VTSDIR

21.03.2011 ©Velleman nv

5

6. Setup

Refer to the illustrations on page 2 of this manual.

Note: never unplug any connection during operation.

•The equipment must be sited on a firm surface at least 1.2M x 0.75M and at a height to suit the operator.

The location should be chosen to suit the flow of work.

•Plug the solder light plug into the socket on the front of the main station.

•Plug the solder light fan into the cooling fan socket [18] and place the solder light in the holder.

•Plug the footswitch into the foot switch socket [17].

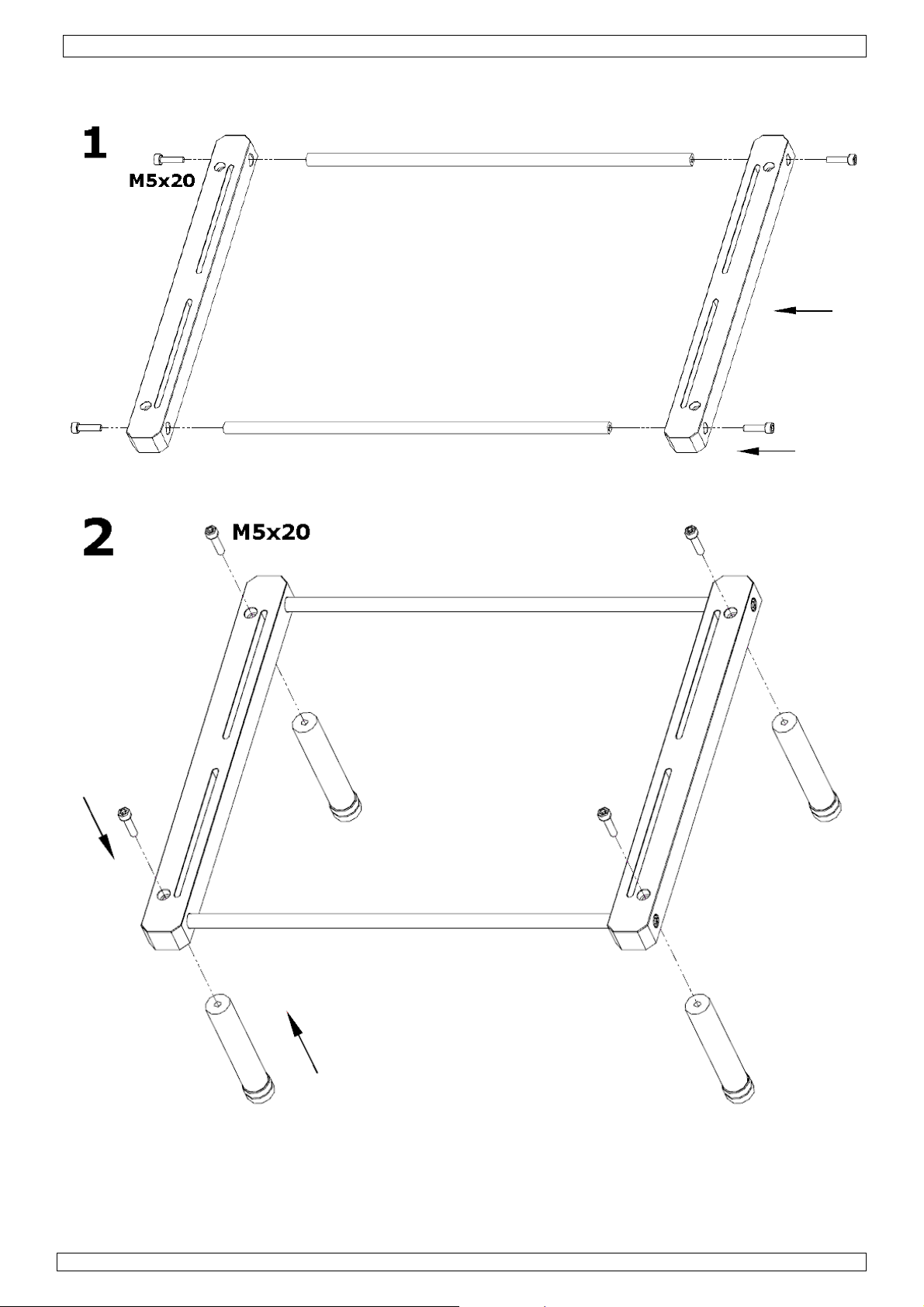

•The quartz heaters are secured against shocks with a metal bar and plastic tubes. Remove these and mount

the metal grid in place (refer to Appendix 1).

•Mount the PCB holder (refer to Appendix 2).

•Plug the power cord into the AC power inlet [21].

7. Operation

•The principle of operation of IR rework system is that whilst being heated from above and below, a single

SMD is subjected to similar temperature/time profile during rework as it experiences during reflow in the

original production process.

Note: wait about 5 minutes for the system to warm up after changing a setting.

IR hand tool operation:

•Set the “SOLDERLIGH/TIMER” switch [1] to the SOLDERLIGHT position (I).

•Set the IR Lamp temperature using the “▼” [3] and “▲” [4] keys. Press and hold ±2s to increase

setting speed. Read the temperature on the display [5].

Note: the temperature depends on the type of work (normally about 240°C)

Standard operation

•Press on the footswitch to start the IR heating; release to stop IR heating.

Timer-up operation

•Set the “SOLDERLIGH/TIMER” switch [1] to the TIMER position (O).

•Set the “Time counting” switch [2] to the UP position (I).

•Press on the footswitch to start IR heating; release to stop IR heating. The timer display [9] will count

the number of seconds that the IR heating was on.

Timer-down operation

•Set the “SOLDERLIGH/TIMER” switch [1] to the TIMER position (O).

•Set the “Time counting” switch [2] to the DOWN position (O).

•Set the timer using the “▼” [3] and “▲” [4] keys. Press and hold ±2s to increase setting speed. Read

the time (in seconds) on the display [9].

•Press on the footswitch to start IR heating; release to stop IR heating. The timer display will count

down the number of seconds that the IR heating was on. When 000 is reached, a warning signal

sounds.

Notes:

•Press the reset switch [8] to return the display to 000.

•To determine the reflow time of a new component, first use the timer up operation until it reflows, than

use the timer value for timer-down operation.

Pre-heater operation:

•Set the pre-heater temperature using the “▼” [12] and “▲” [11] keys. Press and hold ±2s to increase

setting speed. Read the temperature on the display [16].

Note: the temperature depends on the type of work (normally about 220°C)

Actual temperature compensation value

•Press on the MODEL button [13] until the display shows “---” (±4s). The temperature compensation is

shown for ±2s.

•To change the value, press the MODEL button [13] again. The value on the display starts to flash and

can be set using the “▼” [12] and “▲” [11] keys.

Note: when the display shows “00” or “-00” the compensation is “+10”.

E.g. When the temperature is set at 200°C and the measured temperature is only 190°C, then the

value must be set to “00” or “-00”. If the measured value is 180°C, than the compensation value must

be set to “+10” (-20 + 10 = 10).

General operation:

CAUTION: to avoid burns, do not touch the heater or PCB directly, use clips or tweezers to pick up or align

components.

CAUTION: do not allow water/liquids/solvents to touch the heater surface to avoid temperature drop cracks

while the unit is still hot. Such cracks can lead to electrical shorts or failure of the heater.

CAUTION: Do not touch the PCB holder to avoid burning your skin during preheat!