Sices DIPOT User manual

Filename: EAAM024505EN.docx

Rev. 05 Date: 07/05/2013

ID Document: EAAM0245

Product: DIPOT

ii User’s Manual

1. General Information.................................................................................................3

2. Characteristics.........................................................................................................3

2.1 Output...................................................................................................................3

2.2 Power input...........................................................................................................4

2.3 Controls and function............................................................................................4

2.4 Digital inputs.........................................................................................................6

2.5 Analog Inputs........................................................................................................6

2.6 Adjustments..........................................................................................................7

3. Voltage isolator mode .............................................................................................8

4. Connections.............................................................................................................9

4.1 RS485 interface version connections .................................................................10

4.1.1 Modbus addresses and communication protocol .........................................10

4.1.2 ModBus address list.....................................................................................11

4.2 CAN BUS version connection.............................................................................14

4.2.1 CAN BUS communication ............................................................................14

5. Dimensions ............................................................................................................16

User’s Manual 3

This document describes the technical and functional characteristics and how to use the DIPOT board.

The available models are identified by the following codes:

1. E6102094300xx : DIPOT RS485 IN 0÷5V/IN 0÷10V

2. E6102094301xx : DIPOT RS485 IN TEMP./PRESS. VDO

3. E6102094302xx : DIPOT CANBUS IN 0÷5V/IN 0÷10V

4. E6102094303xx : DIPOT CANBUS IN TEMP./PRESS. VDO

Thanks to its versatility, the "DIPOT" device lets you connect most products (Speed regulators, Voltage

regulators, Power factor controllers, etc.) that require a voltage or current input, to suit their variation and

management specifications. The output for piloting the boards is managed by a microcontroller that

controls the regulation of an output proportional current loop (which can be converted into a voltage

output using a simple resistance).

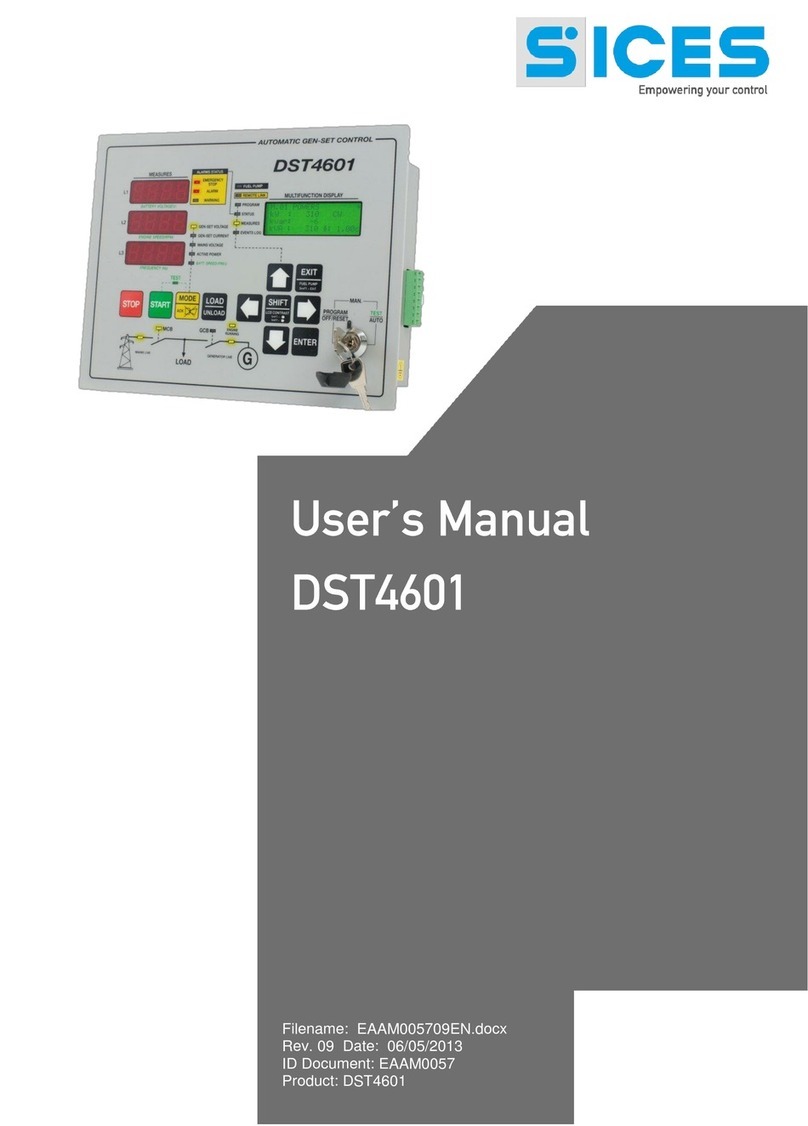

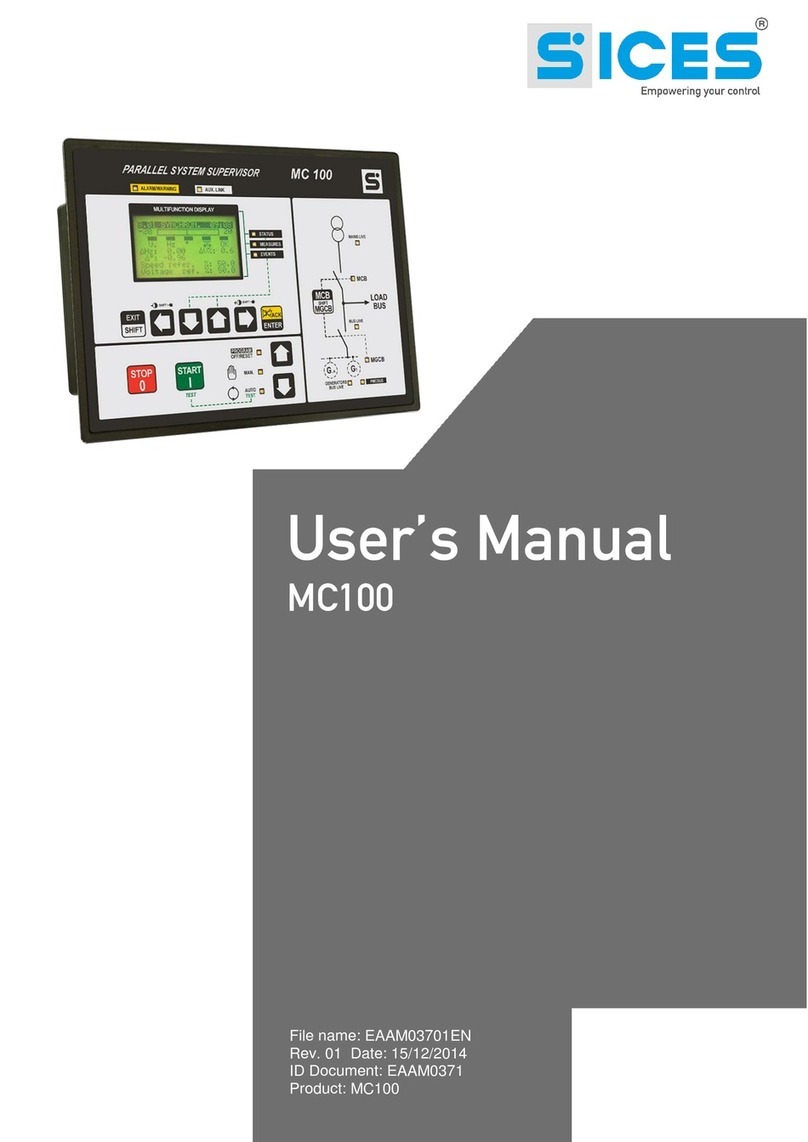

The output can be regulated and piloted with UP and DOWN digital inputs, or by modifying the Modbus

protocol registry value via RS485 connection or CANBUS J1939 connection to our generator

management boards DST4601, DST4601PX, DST4400, etc.

2.1

On all DIPOT models, the regulation of the Current Loop can be selected using three configurations of

dip-switches:

from 0 to +20 mA

from -10mA to +10mA

from -20mA to +20 mA

Using one of the current adjustable outputs we can create a voltage output by connecting a resistor to

pins 2 and 3 of connector J1.

The current loop device output is between pins +4, +3 for the positive, and pins -2, -1 of J1 for the

negative. The resistor can be connected to pin 2and pin 3of J1 .

Warning: Carefully consider the resistor and the dip-switch configuration, as the max.

voltage range is ± 11V.

Here are some examples:

Example 1:

Voltage required: min. -6V to max. +6 V.

Select ± 20mA

The resistance to use is:

300

02,06A

V

I

V

R

The dissipation power of the resistor must be at least:

WAVIVP 12,002,0*6*

The resistor to be used will be 300ohm - 1/4W

4 User’s Manual

Example 2:

Voltage required: min. 0V to max. 11 V.

Select ± 20mA

The resistance to use is:

550

02,011 A

V

I

V

R

The dissipation power of the resistor must be at least:

WAVIVP 22,002,0*11*

The resistor to be used will be 550ohm - 1/4W

2.2

Connector J5 is used for the power input; input voltage can be either 12 or 24VDC, with a self-rearming

internal fuse. The device is protected by input polarity switching.

The maximum current absorption is approximately 80 mA at a voltage of 10V. The input voltage range

is between 7.5 and 32 VDC.

Configuration:

-J5 –PIN 1: positive input

-J5 –PIN2: negative input

-J3 –PIN6: Ground (cable screens)

Wiring Diagram:

The DIPOT board has several dip switches, which let you set the specific functions of the device, the

current loop value and the properties of the serial port.

The SWE switch is an 8-way dip switch for setting the following specific functions of the product:

DIP 1-4 (Communication address: assign the modbus address to the device (in the CANBUS

version, the communication address is fixed)

User’s Manual 5

DIP 5(analog on CANBUS): enables/disables transmission via Can bus of the water temperature

and oil pressure sensors connected to the analog inputs of the DIPOT module (connector J2). In

the Can Bus version of the receiving device, the Can is always enabled, regardless of the state of

this switch, if SWE dip 7 is ON (REMOTE CONTROLS).

DIP 6 (CCW/CW): lets you switch the current loop output in relation to data control (and then

switch from CW to CCW operating mode). In CW mode, the request with a CANBUS/Modbus

message or from the UP button, for an increment in the command, will result in a drop in the value

of the output current while in CCW mode, the request with a CANBUS/Modbus message or from

the DOWN button, for a decrease in the command, will result in an increase in output current.

DIP 7 (REMOTE/LOCAL CONTROL): in "Local" mode the up/down/reset buttons are acquired

and let you change the current loop output value. In "Remote" mode, the current-loop output value

is determined by the CANBUS or Modbus command. With version RS485 in "Remote" mode, the

value of the MIN, MAX, RESET and RAMP trimmer is set in the "Holding register.

DIP 8(Rpm1500/1800 from CANBUS/DIGITAL INPUT): determines if the nominal speed of the

motor (1500 or 1800 rpm) is automatically detected by the CANBUS or digital input J3-2. (If the

input is active, the nominal speed is 1800 rpm, if the input is inactive the nominal speed is 1500

rpm).

Switch SWD is a 4-way switch and sets the properties of the available serial port on stereo jack connector

J6 and connector J4:

DIP 1 (120R ON/OFF): lets you connect/disconnect the 120R termination resistor on serial port

RS485 of J6 (only if necessary and if the port is set as RS485).

DIP 2 (Enable/disable Serial port): enables/disables the serial port on stereo jack J6.

In the versions with isolated RS485 (E6102094300xx and E6102094301xx) serial port of connector J4

is shared with connector J6. Use SWD dip 2 to select which port should be used. The serial ports on J4

and J6 cannot operate simultaneously. If the serial port is used on connector J6, disconnect the female

connector on J4.

In versions with CANBUS (E6102094020xx and E6102094303xx) the serial port on connector J6 is

always available.

DIP 3 (RS232/RS485): configures the serial port on Stereo jack J6 as RS232 or RS485 (not

isolated).

DIP 4 (9600/19200 Bd): sets the baud rate used by the serial port on Jack (J6) and also that of

isolated RS485 serial port (J4) if the product is version RS485.

The SWB switch is a 2-way switch and sets the scale of the current loop used:

from 0 to +20 mA SWB-1 OFF SWB-2 OFF

from -10mA to +10mA SWB-1 ON SWB-2 ON

from -20mA to +20 mA SWB-1 ON SWB-2 OFF

The SWC switch is a 4-way switch that lets you enable the voltage insulator function (Setting ON on

switch no. 1).

Other Sices Industrial Equipment manuals