Neutronics NTRON PERCENT 5124BE-N1-WO User manual

Engineered Solutions for Gas Detection and

A

nalysis

High Purity Instruments

MODEL 5124BE-N1-WO

OXYGEN ANALYZER – PERCENT RANGE

WITH REMOTE SENSOR MODULE

INSTALLATION MANUAL

File Name: MN-A-0177

Manual Part Number: 5-06-4900-65-0

Revision Level: A Revision Date: 8/19/08

ECO: 8541

A DIVISION OF

456 Creamery Way, Exton, PA 19341

www.neutronicsinc.com

Table of Contents

TABLE OF CONTENTS...................................................................................................................3

FOR YOUR SAFETY:.......................................................................................................................4

THANK YOU FOR PURCHASING THE MODEL 5124BE-N1-WO ANALYZER FOR ZERO TO

25 % RANGE OXYGEN MEASUREMENT.........................................................................................5

1CHAPTER 1 – INTRODUCTION AND OVERVIEW .................................................6

2CHAPTER 2 – SYSTEM INSTALLATION AND START-UP ....................................8

STEP 1 – ANALYZER INSTALLATION ..................................................................................................9

STEP 2 – SENSOR INSTALLATION .....................................................................................................10

STEP 3 – ELECTRICAL INSTALLATION ..............................................................................................12

3CHAPTER 3 – OPERATING INSTRUCTION ...........................................................21

A. FIRST TIME POWER UP................................................................................................................21

B. NORMAL POWER UP AND POWER DOWN INSTRUCTIONS.............................................................23

C. OXYGEN ALARM LEVEL SETTINGS..............................................................................................23

D. FEATURES ...................................................................................................................................24

Temperature OK Relay................................................................................................................24

Fault Relay ..................................................................................................................................24

Oxygen Alarm 1 & Alarm 2 Relays .............................................................................................25

Analog Voltage & Analog Current Output..................................................................................26

Range ID Voltage ........................................................................................................................26

RS-232 Port .................................................................................................................................27

4CHAPTER 4 – MAINTENANCE AND TROUBLESHOOTING ..............................29

5CHAPTER 5 – SPECIFICATIONS ****......................................................................31

WARRANTY .....................................................................................................................................33

INTENDED USE FOR THE MODEL 5124BE-N1-WO .........................................................................34

APPENDIX A: AMBIENT AIR CALIBRATION ......................................................................................35

APPENDIX B: SYSTEM FAULTS.........................................................................................................38

APPENDIX C: OXYGEN ALARM LEVEL SETTINGS ............................................................................40

APPENDIX D: RS-232 PORT.............................................................................................................42

APPENDIX E: SYSTEM SETUP ...........................................................................................................44

APPENDIX F – SPARE PARTS LIST ....................................................................................................46

APPENDIX G – MSDS MATERIAL SAFETY DATA SHEET .................................................................47

APPENDIX H – DECLARATION OF CONFORMITY ..............................................................................48

APPENDIX I – DECOMMISSIONING THE MODEL 5124BE-N1-WO ANALYZER .................................49

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 3

For Your Safety:

PLEASE READ THIS MANUAL IN ITS ENTIRETY BEFORE ATTEMPTING

INSTALLATION OR OPERATION! Attempting to operate the

Model 5124BE-N1-WO without fully understanding its

features and functions may result in unsafe conditions.

• Always use protective eye wear and observe proper safety procedures

when working with pressurized gases.

• Always assure the pressure of gas entering the Model 5124BE-N1-WO

sensor is 1-10 psig.

• Always calibrate the Model 5124BE-N1-WO at an equivalent pressure and

flow rate to the measured gas. Maximum pressure should not exceed 10

psig.

• Always allow the Model 5124BE-N1-WO to cool down before attempting to

access the sensor.

• Never expose the Model 5124BE-N1-WO analyzer or the remote sensor

chassis to water, high humidity or moisture. The analyzer chassis is

not watertight.

• Never expose the Model 5124BE-N1-WO analyzer or the remote sensor to

flame or high temperatures.

• Never expose the Model 5124BE-N1-WO analyzer or the remote sensor to

flammable gases or vapors. The unit is not rated Explosion Proof, or

Intrinsically Safe.

• Never expose the Model 5124BE-N1-WO sensor module directly to

unregulated gas lines, cylinder gas. High gas pressures may cause the

sensor components to rupture.

• Ensure the analyzer and the remote sensor unit is mounted in an area

of free airflow to prevent the chassis from exceeding the operating

temperature specifications. Do not mount the analyzer against hot

surfaces. Do not block the ventilation louver on the analyzer

chassis.

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 4

Thank you for purchasing the Model 5124BE-N1-

WO Analyzer for zero to 25 % range Oxygen

measurement.

The Model 5124BE-N1-WO Compact Analyzer is a user friendly, microprocessor

controlled Oxygen measuring instrument. It has many features to offer the

user, which will be described in this manual. We require that all

personnel who use the instrument read this manual to become more familiar

with its proper operation.

For further detail regarding the maintenance and in-field service of the

Model 5124BE-N1-WO analyzer, please contact the Neutronics Inc. Customer

Service Department. If you have questions or comments, we would like to

hear from you.

Neutronics Inc. Customer Service Department

456 Creamery Way

Exton, PA 19341

Tel: (610) 524-8800

Toll Free: (800) 378-2287 (US only)

Fax: (610) 524-8807

Visit us at www.neutronicsinc.com

Equipment Serial Number: ________________

(For faster service, please have this number ready if for any reason you need to contact

us about your instrument)

Copyright 2008 Neutronics Inc.

This work is protected under Title 17 of the US Code and is the sole property of

Neutronics Inc. No part of this document may be copied or otherwise reproduced, or

stored in any electronic information retrieval system, except as specifically permitted

under US copyright law, without the prior written consent of Neutronics Inc.

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 5

Installation and Operations Manual

1 CHAPTER 1 – INTRODUCTION AND OVERVIEW

The Model 5124BE-N1-WO analyzer is a microprocessor-based instrument for

measuring percent level oxygen in an inert gas background.

The analyzer is based on an amperiometric zirconium oxide remote sensor.

This sensor assures reliability and fast response for oxygen

concentration measurements, in inert gas backgrounds, in the percent

range. The solid-state sensor offers long life with little maintenance.

The sensor is not affected by dry atmospheres or by extremely cold

storage temperatures. It also has a very long storage life.

The sample gas is flowed through a self-contained external sensor

housing. The pneumatic connections are made to the 3/4"-16 male

threaded port for ease of use.

The Model 5124BE-N1-WO analyzer is designed to be flush-mounted to a

panel or console. Because of its small size, the analyzer can be

integrated into a variety of equipment or control panels. Some of the

analyzer features include:

• Compact, rapid-response external Zirconia oxygen sensor module

• Two User-adjustable oxygen Alarms with configurable relay outputs for

process control use.

• One System Fault relay output.

• One Temperature OK relay output.

• 4-20 mA Analog Current Output, range configurable.

• 0-1/5/10 VDC Analog Voltage Output, range configurable.

• 0-10V Range Identification Voltage to be used with the Analog Outputs

• RS-232 Serial Interface Port.

Manual Part Number:

5-06-4900-53-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 6

NEMA 4 PANEL

MOUNTING GASKET MOUNTING STUDS

ELECTRICAL

CONNECTION PORT

TO REMOTE

SENSOR

REMOVABLE

TERMINAL BLOCKS

EARTH GROUND

TERMINAL

Figure 1 – Model 5124BE-N1-WO Rear View

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 7

Installation and Operations Manual

2 CHAPTER 2 – SYSTEM INSTALLATION AND START-UP

STEP 1:

ANALYZER INSTALLATION

STEP 2:

SENSOR INSTALLATION

STEP 3:

ELECTRICAL CONNECTIONS

STEP 4:

POWER UP

STEP 5:

AIR VERIFICATION/CALIBRATION

Figure 2 – Power Up Sequence

Manual Part Number:

5-06-4900-53-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 8

Step 1 – Analyzer Installation

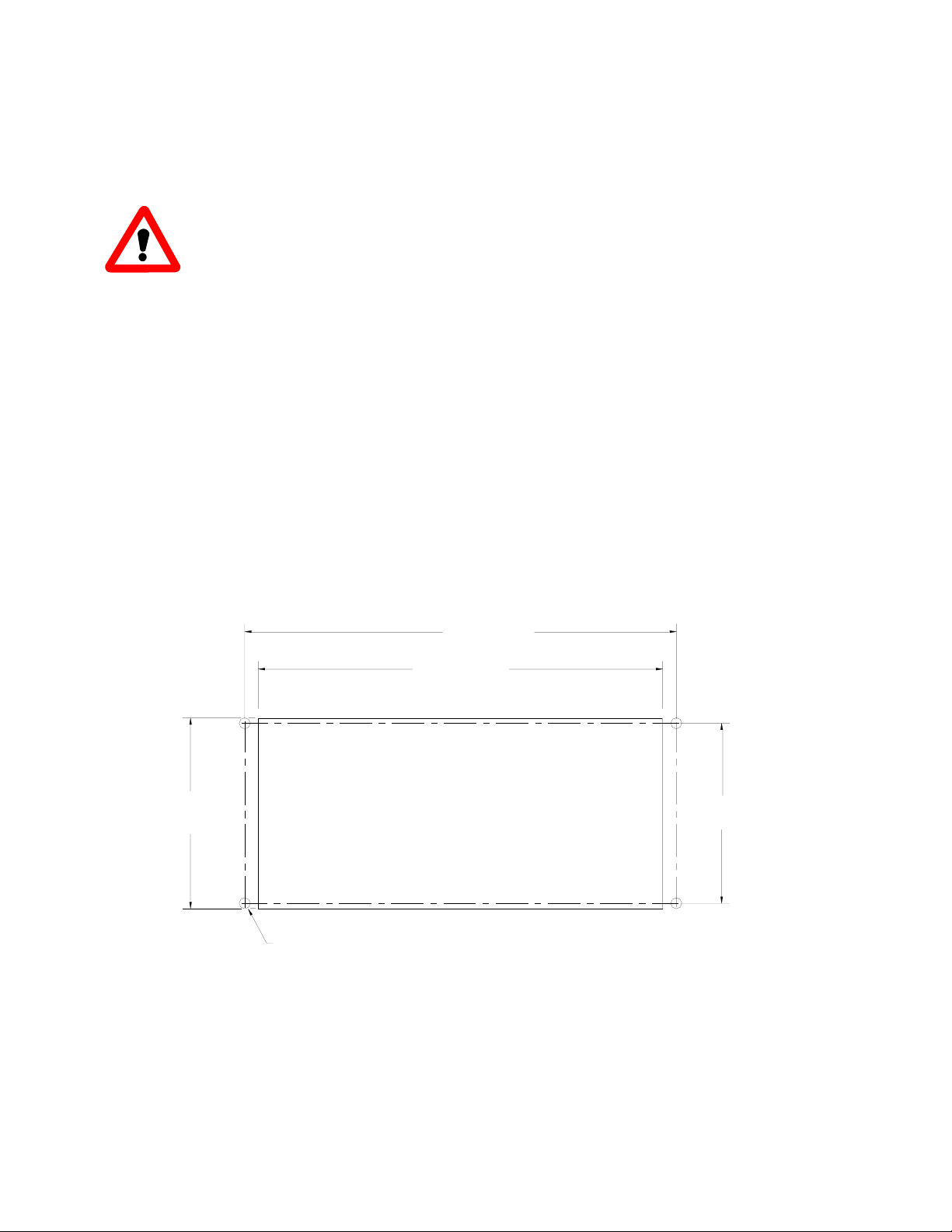

WARNING: The internal components of the Model 5124BE-N1-WO

analyzer and the remote sensor are fragile. Do not drop the

analyzer or the remote sensor during installation. Do not

expose the unit to shock or vibration during installation.

Failure to comply may damage the fragile components inside the analyzer

and remote sensor may result in loss of warranty.

The Model 5124BE-N1-WO analyzer is designed to be mounted flush to the

surface of an equipment control panel. Observe the following guidelines

when installing the analyzer:

• Allow ample space at the rear of the analyzer for easy access to

all electrical and pneumatic connections.

• Be sure that the analyzer will not be exposed to water, adverse

temperature, or shock.

• Be sure that the analyzer has free air flow around the vent slots

on the chassis to prevent overheating.

PANEL CUTOUT & DRILL PATTERN

4 PLACES

6.62" 16.81cm

6.20" 15.50cm

2.75"

6.99cm

2.91"

7.39cm

.189 DIA. HOLE (.429cm)

Figure 3 – Analyzer Panel Cutout Diagram

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 9

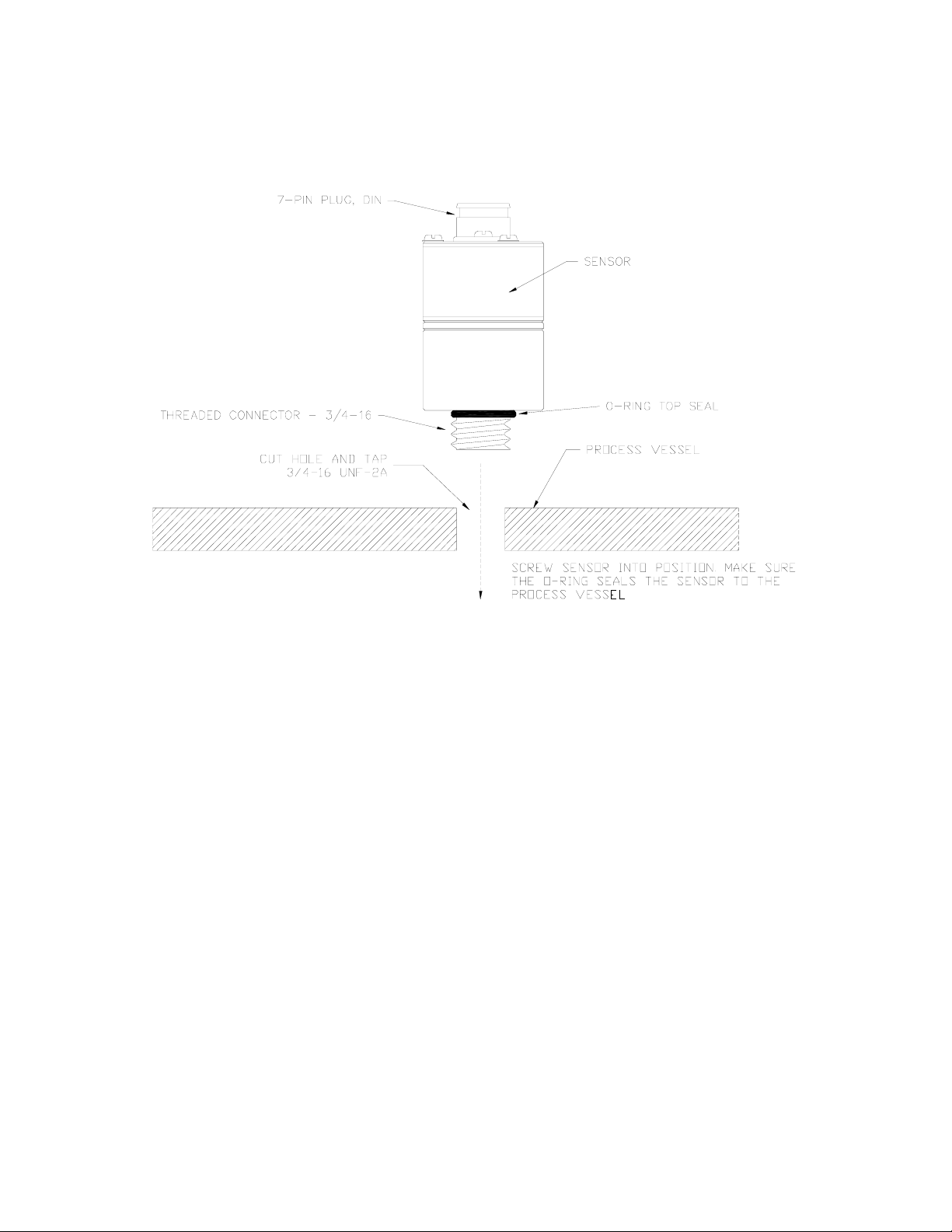

Step 2 – Sensor Installation

All pneumatic connections are to be made to the Model 5124BE-N1-WO

remote sensor. The remote sensor is designed to be screwed-on in-situ

to the process vessel at which the oxygen concentration measurements are

to be made.

Drill the Sample Port. Locate the sample point on the process vessel

at which the oxygen concentration measurements are to be taken. Drill a

hole at the location. The size of the initial drill hole should be

between 0.68” to 0.70” diameter depending on the wall thickness of the

sample process vessel.

Tap Engagement Threads to the Sample Port. Using a 3/4-16 UNF-2A

tap tool, tap the engagement threads to the sample port. If the process

vessel wall is very thick, tap to a minimum depth of 0.5” to ensure

proper engagement of the external sensor to the process vessel.

Thoroughly clean both the sample port and process vessel of any burrs,

slivers, or tap oils before installing the sensor.

Screw the Sensor to the Sample Port. Once the sample port has been

properly threaded and cleaned, screw the sensor to the sensor port.

Make sure that the O-ring at the base of the external sensor port neck

is properly compressed between the sensor body and the process chamber

ball. Failure to comply will cause the process gas to leak into the

atmosphere.

WARNING: The external sensor is designed to measure oxygen

concentrations in gas form in an inert gas background. If

there are fluids in the process vessel, select a sample

location at which the sensor will not be directly exposed to

the fluid.

WARNING: The acceptable background gases for oxygen measurements are

nitrogen and argon. Some gases will affect the accuracy of the sensor

while others may damage the sensor permanently. Contact Neutronics if

you are not sure about the affect of your process gases on the external

sensor.

WARNING: Do not over pressurize the sample inlet port as this may

permanently damage the internal components of the analyzer. Failure to

comply may void the warranty.

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 10

.

Figure 4 – Sensor mounting detail

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 11

Step 3 – Electrical Installation

CAUTION: Be sure all mains power supply is off before

attempting the electrical connections to the analyzer and

remote sensor. DO NOT WORK WITH LIVE WIRES! Do not leave any

exposed wire at the connectors or cables. Before applying

power, ensure terminal blocks are fully inserted into the mating

connector at the analyzer.

DANGER: The Model 5124BE-N1-WO analyzer and its external sensor are

not rated intrinsically safe or explosion proof. Be certain that no

flammable gases are present in the areas where the analyzer and the

external sensor will be installed.

CAUTION: The Model 5124BE-N1-WO analyzer and external housings are

not rated waterproof. Do not mount the analyzer or the sensor in an area

where it may contact water or other liquid elements.

WARNING: The Model 5124BE-N1-WO is not equipped with a circuit

breaker. A disconnecting switch or a circuit breaker must be installed

in series with the mains power to the analyzer.

All electrical connections to the Model 5124BE-N1-WO analyzer is to be

made to the three terminal blocks and sensor interface socket located at

the back of the analyzer chassis. A label depicting the terminal block

arrangement and the location of the bayonet connector is affixed to the

top of the chassis as reference. The terminal blocks may be removed for

wiring.

The electrical connection to the Model 5124BE-N1-WO external sensor is

to be made to the analyzer interface socket. Use the sensor interface

cable provided by Neutronics.

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 12

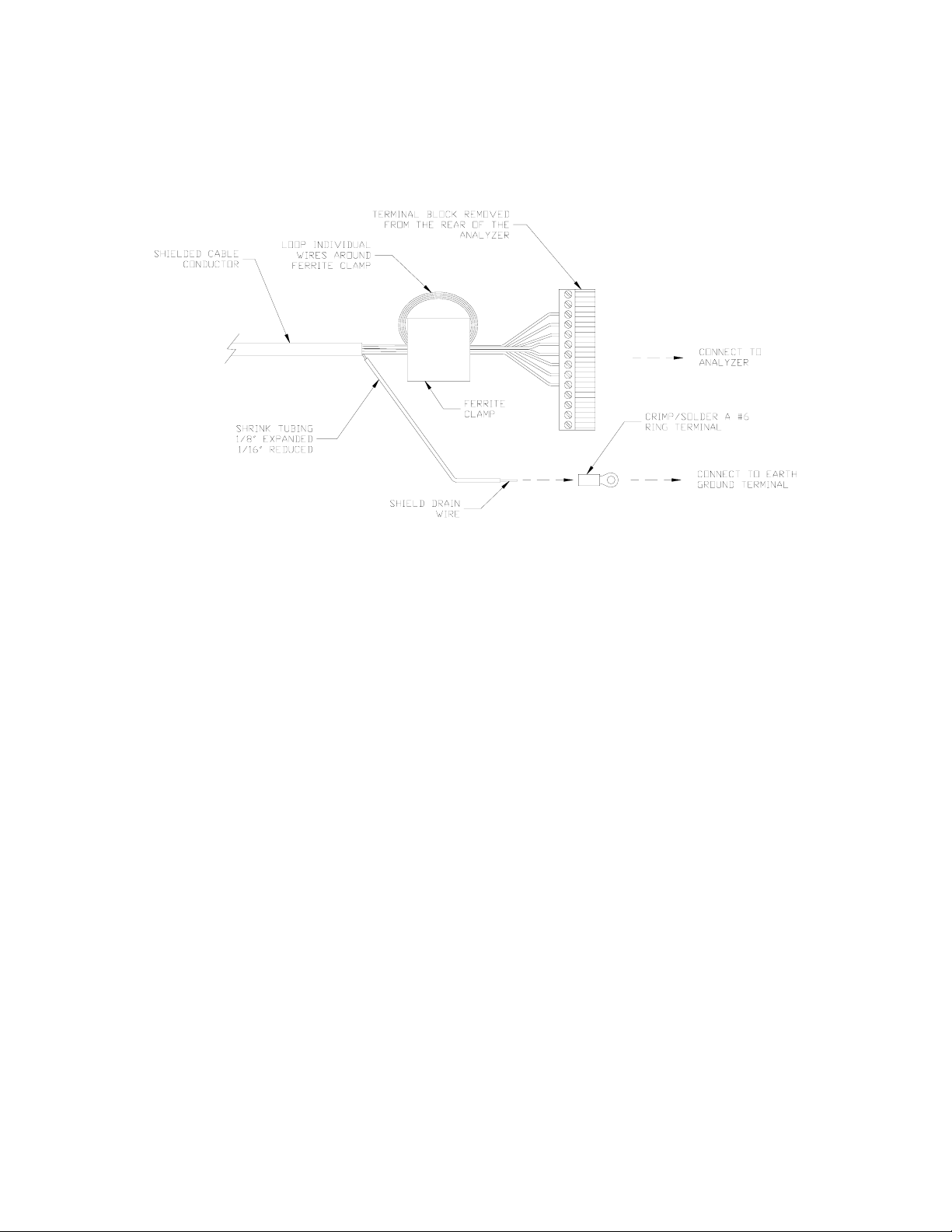

CAUTION: In order to comply with CE EN61326-1:2006

standards, all electrical connections to the three terminal

blocks on the back of the analyzer are to be made using

shielded cable conductors. Each electrical connection to the

terminal blocks must be looped through the ferrite clamp

provided. If more than one shielded cable conductor is used, the

individual wires from the different cables may share the same ferrite

clamp. Strip the cable jacket back about 8 inches to ensure all the

individual wires fit through the ferrite clamp. Additional ferrite

clamps may be purchased from Neutronics if necessary (See Appendix F:

Spare Parts).

CAUTION: Also, in order to comply with CE EN61326-1:2006 standards,

all shielded cable conductors must be earth grounded at both ends of the

cable. The shield drain wire from the cable conductors must be connected

to the earth ground screw terminal located at the back of the analyzer.

It is also recommended that the exposed drain wire be covered with shrink

tubing and the end be terminated with a #6 ring terminal before

connecting it to the earth ground screw terminal. The recommended shrink

tubing size is 1/8” expanded to 1/16” reduced. See Figure 5.

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 13

Figure 5 – Recommended electrical connection to the analyzer

terminal blocks

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 14

A label depicting the terminal block arrangement is affixed to the top

of the chassis for easy reference during installation and maintenance.

The terminal blocks feature screwed terminals. The terminal blocks are

also removable for ease of wiring or removal of the analyzer module.

CONNECTIONS

SEE MANUAL FOR

NO CONNECTION

TB1

ALARM 2

-

BAT. BU

12V DC

TB3

**

1 2

+

3

NO

TEMP

2

TB2 1

C

FAULT

3

C

54

NO C

PROCESS ANALYZER DIVISION

TRON

N

*

12

RS-232

SERVICE PORT

I-OUT

ANALOG

V-OUT

+

45

+-

67

TX-

8

RX

910

ALARM 1

20-30 VDC, 20 W

3

NO

76

NC

8

C

12

NO

109

NC

11

*

45

RTN

11

*

V-OUT

13

+

14

-

RANGE

SENSOR

DC POWER INPUT

*

GND COM VDC+ *

Figure 6 – Model 5124BE-N1-WO Electrical Connections Label

CUS

MET

SENSOR

ANALYZER

Figure 7 – Sensor Interface Cable Connection

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 15

123

TEMP

TB2 45678910 11 12 13 14

FAULT

CNO

Alarm 1

CNC NO

Alarm 2

CNC NO

Range

V-Out

+-

123

TB3 45678910 11

Bat.

BU

+-

V

Out

+-

mA

Out

+-

RS-232

TX RX RTN

12

VDC

no

connection

no

connection

Service

Port

NO = Normally

Open

NC = Normally

Closed

C = Common

VDC POWER INPUT,

18-30 VDC

13

TB1

GND

5

VDC+

24

COM

CNO

FAILSAFE

Figure 8 – Analyzer chassis electrical connections

The following is a list of all possible electrical connections to the

Model 5124BE-N1-WO analyzer:

External Sensor Interface

The Model 5124BE-N1-WO analyzer is electrically connected to the

external sensor via the sensor interface cable. Each end of the

sensor interface cable is labeled. The “ANALYZER” labeled end is to

be connected to the sensor interface socket on the analyzer. The

“SENSOR” labeled end is to be connected to the analyzer interface

socket on the external sensor.

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 16

Oxygen Alarm-1 Relay Output

Use 18-22 AWG, shielded cable for the connections. The shielded

cable must be grounded at both ends to comply with EN61326-1:2006

specifications. Loop individual connectors around the ferrite clamp

provided.

Relay Type: Form 1 C, SPDT, 5A @ 250 VAC, 5A @ 30VDC

Connections: Common: n 8Terminal Block TB2 Pi

Normally Closed Output: Terminal Block TB2 Pin 9

Normally Open Output: Terminal Block TB2 Pin 10

Oxygen Alarm-2 Relay Output

Use 18-22 AWG, shielded cable for the connections. The shielded

cable must be grounded at both ends to comply with EN61326-1:2006

specifications. Loop individual connectors around the ferrite clamp

provided.

Relay Type: Form 1 C, SPDT, 5A @ 250 VAC, 5A @ 30VDC

Connections: Common: Terminal Block TB2 Pin 5

Normally Closed Output: minal Block TB2 Pin 6Ter

Normally Open Output: Terminal Block TB2 Pin 7

System Fault Relay Output

Use 18-22 AWG, shielded cable for the connections. The shielded

cable must be grounded at both ends to comply with EN61326-1:2006

specifications. Loop individual connectors around the ferrite clamp

provided.

Relay Type: Form 1 B, SPST, 5A @ 250 VAC, 5A @ 30VDC

Connections: Common: Terminal Block TB2 Pin 3

Normally Open Output: Terminal Block TB2 Pin 4

Temperature OK Relay Output

Use 18-22 AWG, shielded cable for the connections. The shielded

cable must be grounded at both ends to comply with EN61326-1:2006

specifications. Loop individual connectors around the ferrite clamp

provided.

Relay Type: Form 1 B, SPST, 5A @ 250 VAC, 5A @ 30VDC

Connections: Common: Terminal Block TB2 Pin 1

Normally Open Output: Terminal Block TB2 Pin 2

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 17

Range ID Output

Use the Range ID voltage with either the analog voltage or the

analog current output to identify the full span oxygen concentration

measurement. Use 20-26 AWG, shielded cable for the connections.

The shielded cable must be grounded at both ends to comply with

EN61326-1:2006 specifications. Loop individual connectors around

the ferrite clamp provided.

Output Voltage: 0 - 10 Volts DC

Connections: Voltage + Output: Terminal Block TB2 Pin 13

Voltage - Output: Terminal Block TB2 Pin 14

Analog Voltage Output

The analog voltage output is factory pre-set to be either 0-1, 0-5,

or 0-10 volts. Use 20-26 AWG, shielded cable for the connections.

The shielded cable must be grounded at both ends to comply with

EN61326-1:2006 specifications. Loop individual connectors around

the ferrite clamp provided.

Output Voltage: - 10 Volts DC0 – 1, 0 – 5, or 0

Connections: Voltage + Output: Terminal Block TB3 Pin 5

Voltage - Output: Terminal Block TB3 Pin 6

Analog Current Output

The analog current output is a negative ground, non-isolated 4-20 mA

current loop. Use 20-26 AWG, shielded cable for the connections.

The shielded cable must be grounded at both ends to comply with

EN61326-1:2006 specifications. Loop individual connectors around

the ferrite clamp provided.

Output Voltage: 4 – 20 mA

Maximum Loading: 250 ohms

Connections: Current + Output: Terminal Block TB3 Pin 7

Current - Output: Terminal Block TB3 Pin 8

Battery Backup (Optional)

These terminals may be used to connect the Model 5124BE-N1-WO

analyzer to a 12V battery backup system such as a lead acid battery.

Battery backup function is not required for normal operations.

Input Voltage: 12 volts nominal

Connections: Battery + Terminal: Terminal Block TB3 Pin 3

Battery - Terminal: Terminal Block TB3 Pin 4

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 18

RS-232 Service Port

The RS-232 Service Port is used for interfacing with any standard PC

computer via the communications serial port. Use 20-26 AWG,

shielded cable for the connections. The shielded cable must be

grounded at both ends to comply with EN61326-1:2006 specifications.

Loop individual connectors around the ferrite clamp provided.

SIGNAL

DESIGNATION

AT ANALYZER

ANALYZER TB2

CONNECTION

SIGNAL

DESIGNATION

AT COMPUTER

COMPUTER DB9

SERIAL PORT

CONNECTION

TX Pin 9 RX Pin 2

RX Pin 10 TX Pin 3

RTN Pin 11 RTN Pin 5

Mains Power

Use 18-22 AWG, shielded cable for the connections. The shielded

cable must be grounded at both ends to comply with EN61326-1:2006

specifications. The ground shielding at the analyzer end is to be

connected to terminal block TB1 pin 1. Loop individual connectors

around the ferrite clamp provided.

Mains Power Voltage: ts DC18 – 30 Vol

Connections: DC +: Terminal Block TB1 Pin 4

DC -: Terminal Block TB1 Pin 2

Earth/Shield Ground: Terminal Block TB1 Pin 1

WARNING: Do not apply mains power to the analyzer or the

analyzer until all the electrical and pneumatic connections to

the analyzer and the remote sensor have been properly installed.

Manual Part Number:

5-06-4900-65-0

Revision Level: A

ECO 8541

File Name: MN-A-0177 Page 19

This manual suits for next models

1

Table of contents

Other Neutronics Analytical Instrument manuals