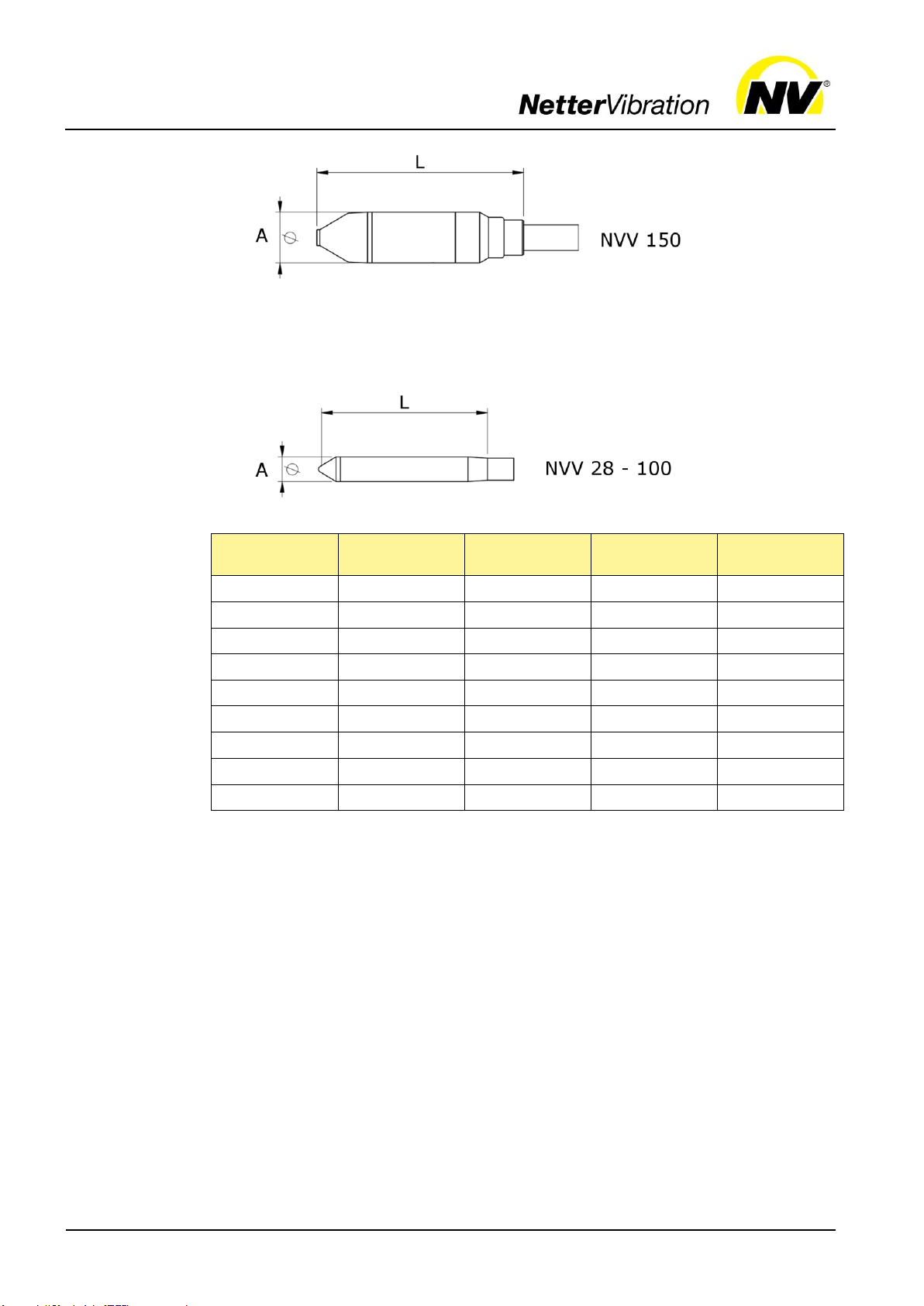

The pneumatic internal vibrators of the series NVV comply with the EC

Machinery Directive 2006/42/EC.

In particular, the standard EN ISO 12100 has been observed.