1.0 INSTALLING LONGITUDINAL (X-AXIS) SCALE – REAR

MOUNTING

1.1 The scale is installed 1

st

, however before installing check that the scale

will be reached by the head once attached to the bracket.

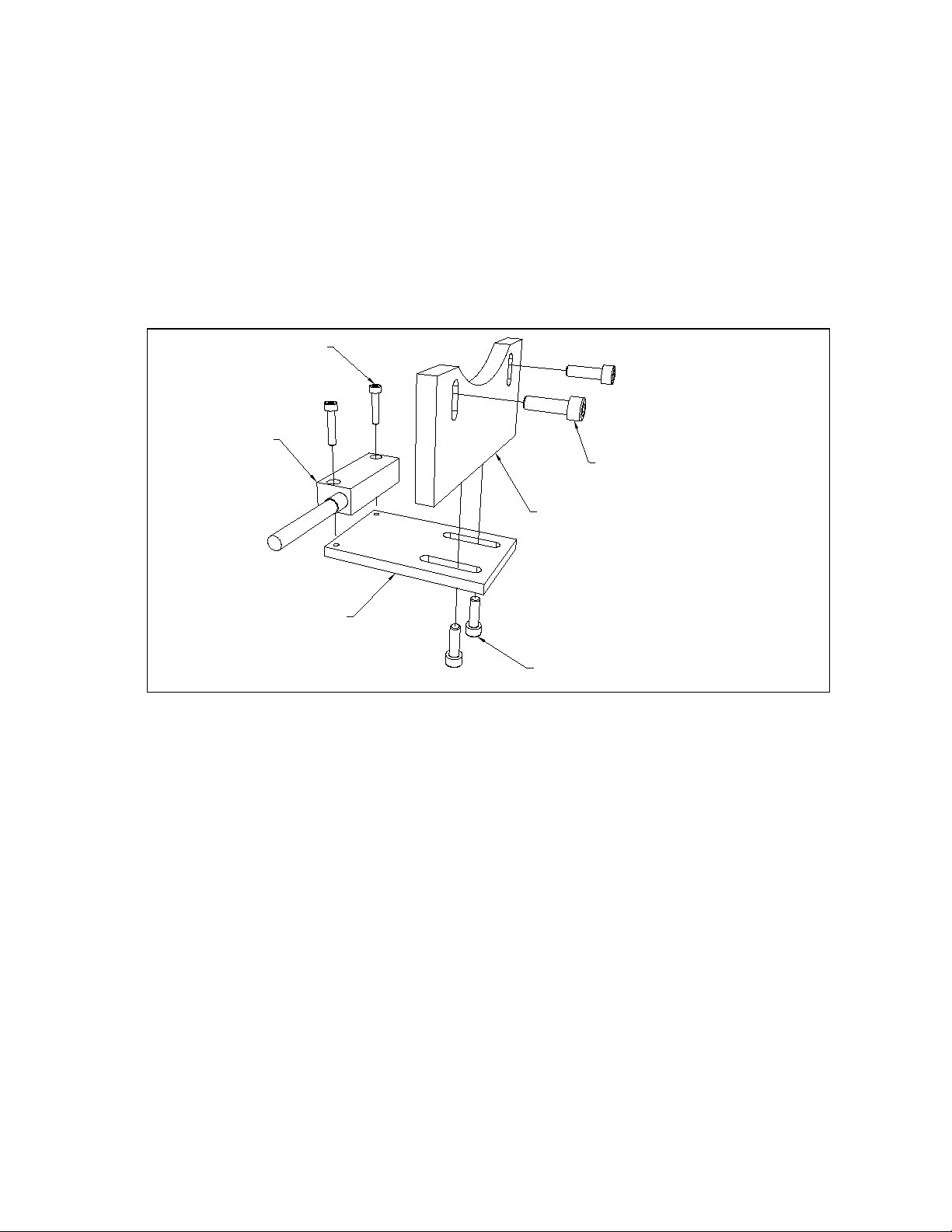

1.2 Fit the scale central on the rear of the table, mark, drill and tap 2 M4 x

20mm deep holes. NB the ‘grating sticker’ should be on the top.

1.3 Loosely fix scale into place using the M4 x 20mm socket cap head

screws (SHCS) provided.

1.4 The scale should be mounted parallel to the machine faces to within

0.1mm(0.004”)/meter. Please see fig below.

1.5 The scale can be adjusted up and down on the slots and in and out via

the grub screws either end of the scale.

1.6 Once parallel tighten up both screws.

1.7 On longer scales side clamps are provided, these can be used on the

top, bottom or both depending on space available.

1.8 Position the side clamp and mark the hole centre.

1.9 Drill and tap M4 x 10mm hole.

0.1 (0.004")

0.1 (0.004")

SCALE

M4 x 20 SHCS

SI E CLAMP (FOR LONGER SCALES)

(CAN USE AT TOP AN BOTTOM)