MCS260

CORNERSTONE 260 MONOCHROMATORS

2

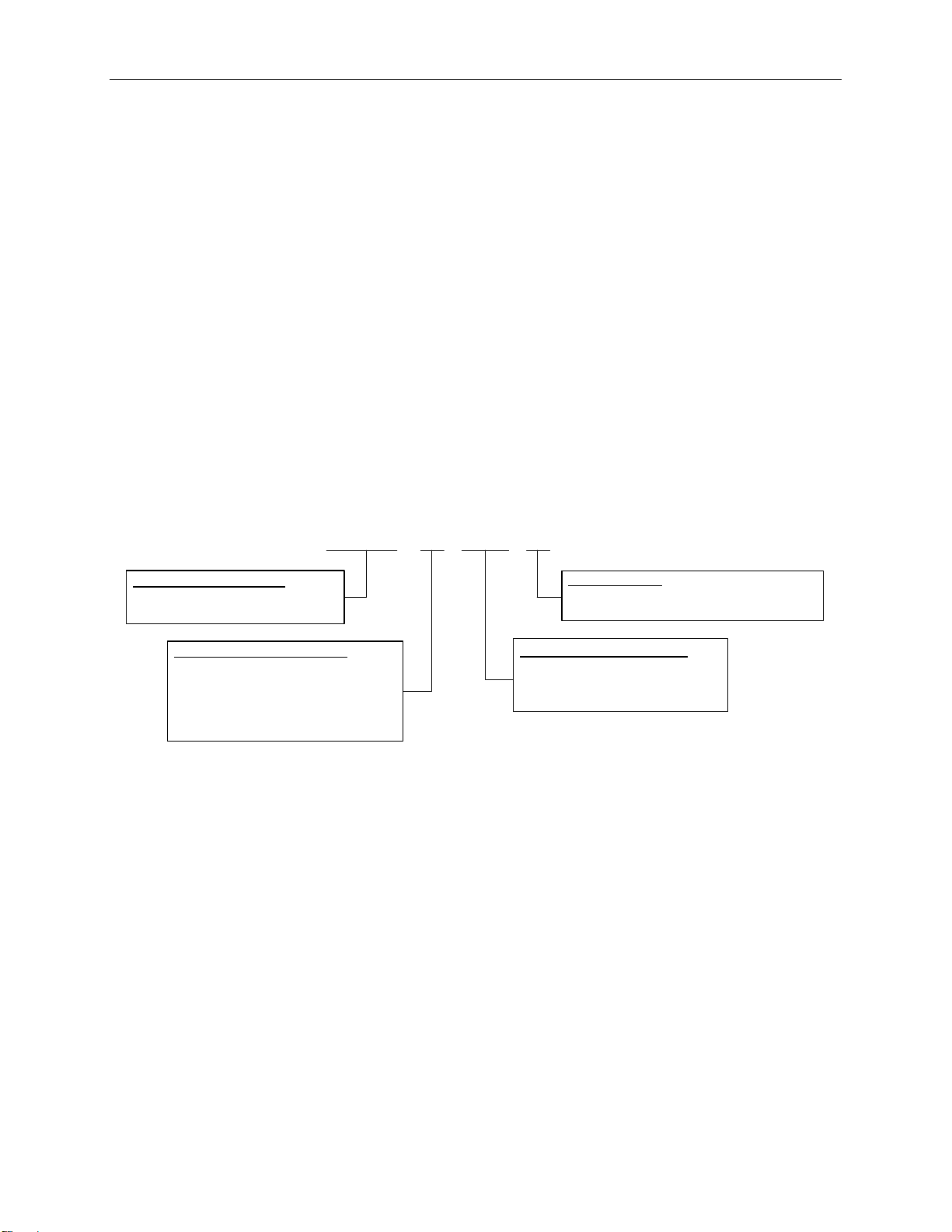

TABLE OF CONTENTS

1GENERAL INFORMATION..................................................................................................................5

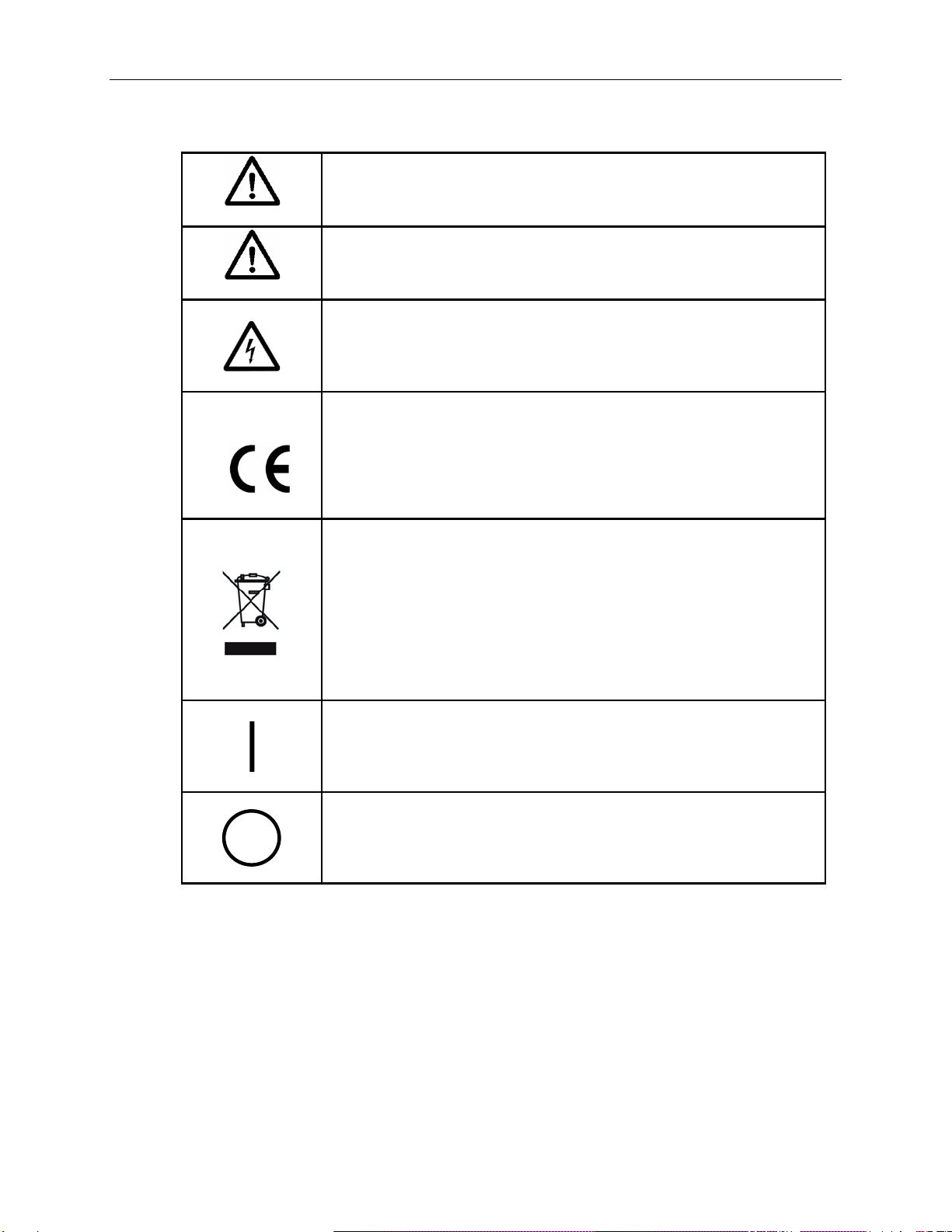

1.1 SYMBOLS AND DEFINITIONS .............................................................................................6

1.2 GENERAL WARNINGS .........................................................................................................7

1.3 ELECTRICAL HAZARDS.......................................................................................................7

1.4 MECHANICAL HANDLING....................................................................................................8

1.5 OPTICS CARE AND HANDLING...........................................................................................8

2INTRODUCTION..................................................................................................................................9

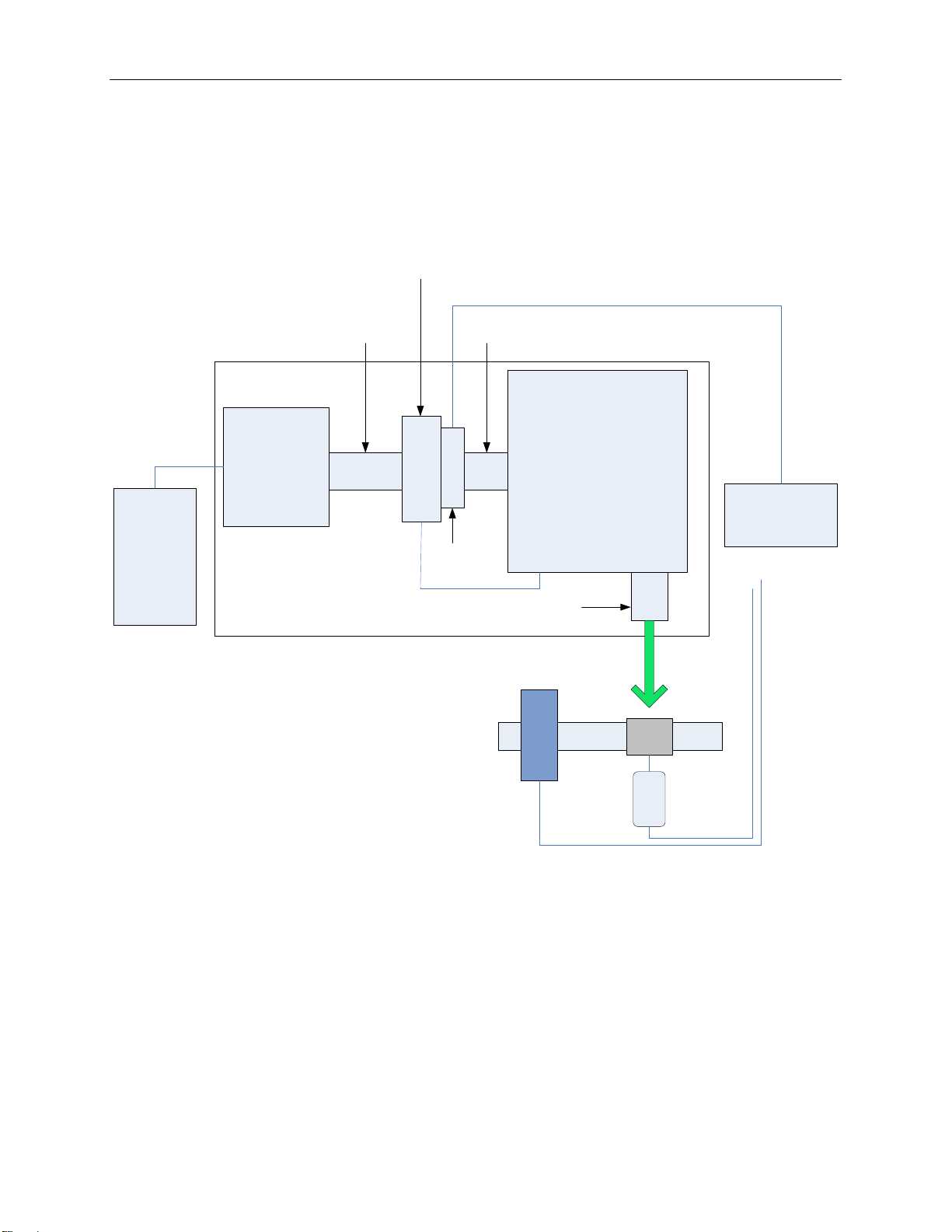

2.1 OPTICAL CONFIGURATION.................................................................................................9

2.2 STRAY LIGHT REJECTION ................................................................................................10

2.3 AVAILABLE MODELS..........................................................................................................10

2.4 TYPICAL APPLICATIONS...................................................................................................11

3INITIAL SETUP ..................................................................................................................................12

3.1 WHAT’S INCLUDED............................................................................................................12

3.2 UNPACKING........................................................................................................................12

3.3 CHOOSING A LOCATION...................................................................................................12

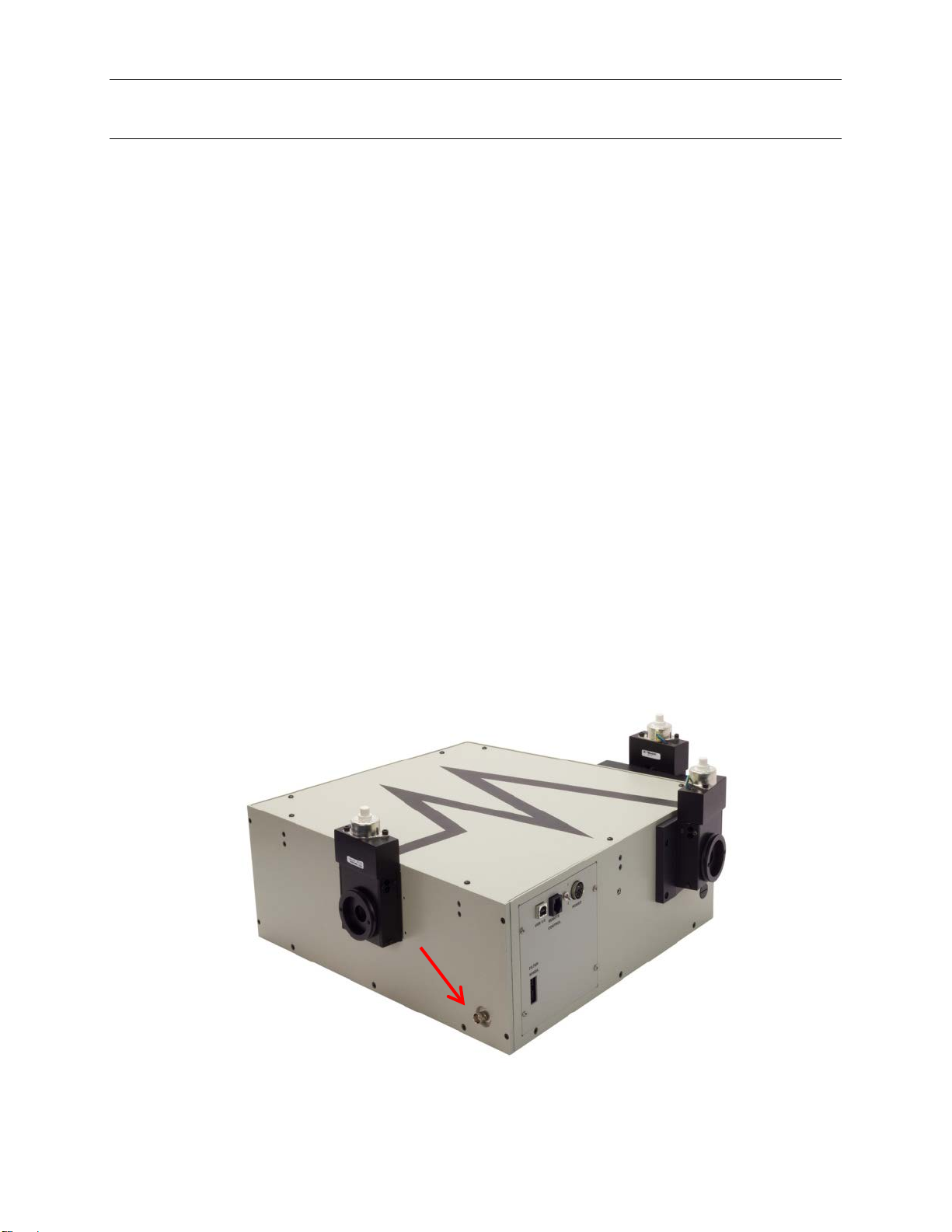

3.4 MOUNTING OPTIONS.........................................................................................................13

3.5 ELECTRICAL AND COMPUTER CONNECTIONS.............................................................14

4SHUTTER...........................................................................................................................................16

4.1 REMOTE OPERATION........................................................................................................16

5INPUT AND OUTPUT SLITS .............................................................................................................17

5.1 FIXED SLITS........................................................................................................................17

5.2 MICROMETER ADJUSTABLE SLITS .................................................................................18

5.3 MOTORIZED SLITS.............................................................................................................20

6DIFFRACTION GRATINGS ...............................................................................................................21

6.1 GRATING TYPES ................................................................................................................22

6.2 GRATING EFFICIENCY AND BLAZING .............................................................................23

6.3 POLARIZATION EFFECTS..................................................................................................26

7MONOCHROMATOR RESOLUTION................................................................................................27

7.1 DETERMINING RESOLUTION............................................................................................28

8GETTING LIGHT INTO A MONOCHROMATOR...............................................................................31

8.1 ACCEPTANCE PYRAMID ...................................................................................................31

8.2 F NUMBER MATCHING ......................................................................................................32

9BLOCKING HIGHER ORDER RADIATION.......................................................................................33

9.1 ORDER SORTING FILTERS...............................................................................................33

10 COMMUNICATION METHODS.........................................................................................................34

10.1 UTILITY SOFTWARE...........................................................................................................35

10.2 HAND CONTROLLER..........................................................................................................36

10.3 TRACQ BASIC SOFTWARE ...............................................................................................37

10.4 LOW-LEVEL COMMANDS ..................................................................................................38

10.5 MONO TERM SOFTWARE AND LABVIEW EXAMPLES...................................................38

11 GRATING INSTALLATION AND CALIBRATION...............................................................................39

11.1 RECALIBRATION SERVICES.............................................................................................39

11.2 SETTING THE WAVELENGTH OFFSET............................................................................39

11.3 DETERMINING THE GRATING CALIBRATION FACTOR .................................................40

11.4 GRATING INSTALLATION ..................................................................................................41

12 TROUBLESHOOTING .......................................................................................................................43

12.1 CORRUPTED MEMORY .....................................................................................................43

12.2 GRATING TURRET POSITION ERROR.............................................................................44

13 SPECIFICATIONS..............................................................................................................................45

14 DIMENSIONS.....................................................................................................................................46

15 EU DECLARATION OF CONFORMITY.............................................................................................48