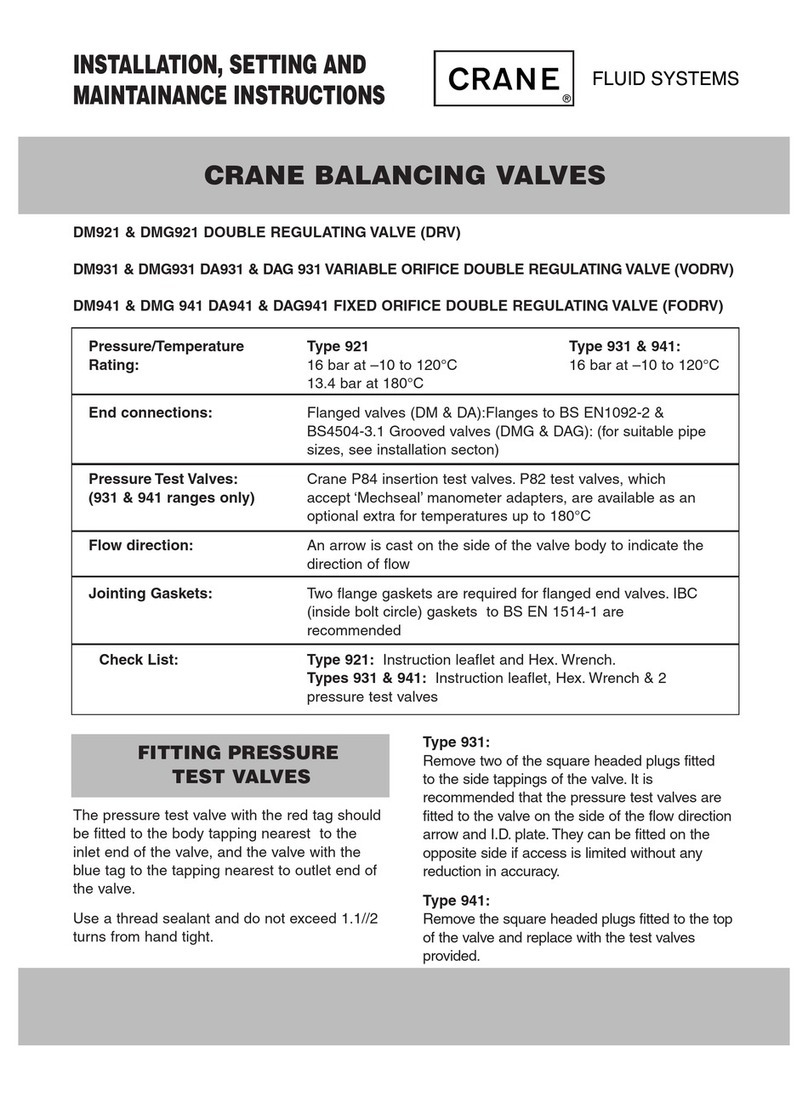

CONDITIONS OF USE

Operating Pressure Range High Pressure Low Pressure

Maximum Static Pressure 10 bar 10 bar

Flow Pressure - Hot & Cold 1 to 5 bar 0.2 - 1 bar

Hot Supply Temperature 52 to 65ºC 52 to 65ºC

Cold Supply Temperature 5 to 20ºC 5 to 20ºC

Table 3 - Normal Conditions of Use for Type 3 Valves

Note 1: The valve may perform adequately outside the conditions in table 3 but the TMV3 scheme approval does

not apply.

Note 2: The highest flow rates will be achieved under balanced pressure conditions, but the pressure at the valve

inlets must be within a ratio of 2:1 under flow conditions and the size and layout of pipe work and fittings must take

this into account.

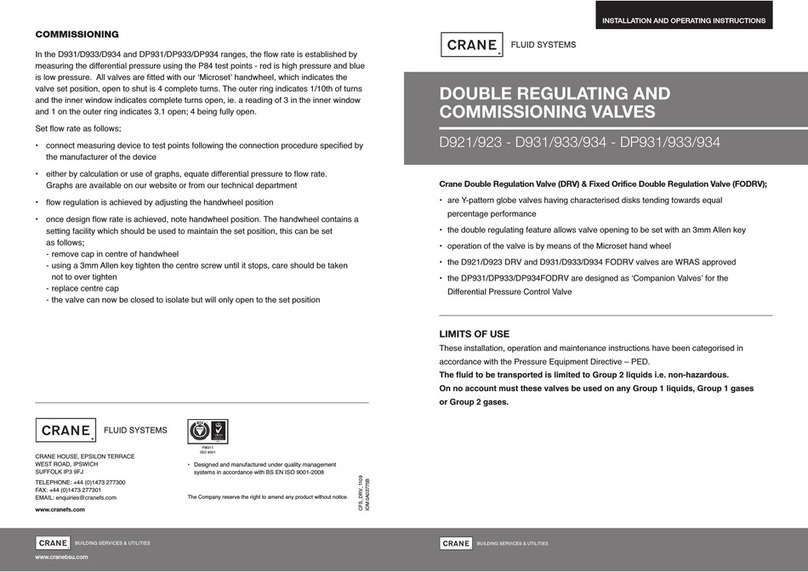

PRE-COMMISSIONING CHECKS

Follow this method for adjusting the water temperature:

1. Remove the maroon plastic protective cap on top of the valve with a

screw-driver.

2. Back-out the nut, using a monkey spanner:

-To increase the temperature turn anti-clockwise

-To decrease the temperature turn clockwise

-To set the valve to a maximum mixed water temperature in

accordance with the valve application (See Table 4).

Once the correct outlet temperature is set the internal mechanism must

be tested at least 3 times by:

•Alternately isolate the hot & cold water supply. This causes the internal

piston to travel its full stroke and will ensure correct operation

of the valve.

•With hot & cold isolation valves and the terminal outlet fully open retest

the flow temperature. If the set temperature has moved, repeat the

commissioning process.

•A fail safe test must be carried out by isolating the cold

supply. Once isolated, the flow must reduce, within a couple

of seconds, to a trickle - depending on site conditions, supply

temperature/pressure.

•Then repeat fail safe test isolating the hot supply. Once

isolated, the flow must reduce to a trickle within a couple of

seconds – depending on site conditions.

•If either the cold or hot fail safe function does not operate, check;

-Supply pressures

-Supply temperatures

-Hot water supply is at least 10ºC above required mix temperature,

i.e. minimum hot to mix temperature

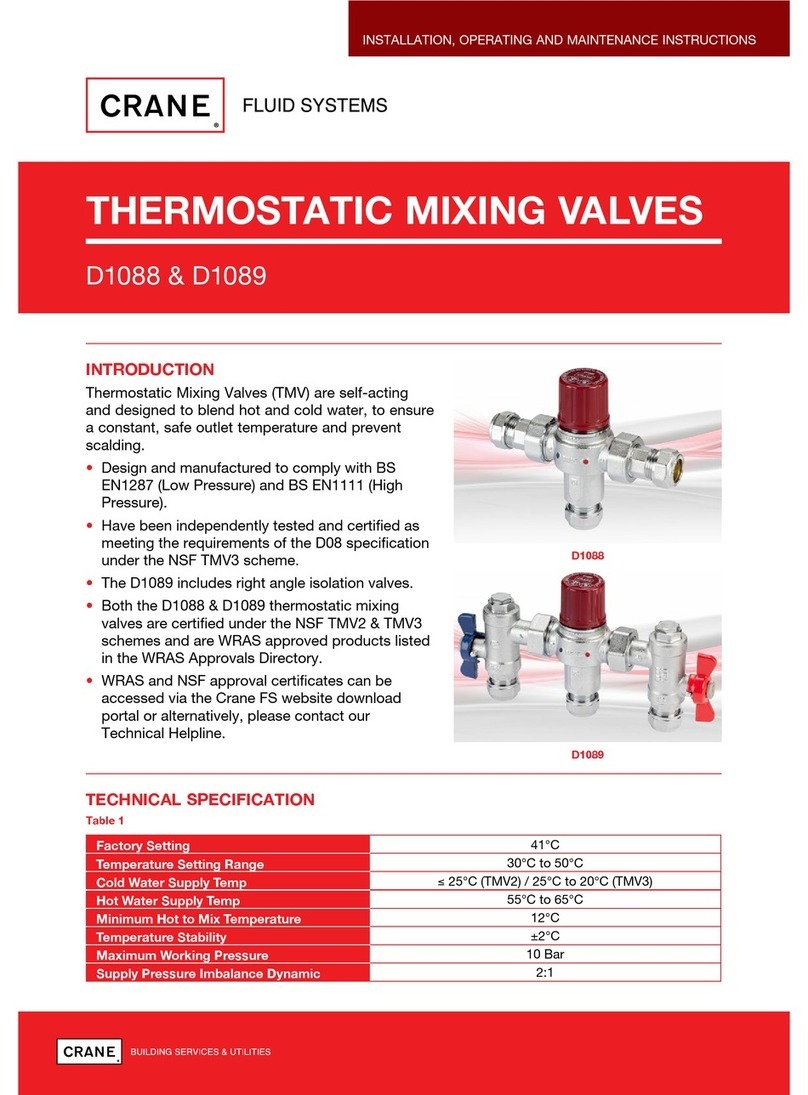

Figure 1 - D1088 pictured,

cap removal

Figure 2 - D1088 pictured,

temperature setting

Screw driver

Screw

The blue plastic

protective cap

Nut