Neutronics 4100 User manual

High Purity Instruments

MODEL 4100

OXYGEN ANALYZER

INSTALLATION MANUAL

MEASUREMENT

RANGE MODE

RUN FAULT ALM 1 ALM 2

20.9

OXYGEN

MODEL 4100 O2Analyzer

NTRON

PERCENT

PPM

PPB

File Name: MN-A-0075

Manual Part Number: C5-06-4900-05-0

Revision Level: B Date: 5/13/08

ECO: 8451

Engineered Solutions for Gas Detection and Analysi

s

Page 3

Table of Contents

TABLE OF CONTENTS 3

FORYOURSAFETY 4

CHAPTER1-INTRODUCTION 6

CHAPTER 2 – INSTALLATION INSTRUCTIONS 8

STEP 1 – ANALYZER AND RSM INSTALLATION 8

STEP 2 – ELECTRICAL CONNECTIONS 11

CHAPTER 3 – OPERATING INSTRUCTIONS 16

A.FIRSTTIMEPOWERUP 16

B. NORMAL POWER UP AND POWER DOWN 20

C. OXYGEN ALARM LEVEL SETTINGS 20

D.FEATURES 20

CHAPTER 4 – MAINTENANCE AND TROUBLESHOOTING 28

CHAPTER 5 – SPECIFICATIONS 30

WARRANTY STATEMENT AND STATEMENT OF INTENDED USE 32

APPENDIX A – AMBIENT AIR CALIBRATION 33

APPENDIXB–SYSTEMFAULTS 35

APPENDIX C – OXYGEN ALARM LEVEL SETTINGS 38

APPENDIXD–RS-232PORT 39

APPENDIXE-SYSTEMSETUP 40

APPENDIX F – SPARE PARTS LIST 43

APPENDIX G – MATERIAL SAFETY DATA SHEET 44

Page 4

For Your Safety:

PLEASE READ THIS MANUAL IN ITS ENTIRETY BEFORE ATTEMPTING

INSTALLATION OR OPERATION! Attempting to operate the Model 4100 without

fully understanding its features and functions may result in unsafe conditions.

•Never expose the Model 4100 analyzer chassis to water, high humidity or moisture. The analyzer

chassis is not watertight.

•Never expose the Model 4100 to flame or high temperatures.

•Never expose the Model 4100 analyzer to flammable gases or vapors. The unit is not rated Explosion

Proof or Intrinsically Safe.

•Ensure the analyzer unit is mounted in an area of free airflow to prevent the chassis from exceeding

the operating temperature specifications. Do not mount the analyzer against hot surfaces. Do not

block the ventilation louver on the analyzer chassis.

Page 5

Thank you for purchasing the Model 4100 Analyzer for your

PPB/PPM/% range Oxygen measurement.

The Model 4100 Compact Analyzer is a user friendly, microprocessor controlled analyzer designed to be used

with either the 4-LP-N1-SS or the 4-SPM-N1-SS remote sensor module for oxygen measurements in inert gas

backgrounds. It has many features to offer the user, which will be described in this manual. We require that

all personnel who use the instrument read this manual to become more familiar with its proper operation.

For further detail regarding the maintenance and in-field service of the Model 4100 analyzer, please contact

the Neutronics Inc. Customer Service Department. If you have questions or comments, we would like to hear

from you.

Neutronics Inc. Customer Service Department

456 Creamery Way

Exton, PA 19341

Tel: (610) 524-8800

Toll Free: (800) 378-2287 (US only)

Fax: (610) 524-8807

Visit us at www.neutronicsinc.com

Equipment Serial Number: ________________

(For faster service, please have this number ready if for any reason you need to contact us about your instrument)

Copyright ©2008 Neutronics Inc.

This work is protected under Title 17 of the US Code and is the sole property of Neutronics Inc. No part of this document may be

copied or otherwise reproduced, or stored in any electronic information retrieval system, except as specifically permitted under

US copyright law, without the prior written consent of Neutronics Inc.

1CHAPTER 1–INTRODUCTION

Page 6

The Model 4100 is a microprocessor-based instrument that indicates the measured oxygen

concentration in either parts-per-billion, parts-per-million, or percent by volume when used with a

Neutronics remote sensor module.

The Model 4100 analyzer is designed to be flush mounted to a panel or console. Because of its small size,

the analyzer can be integrated into a variety of equipment or control panels. Some of the analyzer

features include:

•Large 4-Digit 7-Segment LED display for oxygen readout and system configuration.

•Front panel keypads for user setup access and calibration.

•Two oxygen alarms relays with configurable outputs for process control use.

•One System Fault relay output.

•4-20 mA Analog Current Output, range configurable.

•0-1/5/10 VDC Analog Voltage Output, range configurable.

•0-10V Range Identification Voltage to be used with the Analog Outputs.

•RS-232 Serial Interface Port.

Page 7

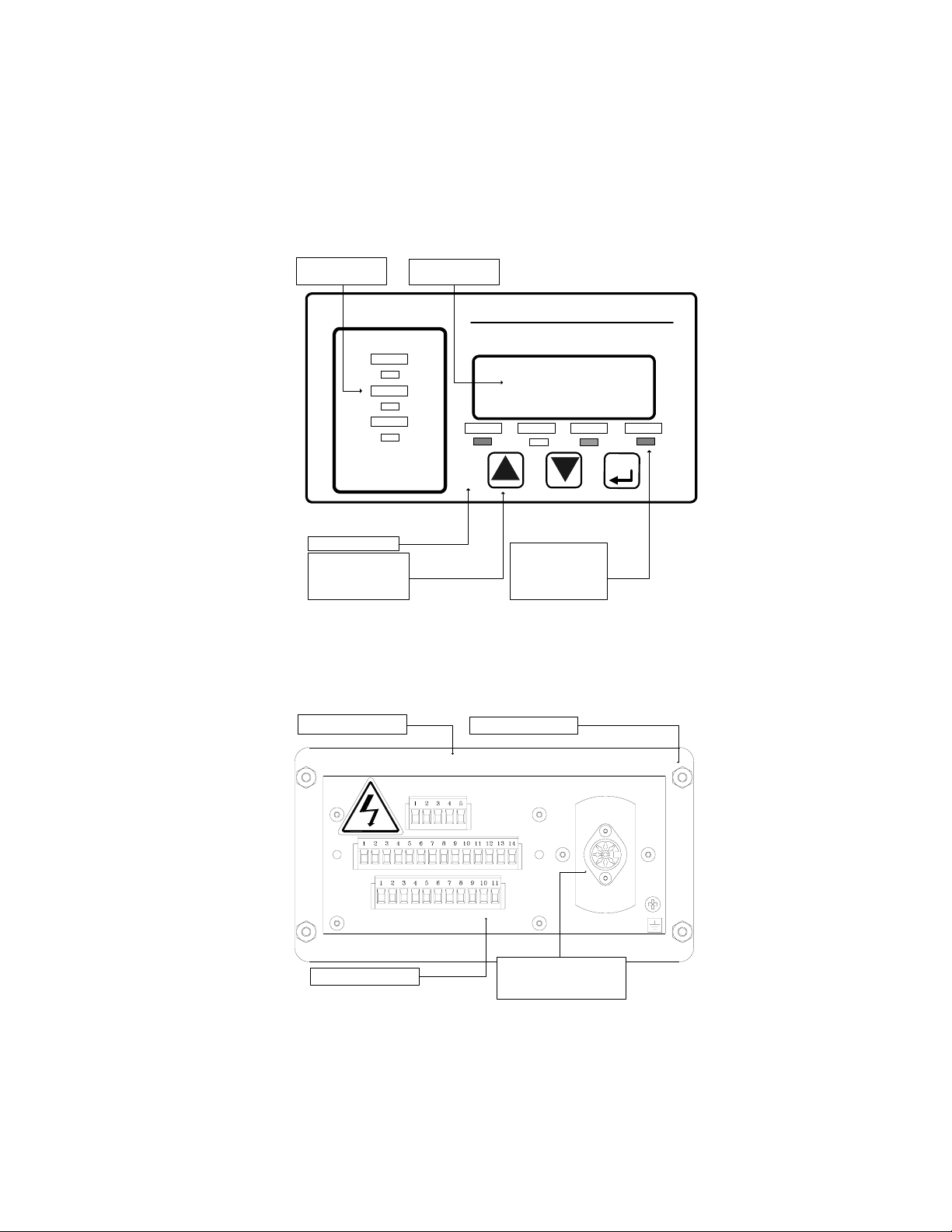

Introduction (continued)

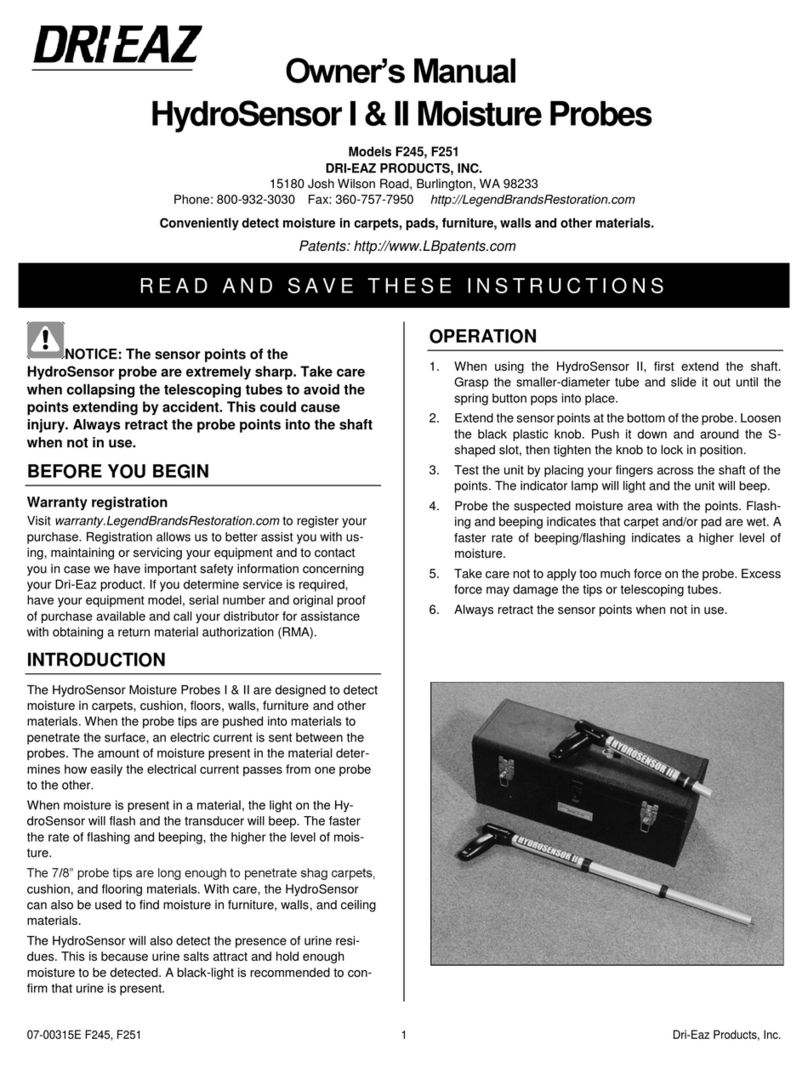

Front View

NEMA 4 Panel Mounting

Gasket Mounting Studs

Removable Terminal Blocks

Interface Port for the Sensor

Interface Cable to the Remote

Sensor

Module

Rear View

Figure 1 – Model 4100 Analyzer Front And Rear View

M

EASUREMENT

R

ANGE

MODE

RUN FAULT ALM 1 ALM 2

20.9

O

XYGEN

MODEL 4100 O

2

Analyzer

N

TRON

PERCENT

PPM

PPB

Measurement Range

Indicator

LED Bank

NEMA 4 Front Panel

Large, Menu-Driven Push-

Button Operators For:

Increment

Decrement

Mode Select

Color Coded Status

Indicators:

RUN = Green

FAULT = Yellow

ALARM 1 = Red

ALARM 2 = Red

Oversized LED Displays

Page 8

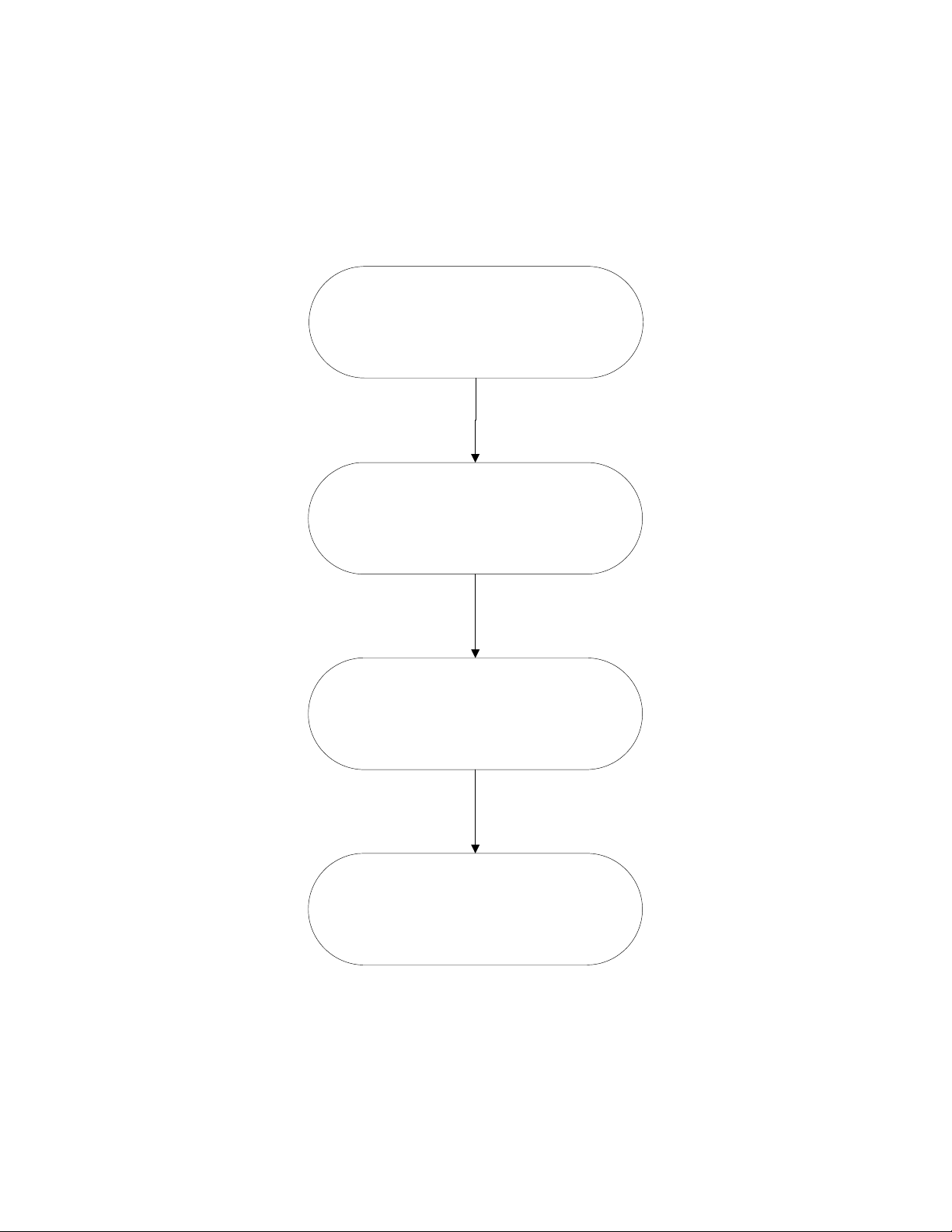

2CHAPTER 2–INSTALLATION INSTRUCTIONS

STEP 1:

ANALYZER/RSM

INSTALLATION

STEP 2:

ELECTRICAL CONNECTIONS

STEP 3:

POWER UP

STEP 4:

AIR VERIFICATION/CALIBRATION

Fi

g

ure 2

–

Power U

p

Se

q

uence

Page 9

Step 1 Analyzer and RSM Installation

Install either the 4-LP-N1-SS or the 4-SPM-N1-SS remote sensor module as detailed by its installation

manual.

WARNING: The internal components of the Model 4100 analyzer are fragile. Do not drop

the analyzer during installation. Do not expose the unit to shock or vibration during

installation. Failure to comply may damage the fragile components inside the analyzer and

may result in loss of warranty.

CAUTION: The Model 4100 analyzer and its remote sensor module are shipped as a matched set. If

installing more than one system, verify that the serial numbers on the analyzer and the remote sensor

module match. Failure to comply may result in reduced measurement accuracy.

Observe the following guidelines when installing the Model 4100 Analyzer.

•Locate the analyzer so that the range and status LEDs, and 7-segment LED readout can be easily

read.

•Locate the analyzer so that the interface buttons on the display panel can be easily accessed.

•Allow ample space at the rear of the analyzer for easy access to all electrical connections.

•Be sure that the analyzer will not be exposed to water, adverse temperature, or shock.

•Be sure that the analyzer has free air flow around the vent slots on the chassis to prevent

overheating.

Cut/drill the mounting panel. Cut panel as shown in Figure 3. Drill four clearance holes for the #8-32

threaded mounting studs. Trim all burrs or sharp edges in the cutout or mounting-holes. Hex nuts and

lock washers are included for securing the unit to a panel.

Page 10

Step 1 Analyzer and RSM Installation (continued)

Slide the analyzer unit into the cutout. Slide the rear-chassis first. Seat the control panel gasket on

the mounting surface. The gasket on the analyzer control panel ensures a watertight seal around the

control panel cutout. Secure the threaded mounting studs with the supplied hex-nuts, and internal-

tooth lock-washers. The front of analyzer is suitable for NEMA Type 4, IP20 environments when

properly installed. The rear electronics chassis is suitable for NEMA Type 1, IP 20 environments.

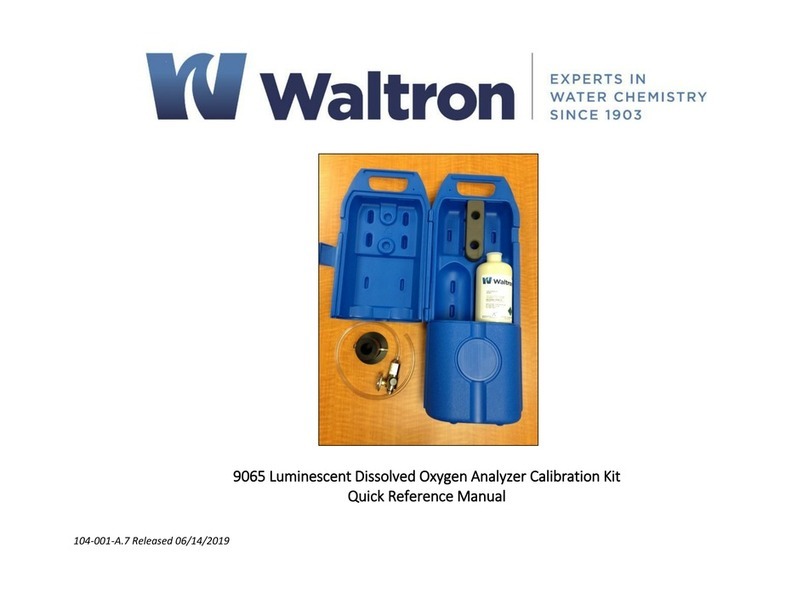

PANEL CUTOUT & DRILL PATTERN

4 PLACES

6.62" 16.81cm

6.20" 15.50cm

2.75"

6.99cm

2.91"

7.39cm

.189 DIA. HOLE (.429cm)

Fi

g

ure 3 – Anal

y

zer Panel Cutout Dia

g

ram

Page 11

Step 2 – Electrical Connections

CAUTION: Be sure all mains power supply is off before attempting the electrical

connections to the analyzer and remote sensor module. DO NOT WORK WITH LIVE WIRES!

Do not leave any exposed wire at the connectors or cables.

DANGER: Electrical connections on the rear of the analyzer may have hazardous voltages present

once power has been applied to the unit. High voltages may remain present for a short time even after

power has been disconnected. All standard electrical safety precautions must be undertaken when

making electrical connections to the remote sensor module.

DANGER: The Model 4100 analyzer is not rated intrinsically safe or explosion proof. Be certain that

no flammable gases are present in the area.

CAUTION: The Model 4100 rear housing is not rated waterproof. Do not mount the analyzer or the

sensor in an area where it may contact water or other liquid elements.

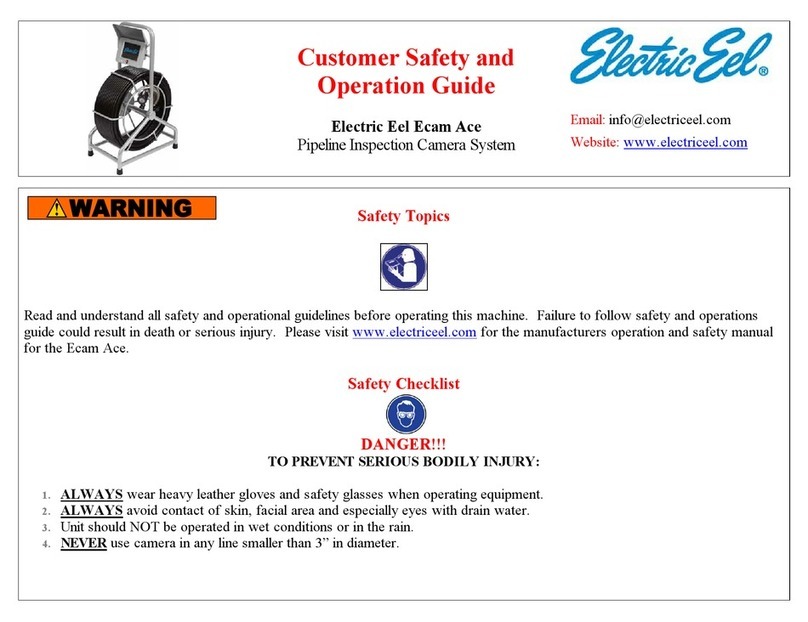

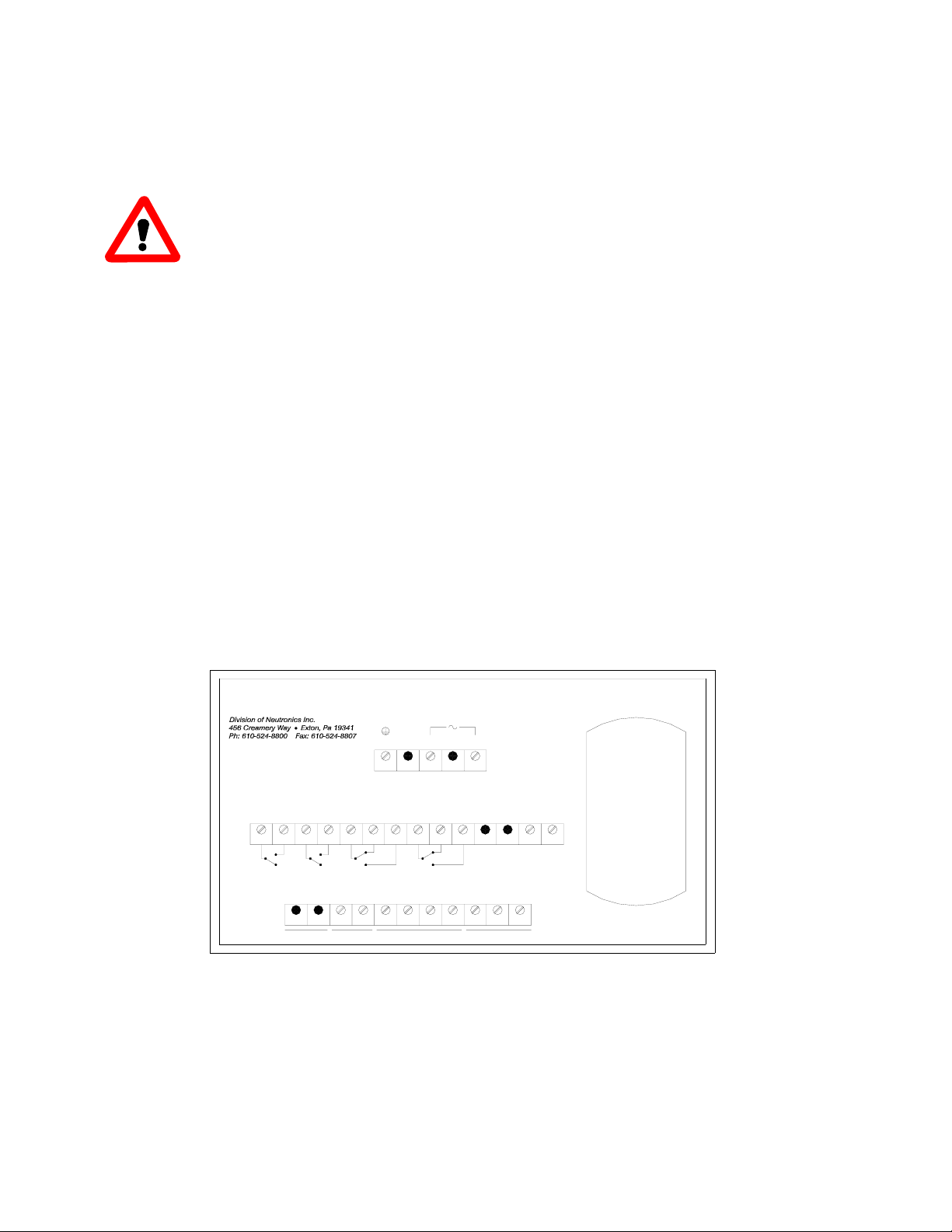

All electrical connections to the Model 4100 Analyzer is to be made to the three terminal blocks and the

sensor interface socket located at the back of the analyzer chassis. A label depicting the terminal block

arrangement is affixed to the top of the chassis as reference. The terminal blocks may be removed for

wiring.

*

12

SERVICE PORT

RS-232

ALARM 1ALARM 2FAULTTEMP

TB3 1

*

321

TB2

CNOC

ANALOG

4

12V DC

3256

-

BAT. BU

+

*

V-OUT

+-

78910

I-OUT

+-TXRX

7654

NO C NC NO

111098

NONCC*

PROCESS ANALYZER DIVISION

TRON

N

90-264 VAC, 47-63 Hz, 20 VA

TB1 12

GND *

34

AC-N *

5

AC-L

AC POWER INPUT

V-OUT

NO CONNECTION

11

*

RTN

1413

+- CONNECTIONS

SENSOR

SEE MANUAL FOR

RANGE

Fi

g

ure 4

–

Electrical Connections Label

Page 12

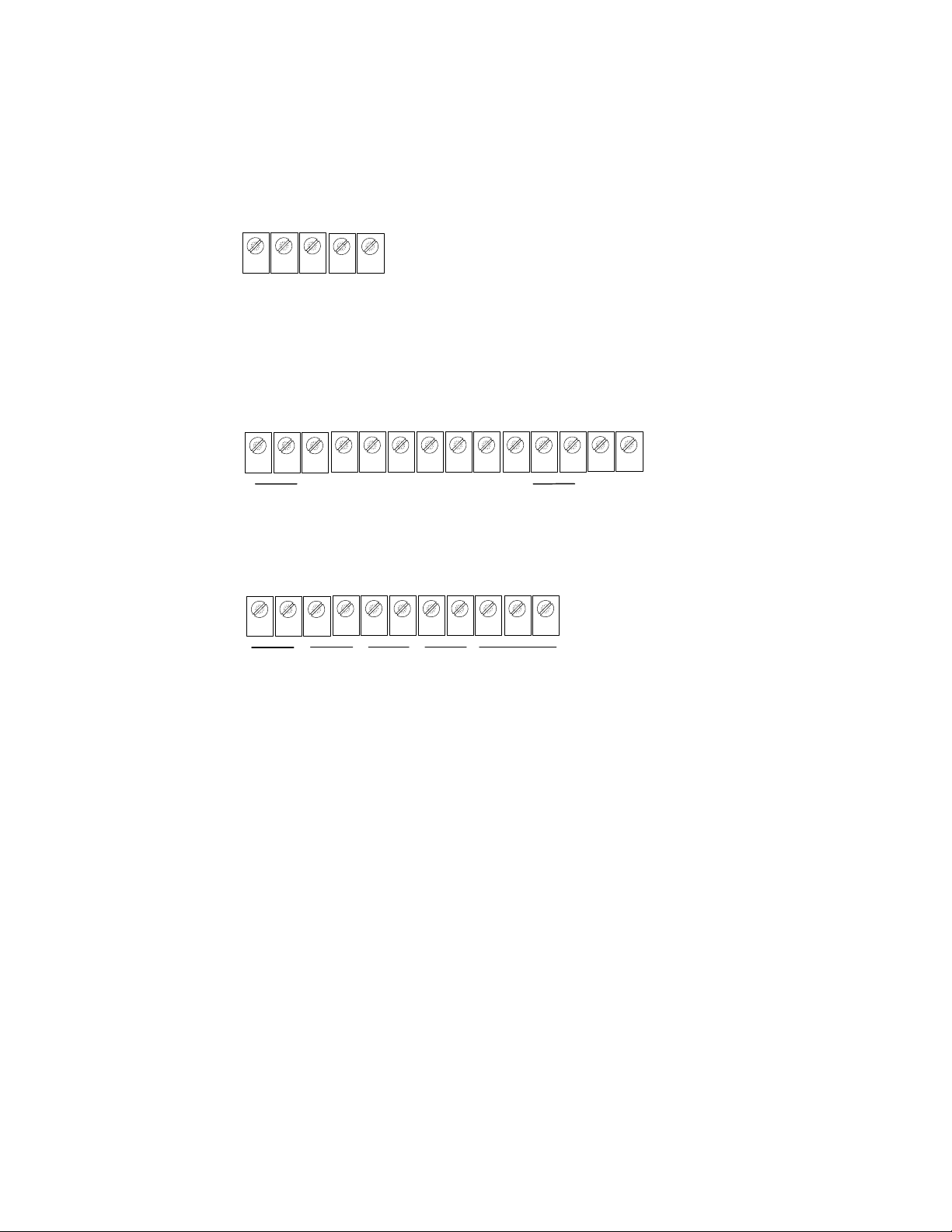

Step 2 – Electrical Connections (continued)

Figure 5 – Analyzer chassis electrical connections (continued).

123

TB2 4 5 6 7 8 9 10 11 12 13 14

Failsafe

Fault

CNO CNCNO

Oxygen

Alarm 2

CNC

NO +-

1 2 3

TB3 45678910 11

Bat.

BU

+-

V

Out

+-

mA

Out

+-

RS-232

TX RX RTN

12

VDC

no

connection

no

connection

Service

Port

NO = Normally Open

NC = Normally Closed

C = Common

VAC POWER INPUT,

90-264 VAC, 47-63 Hz

13

TB1 5

24

GND AC-N AC-L

CNO

Temp

OK Oxygen

Alarm 1 Range ID

Voltage

Page 13

Step 2 – Electrical Connections (continued)

The following is a list of all possible electrical connections to the Model 4100 analyzer

Oxygen Alarm-1 Relay Output

Relay Type: Form 1 C, SPDT, 5A @ 250 VAC, 5A @ 30VDC

Connections: Common: Terminal Block TB2 Pin 8

Normally Closed Output: Terminal Block TB2 Pin 9

Normally Open Output: Terminal Block TB2 Pin 10

Oxygen Alarm-2 Relay Output

Relay Type: Form 1 C, SPDT, 5A @ 250 VAC, 5A @ 30VDC

Connections: Common: Terminal Block TB2 Pin 5

Normally Closed Output: Terminal Block TB2 Pin 6

Normally Open Output: Terminal Block TB2 Pin 7

System Fault Relay Output

Relay Type: Form 1 B, SPST, 5A @ 250 VAC, 5A @ 30VDC

Connections: Common: Terminal Block TB2 Pin 3

Normally Open Output: Terminal Block TB2 Pin 4

Temperature OK Relay Output

Relay Type: Form 1 B, SPST, 5A @ 250 VAC, 5A @ 30VDC

Connections: Common: Terminal Block TB2 Pin 1

Normally Open Output: Terminal Block TB2 Pin 2

Range ID Output

Use the Range ID voltage with either the analog voltage or the analog current output to identify

the full span oxygen concentration measurement. Use 20-AWG, 2-conductor, stranded-wire,

twisted pairs for the connections.

Output Voltage: 0 - 10 Volts DC

Connections: Voltage + Output: Terminal Block TB2 Pin 13

Voltage - Output: Terminal Block TB2 Pin 14

Analog Voltage Output

The analog voltage output is factory pre-set to be either 0-1, 0-5, or 0-10 volts. Use 20-AWG, 2-

conductor, stranded-wire, twisted pairs for the connections.

Output Voltage: 0 – 1, 0 – 5, or 0 - 10 Volts DC

Connections: Voltage + Output: Terminal Block TB3 Pin 5

Voltage - Output: Terminal Block TB3 Pin 6

Page 14

Step 2 – Electrical Connections (continued)

Analog Current Output

The analog current output is a negative ground, non-isolated 4-20 mA current loop. Use 20-

AWG, 2-conductor, stranded-wire, twisted pairs for the connections.

Output Voltage: 4 – 20 mA

Maximum Loading: 250 ohms

Connections: Current + Output: Terminal Block TB3 Pin 7

Current - Output: Terminal Block TB3 Pin 8

Battery Backup (Optional)

These terminals may be used to connect the Model 4100 analyzer to a 12V battery backup system

such as a lead acid battery. Battery backup function is not required for normal operations.

Input Voltage: 12 volts nominal

Connections: Battery + Terminal: Terminal Block TB3 Pin 3

Battery - Terminal: Terminal Block TB3 Pin 4

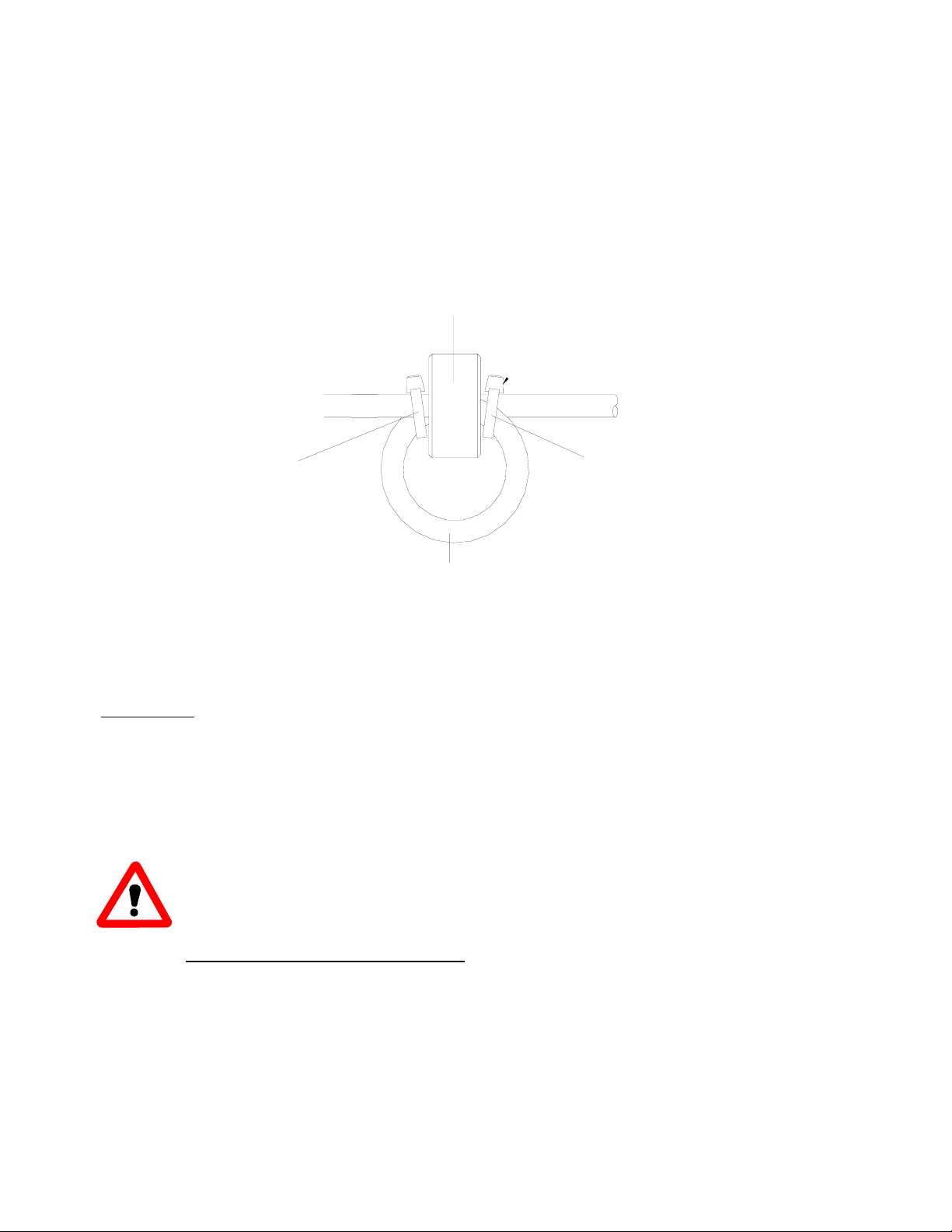

RS-232 Service Port

For interfacing with any standard PC computer via serial port, use 20-AWG, 3-conductor,

shielded, stranded-wire, jacketed cable, terminated on one end with a female DB9 connector. The

shielding should be drained to DC ground at the computer. Use ferrite core is to minimize RFI

interference if necessary. Install the ferrite core within 6 inches of the analyzer service port. Loop

the serial cable around the ferrite core once (the serial cable will pass through the ferrite core

twice). (See Figure 6).

SIGNAL

DESIGNATION AT

ANALYZER

ANALYZER TB2

CONNECTION

SIGNAL

DESIGNATION AT

COMPUTER

COMPUTER DB9

SERIAL PORT

CONNECTION

TX Pin 9 RX Pin 2

RX Pin 10 TX Pin 3

RTN Pin 11 RTN Pin 5

Page 15

Step 2 – Electrical Connections (continued)

Mains Power

Use minimum 16-AWG, 3-conductor, stranded-wire for mains power connections.

Mains Power Voltage: 90-264 Volts AC, 47 – 63 Hz, Single Phase

Connections: AC-Line: Terminal Block TB3 Pin 3

AC-Return: Terminal Block TB3 Pin 3

AC-Ground:Terminal Block TB3 Pin 3

WARNING: Do not apply mains power to the analyzer or the remote sensor module

until all the electrical connections to the analyzer and the remote sensor module, and all the

pneumatic connections to the remote sensor module have been properly installed.

Remote Sensor Module Interface Cable

Use the remote sensor module interface cable as supplied. Connect to the socket located to the rear

of the Model 4100 analyzer. See figure 1 for the location of the socket

Serial Cable

Ferrite Core

Cable Tie

Cable Tie

Figure 6

–

RS-232 Ferrite Core

Page 16

3CHAPTER 3–OPERATING INSTRUCTIONS

A. First Time Power Up

The Model 4100 is shipped ready to use, right from the carton. Its default configuration has been set to

your application. Review the default configuration settings, as shown in the analyzer software setup log

sheet, shipped with your Model 4100 analyzer. Before commissioning your system, ensure that the

default settings match your application. Contact the factory if your default settings do not match your

application.

WARNING: Verify that the Model 4100 analyzer remote sensor module heater voltage

has been properly configured to your mains power voltage: 115 or 230 VAC. Although the

analyzer can operate at any voltage between 90 and 264 VAC, it requires that the heater

voltage be correctly set to properly regulate the sensor heater temperature inside the

remote sensor module. If the heater voltage setting does not match the mains power voltage, the

remote sensor module may be permanently damaged. Failure to comply may result in loss of warranty.

WARNING: Do not apply mains power to the analyzer or the remote sensor module

until all the electrical connections to the analyzer and the remote sensor module, and all

the pneumatic connections to the remote sensor module have been properly installed.

Page 17

First Time Power Up (continued)

FIRST TIME POWER UP CHECK LIST

Have you:

Verified that all the electrical and pneumatic connections to the remote sensor module have been

properly installed?

Verified that all the electrical connections to the analyzer have been properly installed?

Verified that the analyzer is properly connected to the remote sensor module via the sensor

interface cable?

Ensured that none of the mains power wiring to both the analyzer and the remote sensor module

are exposed?

Verified that the 4100 heater voltage setting matches the mains power voltage?

Mounted the analyzer in areas where there are no flammable vapors?

Mounted the analyzer away from exposure to rain, dripping water, or hose down?

Read this manual in its entirety?

Read the remote sensor module manual in its entirety?

First Time Power Up Instructions

1.Apply Ambient Air to the Remote Sensor Module: Apply clean, dry oil-free ambient air to the

remote sensor module. See the remote sensor module installation manual for more detail.

2.Apply Mains Power: Apply mains power to both the analyzer and the remote sensor module. The

Model 4100 analyzer will perform the following power up sequence:

a. Lamp Test (Verify): Verify that all the 7-Segment display and discrete LEDs light up and

flash. If any of the display segments or LEDs do not light up, remove all mains power and

return both the analyzer and remote sensor module to either the factory or a certified

service center for servicing.

b. Software ID (No Action): After completing the lamp test, the 7-Segment display will

show a 4-digit number signifying the software build number.

Page 18

First Time Power Up (continued)

First Time Power Up Instructions (continued)

c. Heater Voltage Setting (Verify): After indicating the software build number, the analyzer

will display either “110” or “220”. If the display shows “110” the analyzer is set up to

operate the sensor heater mains power voltage at 115 +/- 15 VAC. If the analyzer

display shows “220” the analyzer is set-up to operate at mains power voltage of 230 +/-

30 VAC. Verify that the heater voltage setting matches your mains power supply

voltage.

CAUTION: If the Model 4100 analyzer heater voltage setting does not match the mains power

voltage, power down both the analyzer and the remote sensor module immediately.

Contact the factory or an approved service center to correct the heater voltage setting.

Failure to comply may damage the remote sensor module permanently and result in loss

of warranty.

3.Wait 15 Minutes for Sensor to Warm Up to Operating Temperature: Upon completing the power

up sequence, the Model 4100 will bring up the sensor heater temperature to the operating

temperature. This process will take about 15 minutes. During this period the display will

alternate between “nr” for not ready and the sensor temperature in degrees Centigrade.

NOTE: If the Model 4100 fails to increase sensor heater to operating temperature, the display will

flash “HF” for heater failure. Power down both the analyzer and the remote sensor module. Check

the sensor interface cable connection to ensure integrity. Repeat the power up procedure. If

problem persists, return both the analyzer and the remote sensor module to the factory or a certified

service center for servicing.

4.Temperature Stabilization: After completion of the warm-up sequence, the analyzer and the

remote sensor module is ready for calibration and oxygen measurement. However, it is

recommended that the user wait for an additional 1 hour for the system to reach temperature

stabilization for the most accurate calibration and measurements.

5.Measure Air Sample (Verify): After temperature stabilization, if the Model 4100 analyzer displays

between 20.7% and 21.1% at ambient air, calibration is not necessary. Otherwise, verify that

clean, dry, oil-free ambient air is supplied to remote sensor module at the pressure and flow rate

required by the remote sensor module manual. If the sample air supply requirements to the

remote sensor module is met and the reading is not within the stated tolerance, perform air

calibration per Appendix A.

First Time Power Up (continued)

6.Verify Outputs: If the Model 4100 analyzer displays between 20.7% and 21.1% after warm-up,

and all the first time power-up verifications have been completed, Check the fault, temperature

OK, and oxygen alarm relay contacts to ensure that they are wired properly and functioning

normally. Also, check the analog current, analog voltage, and range ID voltage outputs to

ensure that they are functioning normally.

Page 19

7.Apply The Gas To Be Analyzed: Apply the gas that is to be analyzed to the remote sensor module.

Verify that the oxygen concentration display, the status LEDs, relay contact outputs, the analog

outputs and the Range ID outputs are wired properly and functioning normally.

Page 20

B. Normal Power Up and Power Down Instructions

After the instructions for the first time power up has been completed, the Model 4100 analyzer and its

remote sensor module can be run continuously. For periods when the analyzer and remote sensor

module are not in use, power both units down. Wait at least 15 minutes after power down to ensure that

the sensor is cool before reapplying power to both the analyzer and the remote sensor module again.

C. Oxygen Alarm Level Settings

If the user's process requires adjustments to either oxygen alarm level, follow adjustment procedure in

Appendix C.

D. Features

The Model 4100 is intended to be used with the remote sensor module to measure oxygen concentrations

in inert background. The Model 4100 Analyzer comes equipped with several operational features. Each

feature will be discussed in detail separately:

•Three Pushbutton Control Panel Interface.

•4-Digit 7-Segment Oxygen Concentration Display with Measurement Range LEDS.

•Four Status LEDs: RUN, FAULT, ALARM 1 and ALARM 2.

•Four relay outputs: TEMPERATURE OK, FAULT, ALARM 1 and ALARM 2.

•Three outputs: Analog Current, Analog Voltage & Range ID voltage.

•RS-232 output.

D. Features (continued)

Control Panel User Interface

The Model 4100 Analyzer has three pushbuttons labeled as “UP” “DOWN” and “MODE” on the

front panel. These pushbuttons are used for special functions like calibration and accessing the

user setup mode. See the appendices for more details on the usage of the pushbuttons. When

instructions specify pressing the "MODE" key more than once, press and release the "MODE" key

approximately once every half-second.

Table of contents

Other Neutronics Analytical Instrument manuals