Temperature memory function

When you turn off the station at 400 ℉, when you turn on next time, it will

auto heat up to the 400 ℉.

5.When you finish your work, put the blower handle back on the holder,the

station will stop warming automatically,the station will show “---”,that meant

the tool is going to enter standby state

6.To switch off the power and unplug if there is no operation for a long period

of time.

Soldering iron Part

1.Assemble the station with the heat gun and soldering accessories.

2. Make sure to turn off all the on-off buttons before plug in the power supply.

3. set the temp steps can follow (Temperature Adjustment )

PID Temperature Control Technology:This unit features Temperature Control

Technology which the program will cycle every 20 milliseconds to detect the actual

temperature of the soldering iron's heating element, quickly correct it with a rapid return

to the correct set temperature.

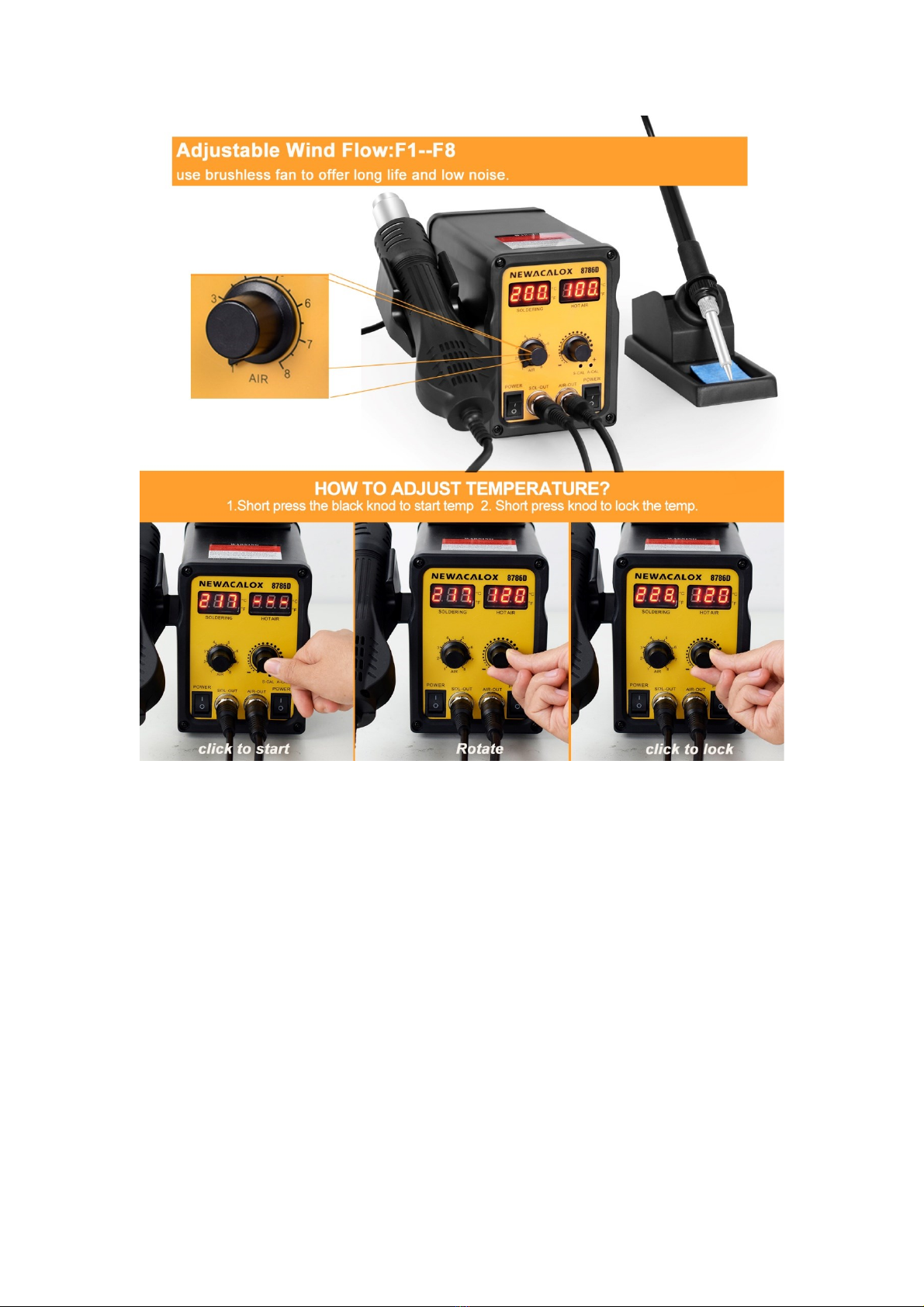

soldering iron was able to heat up quickly. The temperature is set by rotating the black

knob, simple to use and sensitive.

Adjustable Temperature:Temperature Range of 200°C - 480°C/392 - 896℉;

Temperature Stability: ±2.0℉.

With a precise, real-time digital display and adjustable temperature, it can effectively

prevent over temperatureover-temperature from burning components and circuit board

pads.

Complete Kit Includes: Soldering Station with Soldering Iron Holder & 5 piece 900M

Solder Tip.

C/F Function easily changes the LED digital readouts from "Centigrade to Fahrenheit"

for the Soldering Iron Temperature with a flip of the black knob.

FAQ:

Low Airflow when “Air” Dial is Turned Up

If you are getting low airflow when the “Air” Dial is turned up, make sure that

you have the nozzle securely attached. With the nozzle, you will get more air

flowing through the hot-air rework station’s handle.