7

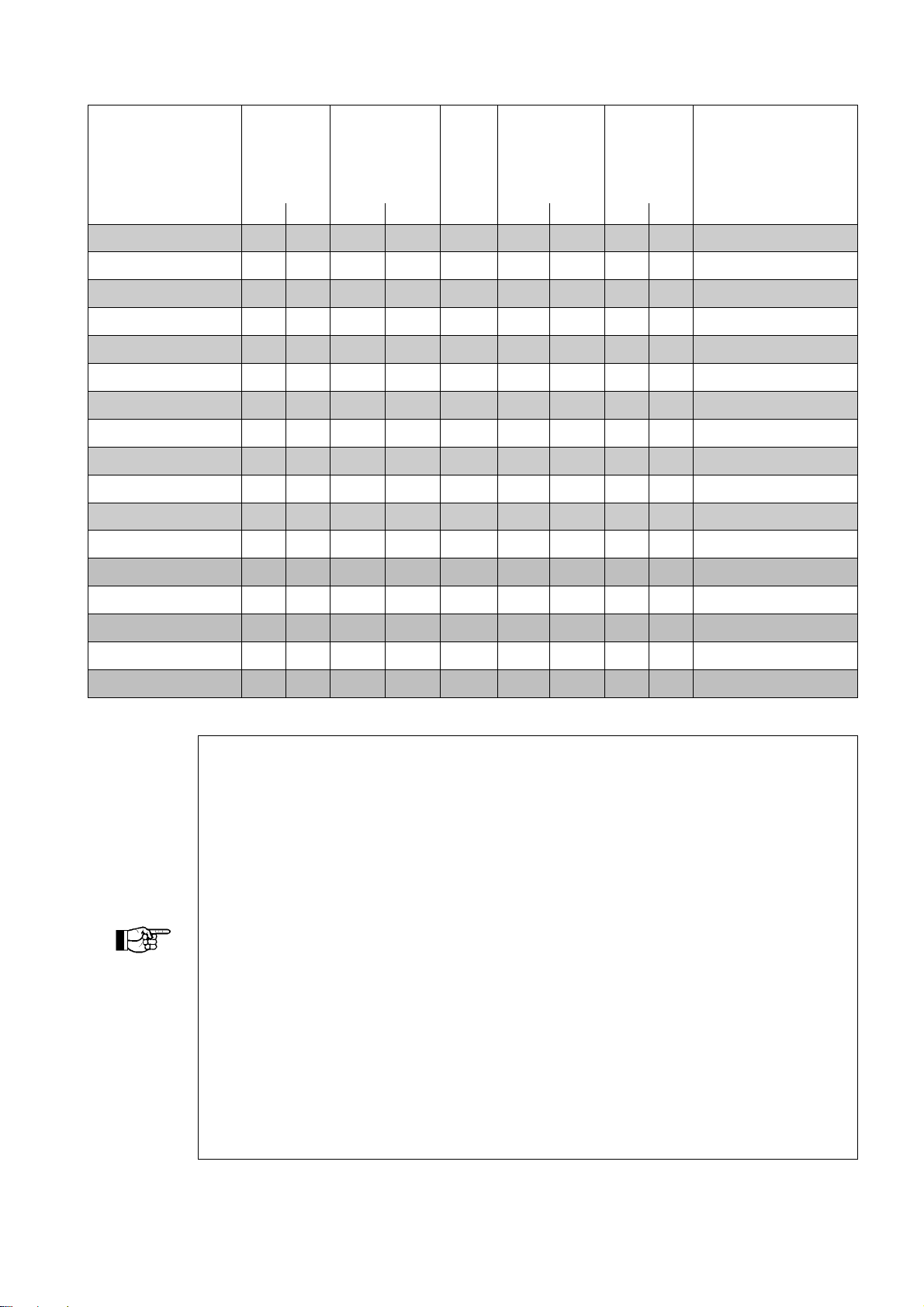

3 Technical data

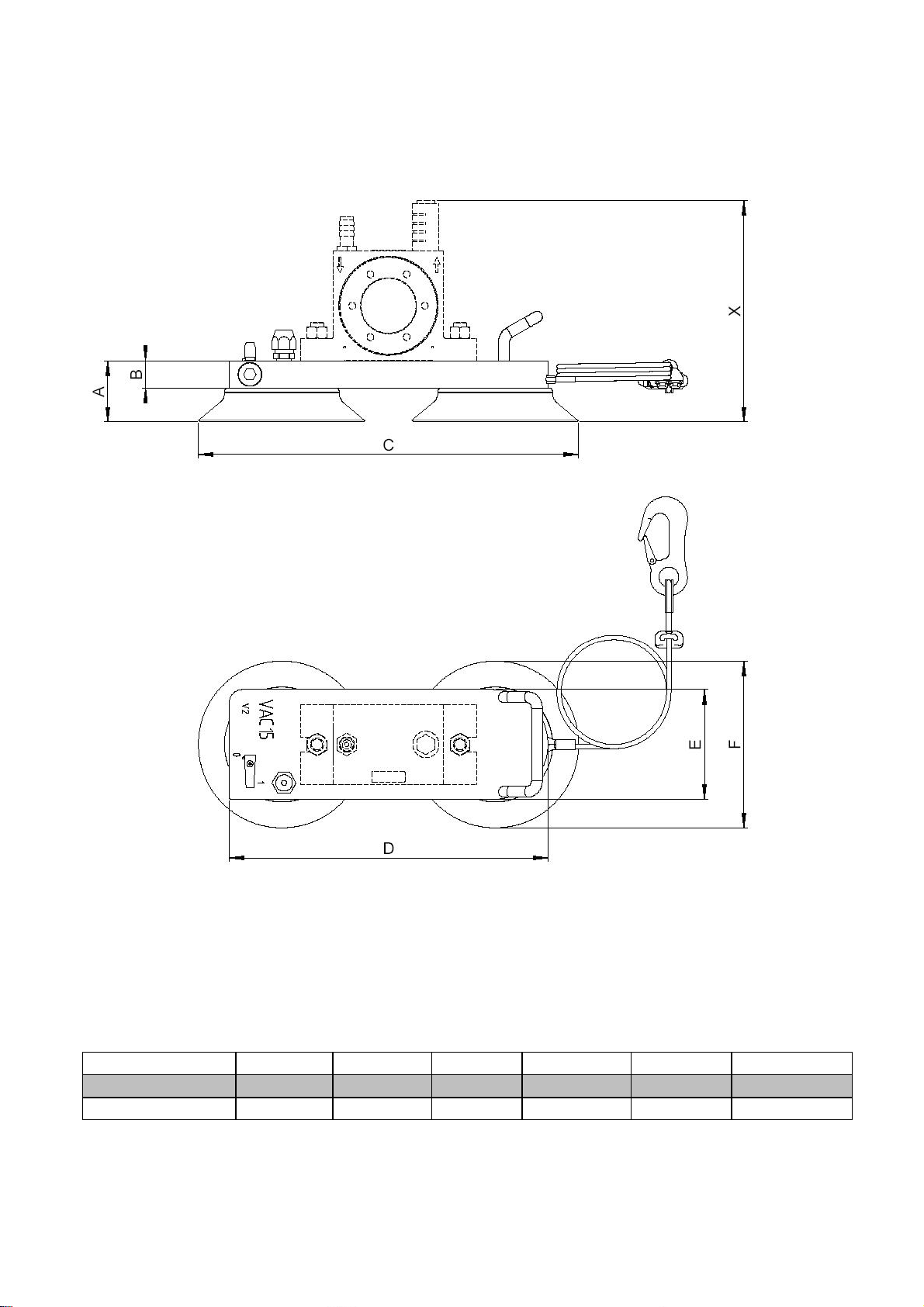

Type Generated

vacuum

[bar]=

Generated

suction

power*

[N]=

Weight

[kg]=

ir

consump-

tion

[l/min]=

Noise

level**

[dB(A)]=

recommended

minimum diameter

for

round containers

[mm]

4 bar6 bar 4 bar 6 bar 4 bar 6 bar 4 bar 6 bar

VAC 8 + HG 10 N 0,60 0,85 340 481 0,95 40 60 68 75 110

VAC 8 + HG 10 S 0,60 0,85 340 481 1,20 20 22 68 75 110

VAC 10 + HG 10 N 0,60 0,85 465 658 1,05 40 60 68 75 110

VAC 10 + HG 10 S 0,60 0,85 465 658 1,30 20 22 68 75 110

VAC 11 + HG 10 N 0,60 0,85 710 1.005 1,25 40 60 74 78 110

VAC 11 + HG 10 S 0,60 0,85 710 1.005 1,50 20 22 74 78 110

VAC 12 + HG 15 N 0,60 0,85 1.250 1.770 2,85 60 122 64 79 350

VAC 12 + HG 15 S 0,60 0,85 1.250 1.770 3,20 29 36 64 79 350

VAC 13 + HG 15 N 0,60 0,85 1.362 1.930 4,20 110 170 83 77 850

VAC 13 + HG 15 S 0,60 0,85 1.362 1.930 4,55 41 52 83 77 850

VAC 15 + HG 15 N 0,60 0,85 1.476 2.091 3,40 110 170 83 89 650

VAC 15 + HG 15 S 0,60 0,85 1.476 2.091 3,75 41 52 83 89 650

VAC 20 + HG 15 N 0,60 0,85 2.724 3.859 7,25 110 170 79 79 850

VAC 20 + HG 15 S 0,60 0,85 2.724 3.859 7,60 41 52 79 79 850

VAC 30 + HG 30 N 0,60 0,85 4.086 5.789 11,50 110 170 79 79 1.500

VAC 30 + HG 30 S 0,60 0,85 4.086 5.789 12,00 49 60 79 79 1.500

VAC 40 + HG 40 N 0,60 0,85 5.448 7.718 20,00 220 340 82 86 1.500

* Maximum suction power at 5 bar. For operation of a vibrator a higher pressure may be required.

**The noise level was measured at a distance of 1 m without vibrator. The noise level of vibrators may be higher.

IMPORTANT

Admissible operating conditions

Drive medium

Clean (Filter 5 µm, quality class 3 according to DIN ISO 8573-1), com-

pressed air or nitrogen.

Unfiltered air will cause damage to the mounted vibrators.

Lubrication

VAC fixing devices do not require lubrication.

For the mounted vibrator lubricated compressed air may be specified. Please

refer to the corresponding operating instructions for the vibrator.

Operating pressure

4 bar to 6 bar*

Operating pressures must not be exceeded or fall short of.

Ambient temperature

-10°C to 60°C

The admissible ambient temperatures must not be exceeded or fallen short of

during operation.

*) Higher operating pressures and temperatures are only permitted after consultation and written confirmation by

application engineers of kÉííÉêVibration.