Newport TSP Series User manual

1

Newport Corporation TSP Stage Series

TSP Series

Precision Linear Stages

Newport Corporation

1791Deere

P.O. Box 19607

Irvine, CA 92606-92623

Tel: 949-863-3144

Fax: 949-253-1800

www.newport.com

2

Newport Corporation TSP Stage Series

Warranty

Newport Corporation warrants its product to be free of defects in material and workman-

ship for a period of twelve (12) months from the date of shipment. During the warranty

period, Newport will repair or replace (at Newport’s discretion) any component within its

product that fails to adhere to published specifications (for standard product) or specifi-

cations in the quotation (for custom/special product).

For warranty service requiring return of a product to Newport, the item(s) must be re-

turned to our Service Center, with all shipping, taxes, or duty charges prepaid unless

special arrangements have been approved beforehand by Newport. The location of

services performed under warranty will be determined by Newport.

If using controller electronics other than Newport’s, the liability of the product rests with

the customer if upon performance evaluation of the stage there are no anomalies exhib-

ited with Newport’s electronics.

Warranty Limitations

The foregoing warranty shall not apply to defects resulting from:

a. Components and accessories manufactured by companies other than Newport,

which causes damage to Newport’s products, nor does Newport’s warranty cover

the cost of the customer’s time and expenses incurred in diagnosing, repairing

and handling Newport’s warranty related issues.

b. Improper or inadequate maintenance by the buyer not in adherence with

Newport’s guidelines.

c. Customer-supplied interfacing.

d. Operation outside the environmental specifications of the product.

e. System malfunctions that are related to or caused by software misuse.

f. Improper site preparation and mainenance of unauthorized product modification

or misuse.

g. Warranty void if not delivered by an authorized Newport Corp distributor.

Newport assumes no liability for customer-supplied material. The obligations of

Newport are limited to repairing or replacing, without charge, equipment which

proves to be defective during the warranty period only. The warranty on parts

purchased after the expiration of the original warranty is ninety (90) days. Our

warranty does not cover damages due to misuse, negligence or accidents, or

damages due to installation, repairs or adjustments not specifically authorized

by Newport Corp.

3

Newport Corporation TSP Stage Series

STATEMENT OF CALIBRATION

This instrument has been inspected and tested in accordance with specifications published by

Newport Corp.

The accuracy and calibration of this instrument (where applicable) is traceable to the National

Institute for Standards and Technology through equipment which is calibrated at planned inter-

vals by comparison to the certified standards maintained at Newport Corp.

ACCURACY AND REVISIONS

The information in this document has been checked and is believed to be entirely reliable.

However, no responsibility is assumed for inaccuracies or inadvertent omissions. Furthermore,

Newport Corp. reserves the right to make changes to any product herin to improve reliability,

function or design.

USE OF THIS MANUAL

Please read through this manual carefully before using the equipment provided. It should be

noted that if the equipment is used in a manner other than that specified by this manual, per-

sonal injury or damage to the equipment may be incurred.

SAFETY CONSIDERATIONS

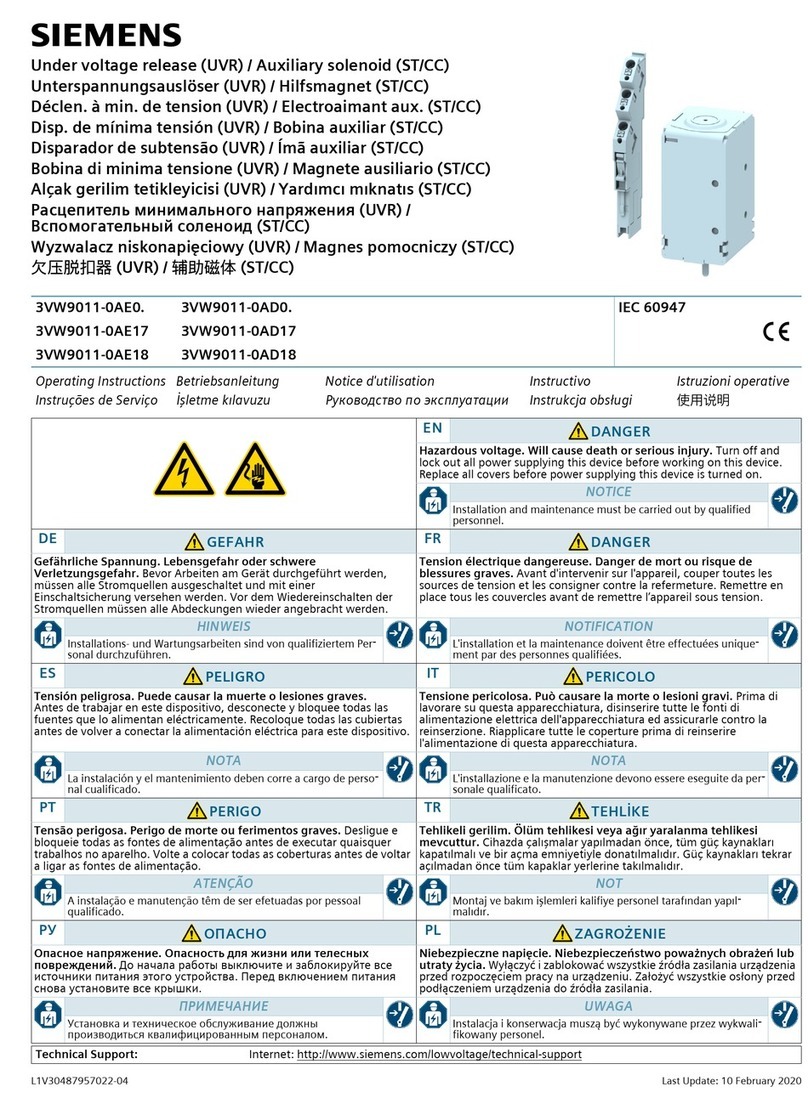

Hazard Warning Labels

The hazard warning labels pictured below are affixed to some Newport equipment. In Figure 1

below, is a Pinch Point warning label. This indicates that injury could occur if extremities are

placed between moving components.

Figure 1

4

Newport Corporation TSP Stage Series

Abbildung 1. Quetschgefahr

Figura 1. Riesgo de Aplastamiento

Figue 1. Risque d’écrasement

In Figure 2 below, is the Electrical Hazard warning label. This is to indicate that injury, such as

electric shock, burns or permanent damage to the equipment could occur if the component

comes into contact with other objects or with the user.

Figure 2

General Safety Precautions

Abbildung 2. Elektroshockgefahr

Figura 2. Riesgo Eléctrico

Figue 2. Risque électrique

Disconnect power to motorized equipment under the following circumstances:

If the unit has been exposed to rain or excessive moisture, or if liquids are spilled on it.

If the unit has been dropped or the case is damaged.

If you suspect service or repair is required.

Whenever you clean the case.

5

Newport Corporation TSP Stage Series

Achtung

Die Stromversorgung motorbetriebener Geräte is in folgenden Situationen zu

unterbrechen:

· Wenn das Gerät Regen oder übermäßigerFeuchtigkeit ausgesetzt ist,

oder wenn Flüssigkeiten in das Gerät geraten sind.

· Wenn das Gerät fallengelassen wurde oder das Gehäuse beschädigt ist.

· Wenn dasangenommen wird, daß Service - oder Reparaturarbeiten

erforderlich sind

· Wenn das Gerät gereinigt wird.

Advertencia

Desconecte el equipo motorizado de la alimentación CC bajo las siguientes

circunstancias:

· Si se expone la unidad alluvia, humedad excesiva o si le cae encim algún

líquido.

· Si la unidad se ha caído o se ha dañado su alojamiento.

· Si se sospecha que requiere mantenimiento o reparción.

· Cada vez que se limpie el alojamiento.

Attention

Débranchez l'alimentation secteur de l'appareil de pilotage dans les cas

suivants:

· Si l'équipement a été exposé à la pluie, à une humidité excessive ou à des

projections de liquide.

· Si l'équipement a subit un dommage durant le transport

(chute ou emballage abîmé).

· Si vous estimez que l'équipement a besoin d'une réparation.

· Chaque fois que vous nettoyez l’équipement.

6

Newport Corporation TSP Stage Series

To avoid hazardous situations and to protect the equipment from danger, observe

the following recommendations:

Do not make any modifications or parts substitutions to the units.

Do not touch, directly or with other objects, live circuits inside motorized units.

Do not operate the units in an explosive atmosphere.

Do not expose the units to excessive moisture (>75% relative humidity).

UNPACKING AND INSPECTION

All Newport products are carefully assembled, tested and inspected before shipment.

Upon receiving this product, please check for any obvious signs of physical damage

that might have occurred during shipment. Report any such damage to the shipping

agent immediately. Retain the original packaging materials in case reshipment

becomes necessary.

If a Newport product must be returned, the following information is needed for proper shipment

back to Newport:

a. Unit Model Number

b. Unit Serial Number

c. Reason for return.

A Return Material Authorization number (RMA) will be issued, which should be referenced on

your shipping documents. Please fill out the included service form and return it with the unit.

Use the proper precautions when shipping the unit. Damage incurred during shipping may

invalidate your warranty. Please contact our technical support or returns group at 800-222-6440

for more information.

SET UP

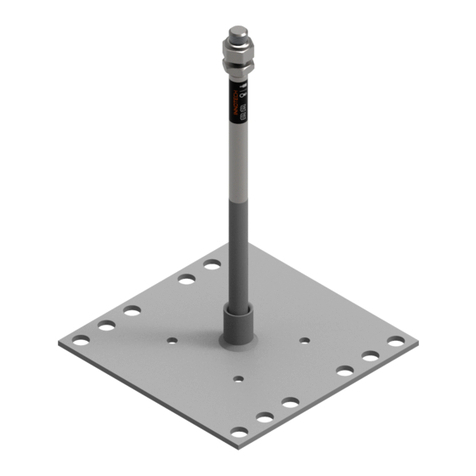

Removing Shipping Tabs (Figure 3)

To prevent damage during shipping, the top plate of the stage has been locked with red anod-

ized tabs. Orange warning tags indicate the position of each tab. To remove the tabs, undertake

the following steps:

1. Use 5mm hex wrench to remove socket head cap screws (M6X1) from each lock tab for

metric stages, or 3/16 hex wrench to remove socket head cap screws (1/4-20) from

each lock tab for english stages.

2. Remove the lock tab and warning tag and retain for future relocation.

7

Newport Corporation TSP Stage Series

Figure 3

Environmental Considerations

Temperature

For optimum performance, the stage should be maintained at a temperature of

20oC (68o F+/- 2oF).

Vibration

The stage should not be set up within the vicinity of vibration or shock. Outside forces, such as

forklifts, compressors and other machinery, can induce unwanted motion in the stages via the

floor on which the whole system is resting. Resulting vibrations can lead to measurement errors.

Surface Plate Flatness

To ensure accuracy, the surface plate on which the stage is mounted should be flat to within

2.5um (0.0001 inch) over all. Granite is the preferred mounting surface.

Fastener Kit

A fastener kit containing screws, and flat washers, are provided for bolting the stage to a sur-

face plate. The kit also contains anti-pinch caps for plugging unused slots.

Table 1

Screw M6-1 x 35mm 1/4-20 x 1 3/8inch

M6

inside diameter

Washer

Metric English

8

Newport Corporation TSP Stage Series

Stage Installation

Allow clearance for the 25 pin connector.

Bolting the Stage to the Surface Plate

1. Clean the surface plate prior to mounting the stage.

2. The stage should be attached at all four corners to the surface plate. To allow access to

the counter bores, move the stage alternately to one end-of-travel limit and then to the

other. Use fastener kit (A00000xxx) provided. The screws should be torqued to between

13-14.7 N-m (115-130 in-lbs).

3. After torquing the fasteners, place the supplied anti-pinch caps into the mounting holes.

Ensure that the caps do not protrude above the surface of the bottom stage plate. Use

of these caps is mandatory to ensure CE compliance.

Figure 4

4. Connect the cable from the stage to the motion contoller using the 25 pin interconnect

cable supplied.

9

Newport Corporation TSP Stage Series

Initial Operation

The TSP Stage has been adjusted and calibrated at the factory, prior to shipment. Under normal

circumstances, no calibrations or adjustments are required after the equipment has been set up.

However, it is highly recommended that initial verifications of proper limit switch operation and of

proper configuration of the controller are performed.

Note: If using a controller other than a Newport controller, the stage may not work properly.

Contact Newport technical assistance for modification instructions.

Verification of Proper Limit Switch Operation

The cable needs to be connected and the controller under power to perform this test. When the

controller is referenced below, refer to the manufacturer’s manual for the controller (and control-

ler software, if in use) to find the relevant procedures.

1. Disconnect power to the motor via the controller.

2. Using the manual knob, move the stage to the counterclockwise end-of-travel limit.

3. Check the status of the limit via the controller.

4. If the controller does not indicate arrival at the limit, refer to the Home and Limit

Switches Troubleshooting guide.

5. Repeat steps 3 to 5 for the clockwise end-of-travel limit.

10

Newport Corporation TSP Stage Series

Verification of Proper Controller Configuration

Before using the stage for any application, the controller should be specifically configured and

programmed for operation with the TSP stage. Refer to the manufacturer’s manual for the

controller to find the relevant procedures. Fine tuning of the controller may also be required.

1. Program the controller so that the first move of the stage is a short distance, low velocity

move. The move should be a distance of less than a quarter of full travel at a velocity of

less than 2 mm/sec (.01 in/sec).

2. Perform the first move. Use a suitable indicator to check that the stage has travelled the

required distance.

3. If the stage has not travelled the required distance, refer to the Stage and Controller

Troubleshooting Guide.

11

Newport Corporation TSP Stage Series

Attaching to the Stage

Components’ Surface Flatness

The mating surfaces of components being attached to the stage should be flat to within 2.5um

(0.0001 inch) overall.

Screw Specifications

Use an M6X1 or 1/4-20 screw, depending on whether the mounting holes are metric or english

to attach other components. The length of the screw protruding into the stage should be no

more than 12mm (1/2 inch).

Torque

Components being attached to the stage should be torqued in an alternating pattern. The

maximum torque should not exceed 11.3 N-m (100 in-lbs).

Moment

Components being attached to the stage should not induce a moment of greater than 22.6 N-m

(200 in-lbs).

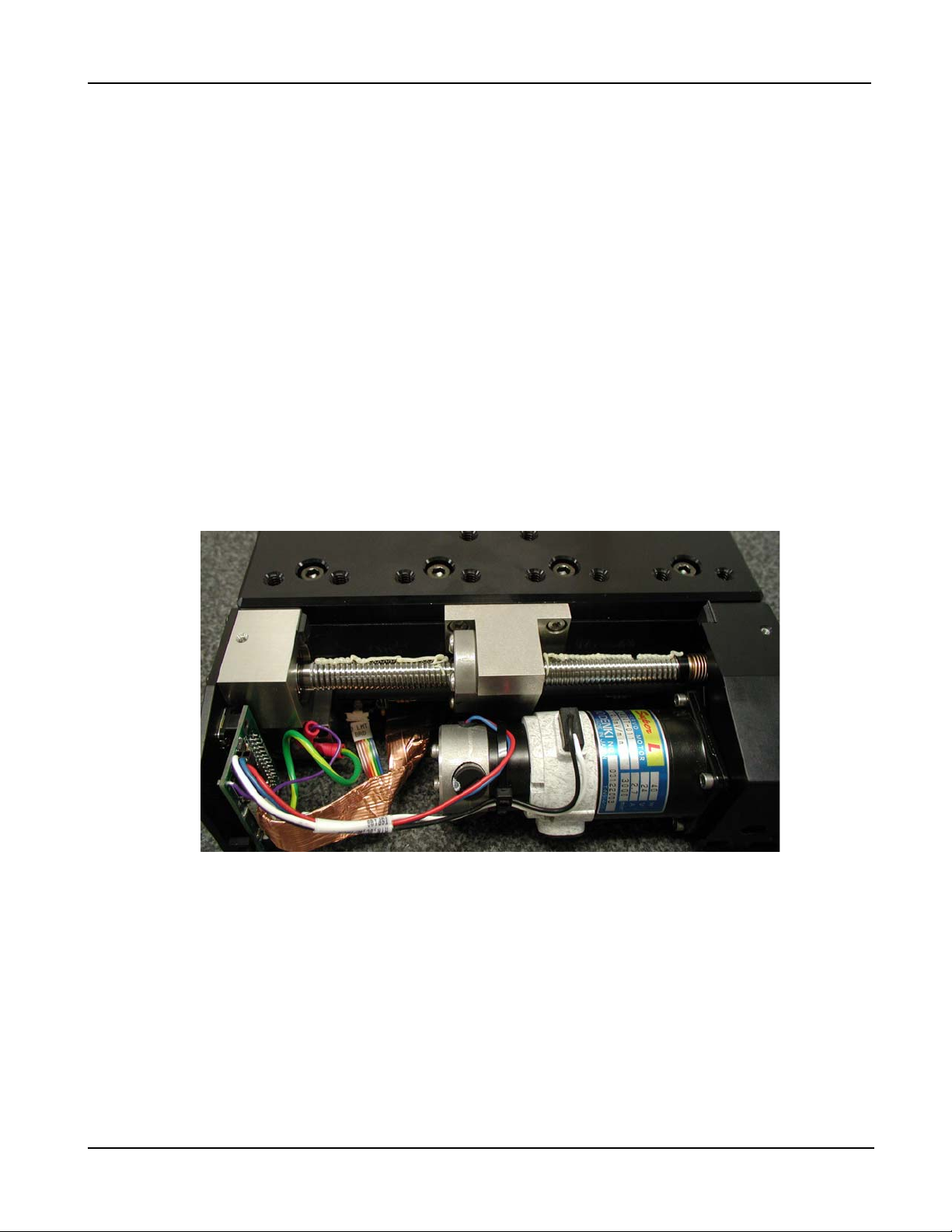

Locations of the connector, end-of-travel (CCW) and (CW), circuit board, home sensor, and ball

screw.

Connector Circuit Board

End Limt

(CW)

Ballscrew

Home Sensor

End Limit

(CCW)

TSP 300 Shown

12

Newport Corporation TSP Stage Series

MAINTENANCE

The frequency of required cleaning, lubrication and testing is highly user dependent. Refer to

Table 2 below to establish a maintenance schedule for your unit.

Table 2

13

Newport Corporation TSP Stage Series

Lubrication

When applying lubricant, do not use either a harsh applicator which may scratch or damage the

stage surfaces, or a fragile applicator, which may generate particles to contaminate the compo-

nent. The recommended lubricant is Lamora® D68 Oil.

Figure 9

14

Newport Corporation TSP Stage Series

1. Inspect the bearing rails for signs of damage or corrosion. Consult Newport’s technical

assistance group if damage or corrosion has occured.

2. Use the manual knob to move the stage to one end-of-travel limit.

3. Clean the exposed bearing rail v-grooves on both upper and lower rails with Isopropyl

alcohol and a lint free cloth.

4. Apply a light film of Lamora® D68 oil to the exposed v-grooves and to the top of the rail

(Figure 9).

5. Move the stage to the other end-of-travel limit and repeat steps 2 and 3.

6. Run the stage from one end-of-travel limit to the other to distribute the lubricant evenly

along the rails.

Ballscrew Lubrication

The recommended lubricant for the ball screw is NBU8 EP grease.

Figure 10

1. Use a 2 mm hex wrench to remove the flat head cap screws from the drive

cover. Remove the drive cover.

2. Inspect the ballscrew for signs of damage or wear.

3. Clean the ballscrew with a lint free cloth, and isopropyl alcohol. Manually move the stage

as required to gain access to all of the ballscrew.

15

Newport Corporation TSP Stage Series

4. Apply light file of the lubricant to the exposed part of the ballscrew (Figure 10).

5. Manually run the stage from one end-of-travel limit to the other to distribute the lubricant

evenly along the ballscrew.

6. Wipe off any access lubricant with a lent free cloth.

7. Replace the drive cover.

16

Newport Corporation TSP Stage Series

17

Newport Corporation TSP Stage Series

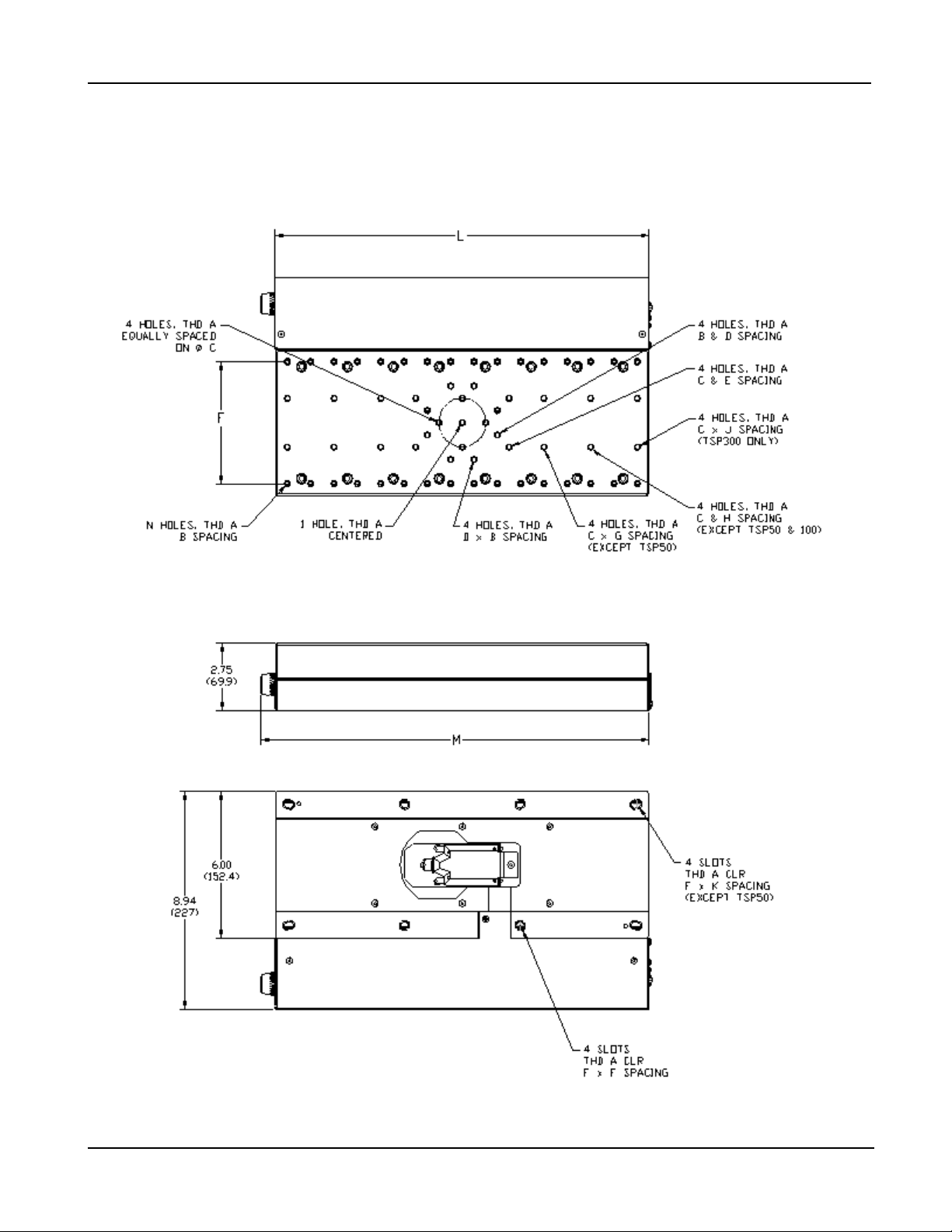

DIMENSIONS

(SEE CHARTS ON NEXT PAGE)

18

Newport Corporation TSP Stage Series

Linear Encoders

Non-Contact Encoder

.1 um Resolution

TTL Quad AB Output (Differential)

4 um Signal Period

Home (Origin) at negative end of travel

19

Newport Corporation TSP Stage Series

STAGE AND CONTROLLER TROUBLESHOOTING GUIDE

provided. The various problems along with the possible causes and corrective actions required are

outlined below.

This section may help you to troubleshoot common problems with operating the equipment

Problem

Stage does not

function

Stage moves a short

distance and stops.

Controller reports

“Following Error” or

other motion error.

Stage motion un-

steady or jerky

Stage travels less

than specifications

Stage does not meet

specifications

Tighten connector.

Check that cables are correctly connected

and wired.

Refer to the manufacturer’s manual for the

controller

Refer to the manufacturer’s manual for the

controller

Check for and remove all obstructions

Tighten coupling

Tighten connector

Motor plus/minus leads reversed and/or

tachometer plus/minus leads reversed

Contact Newport for assistance

Lower velocity and/or acceleration

Check for and remove all obstructions. Clean

rails according to the procedures outlined in

this manual

Tighten connectors. Check cabling and

replace or repair as necessary

Contact Newport for assistance

Refer to the manufacturer’s manual for the

controller

Check for and remove all obstructions

Ensure that all cables are clear of the moving

equipment

If roller creep is suspected, contact Newport

for assistance

Refer to Setup, Environmental consider-

ations in this manual

Refer to Setup, Environmental consider-

ations in this manual

Refer to the specifications in this manual and

consult Newport for assistance

Contact Newport for assistance

Consult Newport for recalibration or certifica-

tion

Loose connector at stage

Stage incorrectly connected to control-

ler

Controller incorrectly programmed.

Limits not enabled via software

Controller not connected to power

source

Obstruction to movement

Loose motor coupling

Loose connectors at stage or controller

Incorrectly wired cabling

Stage incorrectly tuned

Load too large for motion profile used

Obstrucion or foreign object on bearing

rails

Loose connections or faulty cabling

Stage incorrectly tuned

Controller incorrectly programmed

Obstruction to motion

Entangled cables

Roller creep

Improper mounting

Improper attachment

Stage outside of environmental specifi-

cations

Stage incorrectly tuned

Improper handling and/or transport

Cause Corrective Action

20

Newport Corporation TSP Stage Series

Stage makes un-

usual noise

Controller reports

that both end limits

are active

Object contacting the manual operation

knob

Loose covers

Entangled cables

Stage incorrectly tuned

Loose connector

Faulty or miswired cables

Controller incorrectly programmed

Remove object

Tighten screws

Ensure that all cables are clear of the mov-

ing equipment

Contact Newport for assistance

Tighten all connectors

Check cabling and rewire or repair as neces-

sary

Refer to the manufacturer’s manual for the

controller

Problem Cause Corrective Action

This manual suits for next models

5

Table of contents

Other Newport Industrial Equipment manuals

Newport

Newport PM 500 Installation manual

Newport

Newport GTS-V Series User manual

Newport

Newport GTS30V User manual

Newport

Newport New Focus 8892 User manual

Newport

Newport UTM Series User manual

Newport

Newport FMS Series User manual

Newport

Newport ORIEL Instruments Cornerstone 260 User manual

Newport

Newport IDL165-LM Series User manual

Newport

Newport RV User manual