NEUBRONNER ALPHA X1-400 User manual

Operating Manual

ALPHA X1-400

Contents

Operating Manual

ALPHA X1-400

Page 2 of 47

1

Identification.......................................................................................4

2

User information.................................................................................5

2.1 P

URPOSE OF THE DOCUMENT

...................................................................................... 5

2.2 T

ARGET GROUPS

........................................................................................................ 5

2.3 L

IABILITY AND WARRANTY

........................................................................................... 5

2.4 R

EORDERING AND COPYRIGHT

.................................................................................... 6

3

General safety information .................................................................7

3.1 P

ERSONNEL TRAINING

................................................................................................ 8

3.2 R

EPRESENTATION OF SAFETY INFORMATION

................................................................ 8

3.3 P

ERSONAL PROTECTION EQUIPMENT

(PPE) ................................................................. 9

3.4 S

AFETY AND PROTECTIVE SYSTEMS

............................................................................10

3.4.1 Mains isolation device (mains plug)...................................................................10

3.5 I

NDICATIONS OF SPECIAL HAZARD TYPES

....................................................................11

3.5.1 Electrical energy ...............................................................................................11

3.5.2 Securing against start-up/accidental switching-on.............................................11

3.5.3 General operating methods before start-up.......................................................11

3.5.4 Noise.................................................................................................................11

3.5.5 Cleaning............................................................................................................12

3.5.6 Organisational measures ..................................................................................13

4

Description of the Machine...............................................................14

4.1 I

DENTIFICATION DATA

................................................................................................14

4.2 I

NTENDED USE

..........................................................................................................15

4.3 F

ORESEEABLE MISUSE

...............................................................................................16

4.4 E

QUIPMENT SET

-

UP AND COMPONENTS

......................................................................17

4.5 F

UNCTION DESCRIPTION

............................................................................................18

4.6 S

PECIFICATION

.........................................................................................................19

5

Installation and transport..................................................................20

5.1 T

RANSPORTING THE EQUIPMENT

................................................................................21

5.1.1 Connecting the equipment ................................................................................21

6

Start-up and operation .....................................................................22

6.1

P

REHEATING THE EQUIPMENT FOR OPERATION

................................................................23

6.1.1 Filling the water tank .........................................................................................23

6.1.2 Inserting the adhesive tape ...............................................................................24

6.2 C

ONTROLS

...............................................................................................................26

Operating Manual

ALPHA X1-400

Page 3 of 47

6.2.1 Membrane keypad ............................................................................................26

6.2.2 ON/OFF switch (back of the equipment) ...........................................................27

6.2.3 Off button (1.)....................................................................................................27

6.2.4 Standby LED (green) (2.) .................................................................................27

6.2.5 Fault LED (red) (3.) ..........................................................................................27

6.2.6 X2 button with indicator LED (yellow) (4.).........................................................28

6.2.7 +5 button with indicator LED (yellow) (5.) .........................................................28

6.2.8 * Manual feed button (6.)..................................................................................28

6.2.9 20….110 buttons (7.) ........................................................................................28

6.2.8 Auto-button with indicator LED (yellow) (8.)......................................................29

6.2.9 Start button (9.) .................................................................................................29

6.3 O

PERATING MODES

...................................................................................................30

6.3.1 Manual operation ..............................................................................................30

6.3.2 Automatic operation ..........................................................................................30

7

Maintenance and Servicing..............................................................31

7.1 C

LEANING THE EQUIPMENT

........................................................................................32

7.2 G

ENERAL

M

AINTENANCE

S

CHEDULE

..........................................................................34

7.3 T

ROUBLESHOOTING AND FAULT ELIMINATION

...............................................................37

7.4 S

PARE PARTS AND WEAR PARTS

.................................................................................39

8

Decommissioning, Disassembly, Storage and Disposal...................40

8.1 S

TORAGE

.................................................................................................................41

8.1.1 Packaging .........................................................................................................41

8.1.2 Storage .............................................................................................................41

8.1.3 Unpacking.........................................................................................................42

8.2 D

ISPOSAL

.................................................................................................................42

9

EC Compliance Statement...............................................................43

10

Appendix..........................................................................................44

10.1 M

ECHANICAL COMPONENTS

....................................................................................44

10.2

K

NIFE BLOCK COMPONENTS

...................................................................................46

Operating Manual

ALPHA X1-400

Page 4 of 47

1 Identification

Manufacturer's name: NEUBRONNER GmbH & Co. KG

Street: Neubronnerstrasse 1

Location: D-61440 Oberursel / TS

Phone: +49 (0) (6171) 9248-0

Fax: +49 (0) (6171) 9248-99

Internet: www.neubronner.com

Machine designation: Alpha X1-400

Operating Manual

ALPHA X1-400

Page 5 of 47

2 User information

2.1 Purpose of the document

The operating manual contains important information about operating the

equipment safely, professionally and economically. Observing it helps to

avoid hazards, reduce repair costs and breakdown times and to increase

the reliability and working life of the equipment. Every person who is as-

signed to work on the equipment is to read and apply the operating man-

ual.

Any personnel assigned to work on the equipment must have read the

operating manual before commencing work. This applies especially to

personnel who work only occasionally on the equipment, for example dur-

ing maintenance and repair work.

The operating manual must be available at all times. Always keep a copy

of this operating manual at the location where the equipment is used.

In addition to the operating manual, the mandatory regulations on acci-

dent prevention applicable to the country and location of use must be

observed. The recognized technical regulations for safety- and proper

operation must also be followed.

2.2 Target groups

•

As the supervisory legal entity, the operator is responsible for

proper use of the equipment and training and deployment of au-

thorised persons. It defines the mandatory skills and instruction

powers for authorised persons within its operation.

•Specialists are persons who are able to evaluate the work they

are assigned to and to recognise possible hazards because of their

professional training. They also have good knowledge of the appli-

cable regulations. This group only includes trained specialist per-

sonnel or such personnel that the owner considers capable.

•Trained/instructed persons are considered to be persons who

have been instructed and, if necessary, trained, in the work they

are assigned to and the possible hazards of improper use. They

have also been instructed in the necessary safety equipment and

protective measures. Persons being trained, taught or instructed,

or persons carrying out general training, may only work under the

continuous supervision of an experienced person.

Responsibilities are to be clearly delimited and defined. The legally per-

missible minimum age must be observed!

2.3 Liability and warranty

All the information contained in this operating manual is given allowing

for our previous experience and findings to the best of our knowledge.

Operating Manual

ALPHA X1-400

Page 6 of 47

The original version of this operating manual was produced in German

and carefully checked by ourselves. A recognised translation agency

translated it into the relevant national/contractual language.

This operating manual was compiled with great care. If, despite this,

you notice any inadequacies and/or errors, please contact us in writing

to inform us of the above. Your suggestions for improvement help us in

making a user-friendly operating manual.

The warranty period is 1 year from the date of purchase.

Excluded from the warranty are defective parts whose defects are due

to negligence, improper use, wear and tear caused by use and

transport damage.

2.4 Reordering and copyright

Further copies of this operating manual can be reordered from the ad-

dress stated in the chapter entitled Identification. Please note that reor-

dering incurs a charge.

All rights explicitly reserved. Reproduction or communication to third

parties, irrespective of the method, is not permitted without our written

authority.

Operating Manual

ALPHA X1-400

Page 7 of 47

3 General safety information

Knowledge of the basic safety instructions is a basic requirement for safe

handling and fault-free operation of this equipment. The safety instruc-

tions for the supplied components in the documents included in this ap-

pendix are to be obeyed in addition to the instructions specified in this

operating manual.

1. To use the equipment for any purpose other than that intended by

the manufacturer is not allowed.

2. If personnel notice any errors or hazards, the operator or its official

representative must be informed of this immediately.

3. Safety equipment and precautions may never be removed or

bridged during normal operation of the equipment.

4. If it is essential to dismantle safety equipment, it must be reassem-

bled and checked immediately after work is completed.

5. Work on technical equipment (e.g. electrical systems) may only be

carried out by correspondingly skilled personnel.

6. When handling oils, greases and other chemical substances, the

safety regulations applying to the product must be observed!

7. Hot components must not come into contact with explosive or eas-

ily flammable chemicals.

Operating Manual

ALPHA X1-400

Page 8 of 47

3.1 Personnel training

Only the relevant specialist personnel may work on the equip-

ment's electrical and mechanical equipment.

Observe the information to personnel in the relevant chapter of

this operating manual.

3.2 Representation of safety information

The following designations and symbols are used for safety information

in the operating manual:

Failure to observe these instructions can lead to detrimental ef-

fects on health, perhaps extending to life-endangering injuries.

This symbol indicates an imminent danger to life and limb. Failure to ob-

serve these instructions results in serious adverse health effects and

can extend to life-threatening injuries.

This symbol points to potential property and/or environmental damage.

This symbol points to a potentially hazardous situation.

This symbol points out important facts and especially

useful information.

Dangerous electrical voltage warning

Beware of hot surface warning.

Hot surfaces, such as components, vessels or materials, as well as hot

fluids are not always discernible. Please exercise caution when such a

safety marking is attached to a component.

Operating Manual

ALPHA X1-400

Page 9 of 47

Use foot protection

Use hand protection

Environmentally hazardous

3.3 Personal protection equipment (PPE)

Necessary protective equipment required by the regulations must be

provided by the operating company.

Suitable personal protective equipment is prescribed for the respective

tasks to be performed. This is specifically referred to in the individual

chapters of these operating instructions.

Use foot protection

Use hand protection

Operating Manual

ALPHA X1-400

Page 10 of 47

3.4 Safety and protective systems

The equipment has been constructed in accordance with state-of-the-art

technology and the established technical safety regulations. Despite this,

hazardous situations can occur.

All safety and protective equipment must be kept in perfect working order.

Only use the equipment when it is in perfect technical condition, in ac-

cordance with its intended use, safety and hazard-beware and under ob-

servance of the operating manual! Malfunctions which could affect safety

must be rectified immediately!

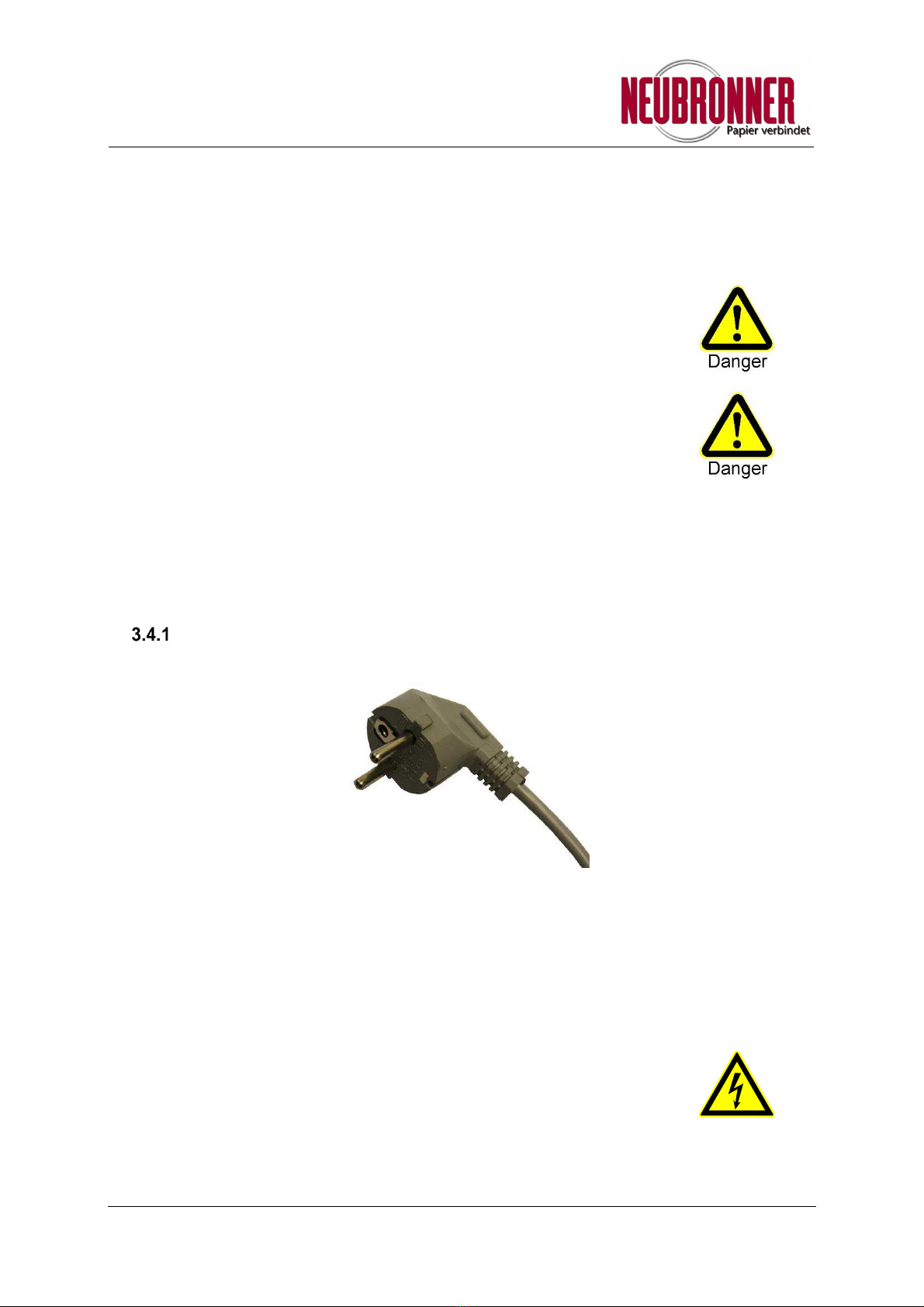

Mains isolation device (mains plug)

Figure 1: Mains isolation device (mains plug)

Before opening the housing and/or before servicing and cleaning, the

mains plug must be pulled out.

Operating Manual

ALPHA X1-400

Page 11 of 47

3.5 Indications of special hazard types

Electrical energy

Hazardous electrical voltage warning!

It is imperative that you observe the following instructions.

Only specialist electrical engineers may work on the equipment's electri-

cal fittings, in accordance with electrical engineering regulations.

Equipment components on which inspection, maintenance and repair

work is being carried out must be isolated if prescribed. Check first that

live components have been isolated from the power supply. Only use

original fuses with the prescribed rating. If there are any malfunctions in

the electrical energy supply, switch the equipment off immediately!

Inspect/check the equipment's electrical fittings, such as mains plugs,

regularly. Remedy defects immediately.

Securing against start-up/accidental switching-on

In order to guarantee that the equipment is isolated from the energy sup-

ply, pull out the mains plug when the equipment is stationary.

General operating methods before start-up

Before the equipment is started up, it is the operator's duty to ensure that

there is nobody inside its danger zones.

Noise

Noise level: < 70 dB(A)

Operating Manual

ALPHA X1-400

Page 12 of 47

Cleaning

Observe safety datasheets!

You should clean water tanks and foam rollers at least once a week!

Cleaning agents can penetrate the skin and remove natural fats. This

means that the skin becomes dry, cracked and particularly receptive for

the admission of pathogens. The skin protection, skin cleansing and

skincare program must match the hazardous materials used.

Before any cleaning and servicing work on the equipment, first pull out

the mains plug.

Operating Manual

ALPHA X1-400

Page 13 of 47

Organisational measures

The operating manual should always be kept ready to hand at the place

where the equipment is installed.

It is imperative that the safety information in the component operating

manuals is observed.

Generally applicable, legal and other binding regulations for accident

prevention and for environmental protection must be observed and noti-

fied!

The owner must train operating personnel extensively. The owner must

ensure that instruction is given about possible hazards. The operating

personnel must be extensively instructed by the owner through safety

training sessions and operational instructions. For this purpose, the op-

erating manual is to be supplemented by instructions, including supervi-

sion and reporting obligations in order to take operational circum-

stances (work organisation, work sequences, personnel used) into ac-

count.

Personnel assigned to work on the equipment must have read the oper-

ating manual, and in this case in particular, the chapter entitled "Safety

information", before commencing work. This applies especially to per-

sonnel who work only occasionally on the equipment (cleaning and

maintenance).

Checks should be made at least occasionally to ensure that personnel

are working in a safety and hazard-aware manner whilst observing the

operating manual!

Personal protective equipment must be used wherever specified by the

operator.

Observe all safety and hazard information on the equipment!

All safety and hazard information on/at the equipment is always to be

kept in a legible condition.

If there are any changes to the equipment or its operation related to

safety, shut it down immediately and report the malfunction to the re-

sponsible agency/person.

Do not make any changes to the equipment which could affect safety

without the manufacturer's authorisation! Spare parts must meet the

technical requirements specified by the manufacturer.

This is always guaranteed by the use of original spare parts.

Observe time limits for repeating tests/inspections.

Appropriate workshop equipment is indispensable for work related to re-

pairs and maintenance.

The operator must ensure that lighting is sufficiently arranged and in-

stalled.

Operating Manual

ALPHA X1-400

Page 14 of 47

4 Description of the Machine

4.1 Identification data

This operator manual is part of the ALPHA X-400

The data shown below is entered on the identification/nameplate.

NEUBRONNER GmbH & Co. KG

Neubronnerstrasse 1

D-61440 Oberursel

Tape dispenser

230V / 120VA Built: 2017

Type: ALPHA X1-400

Serial no.: 001

For information about safe use of the machine, refer to the operating manual.

Check whether the working voltage given on the nameplate is the same

as the local supply voltage.

Operating Manual

ALPHA X1-400

Page 15 of 47

4.2 Intended use

The equipment may only be used in accordance with the guidelines de-

scribed in this operating manual. Any other use beyond this is not con-

sidered intended use. The manufacturer is not liable for any resulting

damage.

This equipment reflects the current state of the art and can be safely op-

erated in compliance with the operating manual and the system and op-

erating specifications.

Nevertheless, dangers to the life and limb of the user or third parties or

damage to the equipment or other property can occur during use.

Only use the equipment when it is in perfect technical condition, in ac-

cordance with its intended use, safety and hazard-aware and in compli-

ance with the operating manual! Malfunctions which could affect safety

must be rectified immediately!

Changes and/or adjustments to the equipment are possible in some

cases. In these cases, prior written authorisation must be obtained from

the manufacturer.

Please refrain from the following in particular:

•non-compliance or insufficient compliance with the information in

this operating manual;

•use of replacement parts or parts not authorised by the manufac-

turer;

•incorrect operation;

•removal, manipulation or non-deployment of protective devices;

•changing functions;

•unauthorised changes to the equipment;

•improper maintenance;

•use not in accordance with the regulations

Operating Manual

ALPHA X1-400

Page 16 of 47

4.3 Foreseeable misuse

Any inappropriate or improper use of the equipment can be dangerous.

The operating manual must be available to the user and any maintenance

and repair personnel during the entire time the equipment is in use. Al-

ways keep a copy of this operating manual at the equipment. Ensure that

a copy of this operating manual is available during maintenance and re-

pair work!

The operational safety of the supplied equipment is guaranteed only if

used for its intended purpose in accordance with this operating manual.

The equipment is not suitable for use in areas where is a danger of ex-

plosion.

It is imperative that information contained in the operating manual is fol-

lowed! Improper use of the equipment voids the manufacturer's liability

and warranty!

Any use of the equipment beyond that intended is forbidden and is con-

sidered as incorrect use/misuse of the equipment.

Operating Manual

ALPHA X1-400

Page 17 of 47

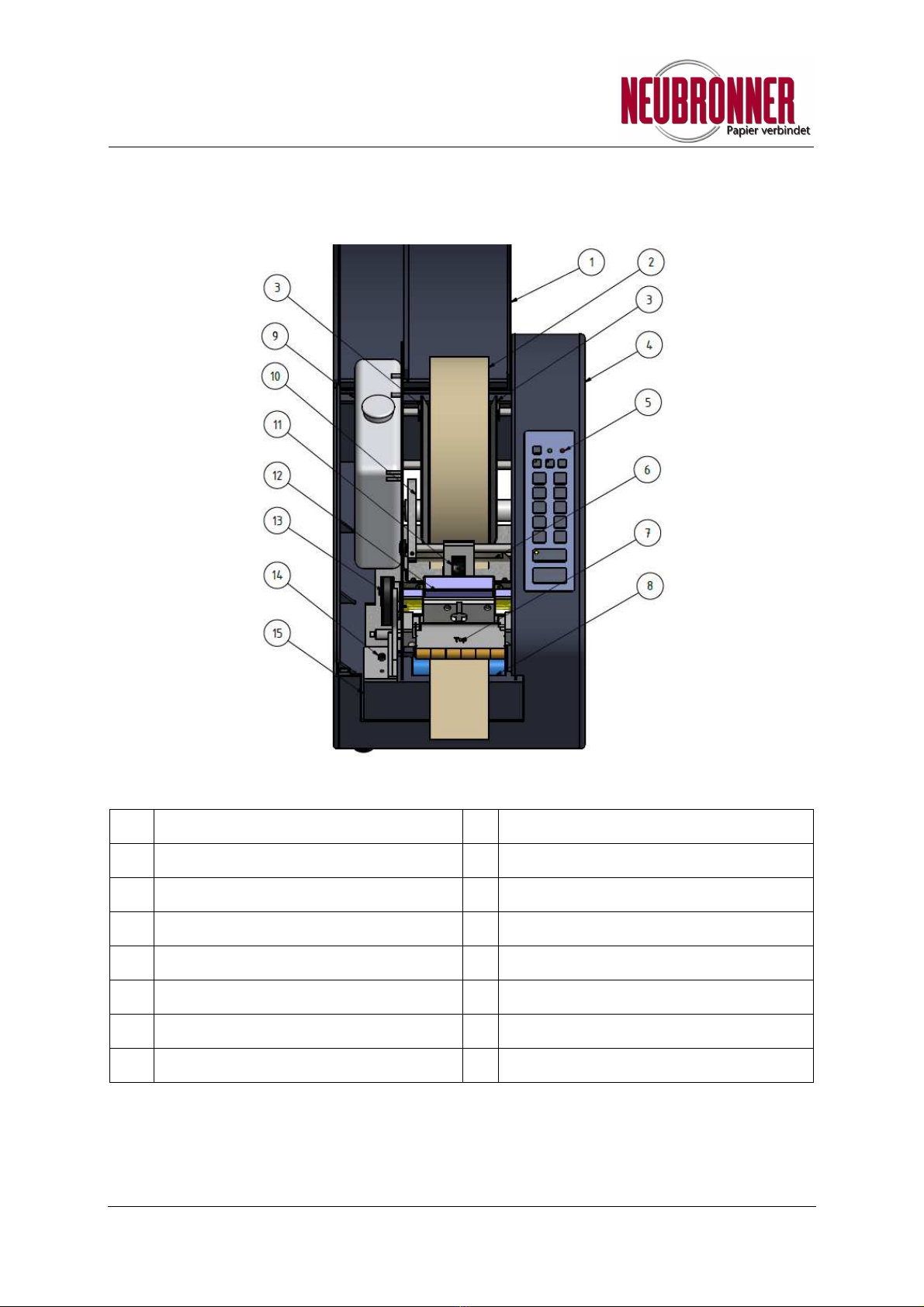

4.4 Equipment set-up and components

Figure 2: Equipment set-up and components

1 Valve 9 Water tank

2 Adhesive tape roll 10

Release lever

3 Roller guide plates (adjustable) 11

Pressure roller

4 Housing 12

Knife

5 Keyboard 13

Toothed belt

6 Inlet plate 14

Valve with level sensor

7 Pressure plate 15

Water container

8 Foam roller

Operating Manual

ALPHA X1-400

Page 18 of 47

4.5 Function description

The ALPHA X1-400 is an electrically driven wet adhesive tape dispenser

with a microprocessor controller.

Figure 3: ALPHA X1-400 figure

The water container is filled automatically from the tank and its level is

kept constant.

The ALPHA X1-400 is equipped with a tape guide.

A step motor conveys the desired length of tape towards the tape output

and moistens it at the foam roller. The tape is cut automatically on reach-

ing the preset length.

A light barrier detects the removal of an adhesive tape strip and re-

leases the keyboard for the next strip.

Operating Manual

ALPHA X1-400

Page 19 of 47

4.6 Specification

Type ALPHA X1-400

Weight (kg) 15

Supply voltage

230 V

–

50 Hz, 1A

Adjustable strip length,

min. 200 mm

Adjustable strip length,

max. 2,300 mm

Max. roller outside diam-

eter 250 mm

Max. roller width

80 mm

Shipping box size 285 × 300 × 500 mm

Operating Manual

ALPHA X1-400

Page 20 of 47

5 Installation and transport

The following personal protective equipment (PSE) must be worn.

•Foot protection (safety shoes)

•Hand protection (protective gloves)

Table of contents