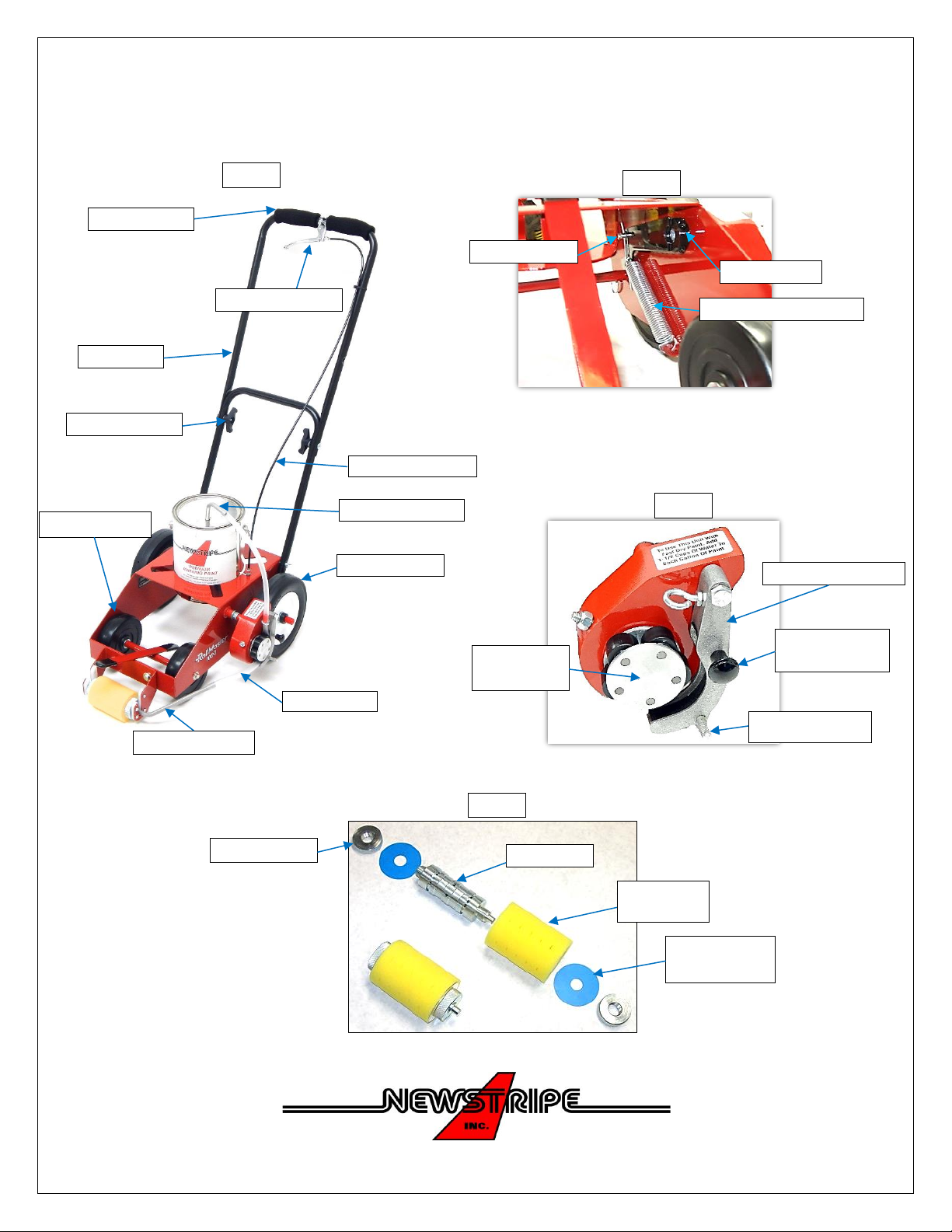

RollMaster™ 1000

ALWAYS wear safety goggles or protective eye-wear when operating the unit!

1700 Jasper St. Unit F, Aurora, CO 80011 T800.624.6706 F303.364.7796 •Newstripe.com

RollMaster™ 1000 Manual / 3856.0917

PARTS LIST

Item Number Description Part Number

1 Tube, Paint Can 10000665

2 Hose, Paint (5 pack) 10002496

3 Mandrel tube assembly 10003864

4 “O” ring 3/8” ID X 1/32” Thick 10000027

5 Knurled Nut (2 req’d) 10000646

6 Mandrel 10000643

7 Trough assembly 10000652

8 Trough Lock Pin Kit 10000671

9 Pump Rotor assembly 10000654

10 Tire, Pump Drive (not shown) 10000650

11 Cable, Control (Sheath cut to 35”) 10000820

12 Handle 10004852

13 Grip, Foam (2 req’d) 10000967

14 Lever, Control 10000821

15 Wheel, Front 10000753

16 Wheel, Rear 10003837

17 Punch, Can Hole 10000669

18 Spring, Actuating Arm 10000692

19 Cable Stop 10001577

20 Cable Adjuster 10000018

21 Roller Carrier with “J” Yokes 10004024

22 Replaceable “J” Yokes 10004023

23 Wing Nut (4 req’d) 10000107

24 Wing Knob (2 req’d) 10004899

25 Replaceable roller covers, regulating discs and paint hoses

3 pack Replacement Roller Kits include 3 roller covers, paint hoses & 12 discs:

4” Replacement Roller Kit 10004377

3” Replacement Roller Kit 10004378

2” Replacement Roller Kit 10004379

12 pack Replacement Rollers include 12 roller covers & 48 discs:

4” Replacement Rollers and discs 10000728

3” Replacement Rollers and discs 10001461

2” Replacement Rollers and discs 10000729

Optional Left Position Roller Kit 10004461

Includes: Mandrel Tube Assembly for left position (10003866), Left Position

Striping Bracket (10003865), 5/16-18 x 3/4” Bolts (2) (10001499),

5/16” Flat Washers (4) (10000095), 5/16-18 KEPS Nuts (2) (10004461)