Newport PM 500 Installation manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Newport PM500-C at our website: Click HERE

i

PM500 SERIES

Operation and Command

Reference Manual

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ii Preface

Warranty

Newport Corporation warrants that this product will be free from defects in material

and workmanship and will comply with Newport’s published specifications at the

time of sale for a period of one year from date of shipment. If found to be defective

during the warranty period, the product will either be repaired or replaced at

Newport's option.

To exercise this warranty, write or call your local Newport office or representative,

or contact Newport headquarters in Irvine, California. You will be given prompt

assistance and return instructions. Send the product, freight prepaid, to the indicated

service facility. Repairs will be made and the instrument returned freight prepaid.

Repaired products are warranted for the remainder of the original warranty period or

90 days, whichever first occurs.

Limitation of Warranty

The above warranties do not apply to products which have been repaired or modified

without Newport’s written approval, or products subjected to unusual physical,

thermal or electrical stress, improper installation, misuse, abuse, accident or

negligence in use, storage, transportation or handling. This warranty also does not

apply to fuses, batteries, or damage from battery leakage.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR USE. NEWPORT CORPORATION SHALL NOT BE

LIABLE FOR ANY INDIRECT, SPECIAL, OR CONSEQUENTIAL DAMAGES

RESULTING FROM THE PURCHASE OR USE OF ITS PRODUCTS.

Trademarks

Windows is a registered trademark of Microsoft Corporation. LabVIEW and

LabWindows are trademarks of National Instruments Corporation.

Copyright 2001 by Newport Corporation, Irvine, CA. All rights reserved. No part of this

manual may be reproduced or copied without the prior written approval of Newport

Corporation.

This manual has been provided for information only and product specifications are subject to

change without notice. Any change will be reflected in future printings.

©2001 Newport Corporation

1791 Deere Ave.

Irvine, CA 92606

(800) 222-6440

P/N 22519-01, Rev. A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Preface iii

Confidentiality & Proprietary Rights

Reservation of Title:

The Newport programs and all materials furnished or produced in connection

with them ("Related Materials") contain trade secrets of Newport and are for

use only in the manner expressly permitted. Newport claims and reserves all

rights and benefits afforded under law in the Programs provided by Newport

Corporation.

Newport shall retain full ownership of Intellectual Property Rights in and to

all development, process, align or assembly technologies developed and other

derivative work that may be developed by Newport. Customer shall not

challenge, or cause any third party to challenge the rights of Newport.

Preservation of Secrecy and Confidentiality and Restrictions to Access:

Customer shall protect the Newport Programs and Related Materials as trade

secrets of Newport, and shall devote its best efforts to ensure that all its

personnel protect the Newport Programs as trade secrets of Newport

Corporation. Customer shall not at any time disclose Newport's trade secrets

to any other person, firm, organization, or employee that does not need

(consistent with Customer's right of use hereunder) to obtain access to the

Newport Programs and Related Materials. These restrictions shall not apply

to information (1) generally known to the public or obtainable from public

sources; (2) readily apparent from the keyboard operations, visual display, or

output reports of the Programs; 93) previously in the possession of Customer

or subsequently developed or acquired without reliance on the Newport

Programs; or (4) approved by Newport for release without restriction.

Service Information

This section contains information regarding factory service for the PM500

System. The user should not attempt any maintenance or service of the

system or optional equipment beyond the procedures outlined in this manual.

Any problem that cannot be resolved should be referred to Newport

Corporation.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iv Preface

Technical Support Contacts

Newport Corporation Service Department.

1791 Deere Ave.

Irvine, CA 92606

Telephone: (800) 222-6440

Newport Corporation RMA Procedures

Each defective part must have an RMA number assigned by a Newport

representative. The serial number of the damaged component must be

provided to the Newport representative. Please refer to Appendix G of this

manual for complete RMA procedure.

Packaging

Stages must be packaged in their original boxes and the stage locking tabs

must be installed prior to shipping. There is a written procedure for removing,

packaging, and shipping Newport stages. Please refer to Appendix F of this

manual.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Preface v

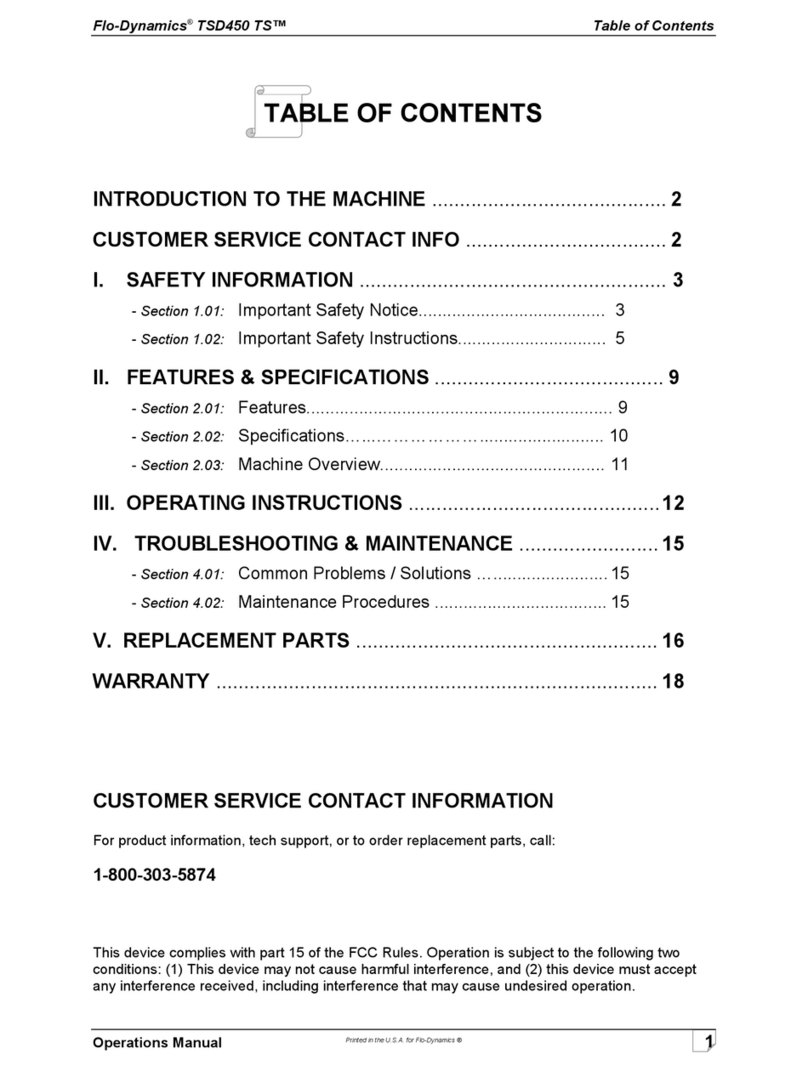

Table of Contents

Warranty.................................................................................................ii

Technical Support Contacts .................................................................. iv

Table of Contents................................................................................... v

List of Figures.......................................................................................xi

1Introduction 13

1.1 Scope of the Manual................................................................... 13

1.2 Manual Conventions................................................................... 14

1.2.1 Keys, Buttons and Icons..................................................14

1.2.2 Key Operation .................................................................14

1.2.3 User Input........................................................................14

1.2.4 The Display .....................................................................14

2Safety Precautions 15

2.1 Definitions and Symbols ............................................................ 15

2.1.1 General Warning or Caution ...........................................15

2.1.2 Grounding........................................................................15

2.1.3 Electric Shock..................................................................15

2.2 Terminology............................................................................... 16

2.3 Warnings and Cautions............................................................... 16

2.4 Safety Considerations................................................................. 17

3Getting Started 19

3.1 Outline of Section 1.................................................................... 19

3.2 Unpacking and Handling............................................................ 20

3.3 Inspection and Damage .............................................................. 21

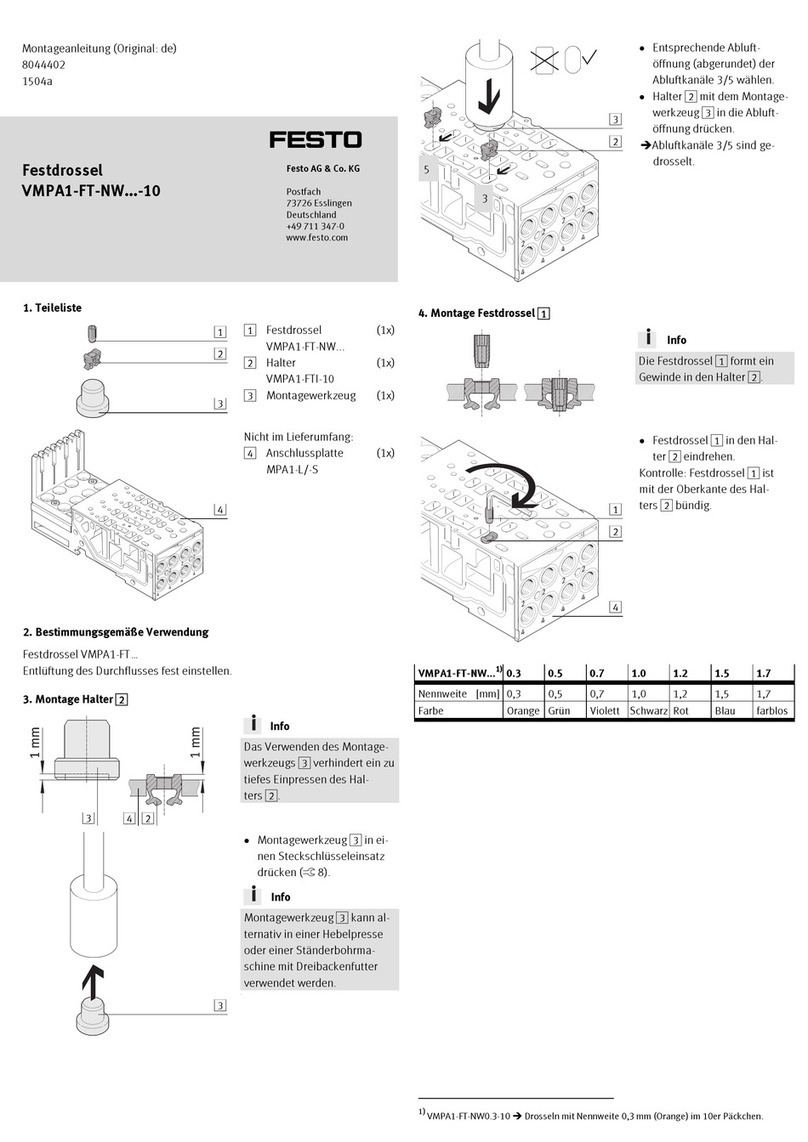

3.4 Linear Stage Shipping Tab Removal (Except PM500-1A, 1L, 1V) .. 22

4Mounting Positioners and Actuators 23

4.1 Outline of Section 4.................................................................... 23

4.2 Preparing the Mounting Surface................................................. 24

4.3 Vertical Stage Mounting............................................................. 24

4.4 Mounting PM500-1A Actuators................................................. 25

4.5 Mounting PM500-1A Linear Stages .......................................... 25

4.6 Mounting PM500 Linear Stages (Except PM500-1L) ............... 26

4.7 Mounting PM500 Rotary Stages................................................ 28

5Device Controller Interconnection 29

5.1 Outline of Section 5.................................................................... 29

5.2 Matching Devices and Axis Cards............................................. 30

5.3 Rack Mounting........................................................................... 30

5.4 Back Panel Connectors............................................................... 31

5.5 Connecting Cables...................................................................... 32

5.5.1 Cable types ......................................................................32

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

vi Preface

5.5.2 Cable routing...................................................................32

5.6 Remote Motor Shutdown Connector.......................................... 33

5.7 Cooling....................................................................................... 33

6Attaching Loads to Positioners 35

6.1 Outline of Section 6.................................................................... 35

6.2 Effect of Vibrations.................................................................... 36

6.3 Constructing fixtures .................................................................. 36

6.3.1 Rigidity............................................................................36

6.3.2 Weight .............................................................................37

6.3.3 Locating the load.............................................................37

6.4 Attaching Cables and Feeds ....................................................... 38

6.5 Vertical Stages............................................................................ 39

6.6 Pneumatic Load Compensation Piston....................................... 41

6.6.1 Regulator compensation adjustment................................41

6.6.2 Routing of air supply line................................................42

7Operation 43

7.1 Outline of Section 7.................................................................... 43

7.2 Choosing an Interface................................................................. 43

7.2.1 RS-232.............................................................................43

7.2.2 GPIB................................................................................44

8PM500-K6 Remote Control Console 45

8.1 Outline of Section 8.................................................................... 45

8.2 Connection.................................................................................. 46

8.3 Operating Modes ........................................................................ 46

8.3.1 Execute mode operation..................................................47

8.3.2 Menu mode operation......................................................47

8.4 Menu Key Functions .................................................................. 48

8.4.1 Main Menu ......................................................................48

8.4.2 Setup Menu......................................................................49

8.5 Controlling the PM500-K6 via RS-232/GPIB ........................... 50

9RS-232 Computer Interface 51

9.1 Outline of Section 9.................................................................... 51

9.2 Setup and Operation................................................................... 51

9.2.1 What you’ll need .............................................................51

9.2.2 Setting the RS-232 parameters........................................52

9.2.3 Configuring for RS-232 communications.......................52

9.2.4 RS-232 interface specifications.......................................53

9.2.5 Description of the PM500 RS-232 port...........................53

9.2.6 RS-232 cable length restrictions......................................54

9.2.7 Sample RS-232 cable configurations ..............................54

9.3 RS-232 Operation....................................................................... 55

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Preface vii

9.3.1 RS-232 Handshaking Modes...........................................55

9.3.2 Synchronous RS-232 Interfacing ....................................56

9.3.3 RS-232 default configuration interfacing........................57

9.3.4 Disabling RS-232 responses............................................58

10 RS-232 Quick Start 59

10.1 Outline of Section 10.................................................................. 59

10.2 PM500-C6 configuration for RS-232 (Quick Start)................... 59

10.2.1 What you’ll need .............................................................59

10.2.2 Verifying communication................................................61

11 GRIP (IEEE-488) Computer Interface 63

11.1 Outline of Section 11.................................................................. 63

11.2 Setup and Operation................................................................... 63

11.2.1 What you’ll need .............................................................63

11.2.2 Setting the GPIB address.................................................64

11.3 GPIB Quick Start with Interactive Control Software................. 65

11.4 4.2.1.2 IEEE-488 Operation....................................................... 66

12 Motion Programming 69

12.1 Outline of Section 12.................................................................. 69

12.2 Command Types and Their Responses ...................................... 69

12.2.1 Device Independent commands.......................................69

12.2.2 Device dependent commands..........................................69

12.2.3Command Types.........................................................70

12.2.4 Motion Response.............................................................70

12.2.5 Read/Status Commands...................................................71

12.2.6 Read response formats.....................................................72

12.2.7 Using hexadecimal numbers............................................72

12.2.8 Parametric Data Commands............................................73

12.2.9 Command Error Messages ..............................................73

12.3 Command Syntax ....................................................................... 74

12.3.1 For system or motion commands: ...................................74

12.3.2 For multiple system or motion commands......................74

12.3.3 For Read/Status and Queries...........................................74

12.3.4 Syntax Definitions...........................................................74

12.3.5 Numeric Formats.............................................................76

12.4 Command Status Characters....................................................... 77

12.5 GPIB Basics................................................................................ 78

12.5.1 Programming the PM500 ................................................78

12.5.2 Service Request...............................................................78

12.6 SRQ Assertion/Serial Polling methods ...................................... 80

12.6.1 Serial Program Execution (Wait for SRQ/RSQ).............80

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

viii Preface

12.6.2 Parallel Program Execution (Serial Poll) ........................80

12.7 Serial Polling .............................................................................. 80

13 Programming the PM500-C6 81

13.1 Outline of Section 13.................................................................. 81

13.2 System Software of PM500 Controllers..................................... 82

13.3 Checking Your System Software Version.................................. 82

13.4 The Difference Between the Modes........................................... 83

13.5 Status and Error Report Flowchart for the PM500..................... 84

13.6 Error Handling............................................................................ 85

13.6.1 Initializing the PM500 (SCUM1 or 6axis controllers)....85

13.6.2 General communication and ‘handshaking’ with PM500

Program Flowchart (under SCUM1) operation mode.....86

13.6.3 Simultaneous Preset Motions..........................................87

13.7 The Motion Profile And Related Motion Commands................ 89

13.8 Motion Speed Loops................................................................... 89

13.9 Motion Device Dependent commands & PM500 devices ......... 90

13.9.1 Linear motion device commands.....................................90

13.9.2 Rotary motion device commands....................................91

13.9.3 Vertical motion device commands..................................93

13.10Essential Motion Commands...................................................... 94

14 Command Index (by Type) 95

15 Command Index (Alphabetical) 99

16 Command Reference 105

17 Functional Description & Specifications 267

17.1 Outline of Section 17................................................................ 267

17.2 Controller.................................................................................. 268

17.2.1 Power supply/motherboard............................................270

17.3 Controller Board....................................................................... 271

17.4 Axis Boards .............................................................................. 273

17.5 Motion Devices ........................................................................ 276

17.5.1 Motion device specifications.........................................278

18 Maintenance 279

18.1 Outline of Section 18................................................................ 279

18.2 Auto-Zero Self Calibration....................................................... 280

18.3 Stages and Actuators- Maintenance ......................................... 280

18.4 Motors- Maintenance................................................................ 281

18.5 Leadscrew- Maintenance.......................................................... 281

18.6 Crossed-Roller Bearings- Maintenance.................................... 282

18.7 Encoders- Maintenance ............................................................ 282

18.8 Cables- Maintenance ................................................................ 282

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Preface ix

18.9 Controller- Maintenance........................................................... 282

18.10Maintenance Schedule.............................................................. 283

19 Service 285

19.1 Outline of Section 19................................................................ 285

19.2 Removing and Installing Axis Boards...................................... 286

19.2.1 Axis card removal..........................................................287

19.2.2 Axis card installation.....................................................288

19.3 Removing and Installing the Controller Board ........................ 289

19.3.1 Controller board installation..........................................291

19.4 Upgrading System Firmware.................................................... 292

19.4.1 What you’ll need ...........................................................293

19.4.2 For axis card firmware upgrades...................................293

19.4.3 For controller card firmware upgrades..........................293

19.4.4 Firmware upgrade procedure.........................................293

19.5 System Initialization................................................................. 294

19.6 Troubleshooting........................................................................ 295

19.6.1 LED diagnostics ............................................................295

19.6.2 Motherboard/power supply ...........................................295

19.6.3 Controller board.............................................................296

19.6.4 Axis boards....................................................................297

19.7 Troubleshooting Tables............................................................ 298

20 Appendix A 307

20.1 Outline of Appendix A............................................................. 307

20.2 Cabling and Communications .................................................. 307

21 Appendix B 309

21.1 Outline of Appendix B ............................................................. 309

21.2 Cleanroom Compatibility and Preparation............................... 309

21.3 Cleanroom Compatibility and Preparation............................... 310

22 Appendix C 311

22.1 Outline of Appendix C ............................................................. 311

22.2 Vacuum Compatabilities .......................................................... 311

23 Appendix D 313

23.1 Outline of Appendix D............................................................. 313

23.2 Memory capacities & capabilities of the controller ................. 313

23.2.1 SBC (Motherboard).......................................................313

23.2.2 Axis Cards.....................................................................314

24 Appendix E 315

24.1 Motion Trajectory Specifications............................................. 315

24.2 Motion Performance Summary ................................................ 316

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

x Preface

25 Appendix F 317

25.1 Outline of Appendix F.............................................................. 317

25.2 Packaging your PM500 System................................................ 317

25.3 Packaging your PM500-C6 Controllers ................................... 318

26 Appendix G 319

26.1 Warranty and Service Policy.................................................... 319

27 Appendix H 321

27.1 Service Form ............................................................................ 321

28 Appendix I 323

28.1 System Settings ........................................................................ 323

Index 325

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Preface xi

List of Figures

Figure 1: General Warning or Caution Symbol......................................... 15

Figure 2: Grounding Symbol ..................................................................... 15

Figure 3: Electrical Shock Symbol ............................................................ 15

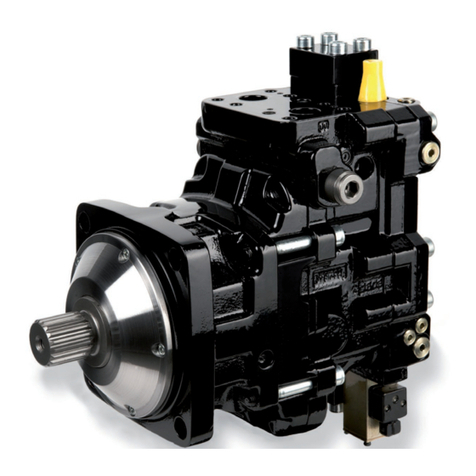

Figure 4: P500 Stage.................................................................................. 20

Figure 5: PM500 Stage Shipping Tab........................................................ 20

Figure 6: PM500 Stage Shipping Tab........................................................ 21

Figure 7: Removing the shipping tab before using the stage..................... 22

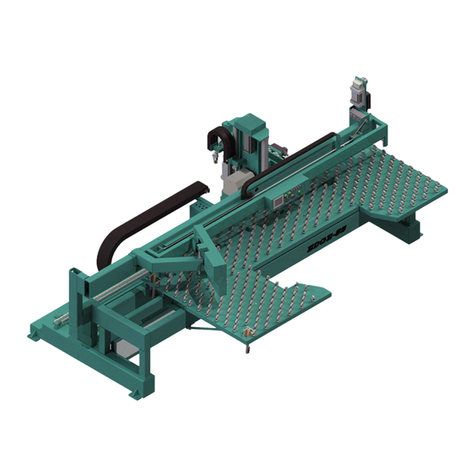

Figure 8: Considerations for mounting motion devices............................. 23

Figure 9: Do not mount standard Linear Stages vertically ........................ 24

Figure 10: Mounting PM500-1 Linear Stage............................................... 26

Figure 11: Exploded view of linear stage. ................................................... 27

Figure 12: PM500 Rotary Stages are sensitive to high-torque loads........... 28

Figure 13: Assignment of axes change. ....................................................... 30

Figure 14: Exploded view of attachment of rack ears on controller............ 30

Figure 15: Rear view of the PM500-C 6-axis controller. ............................ 31

Figure 16: Placeing loads............................................................................. 36

Figure 17: Calculating cantilevered loads.................................................... 37

Figure 18: Attaching cables and feeds........................................................ 38

Figure 19: Placing loads or tightening screws to fasten loads..................... 38

Figure 20: A typical installation of a Z-bracket........................................... 39

Figure 21: Mounting to another stage.......................................................... 40

Figure 22: Routing of air supply line........................................................... 42

Figure 23: DIP switch location in PM500-C6 ............................................. 52

Figure 24: Changing the RS-232 parameters............................................... 52

Figure 25: Back panel of the PM500 controller........................................... 53

Figure 26: DIP switch location in PM500-C6 ............................................. 59

Figure 27: The RS-232 parameters are changed via S1 and S2 switch . ..... 60

Figure 28: Command to complete signaling and echoing............................ 60

Figure 29: PM500 response to firmware version query............................... 61

Figure 30: DIP switch location in PM500-C6 ............................................. 64

Figure 31: The GPIB address is changed via S1 and S2 switch banks........ 64

Figure 32: Flowchart: Status and error reporting registers of the PM 500. . 84

Figure 33: Flowchart: An initialization procedure for the PM 500. ............ 86

Figure 34: A general handshaking and communication method.................. 87

Figure 35: PM500’s simultaneous preset motion. ....................................... 88

Figure 36: Trapezoidal move profile with corresponding commands......... 89

Figure 37: Setting the LSIZE ...................................................................... 90

Figure 38: Linear motion device commands forPM500 Linear Stages....... 91

Figure 39: PM500-360/A Rotary stages. ..................................................... 92

Figure 40: PM500-V1 Vertical stages. ........................................................ 93

Figure 41: Top view of Model PM500 Controller..................................... 268

Figure 42: Rear view of Model PM500 Controller.................................... 268

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

xii Preface

Figure 43: PM500 Controller functional elements. ................................... 269

Figure 44: Motherboard. ............................................................................ 270

Figure 45: Power supply/Motherboard functional elements...................... 270

Figure 46: Controller board........................................................................ 271

Figure 47: High Resolution Axis Board. ................................................... 273

Figure 48: Figure 16.8: Axis board schematic........................................... 273

Figure 49: Schematic of axis board velocity loop...................................... 274

Figure 50: Schematic of axis board position loop...................................... 275

Figure 51: Axis board sine/cosine signals.................................................. 276

Figure 52: Read head. ................................................................................ 277

Figure 53: The retaining bar removal from the controller......................... 287

Figure 54: Cable nuts removal................................................................... 288

Figure 55: The controller board status LEDs............................................. 288

Figure 56: The retaining bar removal ........................................................ 290

Figure 57: The controller board status....................................................... 291

Figure 58: Proper PROM placement in socket and location on card......... 294

Figure 59: D-style 25-pin axis cable connector to rear panel. ................... 308

Figure 60: Axis cable................................................................................. 308

Figure 61: The trajectory error effects of pitch, roll, and yaw................... 315

Figure 62: The typical factory packaging for PM500 devices................... 317

List of Tables

Table 1: A graphical representation of the PM500 SRQ register............. 79

Table 2: Basic Troubleshooting.............................................................. 299

Table 3: Check Power and Lights........................................................... 299

Table 4: Communication Link(s) Troubleshooting................................ 301

Table 5: Check Servo Action and Axis Response.................................. 303

Table 6: Check Marginal Performance/Positioning ............................... 304

Table 7: Check Remote Console (PM500-K)......................................... 305

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

13

1 Introduction

1.1 Scope of the Manual

Welcome to the PM500 Series Operations and Command Reference

Manual.

This manual provides descriptions, operating procedures, and service

requirements for the PM500 Linear and Rotary Stages.

Safety considerations, conventions and definitions are provided in Section

2, Safety Considerations.

Procedures for unpacking the equipment, inspection for damage are

provided in Section 3 - Getting Started. Mounting requirements,

descriptions of controls and indicators, computer interface, motion

programming, setup procedures, and service and maintenance are provided

in sections 1 through 19.

The Following Information Is Provided In The Appendices:

•Appendix A – Cabling And Communications

•Appendix B – Clean Room Compatibility And Outgassing

•Appendix C – Vacuum Compatibilities

•Appendix D – Memory Capabilities

•Appendix E – Motion Specifications

•Appendix F – Packaging

•Appendix G – Warranty Return

•Appendix H– Service Form

•Appendix I – System Settings

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

14 Introduction

1.2 Manual Conventions

The following conventions and standards will be used in this manual.

1.2.1 Keys, Buttons and Icons

Computer keyboard keys and onscreen buttons and icons are used in the text

to describe many user operations. The key-top symbol as it appears on the

keyboard, the button or icon name is represented in boldface type. For

example: Ctrl is used for the Control key or Manual Operation button.

1.2.2 Key Operation

Some operations require simultaneously use of two or more keys. Such

operations are identified by the top symbols on the key separated by a plus

(+) sign. For example, Ctrl + Pause (Break) means hold down the Ctrl key

and at the same time press Pause (Break). If three keys are used, hold down

the first two and at the same time press the third.

1.2.3 User Input

Text that is required to be typed in, will be shown in the boldface type courier

(new) font as shown below:

DISKCOPY A: B:

1.2.4 The Display

Text generated by the computer that appears on its display is presented in the

typeface courier (new) font as shown below:

FORMAT complete

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

15

2 Safety Precautions

2.1 Definitions and Symbols

The following terms and symbols are used in this documentation and also

appear on PM500 Series Products where safety-related issues occur.

2.1.1 General Warning or Caution

Figure 1: General Warning or Caution Symbol

The Exclamation Symbol in the figure above appears in Warning and Caution

tables throughout this document. This symbol designates an area where

personal injury or damage to the equipment is possible.

2.1.2 Grounding

Figure 2: Grounding Symbol

The Grounding Symbol in the figure above appears on labels affixed to the

PM500 Series Products, and this symbol identifies terminal which is intended

for connection to an external (ground) conductor for protection against

electric shock in case of a fault, or the terminal of a protective earth (ground)

electrode. Any mishandling could result in irreparable damage to the

equipment, and personal injury or death.

2.1.3 Electric Shock

Figure 3: Electrical Shock Symbol

The Electrical Shock Symbol in the figure above appears on labels affixed to

the PM500 Series Products, and this symbol indicates a hazard arising from

dangerous voltage. Any mishandling could result in irreparable damage to

the equipment, and personal injury or death.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

16 Safety Precautions

2.2 Terminology

The following is a brief description of the terms specific to PM500 Series

Controller and Stages.

Axis – a logical name for a stage/positioner/ motion device

Encoder – a displacement measuring device, term usually used for

both linear and rotary models.

Fiducial (position) – the unique point in space that can be

accurately found by an axis, also called origin.

Jog – a motion of undetermined-length, initiated manually

Motion device – electro-mechanical equipment. Used

interchangeably with stage and positioner.

Move – a motion to a destination

Positioner – used interchangeably with stage and motion device

Stage – used interchangeably with motion device and positioner

2.3 Warnings and Cautions

The following are definitions of the Warnings, Cautions and Notes that are

used throughout this manual to call your attention to important information

regarding your safety, the safety and preservation of your equipment or an

important tip.

WARNING

Situation has the potential to cause bodily harm or death.

CAUTION

Situation has the potential to cause damage to property or

equipment.

NOTE

Additional information the user or operator should consider.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Safety Precautions 17

2.4 Safety Considerations

The following general safety precautions must be observed during all phases

of operations of this equipment. Failure to comply with these precautions or

with specific warnings elsewhere in this manual violates safety standards of

design, manufacture, and intended use of the equipment.

Disconnect or do not plug in the power cord in the following circumstances:

•If the power cord or any other attached cables are frayed or damaged.

•If the power plug or receptacle is damaged.

•If the unit is exposed to rain or excessive moisture, or liquids are

spilled on it.

•If the unit has been dropped or the case is damaged.

•If you suspect service or repair is required.

•When you clean the case.

To protect the equipment from damage and avoid hazardous situations,

follow these recommendations:

•Do not make modifications or parts substitutions.

•Return equipment to Newport Corporation for service and repair.

•Do not touch, directly or with other objects, live circuits inside the unit.

•Keep air vents free of dirt and dust.

•Do not block air vents.

•Keep liquids away from unit.

•Do not operate the equipment in an environment with humidity levels

(<10% and >90% humidity).

WARNING

All attachment plug receptacles in the vicinity of this unit are to be

of the grounding type and properly polarized. Contact an

electrician to check faulty or questionable receptacles.

WARNING

This product is equipped with a 3-wire grounding type plug. Any

interruption of the grounding connection can create an electric

shock hazard. If you are unable to insert the plug into your wall

plug receptacle, contact an electrician to perform the necessary

alterations to assure that the green (green-yellow) wire is attached

to earth ground.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

18 Safety Precautions

WARNING

This product operates with voltages that can be lethal. Pushing

objects of any kind into cabinet slots or holes, or spilling any

liquid on the product, may touch hazardous voltage points or

short out parts.

WARNING

When opening or removing covers observe the following

precautions:

•Turn power OFF and unplug the unit from its power source

•Remove jewelry from hands and wrists

•Use insulated hand tools only

•Maintain grounding

WARNING

To protect operating and servicing personnel, this instrument is

supplied with a three-prong power receptacle. The center prong

of the receptacle connects the instrument’s chassis, cabinet

and panels to earth ground when used with a properly wired

three-conductor outlet and cable. Improperly grounded

equipment can result in hazardous electrical potentials.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

19

3 Getting Started

3.1 Outline of Section 1

The following topics are covered in this section:

•Unpacking and inspection of the system

•Handling of motion devices

For additional setup and operation information for optional features, refer to

the appropriate sections:

OPTION SECTION

Vertical stages 6.5

Counter balance 6.5

Adding stages to an existing controller 19.3

Updating system firmware 19.4

WARNING

Read this entire section before assembling your system for the

first time. System performance depends on many factors,

including stage mounting and load attachment. Damage to the

system can occur if devices are not connected or operated

correctly.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Other manuals for PM 500

1

Table of contents

Other Newport Industrial Equipment manuals

Newport

Newport RV User manual

Newport

Newport GTS-V Series User manual

Newport

Newport New Focus 8892 User manual

Newport

Newport FMS Series User manual

Newport

Newport TSP Series User manual

Newport

Newport ORIEL Instruments Cornerstone 260 User manual

Newport

Newport GTS30V User manual

Newport

Newport IDL165-LM Series User manual

Newport

Newport UTM Series User manual