New Leader MultiBin Guide

1

MulBin Lid Cylinder Check Valve Replacement Instrucons

WARNING Shut o all power and allow all moving parts to come to rest before performing any maintenance

operaon.

WARNING

To perform the process described, a ladder or personal liing device will be required. Use

extreme cauon when working above ground. Use of 3-point contact when on a ladder, or use

of safety harness when using any type of liing device is highly recommended.

WARNING

Pressurized air may cause sudden movement of parts. Do not service cover components unl

safety precauons have been performed.

• Take preventave measures to prevent falling or runaway of cylinder or mechanism before

maintenance and restart of spreader.

• Exhaust all residual air and cut the pressure supply for components before servicing.

• Injury can occur if precauons are not taken.

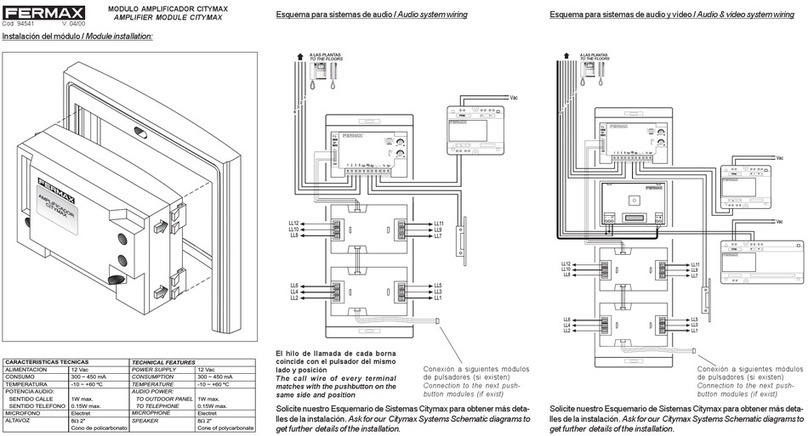

Follow this procedure to replace/re-install the MulBin Lid cylinder check valve. See Figure 1 for list of parts in upgrade

kit.

Item Description Quantity Tools Needed

1Check Valve Assembly 1 Vise Grips Clean Shop Rag

2Spring 1 Flat Blade Screwdriver Small External Snap Ring Pliers

3 Speed Control Fittings 2 20” Wood block Ratchet wrench

4 Inline lter Assembly 1 Pliers 7/16” & 9/16” Sockets

5 Clevis Spring Plates 2 Utility Knife Wrenches:

6 Corrugated tube 1 Small Pin Punch 7/16”, 9/16” & 11/16”

7 1/4” tubing 24” Small Hammer

Figure 1: Parts in Kit

1

4

2

3

6

5

7

2

MulBin Lid Cylinder Check Valve Replacement Instrucons

1. Drain air system and cycle lid control valve to expel any trapped air

2. Figure 2 - Remove 4 cylinder guard retaining bolts (2). Set guard (1) and bolts (2) aside for later use.

Item Description

1 Cylinder guard

2 Retaining bolts

Figure 2

12

2

3

MulBin Lid Cylinder Check Valve Replacement Instrucons

3. Figure 3A - Carefully clean area around all 4 air tubes (1 & 2). Unhook air supply tubes to cylinder (1) and

air tubes between cylinder ngs (2) (as shown in Figure 3B).

Item Description

1 Air Supply Tube

2 Air Cylinder Tube

3 Cylinder Fitting

Figure 3A

Figure 3B

1

23

3

3

4

MulBin Lid Cylinder Check Valve Replacement Instrucons

4. Figure 4 - Remove e-clip (1) and clevis pin (2) from each end of cylinder. Remove cylinder. Set clevis pins

and e-clips aside for later use.

Item Description

1 E-clip

2 Clevis Pin

Figure 4

1

1

2

2

5

MulBin Lid Cylinder Check Valve Replacement Instrucons

5. FIgure 5 - Clean the areas around the cylinder ngs. Remove and discard old ngs (2).

6. Figure 6 - Slide new check valve assembly (3) midway onto cylinder (1). Posion as shown. Note proper

angle in Figure 6A. Tighten hose clamps (4).

Item Description

1 Cylinder

2 Old ttings

3Check Valve Assembly

4 Hose Clamps

Figure 5

Figure 6

1

2

1

4

3

Angle

between

15° - 30°

As viewed from

Rod end of cylinder

Figure 6A

6

MulBin Lid Cylinder Check Valve Replacement Instrucons

7. Figure 7 - Install new speed control ngs (2) onto cylinder (1) as shown. Fings do not require adjust-

ment for proper air ow. NOTE: Do NOT connect air tubes (3) at this me.

Item Description

1 Cylinder

2 Speed Control Fittings

3 Air Tubes

Figure 7

3

1

2

2

7

MulBin Lid Cylinder Check Valve Replacement Instrucons

8. Figure 8 - Reinstall cylinder as shown using original clevis pins (2) and e-clips (1). NOTE: Do NOT connect

air tubes (3) at this me (as shown in Figure 8).

Item Description

1 E-clip

2 Clevis Pin

3 Air Tubes

Figure 8

1

1

2

2

3

8

MulBin Lid Cylinder Check Valve Replacement Instrucons

9. Figure 9 - By Hand, open lid (1) to 20” and insert block (2). Assist spring (3) will be le at its shortest posi-

on.

Item Description

1 Lid

2Block

3 Assist Spring

WARNING Block cover lid to prevent closing. Unintenonal closing could cause injury.

Figure 9

20”

1

2

3

9

MulBin Lid Cylinder Check Valve Replacement Instrucons

10. Figure 10 - Use Vise Grips to secure Eyebolt (1). Carefully remove eyebolt 3/8” nut (2). Set nut (2) and

spring pivot (3) aside for later use.

CAUTION Eyebolt is under tension. Cauon should be used when removing to prevent parts from being

thrown by spring. Safety glasses should be worn when working on this component.

Item Description

1Eyebolt

2 3/8” Nut

3Spring Pivot

Figure 10

1

2

3

10

MulBin Lid Cylinder Check Valve Replacement Instrucons

11. Figure 11 - Remove coer pin (4) and at washer (5). Set hardware aside for later use. Remove spring as-

sembly to workbench and disassemble spring assembly. Save eyebolt (3) and hardware (4-6). Discard old

spring (1) and old clevis plates (2).

Item Description

1 Spring (discard)

2 Old Clevis Plates (discard)

3 Eyebolt (re-use)

4 Cotter pin (re-use)

5 Flat Washer (re-use)

6 Clevis Pin (re-use)

Figure 11

3

4

4

5

5

6

6

5

4

3

1

2

11

MulBin Lid Cylinder Check Valve Replacement Instrucons

12. Figure 12 - Install original spring eyebolt (3) and new longer clevis plates (2) onto new spring (1), reusing

original hardware (4-6). Install new spring assembly using original clevis pin (6), coer pin (4), and wash-

er(5).

Item Description

1 New Spring

2 New longer Clevis plates

3 Eyebolt (re-use)

4 Cotter pin (re-use)

5 Flat Washer (re-use)

6 Clevis Pin (re-use)

Figure 12

1

2

3

4

5

6

12

MulBin Lid Cylinder Check Valve Replacement Instrucons

13. Figure 13 - Use Vise Grips to secure eyebolt (1). Reinstall spring eyebolt using original spring pivot (3) and

hardware. Thread 3/8” nut (2) onto eyebolt ONLY 1/2” at this me.

Item Description

1Eyebolt

2 3/8” Nut

3Spring Pivot

Figure 13

1

2

3

13

MulBin Lid Cylinder Check Valve Replacement Instrucons

14. Figure 14 - Remove block and lower lid. Tension spring (1) to 16-1/4” as shown by adjusng eyebolt hard-

ware. When spring is properly adjusted, ghten the eyebolt jam nut (3/8” Nut) (2).

Item Description

1Eyebolt

2 3/8” Nut

Figure 14

16-1/4”

1

2

14

MulBin Lid Cylinder Check Valve Replacement Instrucons

15. Figure 15 - Connect check valve tubes (1) to cylinder ngs (2) at both ends. Push rmly to seat tubes into

ngs.

Item Description

1Check Valve tube

2 Cylinder tting

Figure 15

2

1

15

MulBin Lid Cylinder Check Valve Replacement Instrucons

16. Figure 16 - Replace short supply tube with new 24” long tube (1) (cut to length as needed) and install into

right-hand check valve ng (3). Clean original long tube (2), cut to length (as needed) and install into le-

hand check valve ng (4). Push rmly to seat tubes into ngs.

Item Description

1 New 24” tube

2 Original long tube

3 Right-hand check valve tting

4 Le-hand check valve tting

Figure 16

1

3

2

4

16

MulBin Lid Cylinder Check Valve Replacement Instrucons

17. Figure 17 - Reinstall cylinder guard (1) and 4 guard retaining bolts (2).

Item Description

1 Cylinder guard

2 Retaining bolts

Figure 17

12

2

17

MulBin Lid Cylinder Check Valve Replacement Instrucons

18. Figure 18 - On right-hand front corner of spreader, remove air supply tube (3) from control valve inlet ng

(2) on control valve assembly (1).

Item Description

1Control valve assembly

2 Inlet tting

3 Air Supply tube

Figure 18

1

3

2

18

MulBin Lid Cylinder Check Valve Replacement Instrucons

19. Figure 19 - Install new inline air lter (5) with corrugated tube (4) into inlet ng (2) on control valve as-

sembly (1). Push rmly to seat tube (3) into ng.

Item Description

1Control valve assembly

2 Inlet tting

3 Short Air Supply tube

4 Corrugated tube

5 Inline lter

Figure 19

1

2

3

45

19

MulBin Lid Cylinder Check Valve Replacement Instrucons

20. Figure 20 - Clean air supply tube (4) and cut to length as needed. Install air supply tube into inline lter

(3) on control valve assembly (1). Push rmly to seat tube into lter. Slide corrugated tube (2) over inline

lter.

Item Description

1Control valve assembly

2 Corrugated tube

3 Inline lter

4 Air Supply Tube

Figure 20

21. Start engine and allow air pressure to build in system. Test operaon by cycling lid control valve several

mes and check for air leaks. Lid will open and close smoothly for correct operaon.

1

234

Popular Control Unit manuals by other brands

Unipower

Unipower SAGEON Site Monitor Application note

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS CTM-EF 3 3 Series Operating and maintenance instructions

EMS

EMS LRP2000 Series Operator's manual

Crane

Crane D1088 Installation, operating and maintanance instructions

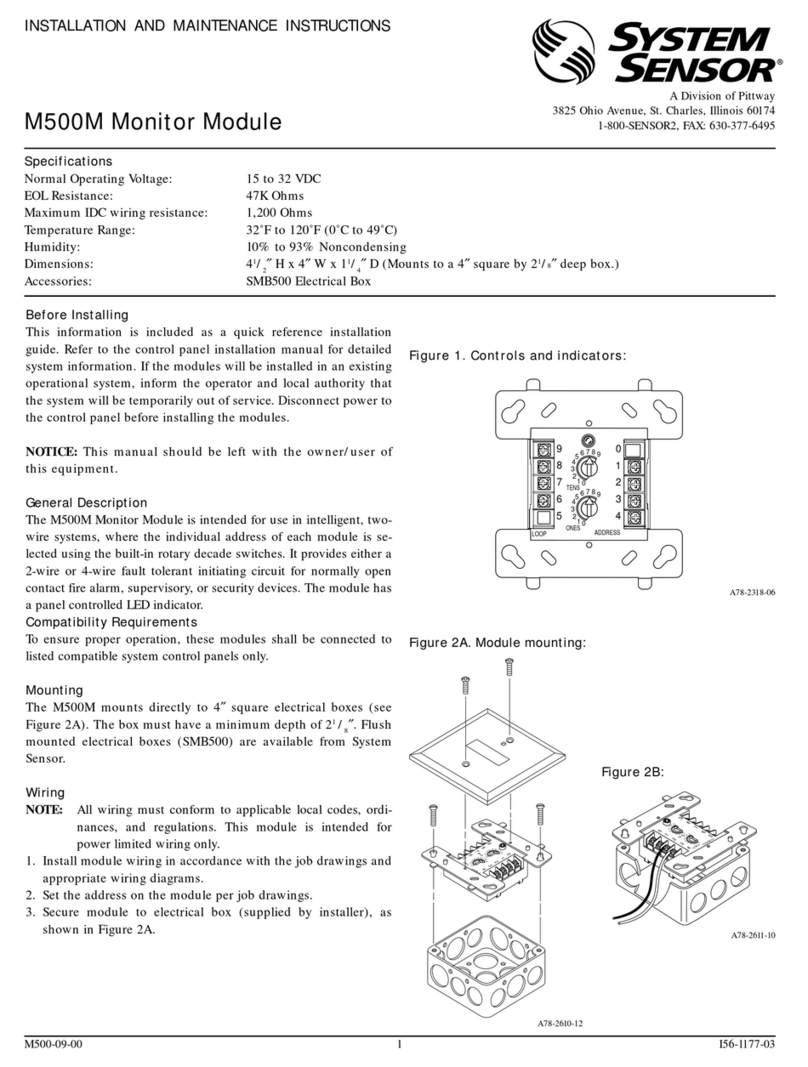

Pittway

Pittway SYSTEM SENSOR M500M Installation and maintenance instructions

Land Pride

Land Pride 380-152A installation instructions