Smipack T450 User manual

61 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

USE AND MAINTENANCE MANUAL

Heat-shrinking tunnel

T450 - T650E- T650EF

T650-T650F

MANUAL CODE:

CREATION DATE:

RELEASE:

RELEASE DATE:

DM210060

31.07.2000

6.0

07.02.2006

+

+

+

+

+

+

+

+

+

+

+

+

+

62 / 284

FOREWORD

In thanking you for the preference given us, SMIPACK S.p.A. is glad to welcome you

to its wide circle of Clients and wishes that the use of this machine will be for you

reason for full satisfaction.

This manual can be used for models T450-T650E-T650EF-T650-T650F and was

prepared with the aim to allow you to operate on the various components, explain the

various operations for maintenance and operation.

Where not expressly indicated by the ,instructions refer to all the above

mentioned models.

In order to guarantee a satisfactory level of efficiency, life and performance of the

machine, we urge you to scrupulously observe the instructions contained in this

manual.

SMIPACK S.p.A. is absolutely not responsible for any direct or non direct consequence

due to proper or non proper use of this publication or of the system software and has

got right to make technical modification on his system and on his manual without

advising the users.

SMIPACK S.p.A. - Viale Vittorio Veneto, 4 - 24016 San Pellegrino T. (BG) - Italy - Tel.

+39.0345.40400 - Fax +39.0345.40409.

PLEASE READ CAREFULLY AND FULLY THIS MANUAL BEFORE

INSTALLING THE MACHINE.

THIS MANUAL IS AN INTEGRAL PART OF THE PRODUCT AND MUST

ALWAYS ACCOMPANY THE SAME UP TO ITS DISMANTLING.

63 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

1. REGULATIONS AND GENERAL INSTRUCTIONS .......................... 65

1.1. HOW TO CONSULT AND USE THIS MANUAL ................................................................. 65

1.2. WARRANTY CONDITIONS ............................................................................................... 65

1.3. LEGAL REFERENCES ...................................................................................................... 66

1.4. REMARKS ON GENERAL SAFETY .................................................................................. 66

1.5. LEGEND ............................................................................................................................. 67

2. TUNNEL INSTALLATION .................................................................. 69

2.1. DESCRIPTION OF THE MACHINE ............................................................................... 69

2.2. CONTROL SYSTEMS ....................................................................................................... 69

2.3. WEIGHT AND DIMENSIONS OF THE PACKED TUNNEL ................................................ 70

2.4. WEIGHT AND DIMENSIONS OF THE TUNNEL ............................................................ 70

2.5. TRANSPORT AND UNPACKING ...................................................................................... 70

2.6. ASSEMBLY OF THE MACHINEFP560/A AND FP870A WITH THE TUNNEL .................. 71

2.7. POSITIONING TUNNEL ROLLER T450 ............................................................................ 72

2.8. POSITIONING THE TUNNEL ROLLER CONVEYOR BELT .............................................. 72

2.9. DEMOLITION AND DISPOSAL .......................................................................................... 72

2.10. ELECTRIC CONNECTION ................................................................................................. 72

2.11. TECHNICAL DATA FOR THE ELECTRIC CONNECTION ................................................ 73

2.12. CONDITIONS OF USE ....................................................................................................... 73

3. INFORMATION ON THE TUNNEL .................................................... 75

3.1. TUNNEL IDENTIFICATION ................................................................................................ 75

3.2. SHRINKING ........................................................................................................................ 75

3.3. DEFLECTOR REGULATION ............................................................................................. 76

3.4. TURNING ROLLERS ADJUSTMENT T450 ...................................................................... 76

3.5. OPERATING THE MACHINE WITH THE OVEN IN HEAT SHRINKING MODE ............... 77

3.6. TUNNEL LIMITATIONS AND SPECIFICATIONS OF USE ................................................ 78

4. PREPARATION TO THE USE OF THE TUNNEL ............................. 79

4.1. MACHINE START UP ........................................................................................................ 79

4.2. TURN ON / TURN OFF MENU [F1] ................................................................................... 79

4.3. OPERATING MODE MENU [F2] ........................................................................................ 80

4.4. QUICK SELECTION OF THE PROGRAMS ....................................................................... 80

4.5. USER MENU [F3] ............................................................................................................... 80

4.6. PARAMETERS MENU [F3 AND +] .................................................................................... 81

4.7. LEGEND OF THE SYMBOLS AND DISPLAY MESSAGES .............................................. 82

5. ROUTINE MAINTENANCE ................................................................ 83

5.1. NATURE AND FREQUENCY OF MAINTENANCE CHECKS AND OPERATION ...... 83

SUMMARY

64 / 284

Summary

5.2. LUBRIFICATION ................................................................................................................84

5.3. LIST OF SPARE PARTS ....................................................................................................84

TAV. 1. TRANSFORMER GROUP T450 - T650E .............................................................................................. 84

TAV. 2. TRANSFORMER GROUP T450 220V 3PH - T650EF - T650 - T650F ................................................. 85

TAV. 3. TRANSFORMER GROUP T650EF 220V 3PHF ................................................................................... 86

TAV. 4. ...................................................................................................................................................... 87

TAV. 5. ............................................................................................................................................................... 88

TAV. 6. ................................................................................................................................................................ 89

TAV. 7. T450 WITH TURNING ROLLER ..................................................................................................... 90

TAV. 8. T450 WITH TURNING ROLLER ....................................................................................................... 91

TAV. 9. T450 .................................................................................................................................................. 92

TAV. 10. T450 .................................................................................................................................................... 93

TAV. 11. T650E WITH TURNING ROLLER ................................................................................................... 94

TAV. 12. T650E WITH TURNING ROLLER ................................................................................................... 95

TAV. 13. T650EF ............................................................................................................................................ 96

TAV. 14. T650EF .............................................................................................................................................. 97

TAV. 15. T650 ................................................................................................................................................. 98

TAV. 16. T650 .................................................................................................................................................. 99

TAV. 17. T650 WITH TURNING ROLLER .................................................................................................... 100

TAV. 18. T650 WITH TURNING ROLLER .................................................................................................... 101

TAV. 19. T650F ............................................................................................................................................ 102

TAV. 20. T650F ............................................................................................................................................. 103

TAV. 21. ............................................................................................................................................................ 104

TAV. 22. ............................................................................................................................................................ 105

5.4. WIRING DIAGRAM T450 ............................................................................................106

5.5. WIRING DIAGRAM T450 (220V) ..............................................................................107

5.6. WIRING DIAGRAM T650E ......................................................................................108

5.7. WIRING DIAGRAM T650EF .....................................................................................109

5.8. WIRING DIAGRAM T650EF (220) ...................................................................................110

5.9. WIRING DIAGRAM T650 ....................................................................................111

5.10. WIRING DIAGRAM T650F ............................................................................................112

6. ANOMALIES AND FAILURES – HOW TO REMEDY ..................... 113

6.1. POSSIBLE CAUSES AND REMEDIES ............................................................................113

6.2. AUDIO WARNING OF PROBLEMS .................................................................................113

65 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

1.1 HOW TO CONSULT AND USE THIS MANUAL

Keeping of this manual

• This manual costitutes integral part of the machine and thus must be kept for as long

as the machine is in the user’s possession or, if that be the case, handed over to

any other user or subsequent owner.

• Use this manual in a way that will not damage all or part of its contents.

• Do not remove, tear or rewrite parts of this manual for any reason.

• Ensure that any amendment to this manual sent to you is incorporated in the manual

itself.

Consultation of the manual

The consultation of this manual is made easy be the insertion, in the first pages, of a

summary, which allows those consulting it to immediately locate the topic required and,

in the last pages, of an analytical index. The chapters are ordered following such a

structure to facilitate the research of the required information.

Method of updating the manual in case of modifications to the machine

The descriptions and drawings contained in the present manual are intended as non

refutative. SMIPACK S.p.A. reserves the right at any moment to apport modifications

to its machines (while keeping their essential characteristics), for the purpose of

improving their functionality and commercial and aestethic value, with no obligation to

update manuals and previous production except in exceptional cases.

Any updating or integration of the manual are to be considered as integral parts of the

manual. We would like to thank you in advance for all the suggestions that you may

want to forward to us in order to bring about further improvements to the machine.

SMIPACK S.p.A. - Viale Vittorio Veneto, 4 - 24016 San Pellegrino T. (BG) - Italy - Tel.

+39.0345.40400 - Fax +39.0345.40409

1.2 WARRANTY CONDITIONS

The machine is sent to the Client ready to be installed, and having passed, at our

factory, all expected tests and trials, in compliance with the current regulations. Within

the guarantee period SMIPACK S.p.A. undertakes to remove any eventual flaws and

defects, on the condition that the machine has been correctly used, and that the

indications found in its manuals have been respected. The warranty has a validity of

365 days from the date of purchase and covers all the materials and manufacturing

defects found by the builder. The warranty is valid only for the original buyer and

subject to the condition that the warranty certificate is duly filled in all its sections and

posted within 20 days from the date of purchase. The warranty is no longer valid if the

machine has been damaged through accident, misuse, breakdowns due to

atmospheric agents, maintenance operations or modifications carried out by

unauthorised personnel or not belonging to the servicing department of SMIPACK

S.p.A. Consumption materials, parts subject to normal wear and tear, transport from

the user to the servicing centre or vice-versa as well as labour are excluded from the

warranty and therefore are to be paid by the Buyer.

1. REGULATIONS AND GENERAL INSTRUCTIONS

66 / 284

1. Regulations and general instructions

1.3 LEGAL REFERENCES

The machine "heat-shrinking tunnel" complies to the Legislative Provisions of the law

that regulates the following Directives:

• MACHINE DIRECTIVE: 89/392/CEE, 91/368/CEE, 93/44/CEE, 93/68/CEE, 98/37/

CE.

• ELECTROMAGNETIC COMPATIBILITY DIRECTIVE: 89/336/CEE, 92/31/CEE,

and 93/97/CE.

• LOW TENSION DIRECTIVE: 73/23CEE

The directives have been followed considering the agreed norms, including:

• EUROPEAN SAFETY REGULATION FOR MACHINERY:

• EN 292/1 - EN 292/2 - EN 292/2/A1 - EN 294 - EN 349.

• ELECTRIC EQUIPMENT OF THE MACHINES: EN 60204-1.

• ASSEMBLED PROTECTION EQUIPMENT AND TRANSITION FOR LOW

TENSION (BOARD B.T.): EN 60439-1

1.4 REMARKS ON GENERAL SAFETY

The operator, before starting to work with this machine, must have acquired enough

knowledge on the location, function of the controls, characteristics of the machine, and

must have read this manual in all its entirety.

The employer must see to it that its personnel is informed on the following topics

relative to the safe usage of the machine:

• Accidents risks.

• Devices meant for the safety of the operator.

• General accidents prevention rules as provided by international directives and by

the laws of the country of destination of the machines.

It is necessary to comply to the following general precautions:

• Do not install the machine in areas posing a risk of explosion or fire.

• Do not temper with, remove or modify the safety devices; in such cases SMIPACK

S.p.A. declines any responsibility on the safety of its machines.

• Do not modify parts of the machine to install other devices without prior

authorization by SMIPACK S.p.A.; in case of unauthorized modifications the former

will not be held responsible for any possible consequences.

• Do not operate the machine in automatic mode with the fixed or mobile protections

removed.

• Do not open the fuse blocks with the mains on.

• Do not intervene on switches, valves and sensors without authorization.

• Do not intervene on the moving parts even without the aid of objects or tools.

• Do not manually oil or grease any moving part.

• Before carrying out any work on the electrical installation, ensure that the voltage

has been disconnected.

• After an adjustment or security operation, restore the state of the machine with

active protections.

ATTENTION!

The operator, the maintenance and cleaning personnel must scrupulously

67 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

adhere to both the regulations for the prevention of accidents and the safety

regulations of the Country of destination of the machine and the plant, besides

the instructions, warnings and general rules concerning the safety included in

this manual.

During maintenance or repair work on the machine, the latter has to be shut

down, and the special signals (MACHINE OFF FOR MAINTENANCE, DO NOT

START,etc...) have to be used. Make sure that the switches are not re-inserted

by unauthorized personnel.

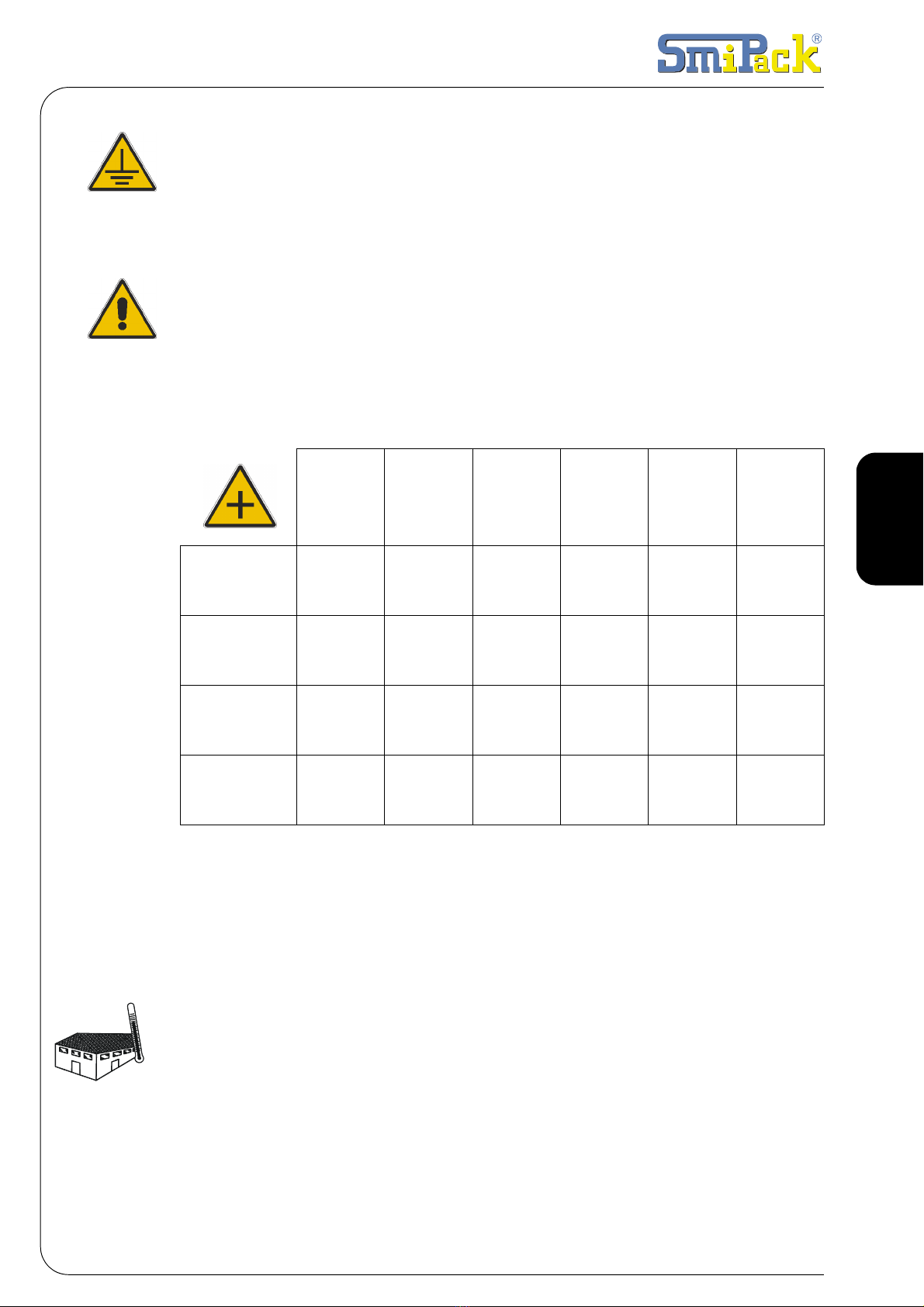

1.5 LEGEND

All instructions and notes contained in this manual are graphically represented in the

following way:

ATTENTION: READ CAREFULLY BEFORE

OPERATING.

DANGER OF ELECTROCUTION: REMOVE

VOLTAGE BEFORE PERFORMING THE

INDICATED OPERATIONS.

DANGER OF ELECTROCUTION: EARTHING

IS COMPULSORY.

DANGER OF BURNING DUE TO HIGH

TEMPERATURE SURFACES.

WARNING! DON’T TOUCH.

68 / 284

1. Regulations and general instructions

DANGER OF TRAPPING BETWEEN

MECHANICAL MEMBERS.

DANGER OF SHEARING.

DO NOT CARRY OUT MAINTENANCE WITH

MEMBERS IN MOVEMENT.

WARNING! BEFORE OPERATING, CHECK

THAT THE MACHINE TYPE IS THE ONE THAT

HAS BEEN BOUGHT.

69 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

2.1 DESCRIPTION OF THE MACHINE

2.2 CONTROL SYSTEMS

2. TUNNEL INSTALLATION

Fig. 2.1.1

GLOSSARY

1OUTLET FAN ( T650EF - T650F)

2FANS MOTOR

3DEFLECTORS

4MAIN SWITCH

5CONVEYOR COOLING FANS

( T650EF - T650F)

2

3

4

5

1

Pos. Code Description Function

1EN200043

(T450 - T650E)

ELECTRONIC

CARD

IT ALLOWS THE CONFIGURATION

OF THE MACHINE ACCORDING

TO THE KIND OF TASK IT IS

SUPPOSED TO CARRY OUT

EN200044

(T650 - T650F

T650EF)

ELECTRONIC

CARD

EN200050

(T450 220V-T650EF

220V-T650E 220V)

ELECTRONIC

CARD

2EP010095 EMERGENCY

PUSH-BUTTON

IT STOPS THE MACHINE IN CASE

OF AN EMERGENCY

1

2

Fig. 2.2.1

70 / 284

2. Tunnel installation

2.3 WEIGHT AND DIMENSIONS OF THE PACKED TUNNEL

2.4 WEIGHT AND DIMENSIONS OF THE TUNNEL

2.5 TRANSPORT AND UNPACKING

Fig. 2.3.1

T450 T650E T650EF T650 T650F

X1420

mm

1415

mm

1845

mm

2280

mm

2280

mm

Y1030

mm

1220

mm

1220

mm

1220

mm

1220

mm

Z1555

mm

1725

mm

1725

mm

1725

mm

1725

mm

WEIGHT

Kg. 223 315 350 450 470

Y

Z

X

Fig. 2.4.1

T450 T650E T650EF T650 T650F

X1310

mm

1316

mm

1749

mm

1846

mm

2285

mm

Y933

mm

1147

mm

1147

mm

1147

mm

1162

mm

Z1439

mm

1615

mm

1570

1630

1615

mm

1570

1630

W500

mm

1010

mm

WEIGHT

Kg. 187 241 276 350 375

W

X

Y

Z

SMIPACK S.p.A. in function of the means of

transport and of the type of products to be

shipped utilizes packagings adequate to

guarantee the integrity and preservation

during transportation. It is recommended to

handle with great care the machine during

transport and positioning. The forwarder is

responsible for every damage that may

occur during transport. Unpack the unit

making sure not to damage any exposed

parts.

71 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

The lifting of the machine module must be carried out by means of hoisting systems

operating from below; due to the packaging modalities, it is not possible to use hoisting

systems operating from above.

Lift the machine from the longer side and adjust the forks of the forklift at the maximum

distance from each other.

ATTENTION!

Before handling make sure that the hoisting equipment are suitable to lift the

load that has to be handled.

In the case of long storing, place the machine in a sheltered environment with a

temperature between -15°C and +55°C degree of humidity, variable between 30% and

90% without condensation.

2.6 ASSEMBLY OF THE MACHINEFP560/A AND FP870A WITH THE

TUNNEL

After having unpacked the tunnel join the machine's conveyor belt to the tunnel's belt.

Insert the hooks of the machine's belt 1onto the roller 2placed in the tunnel entrance.

Fig. 2.6.1

2

1

72 / 284

2. Tunnel installation

2.9 DEMOLITION AND DISPOSAL

The tunnel does not contain dangerous components or substances that require

particular removal procedures. After the tunnel has been dismantled you must get rid

of the various materials according to the rules and regulations of the Country in which

the tunnel has to be disposed of.

2.10 ELECTRIC CONNECTION

ALL OPERATIONS FOR THE CONNECTION TO THE MAINS MUST BE CARRIED

OUT WITH NO VOLTAGE APPLIED TO THE TUNNEL.

2.7 POSITIONING TUNNEL ROLLER T450

Fig. 2.7.1

Insert the roller conveyor

belt into 1 the attachments of

the tunnel's conveyor belt

and lock it with the roller 2in

the special holes 3. In

assembly phase do not push

the roller conveyor belt

sideways because the

attachments could be

damaged 1.

Just make it slide as shown

by the arrow in the figure.

2.8 POSITIONING THE TUNNEL ROLLER CONVEYOR BELT T650

Fig. 2.8.1

Insert the roller conveyor

belt into the external side 1

of the tunnel's conveyor belt

and lock it with the supplied

screws 2. Make sure that the

roller conveyor belt is level

on the ground when the

tunnel's belt is tilted.

2

1

3

1

1

73 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

EARTHENING IS COMPULSORY!

The connection of the tunnel to the mains must be performed in compliance with the

regulation s in force in the country of the user.

Check that the tunnel frequency and supply voltage values (see data plate on the rear

side of the tunnel) correspond to the main's value.

ATTENTION!

IF THE ELECTRONIC CARD HAS TO BE EXTRACTED, REMEMBER TO REMOVE

THE VOLTAGE AND TO WAIT AT LEAST 5 MINUTES BEFORE OPERATING.

2.11 TECHNICAL DATA FOR THE ELECTRIC CONNECTION

2.12 CONDITIONS OF USE

THE MACHINE NEEDS AN INSTALLATION IN A CLOSED AND WELL AIRED

SURROUNDING,WHERE THERE ARE NOT ANY EXPLOSION OR FIRE

DANGEROUS. THE MINIMUM LIGHTING MUST BE 300 LUX.

Make sure that there is enough space for easy application and maintenance. Position

the machine in the planned space with no humidity, flammable materials, gas, and

explosives and making sure that it is level on the floor.

We suggest operating temperatures varying from +10°C to +40°C with a relative

humidity from 30% to 80% with no condensation.

The airborne noise is lower than 70 dB.

MACHINE PROTECTION DEGREE = IP32

Tab. 2.11.1

T450 T450

THREEPHASE T650 T650EF T650EF

THREEPHASE T650F

RATED

VOLTAGE 380-415 V ~ 220-240 V ~ 380-415 V ~ 380-415 V ~ 220-240 V ~ 380-415 V ~

RATED

FREQUENCY 50-60 Hz 50-60 Hz 50-60 Hz 50-60 Hz 50-60 Hz 50-60 Hz

RATED

POWER 7950 W 7950 W 15900 W 13850 W 13850 W 21300 W

RATED

CURRENT 11.5 A 21 A 23 A 23 A 40A 30.5 A

+40°C

+10°C

74 / 284

2. Tunnel installation

ATTENTION!

The pressure and the plate acoustical power of the machine can change

depending on the material of containers to be packaged. Therefore, the user

must perform an assessment on the noise exposure of his personnel in

accordance with the types of packages worked, so as to equip his operators with

suitable personal protection equipment.

75 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

The Tseries tunnel has been

designed to heat shrink the film.

The tunnel's conveyor belt is

connected to the machine's belt

FP end BP. For a good

packaging, film sealing must

take place at half the product

height. The raising (or the

lowering) of the belt implicates

the regulation of the tunnel's

curtain, this is necessary as it is

essential not to disperse heat

during the heat-shrinking

operation.

Adjust the height of the T650

tunnel and lock the belt with the

two screws 1.

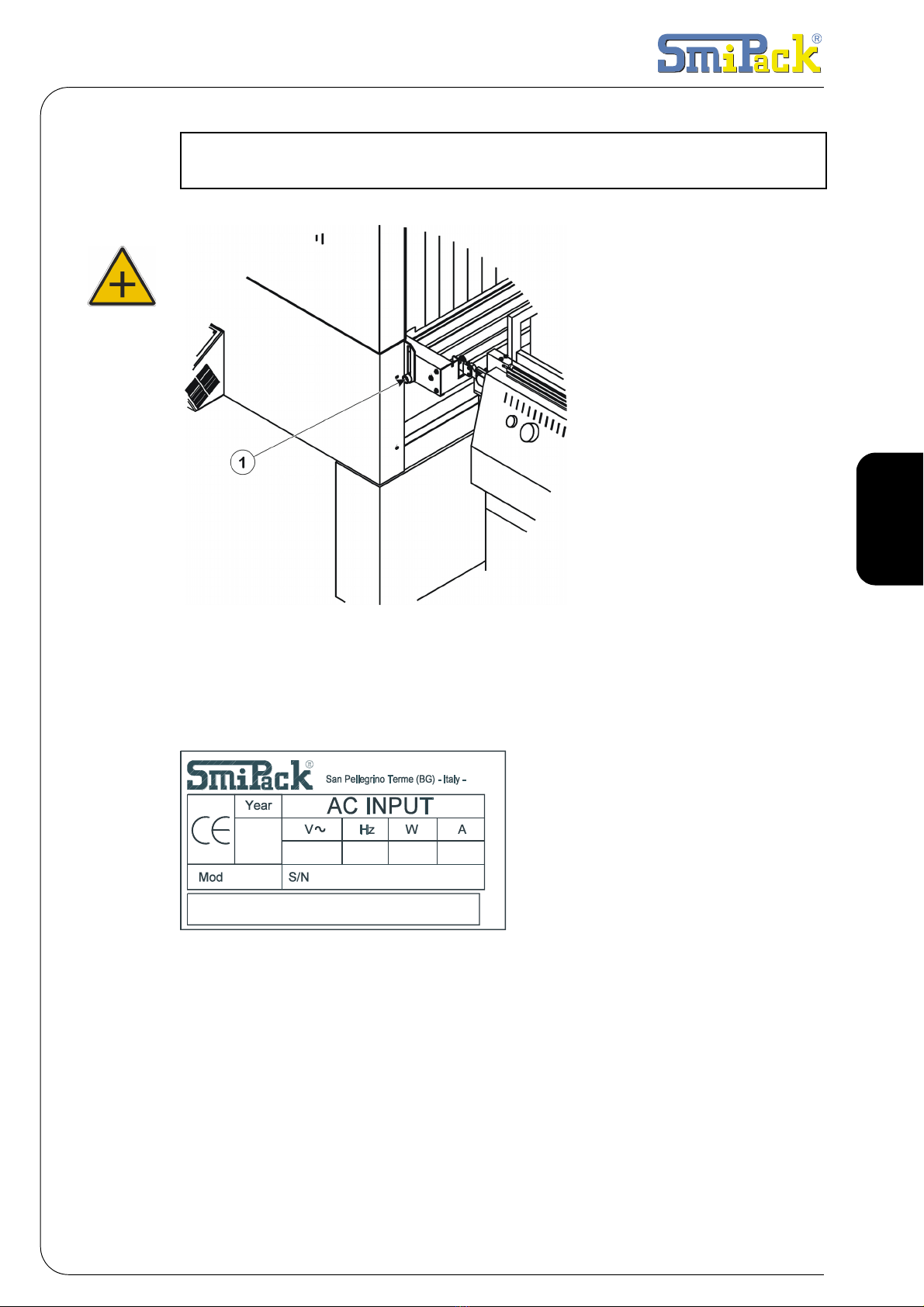

3.1 TUNNEL IDENTIFICATION

Fig. 3.1.1

On the rear of every tunnel

there is a data plate showing

the EC marking, the main

technical data such as model,

serial number, power, etc., that

will be notified to the builder in

case of problems.

3.2 SHRINKING

Film shrinking is obtained in the oven and is produced by the forced circulation of hot

air around the packaging. Air heating is obtained by making the same go through a

group of thermo-controlled resistors: a centrifugal fan moves the air. If the sealing

breaks during the shrinking it is possible to increase the speed of the belt or to lower

the temperature of the resistors by acting on the tunnel's control panel. Air heating is

obtained by making the same go through a group of thermo-controlled resistors: a

centrifugal fan moves the air. If the sealing breaks during the shrinking it is possible to

increase the speed of the belt or to lower the temperature of the resistors by acting on

the tunnel's control panel.

3. INFORMATION ON THE TUNNEL

76 / 284

3. Information on the tunnel

3.3 DEFLECTOR REGULATION

The T450, T650E, T650EF tunnels are equipped with a thermal chamber on which two

couples of deflectors are placed. The T650 and T650F tunnels are equipped with a

double thermal chamber and for each thermal chamber two couples of deflectors are

assembled. The top deflectors 1improve the heat shrinking of particularly high packs.

The low deflectors 2direct the air toward the low side of the product.

If the deflectors are opened, the air directed under the product decreases. Try to obtain

the best adjustment for the best heat shrinking.

Fig. 3.3.1

3.4 TURNING ROLLERS ADJUSTMENT T450

The product is normally conveyed by turning rollers, which grants a more

homogeneous film shrinking and a better packaging.

However, some films might tear if the rollers turn, because of the strict adherence of

the film to the rollers.

In order to find the best solution for each kind of film, the tunnel T450 can handle the

product both with turning rollers and with fixed rollers.

By means of lever A, situated on the outlet conveyour, it is possible to make the

following adjustments:

Fig. 3.4.1

1 • By keeping the lever in horizontal position, the rollers remain fixed.

2 • By turning the lever downwards, the rollers turn.

111

222

A

77 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

3.5 OPERATING THE MACHINE WITH THE OVEN IN HEAT

SHRINKING MODE

Fig. 3.5.1

Once the sealing on the packaging machine has concluded, the machine’s conveyor

belt transports the product onto the tunnel’s belt. The pack enters the tunnel for the

heat shrinking process. The electronic card positioned on the tunnel commands all the

variables of this process (internal temperature and belt speed). In the end, the heat-

shrunk product moves out of the tunnel and runs on the roller.

In case of emergency, stop the machine by pressing the STOP push-button. Then

open the curtains so that the tunnel cools down quicker. If necessary start the cooling

procedure (See Par. 5-2). Restore the tunnel’s normal operation as soon as possible.

78 / 284

3. Information on the tunnel

3.6 TUNNEL LIMITATIONS AND SPECIFICATIONS OF USE

DANGEROUS AREAS:

• Do not touch the inside of the oven during or immediately after a packaging. Danger

of burns due to the residual heat.

• Do not use the machine if the fans break.

• Do not touch the fan in movement or use the machine without curtains.

79 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

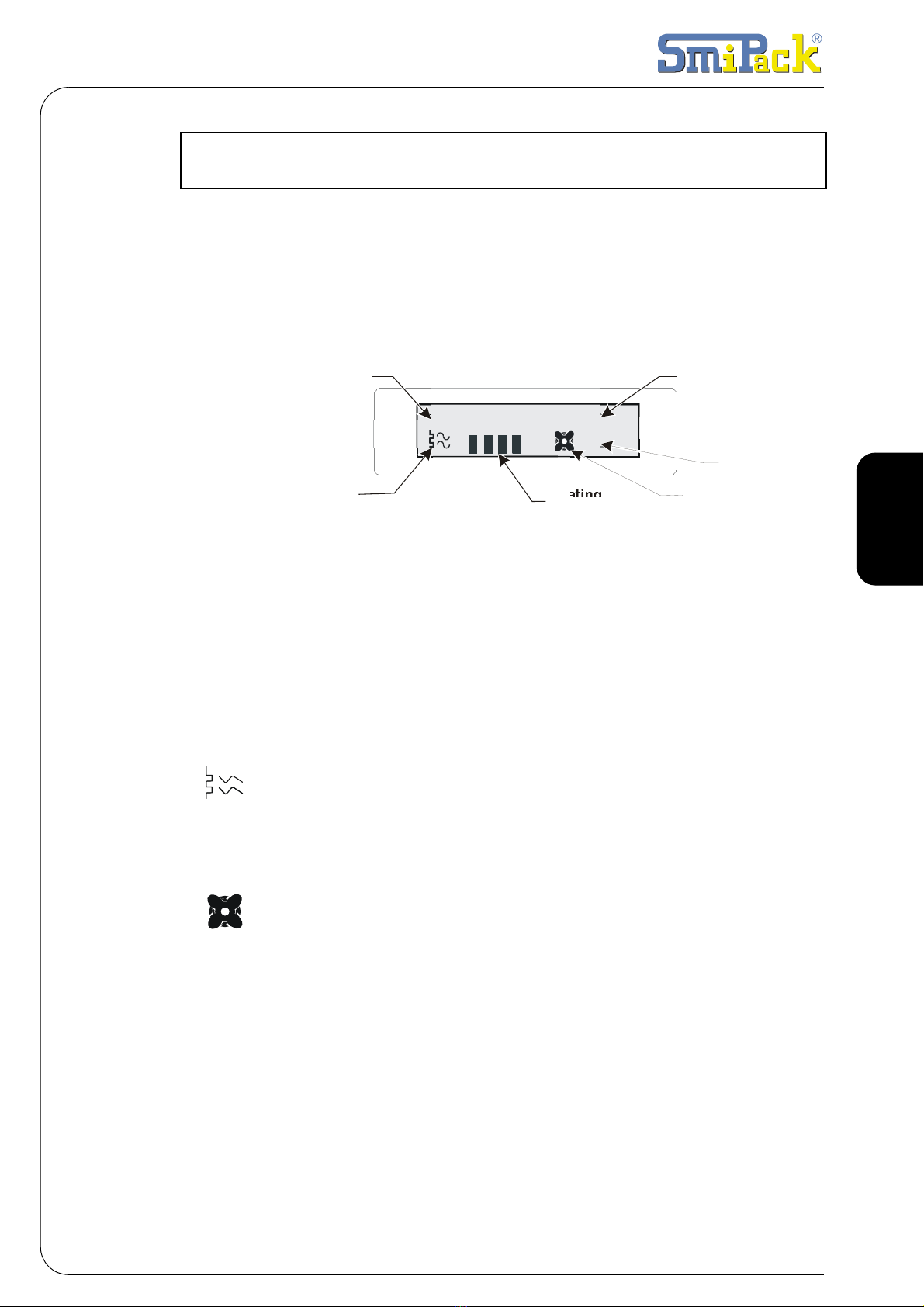

4.1 MACHINE START UP

Rotate the main switch to position 1. After the main video page, the tunnel's present

temperature is signalled on the first line while symbols indicate the state of operation

on the second line.

Fig. 4.1.1

The states of the machine that are displayed are:

• TUNNEL OFF: power is activated but the tunnel and belt are turned off.

• TUNNEL ON: tunnel and belt turned on.

• P.FREE: belt turned on and tunnel heating switched off.

• COOLING: tunnel off but belt and ventilation turned on to allow the tunnel to cool

down.

• FREE P/ COOLING: they flash alternatively to point out that the free passage mode

has been chosen but the tunnel cooling is in progress.

The first symbol on the left represents the operation mode:

• operation with tunnel heating ( “heat shrinking” mode); The symbol appears

between brackets when the oven is in “OFF.” A bar follows that indicates the

resistor's heating state. As soon as the 5 rectangles have disappeared it is possible

to carry out the heat shrinking. Each rectangle indicates a temperature lower than

20% compared to the set value.

• indicates that the tunnel fans are turned on. By deactivating the “heat

shrinking” mode the fans remain turned on until the temperature has dropped below

80 °C.

• The letter “M” indicates the selected memory.In the 6 available memory different

values can be saved according to the various products.

• To change video pages in the menu use the keys [×]or [Ø].

• To operate the change now use the keys [+] or [-].

4.2 TURN ON / TURN OFF MENU [F1]

To turn on the tunnel press the push-button [POWER] and then the push-button [F1].

The following video page will appear:

4. PREPARATION TO THE USE OF THE TUNNEL

TUNNEL ON °C:180

M1

Tunnel state

Switch on

tunnel resistor Heating

state

The tunnel

fans turn on

Memory

P

resent

temperature

80 / 284

4. Preparation to the use of the tunnel

Fig. 4.2.1

The tunnel can be turned off in the same way.

When the tunnel is hot always turn it off using the push-button [F1].

IIn this way the oven's cooling procedure is activated: fans and belt keep on turning

until the temperature drops below 80°C.

During this phase the following video page will be displayed:

Fig. 4.2.2

Turning off the tunnel according to a non-standard procedure (example pressing the

emergency push-button) is signalled by problem 9. To restore the normal operations

press the push-button [POWER] and then the push-button [F1].

4.3 OPERATING MODE MENU [F2]

This menu allows you to choose the operating mode.

By pressing the push-button [F2] the following video page will appear:

Fig. 4.3.1

By pressing the key [ENTER] the tunnel heating and the belt movement starts.

Pressing the key [ESC] will only start the belt movement.

4.4 QUICK SELECTION OF THE PROGRAMS

The microprocessor allows us to store up to 6 different programs, both in manual and

automatic cycle according to the size of the pack. The number of the program appears

at the end of the second line of the display. Press the push button [ENTER] and then

the keys [+] or [-] to modify the memory ( the power is disabled automatically). At this

point confirm the position of the memory with [ENTER] and enable the power again by

pressing the push button [POWER].

4.5 USER MENU [F3]

By pressing the push-button [F3] you can access to the following parameters:

1 • Belt speed

The following is the first video page displayed:

Tunnel

Esc=OFF Enter=ON

COOL.DOWN °C:180

M1

SHRINKING?

Esc=No Enter=Yes

This manual suits for next models

4

Table of contents

Other Smipack Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

HUALIAN

HUALIAN M-PE Series Operation manual

Pro Pack Solutions

Pro Pack Solutions Eagle 710 Operation manual

Oliver

Oliver 1808-D User's operation

Kronos

Kronos H-46 Series Operation, safety and spare parts manual

Robopac

Robopac ROBOT S7 Use and maintenance manual