Table of Contents

Table of Contents

1 General instructions................................................................................................. 5

1.1 Information about this manual ............................................................................ 5

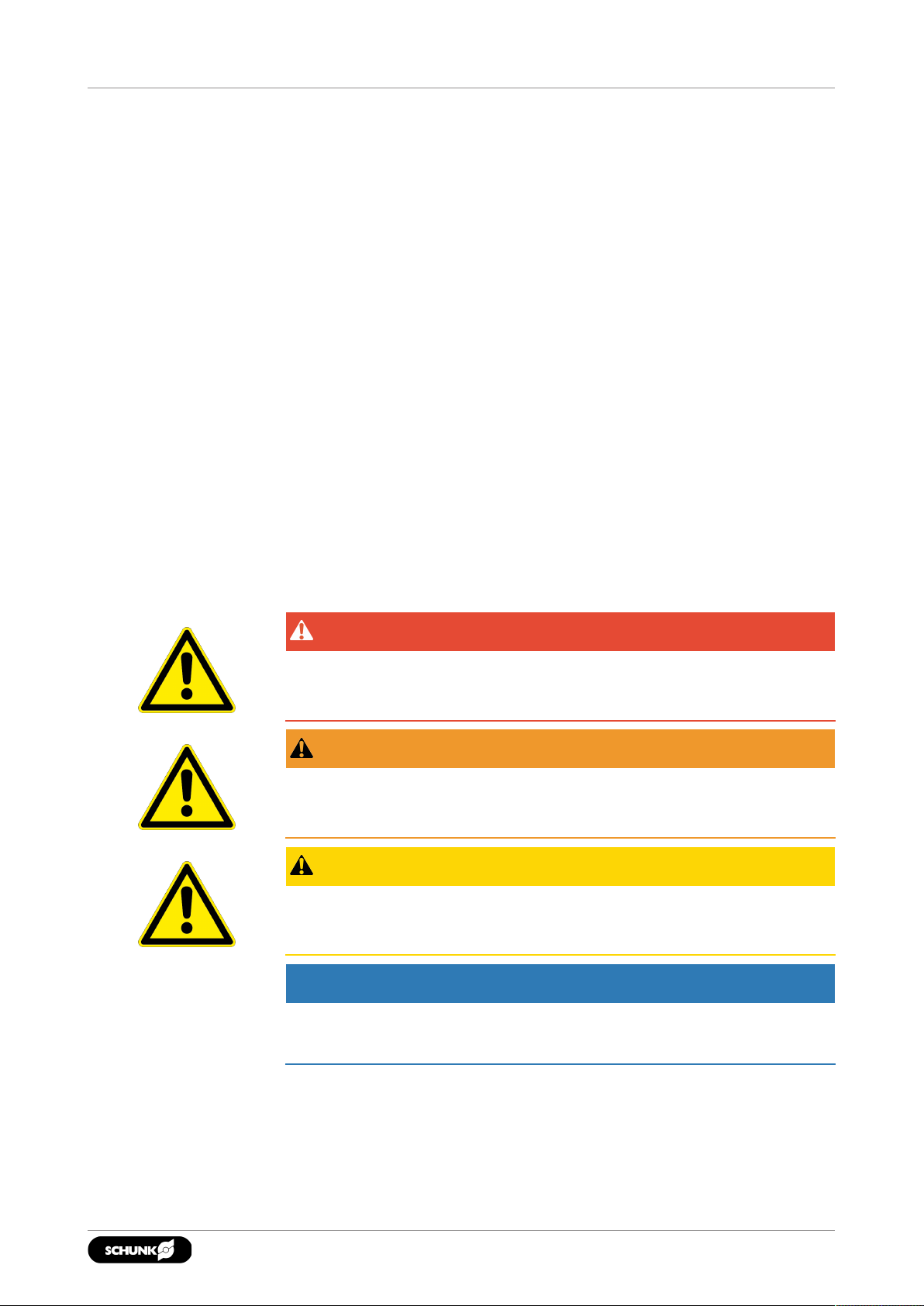

1.1.1 Presentation of Warning Labels ...............................................................5

1.1.2 Applicable documents ..............................................................................6

1.2 Warranty .............................................................................................................. 6

1.3 Scope of delivery .................................................................................................. 6

2 Basic safety notes .................................................................................................... 7

2.1 Intended use......................................................................................................... 7

2.2 Not intended use.................................................................................................. 7

2.3 Structural changes................................................................................................ 7

2.4 Spare parts ........................................................................................................... 8

2.5 Ambient conditions and operating conditions ..................................................... 8

2.6 Personnel qualification......................................................................................... 8

2.7 Personal protective equipment............................................................................ 9

2.8 Instructions for safe operation............................................................................. 9

2.8.1 Constructional changes, attachments, or modifications ..........................9

2.9 Transport .............................................................................................................. 9

2.10 Malfunctions....................................................................................................... 10

2.11 Disposal .............................................................................................................. 10

2.12 Fundamental dangers......................................................................................... 10

2.12.1 Notes on particular risks.........................................................................10

3 Technical Data ........................................................................................................11

3.1 Tablet technical data: ......................................................................................... 11

3.2 Measuring head technical data .......................................................................... 11

4 Functional description and operation......................................................................12

4.1 Overview............................................................................................................. 12

4.2 Measuring head.................................................................................................. 12

4.2.1 General ...................................................................................................12

4.2.2 Charging process / state of charge .........................................................13

4.2.3 Changing the clamping inserts................................................................14

4.3 Tablet and APP ................................................................................................... 14

4.3.1 Functional description of the tablet .......................................................14

4.3.2 Operating the APP ..................................................................................15

4.3.3 Live screen ..............................................................................................16

4.3.4 History ....................................................................................................18

4.3.5 Images ....................................................................................................19

4.3.6 Machines and clamping devices editor ..................................................20

4.3.7 Calculation method of the clamping force .............................................20

4.3.8 Measuring procedure .............................................................................21

5 Calibration and recalibration ..................................................................................22

6 Charging adapter ....................................................................................................23

301.00 | | SCHUNK IFT SST Clamping Force Tester | en | 1501182