Netzer VLX Series User manual

VLX-170

PRODUCT GUIDE

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

PRODUCT GUIDE

VLX-170

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

Table of Contents

1. VLX Encoders Introduction...............................................................................................................................................4

2. Technical Specifications.....................................................................................................................................................5

3. Ordering Code.......................................................................................................................................................................6

4. Mechanical Drawings..........................................................................................................................................................7

5. Mechanical Interface Control Drawing.........................................................................................................................8

6. Storage and Handling.........................................................................................................................................................9

7. ESD Protection.......................................................................................................................................................................9

8. Product Overview ......................................................................................................................................................... 9-10

8.1 Overview........................................................................................................................................................................................................9

8.2 Unpacking - Standard order ..........................................................................................................................................................10

8.3 Installation flow chart .........................................................................................................................................................................10

9. Electric Encoder Software Installation.......................................................................................................................11

9.1 Minimum requirements ....................................................................................................................................................................11

9.2 Installing the software........................................................................................................................................................................11

10. Mechanical Mounting................................................................................................................................................11-12

10.1 Encoder mounting - End-of-Shaft Installation ....................................................................................................................11

11. Electrical Connection.................................................................................................................................................13-16

11.1 Absolute position over SSi or BiSS-C .........................................................................................................................................13

11.2 Digital SSi Interface...............................................................................................................................................................................14

11.3 Digital BiSS-C Interface.......................................................................................................................................................................15

11.4 Setup mode over NCP (Netzer Communication Protocol)..........................................................................................16

11.5 Electrical connection and grounding.......................................................................................................................................16

12. Signal Verification........................................................................................................................................................17-19

12.1 Starting the Encoder Explorer........................................................................................................................................................17

12.2 Signal verification process................................................................................................................................................................18

13. Calibration......................................................................................................................................................................20-29

13.1 Auto-calibration......................................................................................................................................................................................20

13.2 Manual calibration ................................................................................................................................................................................23

13.3 Setting the encoder zero-position.............................................................................................................................................. 27

13.4 Jitter test......................................................................................................................................................................................................29

14. Operational Mode.............................................................................................................................................................29

9.1 SSi / BiSS ......................................................................................................................................................................................................29

4Product GuideVLX-170-PG-V02

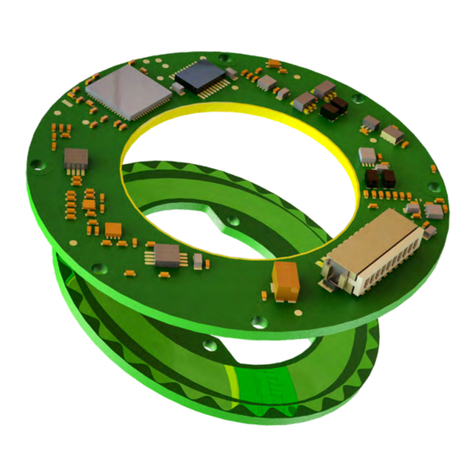

1. VLX Encoders Introduction

Designed to meet the requirements of the most demanding applications

The VLX series of Electric Encoders™ are a line of encoders designed for high accuracy motion control for

industrial, automation and robotic applications.

These encoders are based on capacitive technology which have been developed and improved for over 20

years by Netzer Precision Position Sensors.

The VLX encoders are characterized by the following features that sets them apart from

other similar encoders:

●Low profile (<10 mm)

●Hollow shaft (Stator / Rotor)

●No bearings or other contact elements

●High resolution and excellent precision

●Immunity to magnetic fields

●High tolerance to temperature extremes, shock, moisture, EMI, RFI

●Very low weight

●Holistic signal generation and sensing

●Digital interfaces for absolute position

The holistic structure of the VLX Electric Encoder™ makes it unique. Its output reading is the averaged outcome

of the entire circumference area of the rotor. This inherent design characteristic provides the VLX encoder with

outstanding precision as well as a tolerant mechanical mounting.

The absence of components such as ball bearings, flexible couplers, glass discs, light sources & detectors, along

with very low power consumption, enables the VLX encoders to deliver virtually failure-free performance.

VLX-247

VLX-140

VLX-80

VLX-60

VLX-170

VLX-100

PRODUCT GUIDE

5

Netzer Precision Position Sensors

VLX-170

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

VLX-170-PG-V02

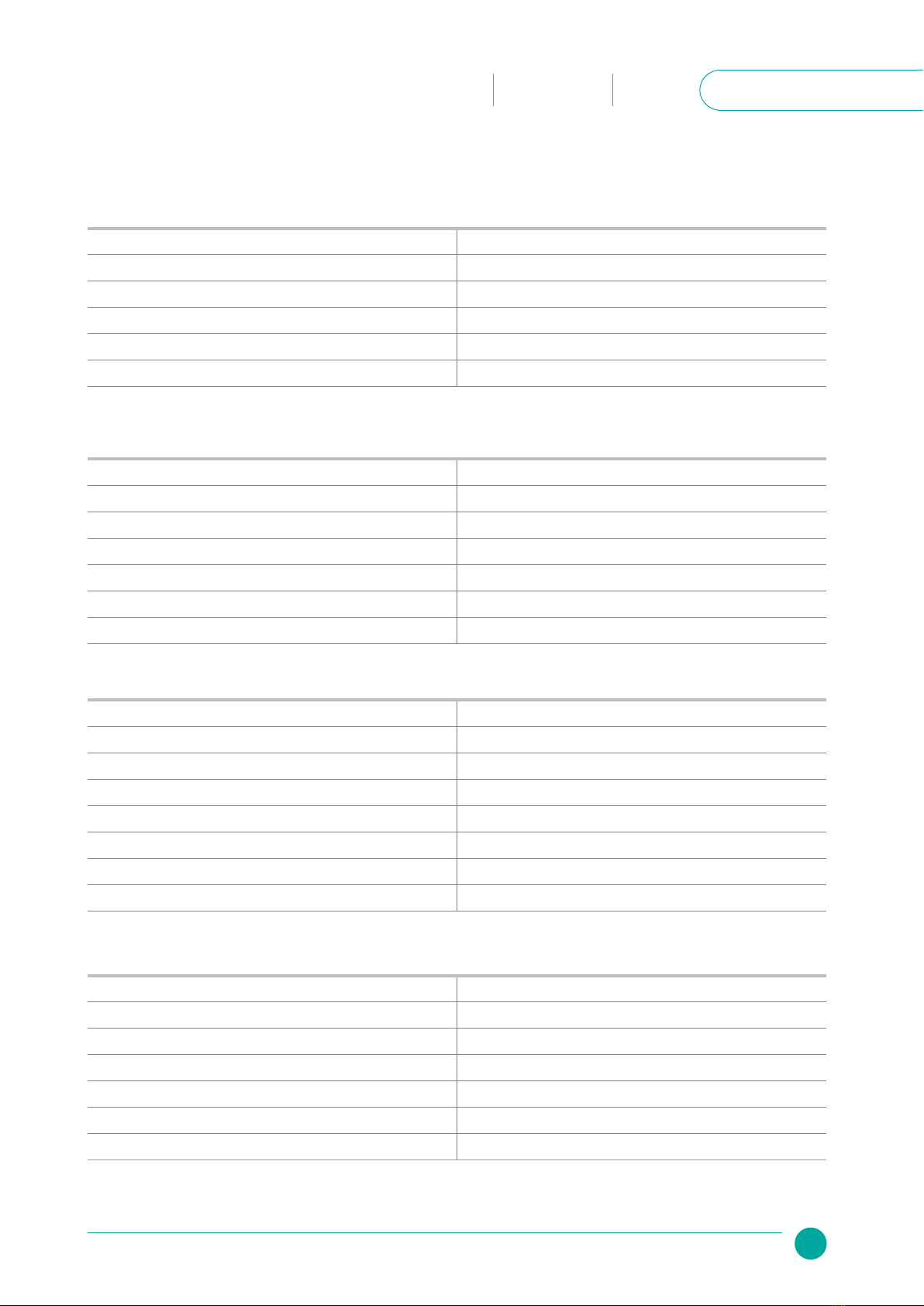

2. Technical Specications

General

Angular resolution 19-21 bit

Nominal position accuracy

±0.010° / ±0.006°

Maximum operational speed 2,000 rpm

Measurement range Single turn, unlimited

Built In Test BIT Optional

Rotation direction Adjustable CW/CCW*

* Default same direction from bottom side of the encoder

Mechanical

Allowable mounting eccentricity ±0.1 mm

Allowable axial mounting tolerance

±0.3 mm

Rotor inertia 205,330 gr · mm2

Total weight 106 gr

Outer Ø / Inner Ø / Height 170 / 110 / 10 mm

Material (stator / rotor) PCB (FR4)

Nominal air gap (stator, rotor) 1 mm

Electrical

Supply voltage 5V ± 5%

Current consumption ~90 mA

Interconnection Connector: DF13A-10P -1.25H

Communication SSi, BiSS-C

Output code Binary

Serial output Dierential RS-422

Clock frequency 0.1- 5.0 MHz

Position update rate 35 kHz (Optional - up to 375 kHz)

Environmental

EMC IEC 6100-6-2, IEC 6100-6-4

Operating temperature -40°C to +85°C

Storage temperature -40°C to +85°C

Relative humidity 98% Non condensing

Shock endurance / functional 100g 6msec saw-tooth per IEC 60068-2-27:2009

Vibration functional 20g @ 10 to 2000 Hz sweep per IEC 60068-2-6

Protection IP 40

6Product GuideVLX-170-PG-V02

3. Ordering Code

EA Extended Accuracy

nnn Custom

Interconnection

HHorizontal (Connector)

VVertical (Connector)

CConnector

VLX -170 -S G -C H -nnn

VLX Product Line

Outer Diameter

Output

SSSi

IBiSS

Resolution

Code Bit CPR

H19 524,288

I20 1,048,578

J21* 2,097,156

*SSi only

PRODUCT GUIDE

7

Netzer Precision Position Sensors

VLX-170

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

VLX-170-PG-V02

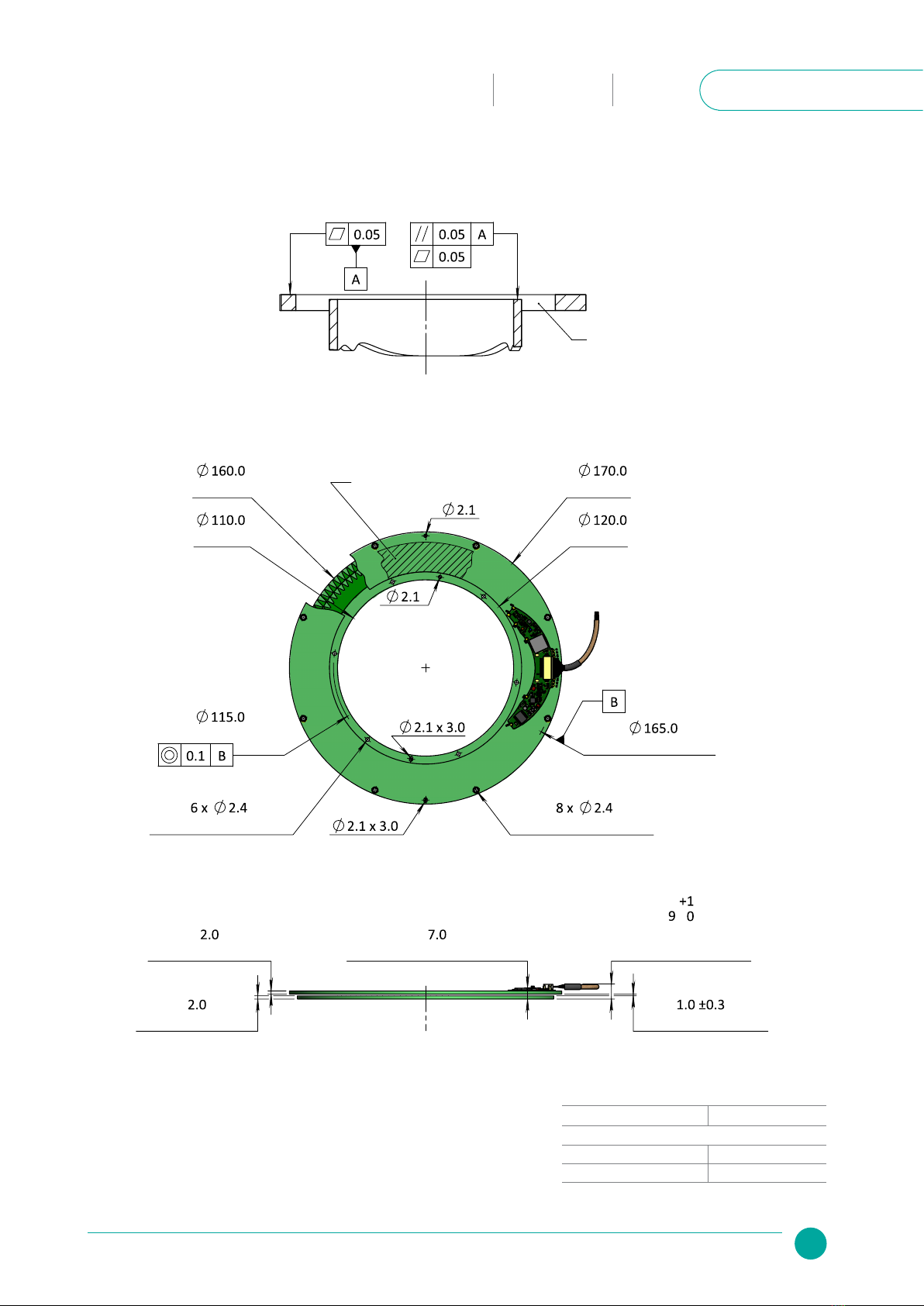

4. Mechanical Drawings

Unless otherwise specied

Dimensions are in: mm Surface nish: N6

Linear tolerances

0.5-4.9: ±0.05 mm 5-30: ±0.1 mm

31-120: ±0.15 mm 121-400: ±0.2 mm

rotor ID

rotor OD

stator ID

stator OD

rotor mounting PCD

stator mounting PCD

The functional zone is

within the ring between

radii 60 and 80 on both

the stator and rotor

encoder height include stamp

encoder height include

canle and connector

Avoid presence of any body

made of conductive material

belows the rotor’s lower surface

within 1 mm under the rotor and

within the functional zone -

to prevent parasitic capacitance

for M2 DIN 912 screwsfor M2 DIN 912 screws

stator PCB thickness

rotor PCB thickness air gap between PCBs

8Product GuideVLX-170-PG-V02

5. Mechanical Interface Control Drawing

SSi / BiSS Remarks

CB-00088-250 AWG30, 250 mm

CB-00088-500 AWG30, 500 mm

Accessories cables (optional)

horizontal connector

Customer interface, example, exploded view

vertical connector

Mounting screws

(not included)

Encoder’s stator

Encoder’s rotor

Customer’s base

Mounting dowel M2 pins

Customer’s shaft

PRODUCT GUIDE

9

Netzer Precision Position Sensors

VLX-170

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

VLX-170-PG-V02

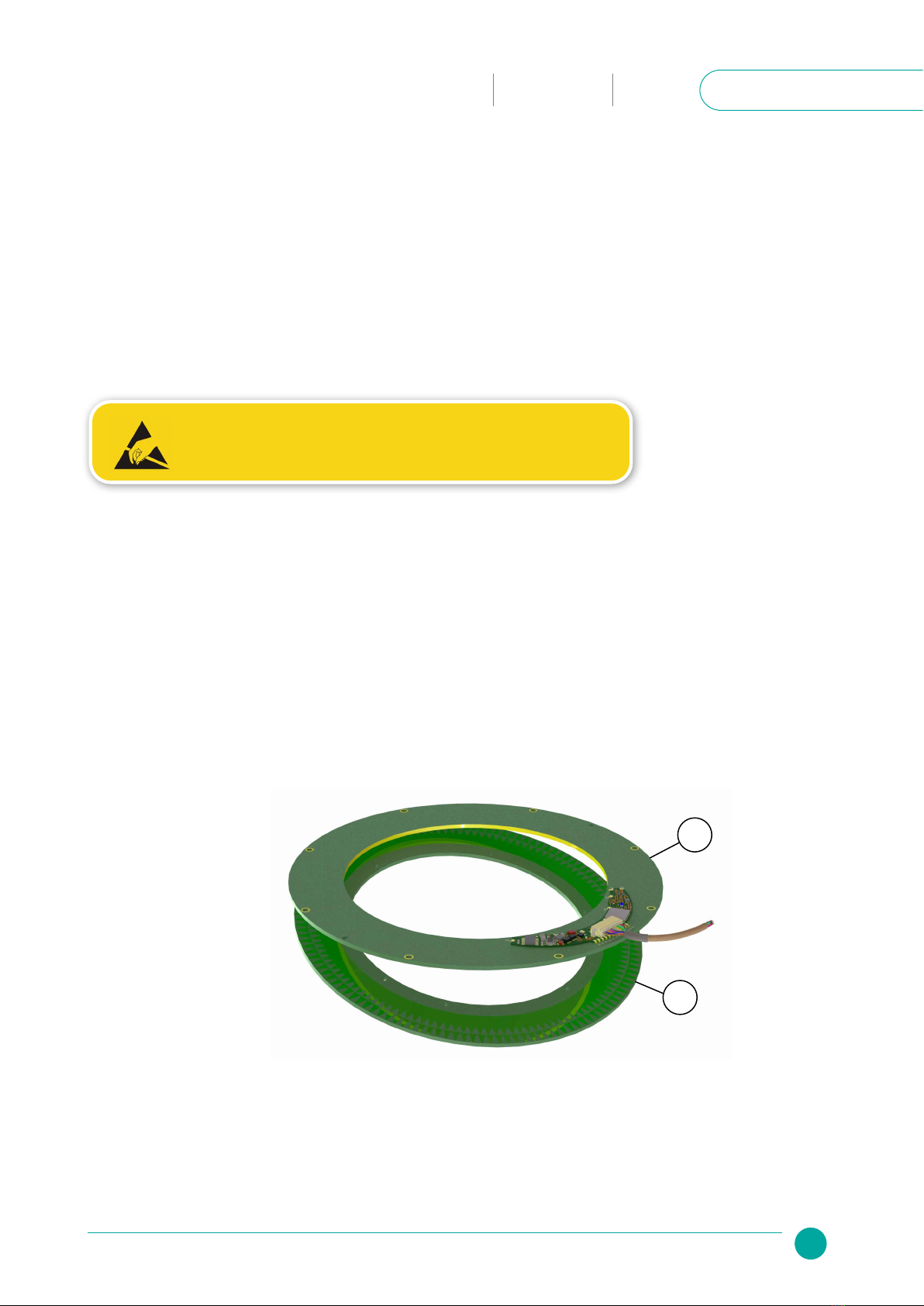

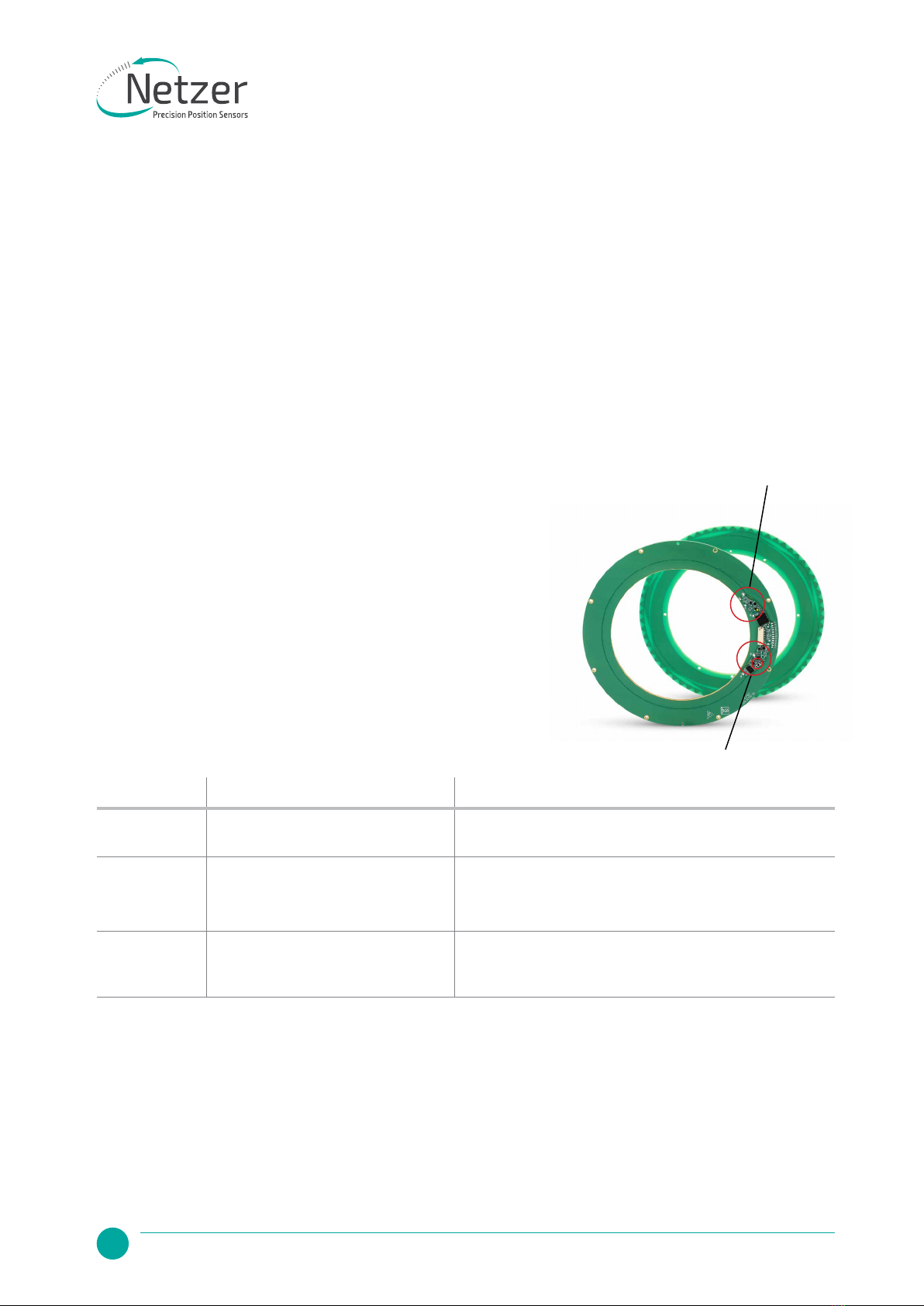

8. Product Overview

8.1 Overview

The VLX-170 absolute position Electric Encoder™ is a rotary position sensor developed for demanding

applications. Currently it performs in a broad range of robotic ,automation and industrial applications.

The Electric Encoder™ non-contact technology provides accurate position measurement through the

modulation of an electric field.

The VLX-170 Electric Encoder™ is a kit-encoder, i.e., its rotor and stator are separate.

7. ESD Protection

As usual for electronic circuits, during product handling do not touch electronic circuits, wires, connectors or

sensors without suitable ESD protection. The integrator / operator shall use ESD equipment to avoid the risk

of circuit damage.

6. Storage and Handling

Storage temperature: -40°C to +85 °C

Humidity: Up to 98% non-condensing

ATTENTION OBSERVE PRECAUTIONS FOR HANDLING

ELECTROSTATIC SENSITIVE DEVICES

(1) Encoder stator

(2) Encoder rotor

1

2

10 Product GuideVLX-170-PG-V02

8.2 Unpacking - standard order

The package of the standard VLX-170 contains the encoder Stator & Rotor

.

Optional accessories:

(1)

CB-00088-250, 250mm connection harness

.

(2)

CB-00088-500, 500mm connection harness.

(3) CNV-00003, RS-422 to USB converter (with USB internal 5V power supply path).

(4) NanoMIC-KIT-01, RS-422 to USB converter. Setup & Operational modes via SSi /BiSS interface.

(5) DKIT-VLX-170-SG-CH, Mounted SSi encoder on rotary jig, RS-422 to USB converter and cables.

(6)

DKIT-VLX-170-IG-CH

, Mounted BiSS encoder on rotary jig, RS-422 to USB converter and cables.

8.3 Installation ow chart

Calibration Mounting

correction

YES NO

Mechanical

mounting

Signal

verication

Electric Encoder

Software

installation on PC

Electrical

connection

PRODUCT GUIDE

11

Netzer Precision Position Sensors

VLX-170

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

VLX-170-PG-V02

9. Electric Encoder Software Installation

The Electric Encoder Explorer (EEE) software:

●Verifies correct mounting for an adequate signal amplitude

●Calibration of offsets

●General set up and signal analysis

This section describes the steps associated with installing the EEE software application.

9.1 Minimum requirements

●Operating system: MS windows 7/ 10, (32 / 64 bit)

●Memory: 4MB minimum

●Communication ports: USB 2

●Windows .NET Framework, V4 minimum

9.2 Installing the software

●Run the Electric Encoder™ Explorer file found on Netzer website: Encoder Explorer Software Tools

●After the installation you will see Electric Encoder Explorer software icon on the computer desktop.

●Click on the Electric Encoder Explorer software icon to start.

10. Mechanical Mounting

10.1 Encoder mounting - End-of-Shaft Installation

Typical encoder installation uses

●Mounting screws Socket Head Cup Screw 8xM2, 4 each per stator & rotor.

●Mounting dowel pins 4xØ2, 2 each per stator & rotor (not included with the encoder).

12 Product GuideVLX-170-PG-V02

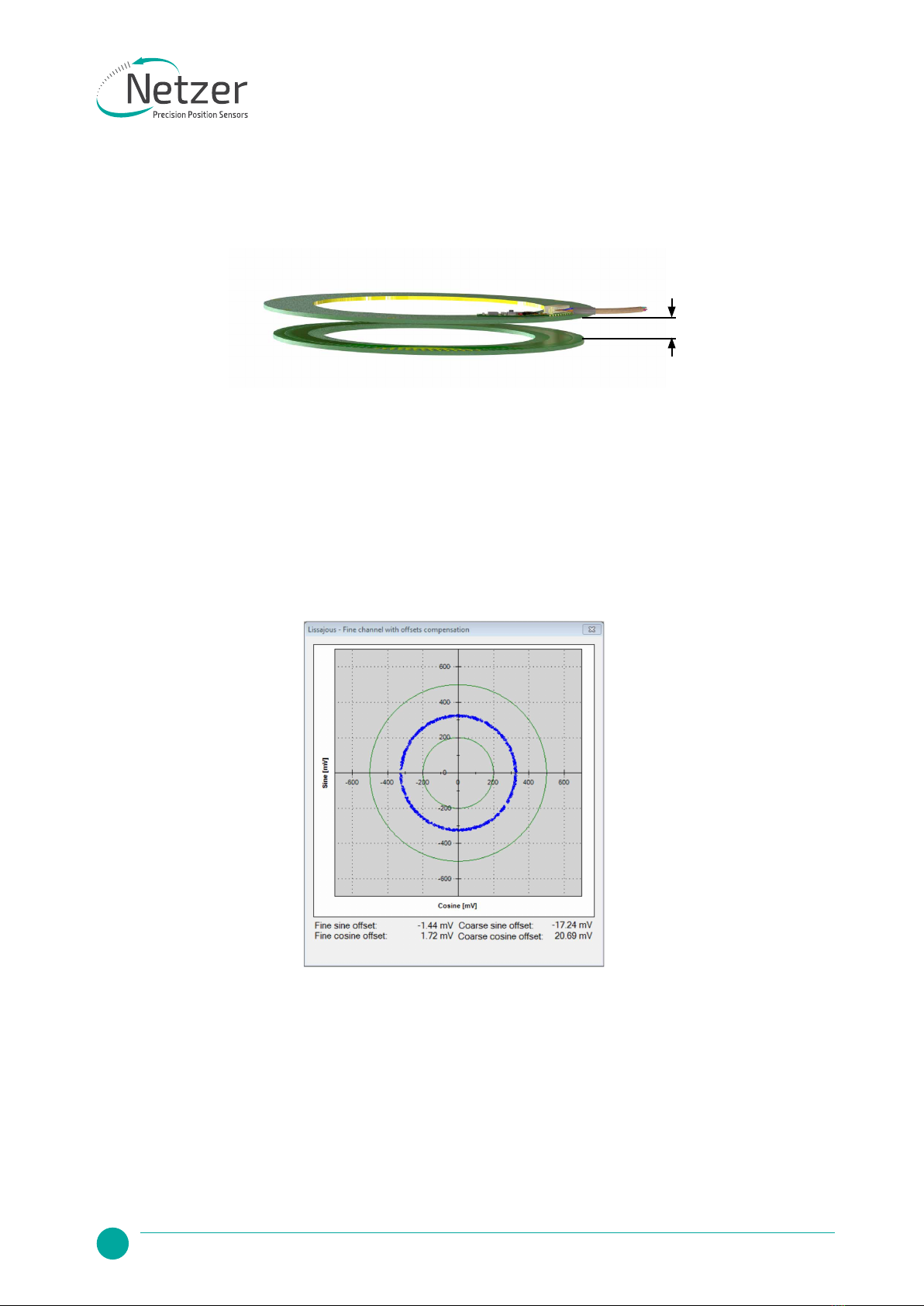

Encoder stator / Rotor relative position

For proper performance the air gap should be 1 mm ±0.3 mm

Note: for more information please read section 7

In an optimal mounting, the signal amplitude values generated by the encoder, would be in the middle of

the range of the signal plot shown in the Encoder Explorer software (see plot below). This may vary according

to the encoder type.

Verify proper rotor mounting with the Encoder Explorer tools “Signal analyzer” or“Signal verification process.”

1 mm

PRODUCT GUIDE

13

Netzer Precision Position Sensors

VLX-170

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

VLX-170-PG-V02

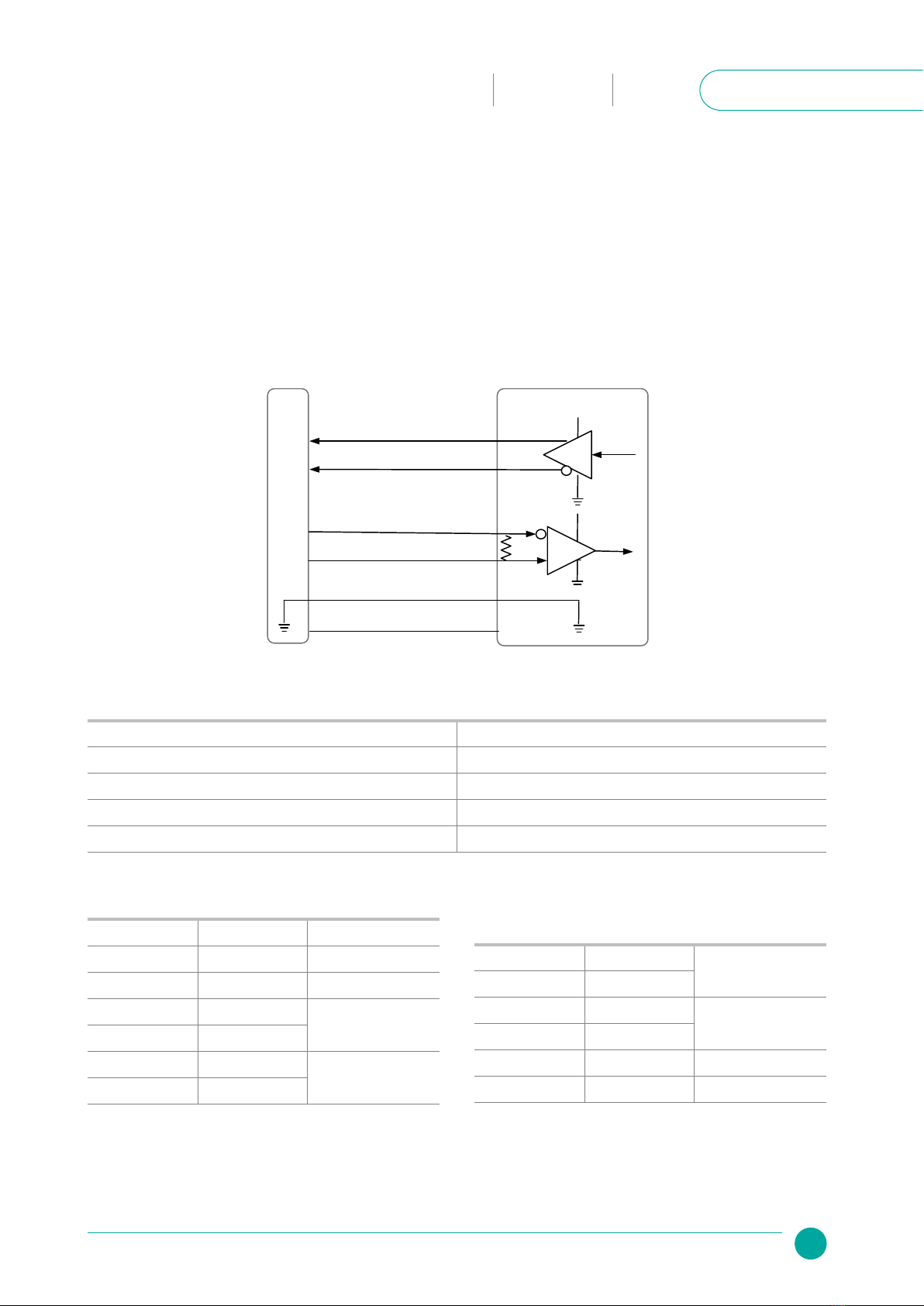

11. Electrical Connection

This chapter reviews the steps required to electrically connect the encoder with digital interface (SSi or BiSS-C).

Connecting the encoder

The encoder has two operational modes:

11.1 Absolute position over SSi or BiSS-C

This is the power-up default mode

5V

Host System

CLK / NCP RX [+]

CLK / NCP RX [-]

5V

5V

120 Ω

(red)

(yellow)

(green)

(blue)

(gray)

(black)

Electric Encoder™

Gnd

DATA / NCP TX [-]

DATA / NCP TX [+]

Accessory cable (optional)

SSi / BiSS interface wires color code

Clock + Grey Clock

Clock - Blue

Data - Yellow Data

Data + Green

GND Black Ground

+5V Red Power supply

SSi / BiSS output signal parameters

Output code Binary

Serial output Dierential RS-422

Clock Dierential RS-422

Clock frequency 0.1÷ 5.0 MHz

Position update rate 35 kHz (Optional - up to 375 kHz)

Connector Pinout

Pin No. SSi / BiSS Remarks

8 +5V P.S.

7 GND GND / RTN

6 Data + Data / NCP TX

5 Data -

4 Clock - Clock / NCP RX

3 Clock +

14 Product GuideVLX-170-PG-V02

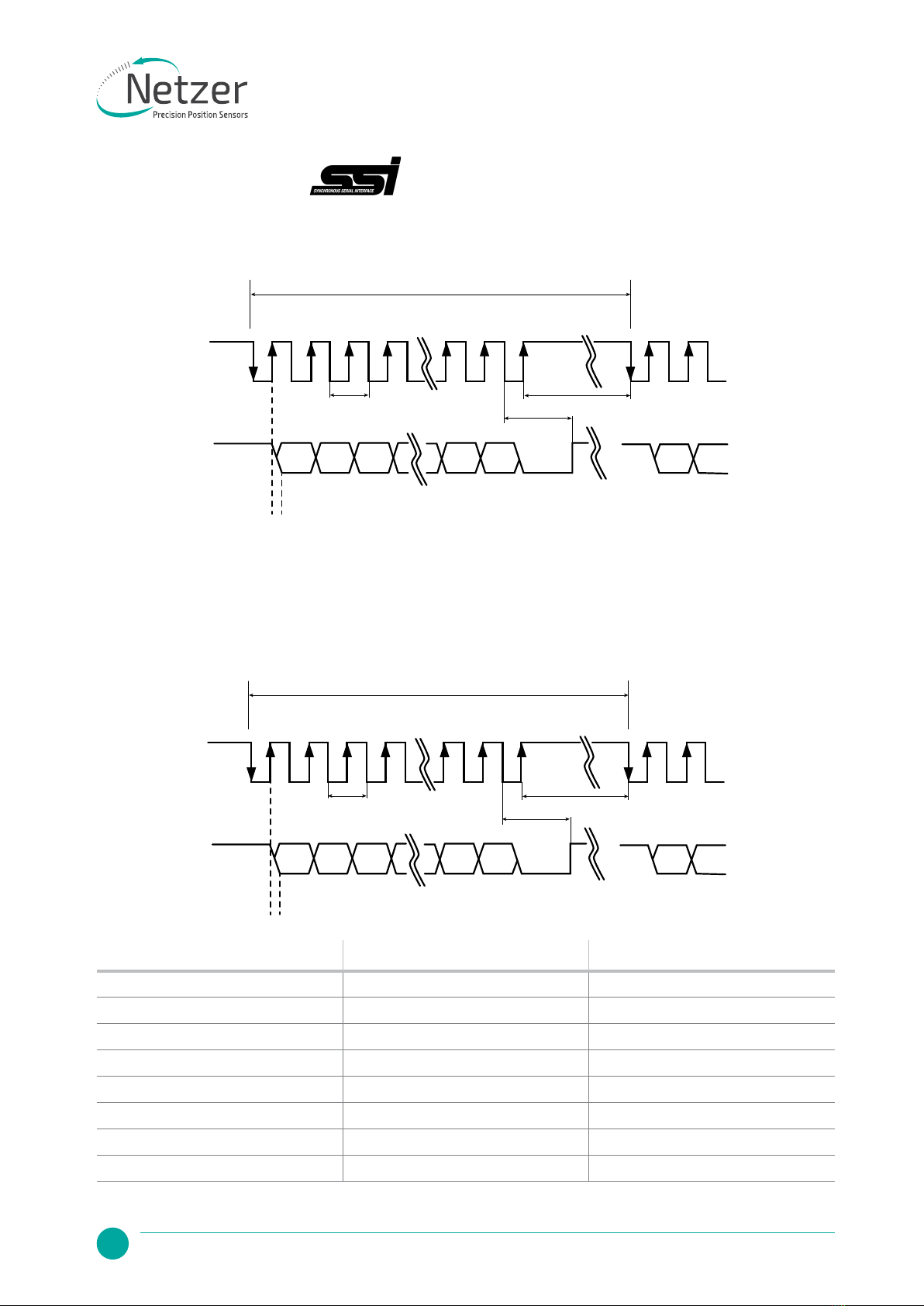

11.2 Digital SSi Interface

Master

Clock

Encoder

Data

Tr

1 2 3 4 n n+1

Tp

T

MSB

Tu

n-1 n-2 n-3 0

LSB

Tm

MSB

Synchronous Serial Interface (SSi) is a point to point serial interface standard between a master (e.g. controller)

and a slave (e.g. sensor) for digital data transmission.

Master

Clock

Encoder

Data

Tr

1 2 3 4 n+1 n+2

Tp

T

MSB

Tu

BIT n-1 n-2 0

LSB

Tm

MSB

Description Recommendations

n Position resolution 12-20

T Clock period

f= 1/T Clock frequency 0.1-5.0 MHz

Tu Bit update time 90 nsec

Tp Pause time 26 - ∞ μsec

Tm Monoop time 25 μsec

Tr Time between 2 adjacent requests Tr > n*T+26 μsec

fr=1/Tr Data request frequency

Built In Test option (BIT)

The BIT indicates critical abnormality in the encoder internal signals.

'0' – the internal signals are within the normal limits, '1' – Error

The Part Number of the encoder indicates whether the encoder includes BIT. If no BIT is indicated in the PN,

there is no additional error bit.

PRODUCT GUIDE

15

Netzer Precision Position Sensors

VLX-170

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

VLX-170-PG-V02

BiSS – C Interface is unidirectional serial synchronous protocol for digital data transmission where the Encoder

acts as “slave” transmits data according to “Master”clock. The BiSS protocol is designed in B mode and C mode

(continuous mode). The BiSS-C interface as the SSi is based on RS-422 standards.

Built In Test option (BIT)

The BIT indicates critical abnormality in the encoder internal signals.

'1' – the internal signals are within the normal limits, '0' – Error

The Part Number of the encoder indicates whether the encoder includes BIT. If no BIT is indicated in the PN,

the error bit is always 1.

11.3 Digital BiSS-C Interface

Master

Clock

Position ErrStart TimeoutAck 0 (bits)

Encoder

Data

WCRC (6 bits)

Bit allocation per

encoder-resolution Description Default Length

17bit 18bit 19bit 20bit

27 28 29 30 Ack Period during which the encoder calculates the

absolute position, one clock cycle

0 1/clock

26 27 28 29 Start Encoder signal for “start” data transmit 1 1 bit

25 26 27 28 “0” “Start” bit follower 0 1 bit

8...24 8...25 8...26 8...27 AP Absolute Position encoder data Per

resolution

7777Error BIT (Built In Test option) 1 1 bit

6666Warn. Warning (non active) 1 1 bit

0...5 0...5 0...5 0...5 CRC The CRC polynomial for position, error and warning

data is: x6+ x1+ x0. It is transmitted MSB rst and

inverted.

The start bit and “0”bit are omitted from the

CRC calculation.

6 bits

Timeout

Elapse between the sequential “start”request cycle’s 25 μs

16 Product GuideVLX-170-PG-V02

11.4 Setup mode over NCP (Netzer Communication Protocol)

This service mode provides access via USB to a PC running Netzer Encoder Explorer application (on MS

Windows 7/10). Communication is via Netzer Communication Protocol (NCP) over RS-422 using the same set

of wires.

Use the following pin assignment to connect the encoder to a 9-pin D-type connector to the RS-422/USB

converter CNV-0003 or the NanoMIC.

Connect Netzer encoder to the converter, connect the converter to the computer and run the Electric Encoder Explorer

Software Tool

Electric encoder interface, D Type 9 pin Female

Description Color Function Pin No

SSi Clock / NCP RX Gray Clock / RX + 2

Blue Clock / RX - 1

SSi Data / NCP TX Yellow Data / TX - 4

Green Data / TX + 3

Ground Black GND 5

Power supply Red +5V 8

Setup

USB

Setup

USB

SSI / BiSS

Electric

Encoder

NanoMIC

Blue Box Electric

Encoder

or

11.5 Electrical connection and grounding

Observe the following grounding consideration:

1. The cable shield electrically floating (unconnected) by default.

2. Make sure the chassis is grounded.

3. It’s highly recommended to keep the motor PWM wires electrically shielded and/or kept away from the

encoder.

Note: 4.75 to 5.25 VDC power supply required

PRODUCT GUIDE

17

Netzer Precision Position Sensors

VLX-170

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

VLX-170-PG-V02

12. Signal Verication

12.1 Starting the Encoder Explorer

Make sure to complete the following tasks successfully:

●Mechanical Mounting

●Electrical Connection to the encoder

●Encoder Explore Software Installation

Run the Encoder Explorer tool (EE)

Ensure proper communication with the encoder: (Setup mode by default).

The Encoder position-dial is colored blue when in Setup Mode, either through the NanoMic or the BlueBox (a).

Note that the operational mode is not available through the BlueBox (b).

The Signal amplitude bar indicates whether the signal is within the acceptable tolerance (c) . Note that prior to

performing the Signal Verification process the bar could indicate an out of tolerance signal (d).

Encoder data is displayed in the encoder data area (CAT No., Serial No.) (e).

The position dial display responds to shaft rotation (f).

It is important to perform the Signal Verification process prior to the calibration of the encoder to ensure

optimal performance.

a

b

c

d

f

e

18 Product GuideVLX-170-PG-V02

12.2 Signal verication process

The Signal Verification process ensures that the encoder is mounted correctly and provides good signal

amplitudes. This is performed by collecting raw data of the fine and coarse channels during rotation.

●Select <Signal Verification> on the main screen (a).

●Select <Start> to initiate the process (b).

●Rotate the shaft in order to collect the fine and coarse channels data (c).

b

c

a

PRODUCT GUIDE

19

Netzer Precision Position Sensors

VLX-170

Hollow Shaft

Kit Encoder

Absolute

Rotary Encoder

VLX-170-PG-V02

If the process is successful, the status “Signal verification successful” would appear (d).

The ‘amplitude circle’ would be centered between the two green circles, preferably in the middle of the

tolerance (e).

d

e

g

h

Note however, that mounting the encoder towards the extreme mechanical tolerances might cause the

amplitude circle to be offset from the exact middle of the nominal position.

If the signal is out of tolerance the Error notification“Amplitude is lower/higher than the min/max limit of XXX”

would appear (g).

In Addition, the status “Signal verification failed – perform calibration amplitude”would appear at the top (h).

●Stop the process and re-mount the encoder, making sure that the mechanical installation tolerances are

not exceeded, removing or adding shims as required.

●Repeat the Signal Verification process after the remount.

Once the signal verification process is successfully completed, proceed to the encoder calibration phase,

Section 13

20 Product GuideVLX-170-PG-V02

13. Calibration

The VLX encoders include several options for performing calibration:

●'Push-Button' Calibration

●Auto-calibration

●Manual Calibration

13.1 ‘Push-Button’ calibration

This simple calibration procedure is possible once the encoder is mounted and connected to the application,

without using the Encoder Explorer software or connecting to a PC.

In this calibration procedure, the zero point cannot be changed ans is set at the factory default zero point.

It is not possible to use the Push-Button calibration if the encoder rotation sector is less than 360 degrees.

13.1.1 ‘Push-Button’ calibration process

Connect a 5V power supply to the encoder and the calibration process can be started.

●Upon power connection the LED should continuously blink

green.

This means the encoder is ready for calibration

●Press the Push-Button (a) for 5 seconds.

●Continuously rotate the rotor for about 10-20 seconds.

The LED will blink alternately red & green (b).

●When the LED is showing constant green the calibration

process has ended successfully.

●If the LED blinks red this means that the calibration process

failed. In case of failure - refer to the troubleshoot table

below:

No. of blinks Calibration step with error Recommended corrective action

1 Noisy electrical environment 1. Improve grounding

2. Repeat calibration process

2 1. Signal Amplitude out of tolerance

2. Osets cannot be calibrated

1. Check Amplitudes via Encoder Explorer. (See Section 12)

2. Correct the mechanical installation and remount encoder

3. Repeat calibration process

3 1. Rotation speed too high for

calibration process

2. Process timed-out

Repeat calibration process at lower speed

If ‘Push Button’calibration repeatedly fails after the applying the corrective actions, revert to the auto or

manual calibration processes (sections 13.2 & 13.3).

If calibration still fails – contact Netzer support department.

(b)

(a)

This manual suits for next models

1

Table of contents

Other Netzer Media Converter manuals