5FORM NO. L-20077-X-1018

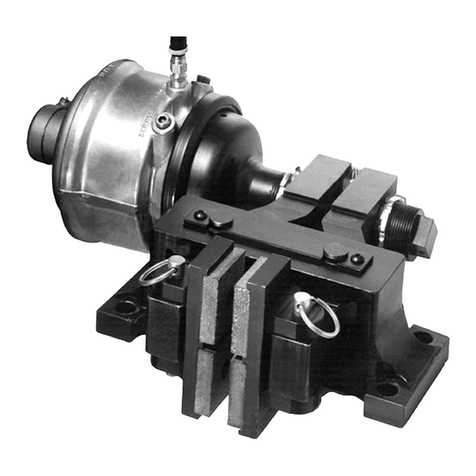

INSTALLATION

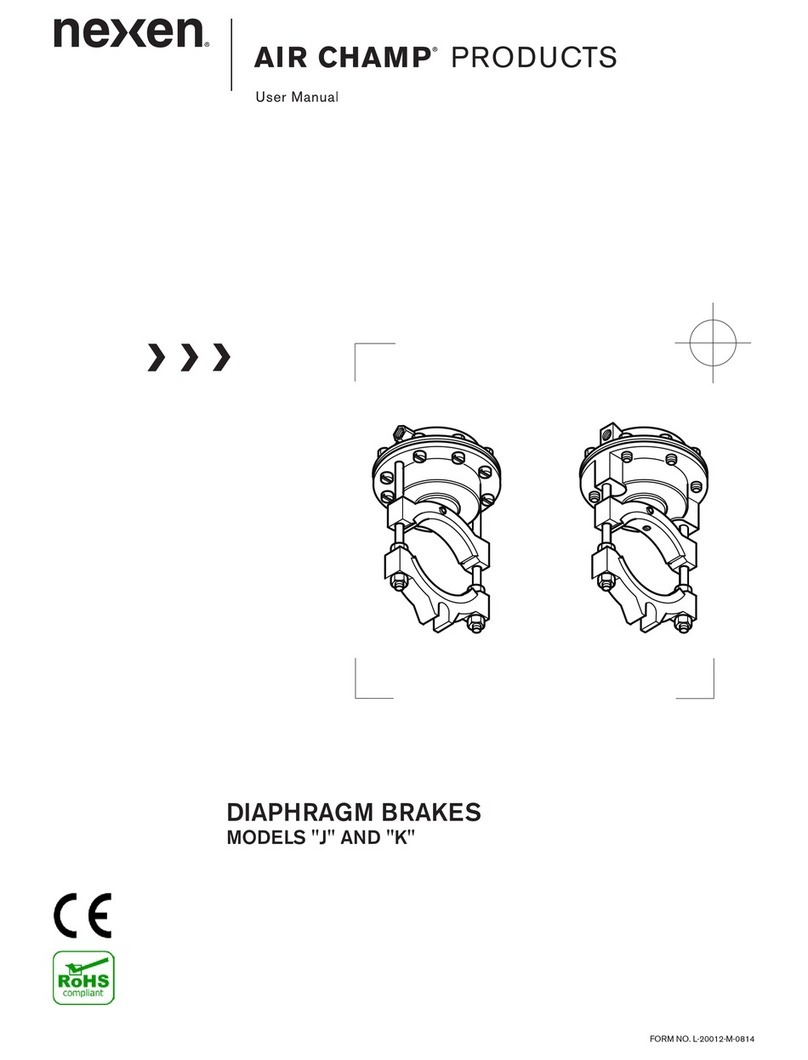

1. Before mounting, ensure Cylinder (Item 10) has

adequate clearance to move freely (See Figure 1 and

Table 1).

2. Remove any dirt, grease, or foreign material from

the Friction Disc Hub (Item 1) bore and the tapered

surfaces of the Q.D. Bushing.

NOTE: Do not use lubricants when installing

Q.D. Bushing.

Do not strike Q.D. Bushing to “set” it in the bore

of the Friction Disc Hub.

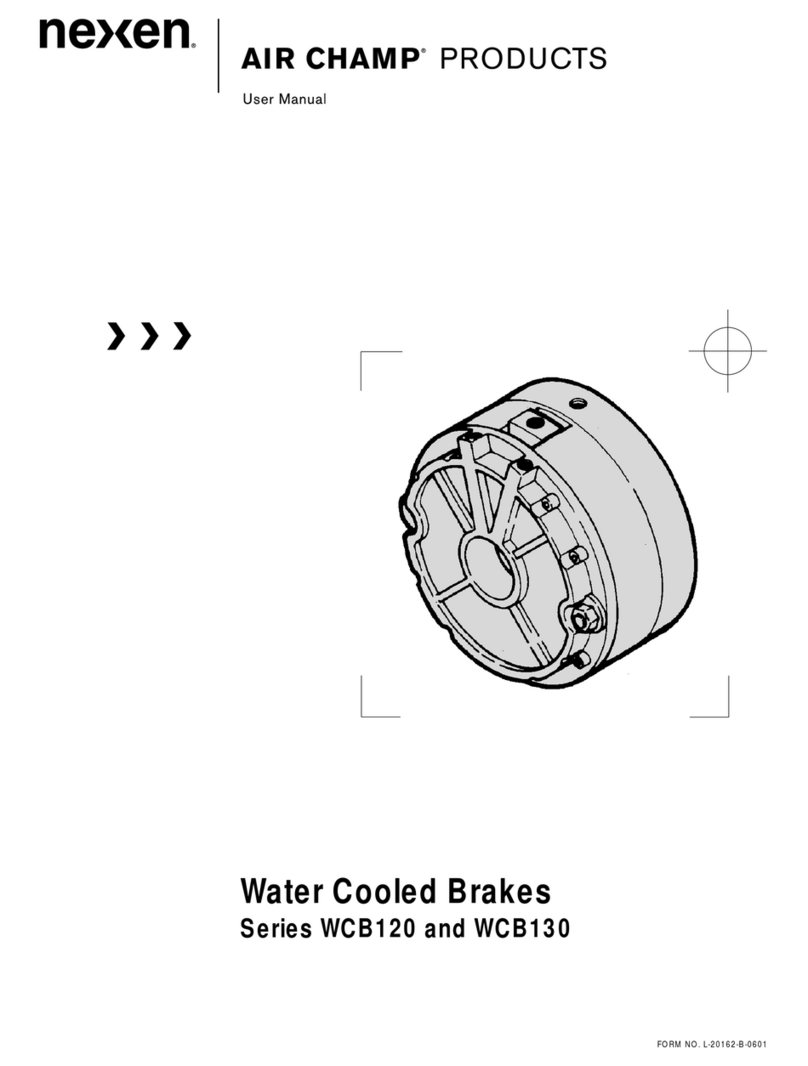

3. Slide Q.D. Bushing into the bore of the Friction Disc

Hub (Item 1) (See Figure 2).

4. Insert cap screws into Q.D. Bushing, aligning them

with the tapped holes in the Friction Disc Hub (Item

1) (See Figure 2).

5. Position TSE Brake on the shaft (See Figure 2).

NOTE: There should be an 1/8 - 1/4" gap between

the Q.D. Bushing flange and the Friction Disc Hub

after the cap screws have been tightened to the

recommended torque.

Runout is minimized if a Dial Indicator is used as

the Q.D. Bushing cap screws are tightened. Place

contact tip of Dial Indicator on smooth surface of

Cylinder moves axially

to engage and disengage.

See Table 1 for clearance

requirements.

FIGURE 1

Friction Disk Hub

(Item 1)

Motor or

Machine

Frame

Cylinder

(Item 10)

FIGURE 2

Friction Disk Hub

(Item 1)

Q.D.

Bushing

Pull-Up

Bolts

Spring Housing

(Item 4)

Torque

Pin Slot

Plate

Check runout with Dial Indicator

on Friction Disc Hub (Item 1).

CAUTION

Do not flange mount TSE Brakes.

Bearing preloadwill resultafter bushing

is installed and premature bearing

failure will ensue.

CAUTION

Do not install bolts into the threaded holes

of the Q.D. Bushing. The threaded holes

in the Q.D. Bushing are only used for

removal of the Q.D. Bushing.

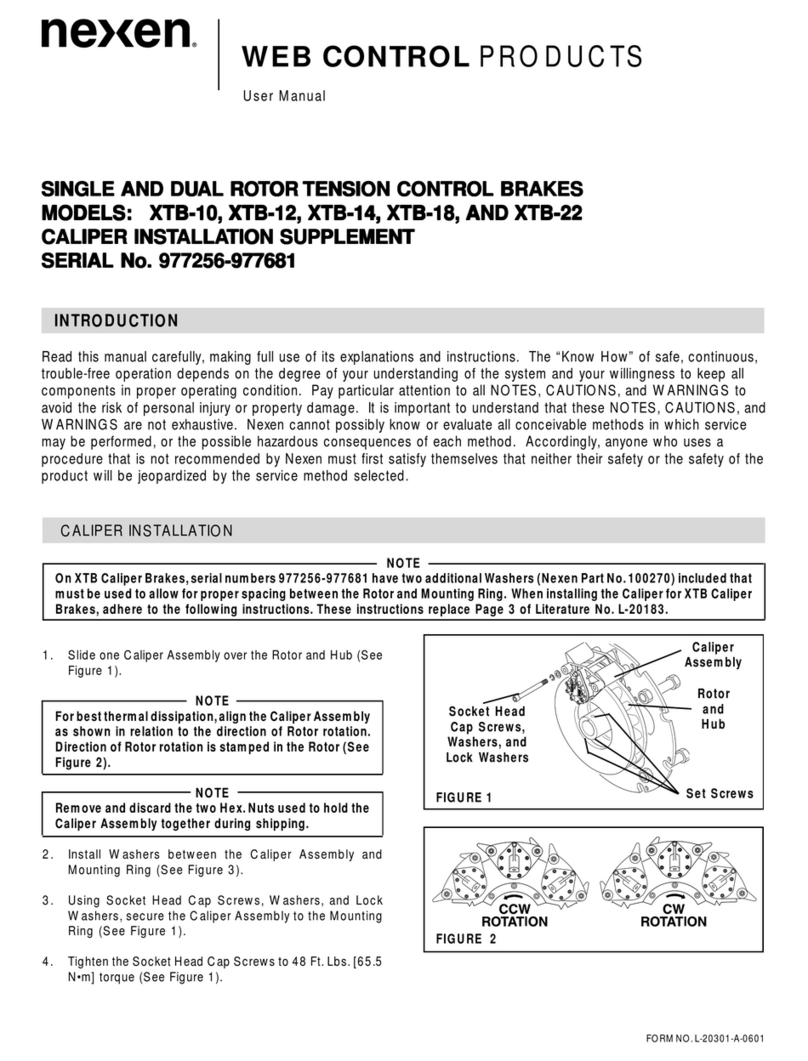

TABLE 1

Model

Minimum

Shaft

Length

Maximum

Shaft

Diameter

(Full KW)

Minimum

Clearance

at the

Rear of

the Brake

QD

Bushing

Size

Pull-up Bolt

Tightening

Torque

Torque Pin

Slot Width

Torque Pin

Diameter

TSE-450 3.68 1.000 .125 JA 5 ft.-lbs. .377 .375

TSE-600 4.10 1.375 .125 SH 9 ft.-lbs. .627 .625

TSE-800-1 4.74 2.125 .125 SK 15 ft.-lbs. .752 .750

TSE-1000 5.98 2.875 .375 E 60 ft.-lbs. .877 .875

All dimensions are inches.

Measure the minimum shaft length from the bulkhead to the outer edge of the QD

Bushing Flange. Embed a torque pin into the bulkhead to prevent brake housing rotation.

the Friction Disc Hub (Item 1) to measure runout.

Runout on this surface must not exceed 0.005 TIR

when cap screws are tightened (See Figure 2).

6. Alternately and evenly tighten Q.D. Bushing cap screws

to the recommended torque (See Table 1).

NOTE: Keep torque pin as short as possible.

7. Secure brake Spring Housing (Item 4) to prevent

rotation and take up brake torque. A torque pin slot

is provided in the Spring Housing flange (See Figure

2).