3

Table of Contents

1Safety Precautions.........................................................................................4

Users (Important)...............................................................................................4

Graphical Symbols ............................................................................................4

Caution Labels...................................................................................................6

2About this Product.........................................................................................7

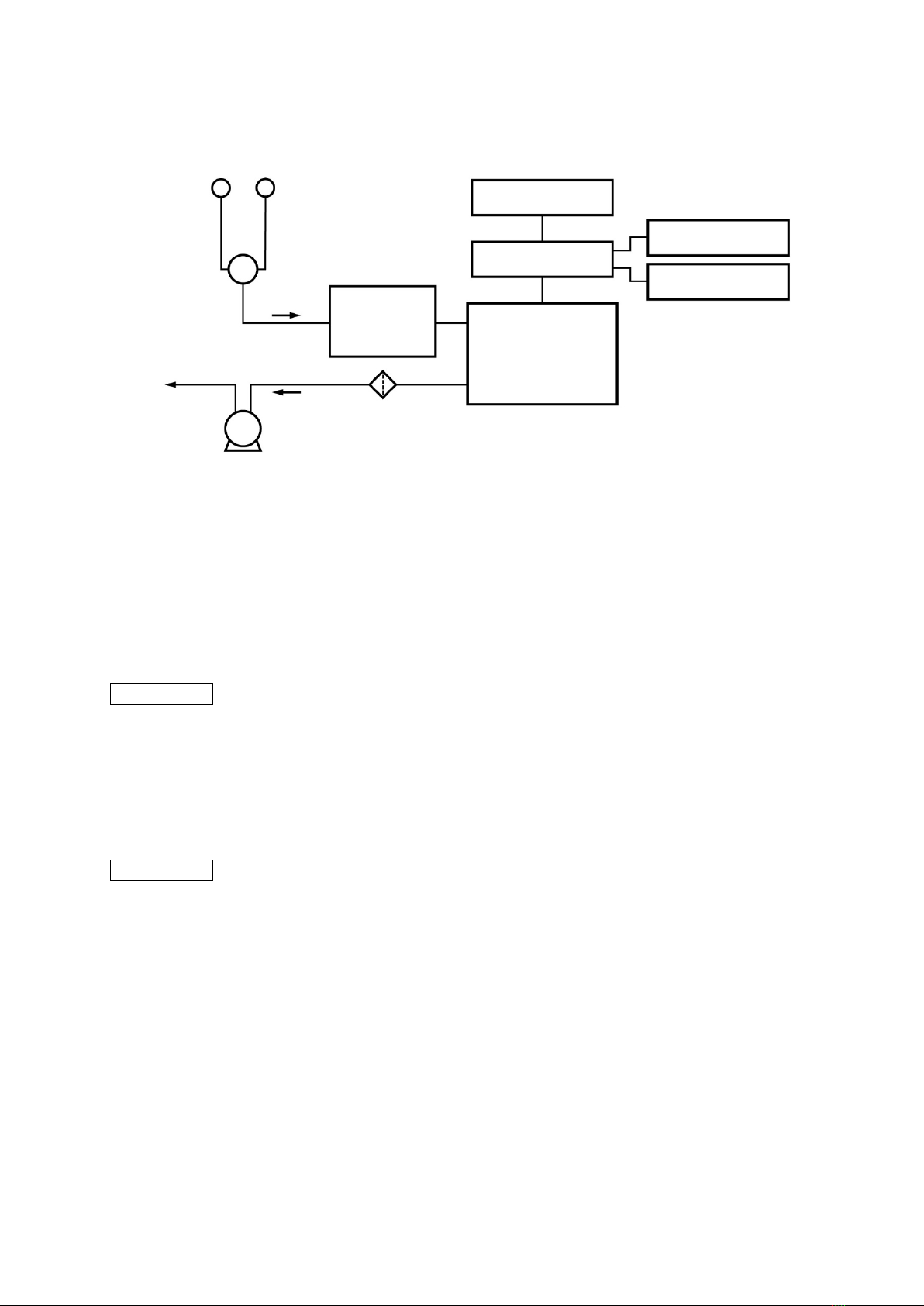

Overview............................................................................................................7

Measurement Principle......................................................................................7

Precautions......................................................................................................10

Names of Parts................................................................................................12

3Preparation ...................................................................................................13

Types of Data and Measurement Results.......................................................13

Preparation of the Alcohol ...............................................................................13

Supplying Power, Startup, and Shutdown.......................................................16

Main Menu Screen ..........................................................................................17

3-4-1 Checking the Version Information......................................................17

Basic Screen Configuration and Operations...................................................18

Preparing for Measurement.............................................................................21

3-6-1 Connecting the Sampling Tube..........................................................21

3-6-2 Selecting How to Connect to the Respirator......................................22

3-6-3 Checking the Particle Concentration in the Environmental Air..........24

3-6-4 If Condensation Develops in the Test Guide or Sampling Tube........24

3-6-5 Checking and Cleaning the Suction Ports .........................................25

4Measurement................................................................................................26

Measurement Modes.......................................................................................26

Configuration of the Measurement Mode Screen ...........................................27

Daily Check Mode ...........................................................................................29

Fit Test Mode ...................................................................................................31

Fit Check Mode ...............................................................................................36

Training Mode..................................................................................................38

5Settings.........................................................................................................40

Setting Menu ...................................................................................................40

Fit Test Settings ...............................................................................................40

Fit Check Settings ...........................................................................................43

Daily Check Settings .......................................................................................44

Training Settings..............................................................................................45

Date/Time Settings ..........................................................................................46

Basic Settings..................................................................................................47

Touch Panel Correction ...................................................................................50

6Database .......................................................................................................51

Database Menu ...............................................................................................51

Database Selection .........................................................................................52

Database Management ...................................................................................53

People Data.....................................................................................................54

Respirator Data ...............................................................................................55

Operator Data..................................................................................................56

7External Output ............................................................................................57

8Maintenance .................................................................................................59

Inspections and Maintenance .........................................................................59

Operational Check with Clean Air ...................................................................61

Consumables...................................................................................................61

9Troubleshooting ...........................................................................................62

10 Main Specifications......................................................................................64

11 Warranty and Repairs ..................................................................................67